Ценовое целлюлозное волокно CF800 для бетонного раствора гипсовые изделия ацетатное изоляция из целлюлозного волокна

- Категория: >>>

- Поставщик: Henan Botai Chemical Building Materials Co. Ltd.

Сохранить в закладки 1600996967029:

Описание и отзывы

Характеристики

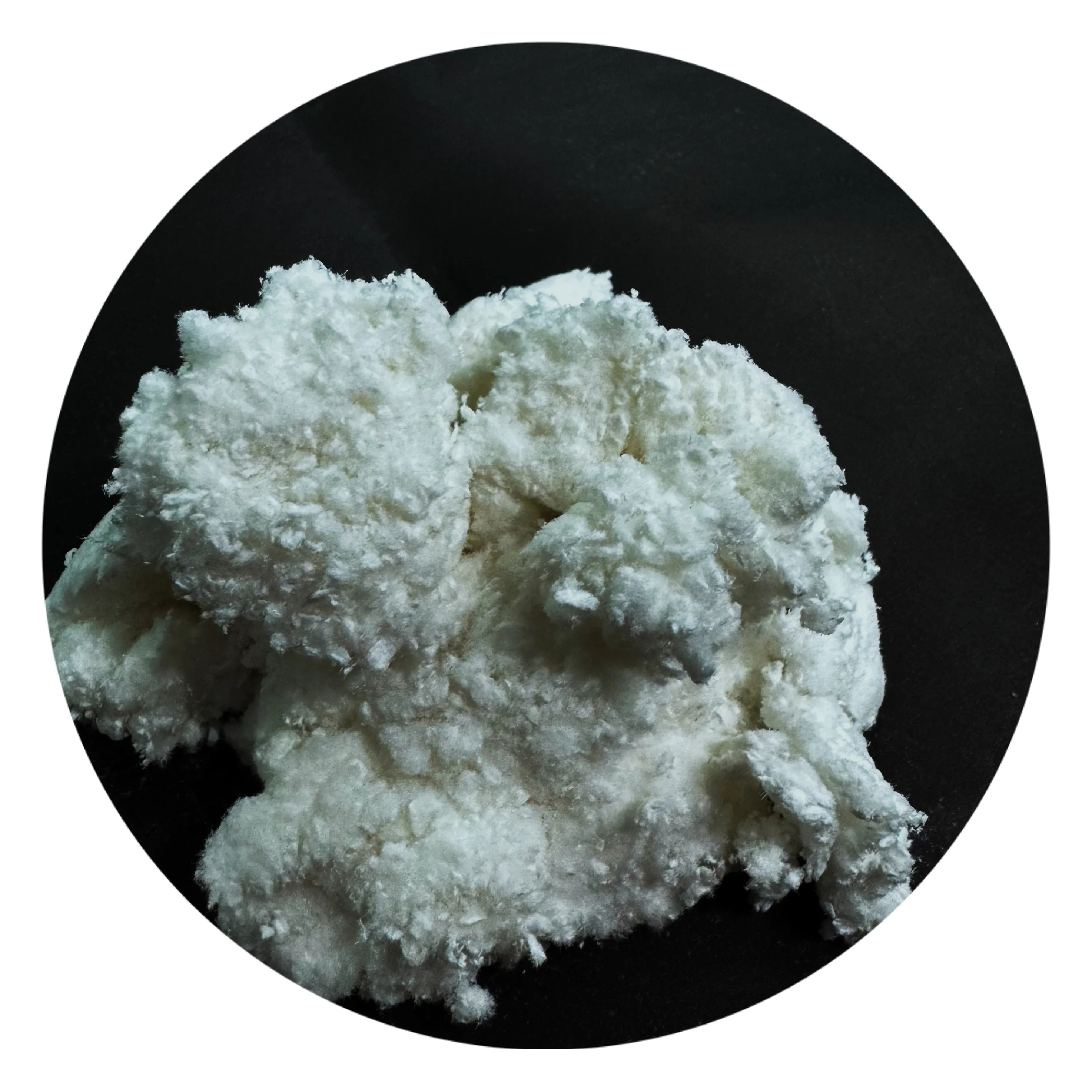

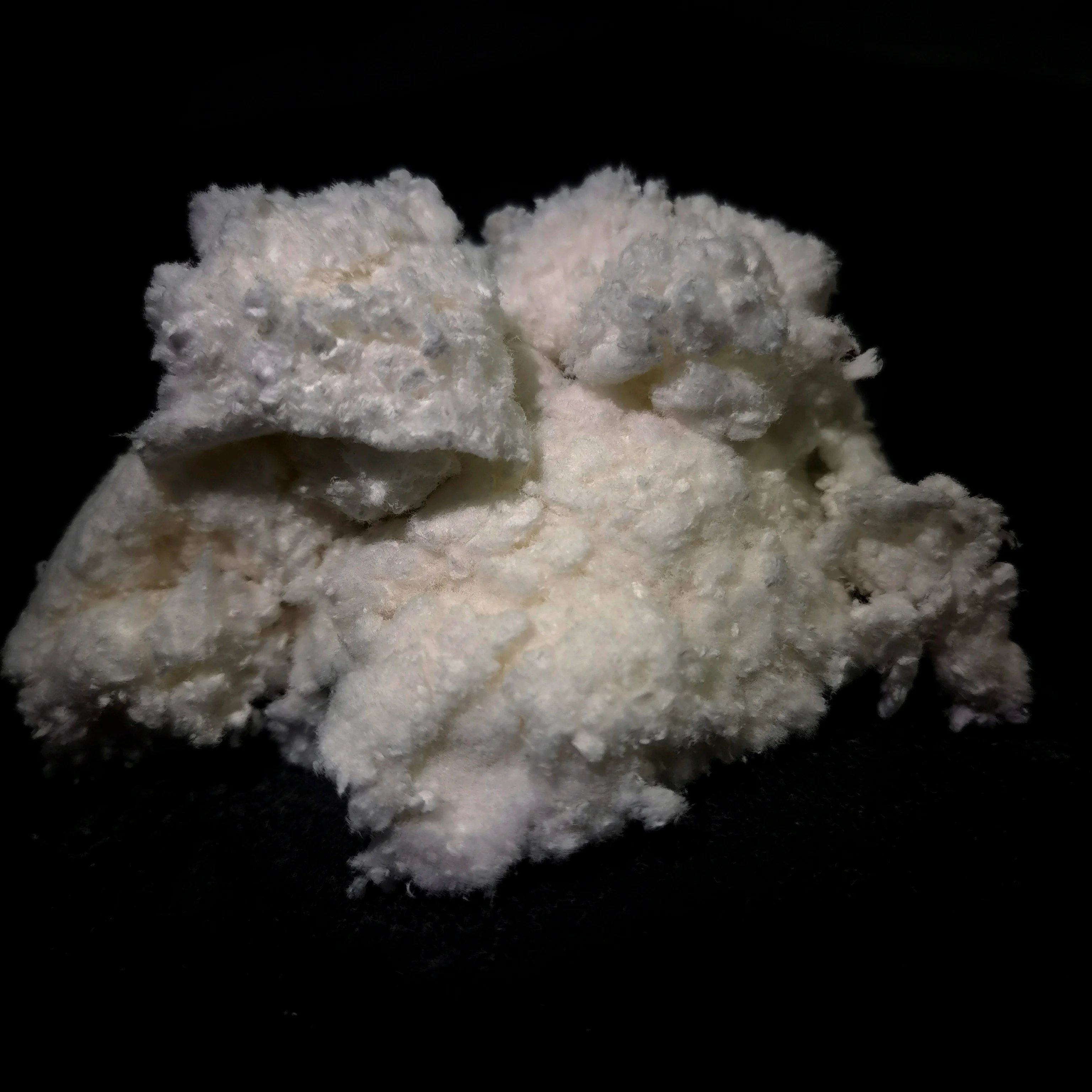

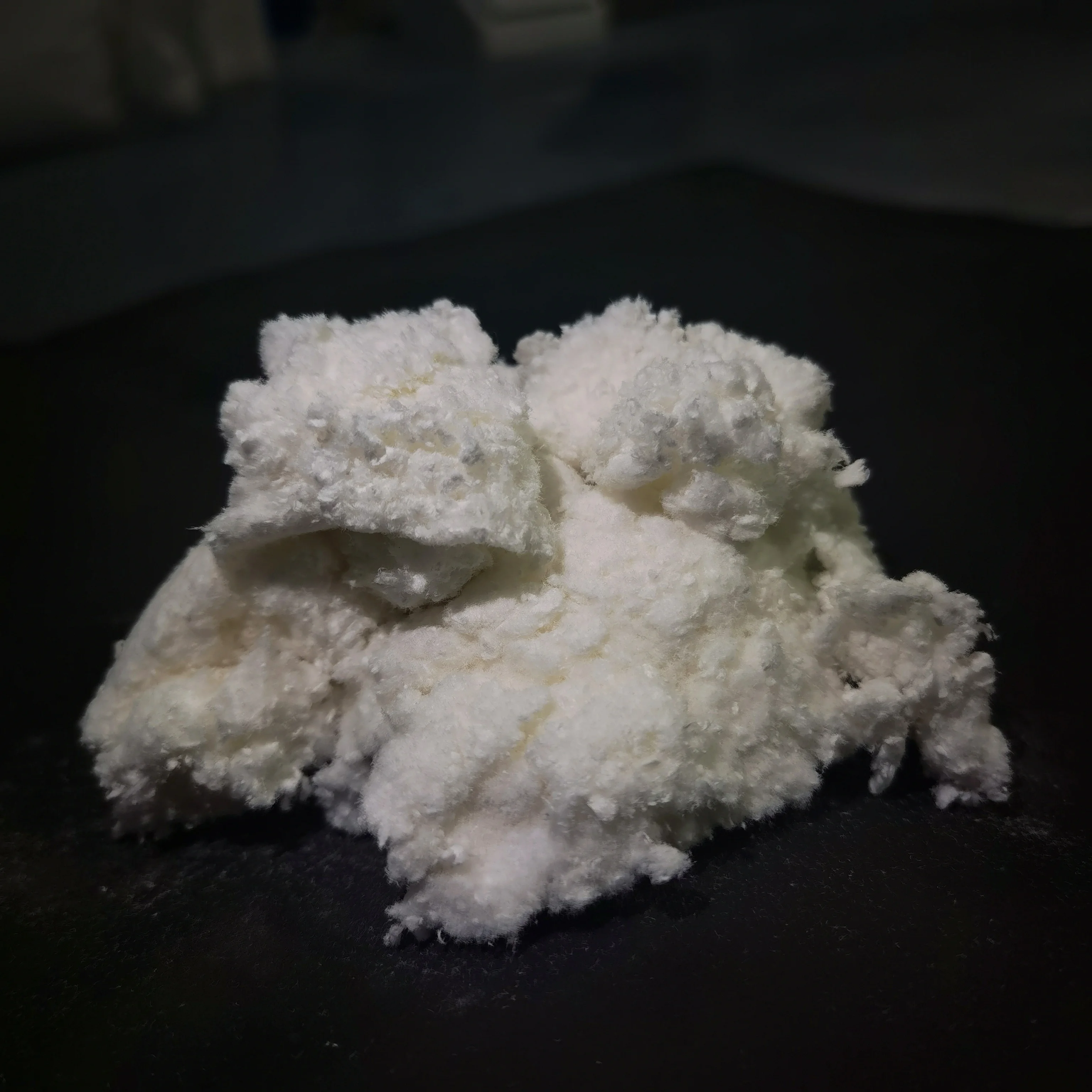

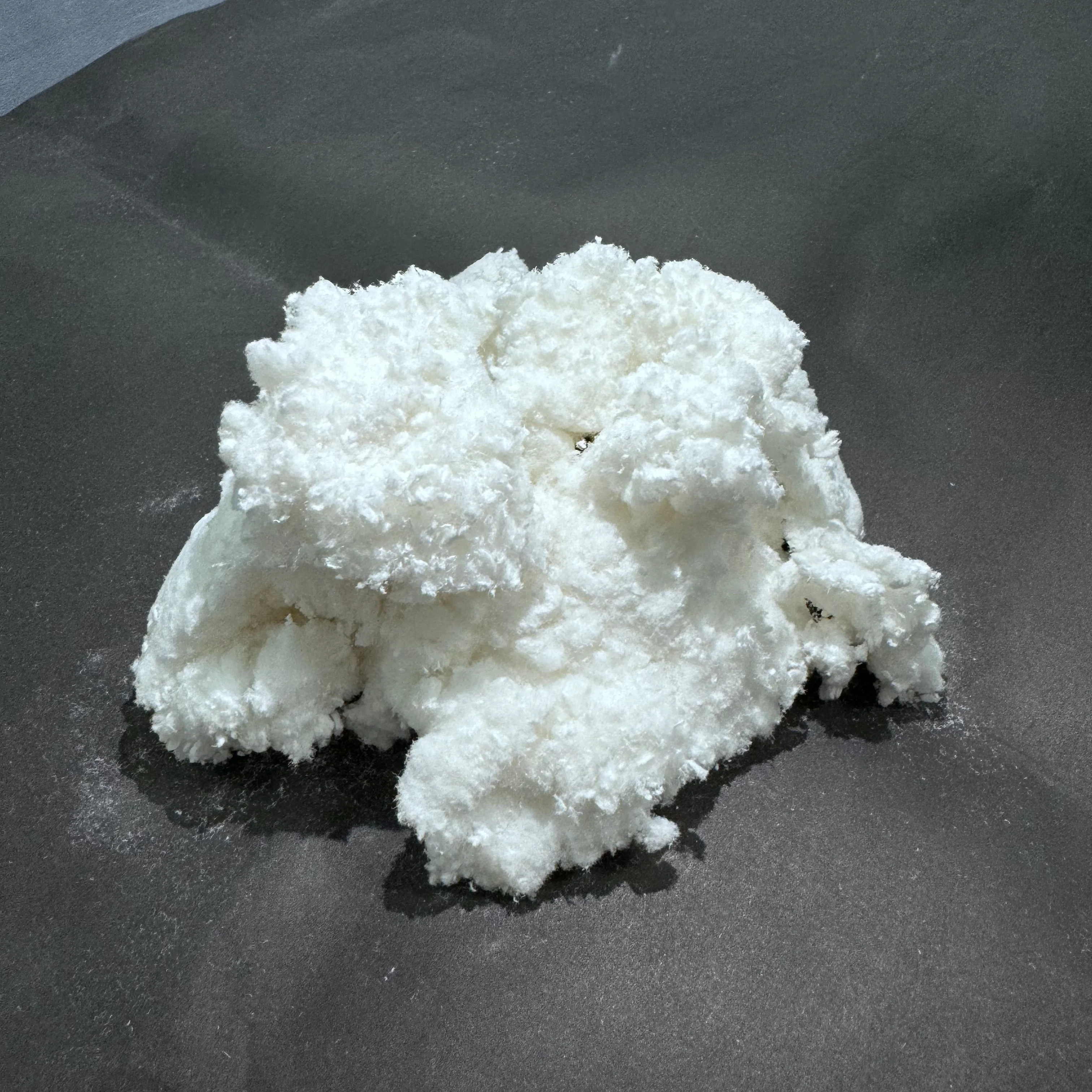

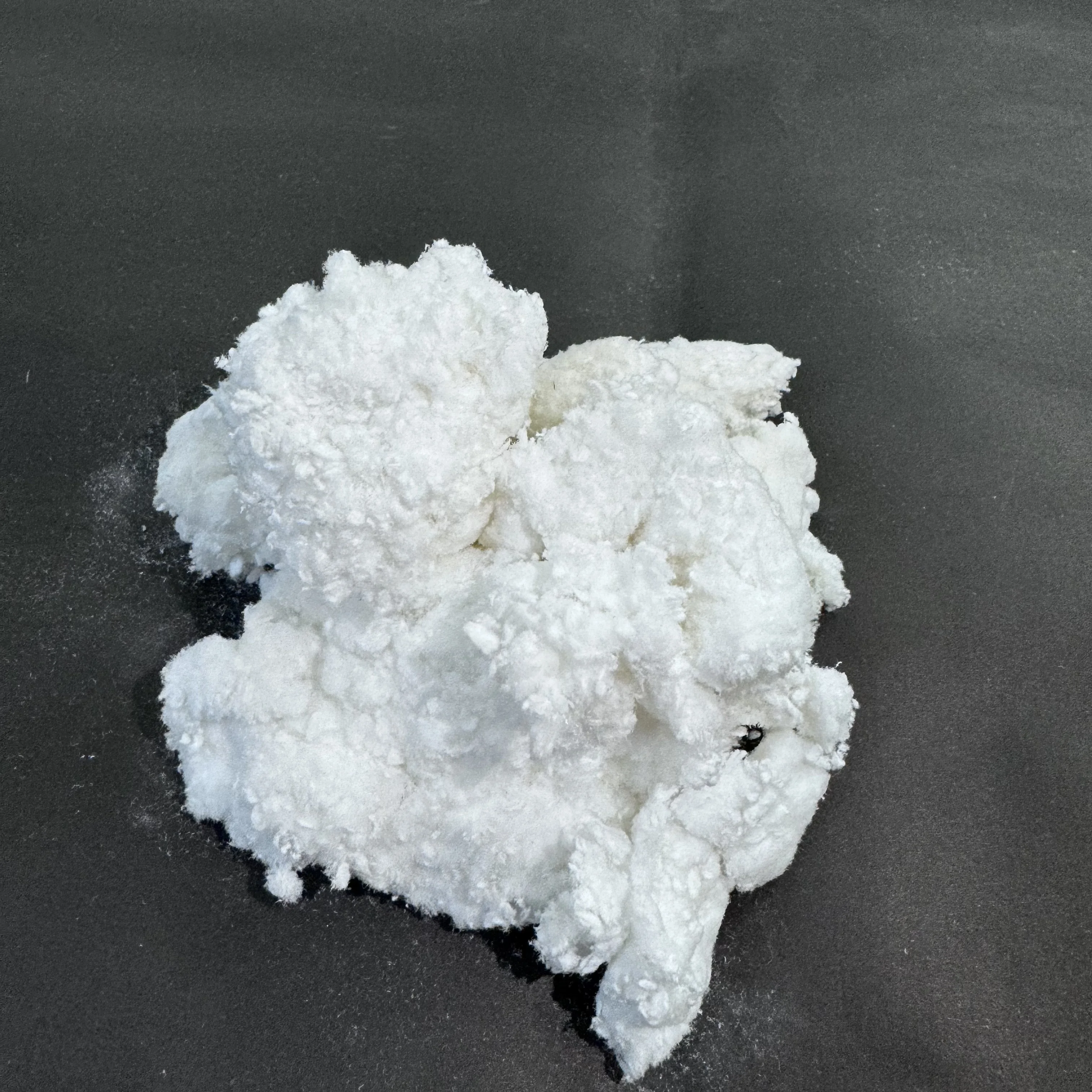

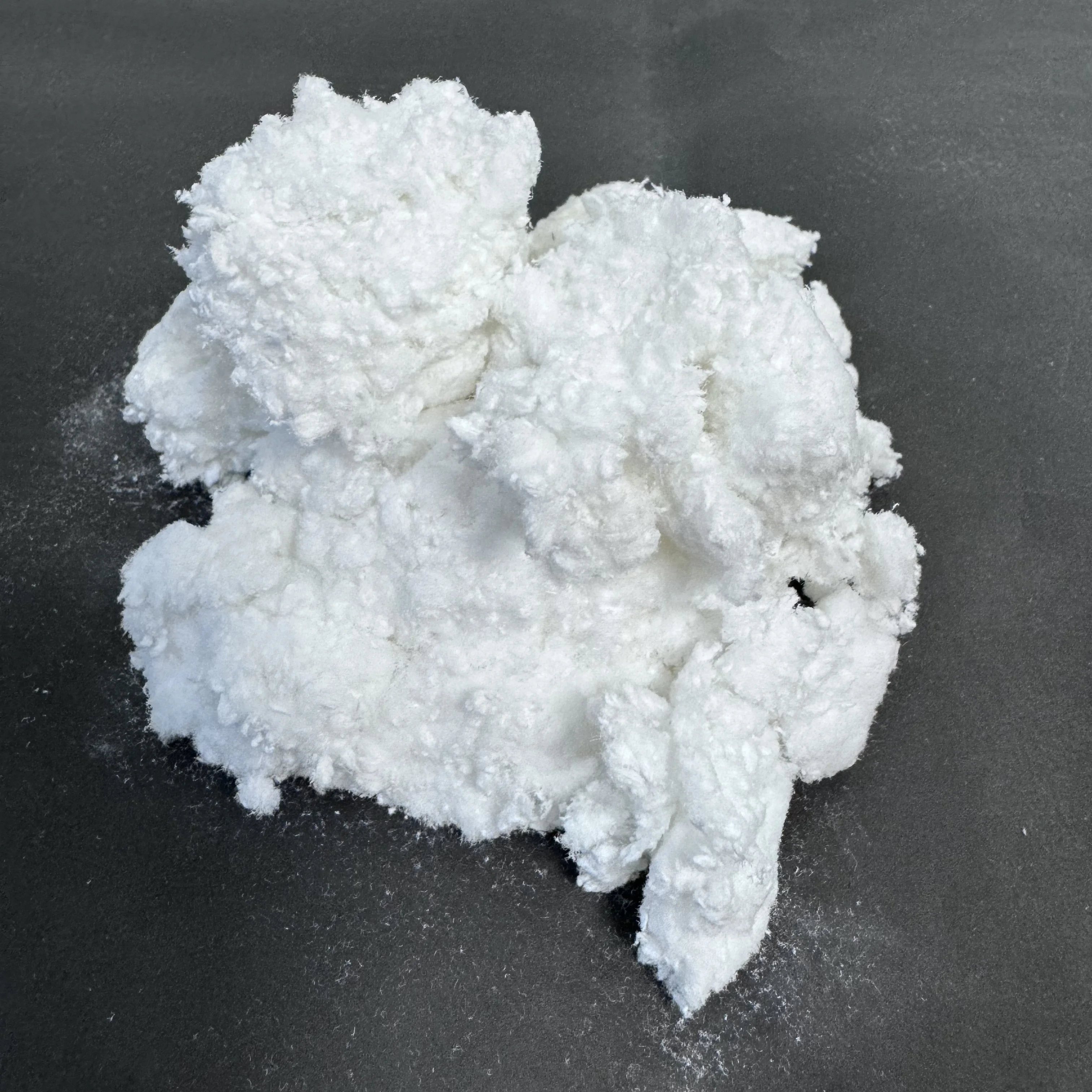

Cellulose Fibers CF800 xylem fiber

Cellulose Fibers (Xylem fiber), organic flocculent fiber material, is natural renewable wood through chemical treatment, mechanical processing of organic flocculent fiber material, widely used in concrete mortar, gypsum products, wood pulp sponge, asphalt road and other fields.

Non-toxic, tasteless, pollution-free, non-radioactive. Fiber is not the same as cellulose

● Lignocellulose is insoluble in water, weak acid and alkaline solutions; Neutral PH for increased corrosion resistance.

● Lenticellulose has small specific gravity, large specific surface area, excellent thermal insulation, heat insulation, sound insulation, insulation and air permeability, uniform thermal expansion does not crack the shell; Higher wet film strength and coverage effect.

● Lignocellulose has excellent flexibility and dispersion, and forms a three-dimensional network structure after mixing, which enhances the supporting force and durability of the system, and can improve the stability, strength, compactness and uniformity of the system.

● The structural viscosity of xylem fibermakes the uniformity of processed prefabricated slurry (dry and wet material) remain intact and stable, and reduces the shrinkage and expansion of the system, greatly improving the accuracy of construction or prefabricated parts.

● Cellulose Fibers has strong anti-freeze and anti-heat ability, when the temperature reaches 150℃ can be insulated for several days;When up to 200℃ can be insulated for tens of hours; It can also be insulated for several hours when it exceeds 220 ° C.

● Lignocellulose is insoluble in water, weak acid and alkaline solutions; Neutral PH for increased corrosion resistance.

● Lenticellulose has small specific gravity, large specific surface area, excellent thermal insulation, heat insulation, sound insulation, insulation and air permeability, uniform thermal expansion does not crack the shell; Higher wet film strength and coverage effect.

● Lignocellulose has excellent flexibility and dispersion, and forms a three-dimensional network structure after mixing, which enhances the supporting force and durability of the system, and can improve the stability, strength, compactness and uniformity of the system.

● The structural viscosity of xylem fibermakes the uniformity of processed prefabricated slurry (dry and wet material) remain intact and stable, and reduces the shrinkage and expansion of the system, greatly improving the accuracy of construction or prefabricated parts.

● Cellulose Fibers has strong anti-freeze and anti-heat ability, when the temperature reaches 150℃ can be insulated for several days;When up to 200℃ can be insulated for tens of hours; It can also be insulated for several hours when it exceeds 220 ° C.

PRODUCT SPECIFICATION

ITEM | PARAMETER | |

Appearance | white fiber | |

Fiber content | ≥80% | |

Fiber length | 400~550 µm | |

Brightness | ≥75%ISO | |

Ash content,% | ≤20% | |

PH-value (1% solution | 7.0±1.0 | |

Moisture,% | ≤6% | |

As with all natural products slight differences to the above given values may arise. | ||

The Cellulose Fibers is easily dispersed in the insulation material to form a three-dimensional space result, and can absorb 6-8 times the moisture of its own weight. This combination improves the workability, operation performance, anti-slip performance of the material, and speeds up the construction speed; The dimensional stability and thermal stability of Cellulose Fibers play a good role in insulation and crack resistance. The moisture transfer function of the Cellulose Fibers makes the hydration reaction between the surface of the slurry and the base layer sufficient, thus improving the surface strength of the insulation material, the bonding strength with the base layer and the uniformity of the material strength. These properties make Cellulose Fibers an indispensable additive in thermal insulation materials.

Comparisons with other synthetic fibers

Main use

● Water resistant putty powder ● External wall insulation paste ● Mineral mortar ● Tile binder ● Wall mortar ● PVC filter ● Water resistant putty powder ● External insulation mortar ● Mineral mortar ● Tile binder ● Relief paint ● Interior and exterior paint ● External insulation mortar ● Water resistant putty powder ● Mineral mortar ● Ceramic tile binder ● Relief paint

● Water resistant putty powder ● External wall insulation paste ● Mineral mortar ● Tile binder ● Wall mortar ● PVC filter ● Water resistant putty powder ● External insulation mortar ● Mineral mortar ● Tile binder ● Relief paint ● Interior and exterior paint ● External insulation mortar ● Water resistant putty powder ● Mineral mortar ● Ceramic tile binder ● Relief paint

Since Cellulose Fibers is an organic fiber, it is inevitable that it will be affected by the environment in the cement machine material, such as corrosion, resulting in a reduction in the effect. In modern engineering , most of the wood fiber upgrades are used - "dispersible fiber" Dispersible fiber is a special anti-cracking additive developed for mortar, with ideal long and short grading. This product is off-white, inorganic flocculent fiber. Can completely replace wood fiber. Added to mortar products can resist the cracking caused by dry shrinkage, improve the consistency of wet mortar and water retention rate, and extend the opening time. Improve construction performance and reduce adhesion to tools. Resistant to cracking during drying. This product is inorganic material corrosion resistant, used in cement products can maintain strength for a long time.

RECOMMEND PRODUCTS

PACKING AND STORAGE

PACKING

●12.5KG/Bag, 40Bags/Pallet , 8Pallets/20'container 4000KGS

●Packaging on client's request

FAQ

●1. who are we?

We are based in Henan, China, start from 2013,sell to Southeast Asia(30.00%),Mid East(30.00%),South America(20.00%),Western Europe(10.00%),Africa(5.00%),Central America(5.00%). There are total about 11-50 people in our office.

●2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

●5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Western Union,Escrow;

Language Spoken:English,Chinese,German,Russian

We are based in Henan, China, start from 2013,sell to Southeast Asia(30.00%),Mid East(30.00%),South America(20.00%),Western Europe(10.00%),Africa(5.00%),Central America(5.00%). There are total about 11-50 people in our office.

●2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

●3. what can you buy from us?

Cellulose Ether(MC,HEMC,HPMC,HEC), Redispersible Polymer Powder,Calcium Formate, Superplasticizer(SMF ,PCE),Polypropylene Fibers,Zinc Stearate,Calcium Stearate.

●4. why should you buy from us not from other suppliers?

Over 15 years export experience to more than 60 countries ,leading producer of Cellulose ethers,calcium formate and redispersible polymer powder in China, patent products, R&D department,QC and service system, Till noiw, Botai has registered more than 20 trademarks,obtained 25 patents and passed ISO9001, EU REACH, HALAL, FAMI-QS certification and so on.

Over 15 years export experience to more than 60 countries ,leading producer of Cellulose ethers,calcium formate and redispersible polymer powder in China, patent products, R&D department,QC and service system, Till noiw, Botai has registered more than 20 trademarks,obtained 25 patents and passed ISO9001, EU REACH, HALAL, FAMI-QS certification and so on.

●5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Western Union,Escrow;

Language Spoken:English,Chinese,German,Russian

Похожие товары

Силиконовый пеногаситель

421,53 ₽ - 499,18 ₽

Пеногаситель полиэфирного бетона

KH-WR водоотталкивающая смесь порошок PCE бетона Водонепроницаемый Агент

188,58 ₽ - 232,95 ₽

Тисненое макро скрученное синтетическое полипропиленовое волокно для бетонного армирования 54 мм

153,08 ₽ - 166,40 ₽

Полипропиленовая сетка из полипроплена

153,08 ₽ - 166,40 ₽

Горячая распродажа Hpmc MERICA гидроксипропилметилцеллюлоза для загустителя гидроксипропилметилцеллюлозы поставка от производителя

Заводская продажа SAF альдегид-кетон сульфонированный полимер для укрепления нефтяных скважин бетон и смеси раствора

122 334,55 ₽ - 130 049,34 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $