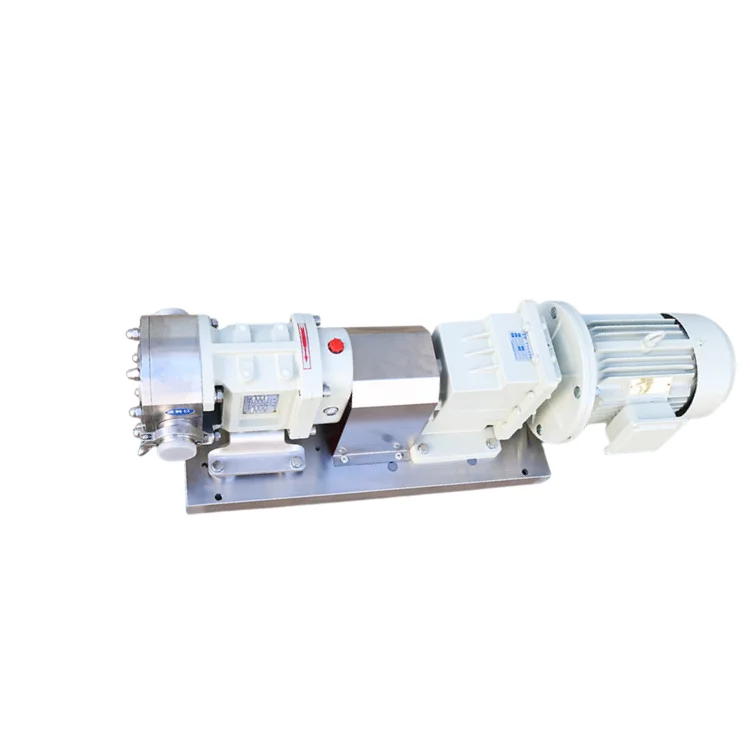

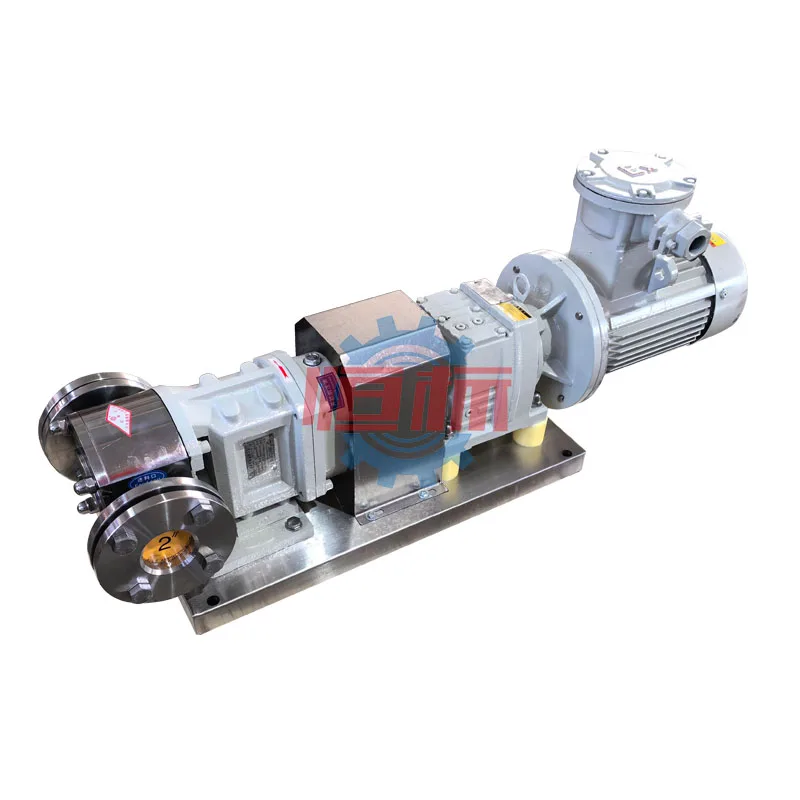

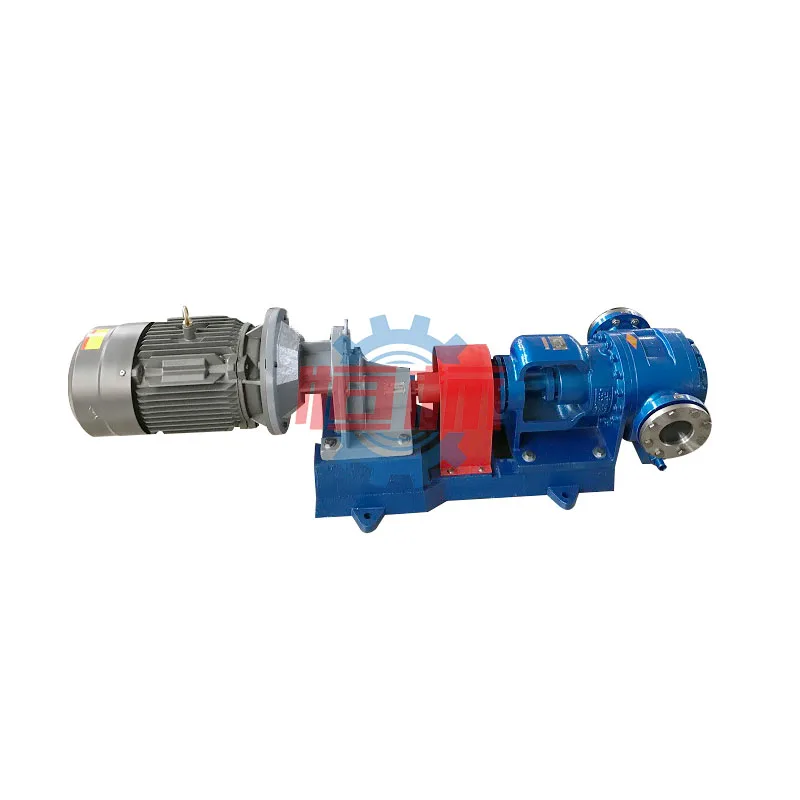

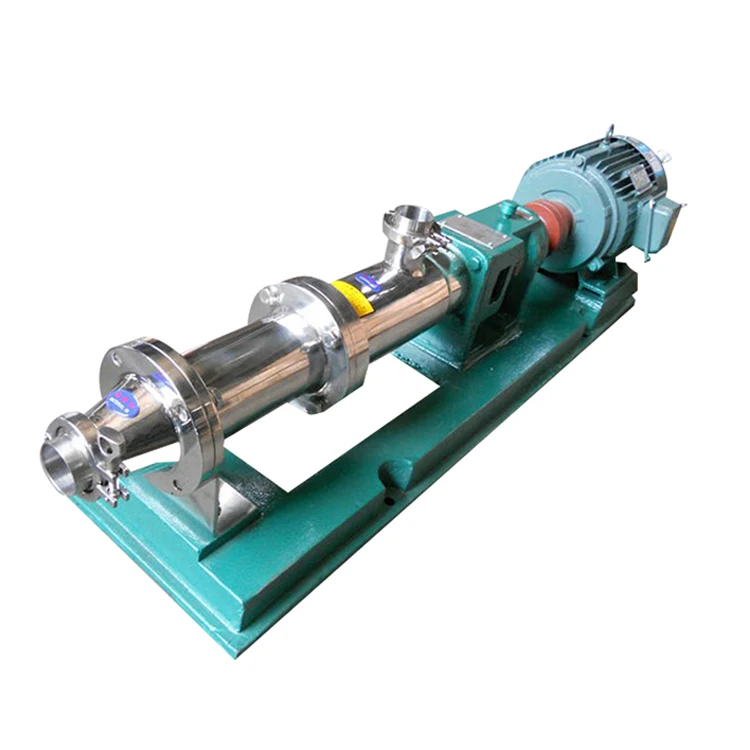

Стальной двухколесный роторный насос для напитков и соков

- Категория: >>>

- Поставщик: Zhejiang L&b Machinery Co. Ltd.

Сохранить в закладки 1600999428558:

Описание и отзывы

Характеристики

Pump Materail:

1.SS304 and SS316 sanitary stainless steel

2. sanitary polishing, 3A standard

adopt rapid installation type connection form, with convenient assembly, disassembly and cleaning.

Various Rotors:

1. Single impeller: transfer medium with a little large grains, not serious to damage grains

2. Double impeller: transfer medium with middle or small grains, low damage rate, low impulse, the capacity is smaller than tri-impeller

3. Tri-impeller: common type, capacity and performance is better than other rotors

Speed adjustment:

Standard stepless and frequency control can be avaible

Sealing option:

1)Single machine seal (single machine seal below 80C)

2)Double machine seals (double machine seals above 80C, cooling water must be connected when starting up)

Available inlet/outlet connection:

Clamp, Union, Flange etc.

Motor device

Pure copper motor: low noise, stable dynamic, sustainable work.

This way can realize the automatic adjustment of the speed, that is, the realization of the meteor stepless adjustment, its advantage is a high degree of automation.Low speed torque is short, the disadvantage is that the inverter price is higher

a) Lobe pump belongs to positive displacement pump, flow can be controlled accurately and can change to variable pump conveniently. But the flow of centrifugal pump can not be controlled and falling as the increase of resistance; lobe pump has rather strong suction capacity but centrifugal pump has to be filled of liquid before operating.

b) The rotation speed of lobe pump is very low, normally between 100rpm and 500rpm, the material is sent out smoothly and the component is not changed. The rotation speed of centrifugal pump is very high, the material is impacted strongly and for the effect of the centrifugal pull, the

component is often different when transfer mixture, it will decrease the quality of the finish product. So the lobe pump is the best choice to solve this problem, it is most suitable to used on transfer mixture even material that contains solid particles.

c) Lobe pump can transfer high viscosity material, so it also called colloid pump. But centrifugal pump has no this characteristic.

d) Lobe pump can be made as rather high output pressure conveniently, suitable to long distance or high resistance dosing transfer.

e) The production of lobe pump is more complicated, the cost is higher, it is the biggest defect compared with centrifugal pump.

But the biggest defect of screw pump is it is not sanitary grade, the abrasion of parietal rubber may pollute the material.

Lobe pump has streamline construction and there are no dead center and non-metal element in the rotor room, so it is more suitable to industries of higher hygiene requirement. Particularly as automatic degree of the production line is higher, and the adoption of CIP, it is better to choose lobe pump.

The rotation speed of lobe pump is very low, normally between 100rpm and 500rpm, the material is sent out smoothly and the component is not changed.

Lobe pump can transfer high viscosity material, so it also called colloid pump. Lobe pump can be made as rather high output pressure conveniently, suitable to long distance or high resistance dosing transfer.

Model | L/100R (L) | Speed range (rpm) | Flow rate (L/H) | Power (kw) |

BLS-3 | 3L | 200-500 | 300-800 | 0.55 |

BLS-6 | 6L | 200-500 | 650-1600 | 0.75 |

BLS-8 | 8L | 200-500 | 850-2160 | 1.5 |

BLS-12 | 12L | 200-500 | 1300-3200 | 2.2 |

BLS-20 | 20L | 200-500 | 2100-5400 | 3 |

BLS-30 | 30L | 200-400 | 3200-6400 | 4 |

BLS-36 | 36L | 200-400 | 3800-7600 | 4 |

BLS-52 | 52L | 200-400 | 5400-11000 | 5.5 |

BLS-66 | 66L | 200-400 | 7100-14000 | 7.5 |

BLS-78 | 78L | 200-400 | 9000-18000 | 7.5 |

BLS-100 | 100L | 200-400 | 11000-22000 | 11 |

BLS-135 | 125L | 200-400 | 15000-30000 | 15 |

BLS-160 | 160L | 200-400 | 17000-34000 | 18.45 |

BLS-200 | 200L | 200-400 | 21600-43000 | 22 |

Description: | Designed according to ISO9001 standard, widely used for transfer liquid media in the food-processing, cosmetics and sometimes, the media can contain a little solids. |

Construction: | pump body, gear box, different rotor shapes(tri-lobe rotors, butterfly type rotors, single impeller etc) |

Rotor Type: | 2-leaves(butterfly shape), 3-leaves, single butterfly |

Rotors | Single impeller: transfer medium with a little large grains, not serious to damage grains Double impeller: transfer medium with middle or small grains, low damage rate, low impulse, the capacity is smaller than tri-impeller Tri-impeller: common type, capacity and performance is better than other rotors |

Material: | SS304/SS316L |

Maximum rotational speed: | 600r/min |

Suggested rotational speed: | 200-500rpm |

Speed adjustment: | stepless speed control and frequency control |

Flow: | 5600-11000 L/H |

Max. Flow: | 43000L/H |

L/100R | 3L, 6L, 8L, 12L, 20L, ...200L |

Max.outlet pressure: | 0.6Mpa(media viscosity would make it different) |

Highest media temperature: | 80°c, more higher adopts Double mechanical seal |

Mechanical seal: | SIC/SiC/EPDM(Standard) |

Motor power: | 0.55kw, 0.75kw, 1.5kw, 2.2kw, 3kw, …22KW |

Sealing option: | Sanitary single mechanical seal/Double mechanical seal with cooling water port |

Voltage: | 110-480V |

Motor: | Siemens, ABB, LOCAL,50hz/ 60hz |

Surface treatment: | Inner polished and Sandblast outside |

Available connection: | Clamp, Union, Flange |

Available standard: | DIN, SMS, 3A, RJT, ISO/IDF |

Operated: | Electric |

Application scope: | Dairy, food, beverage, cosmetic, etc |

Packaging Details: | Plywood case Or as per the request of customers |

Zhejiang L&B Fluid Equipment co., Ltd

a modern enterprise which combine the ability of design, development, manufacturing, engineering, installation, technical services, has special technology to design and exploit by CAD software and computer and is a outstanding leader among valve fields.

We have advanced CNC lathes imported from Japan.We can manufacture the valves and fitting according to ISO, DIN, IDF, SMS, 3A, while we can produce the products per as the requirement from the clients(non-standard).

We are specialized in producing different kinds of valves, pipe fitting, tubes, manhole covers, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Please contact our After-sales service department in time within 30days after you received the cargo. | ||

Tel: 86-577-86821328 Time: 9:00 a.m.- 6:00 p.m. (Beijing time) | ||

Process | Please provide the copy of Sales Contract and describe the problems appeared. | |

Problems confrimation: | ||

Slight problem: | Please send the proof to our After-Sales Department, we will reply within two days. | |

Serious problem: | ||

a | We will dispatch our Quality and Problems Appraisers to make a confirmation. | |

b | Have a negotiation of the compensation and sign agreements | |

c | Our After-Sales Department will perform the duties as the agreements | |

Похожие товары

Шестеренчатый роторный насос для перекачки масла Чили и перца санитарные машины откачки шоколадного соуса из нержавеющей стали

Высокая скорость вязкости сыр Шоколад Арахисовое Масло Электрический с перемешивающим лопастным насосом наполнитель роторного насоса разливочная машина

Высоковязкий роторный насос для пищевых продуктов санитарный зубчатый доставки мясной пасты прямой производитель

Высоковязкий роторный насос медового сиропа серии NYP от производителя

Оптовая продажа от производителя винтовой водяной насос для томатного соуса роторного винтового вакуумного насоса шлама

Санитарный трехлопастной роторный насос для переноса лосьона

Высоковязкие зубчатые насосы ротора передачи тяжелого масла

Новые поступления

Новинки товаров от производителей по оптовым ценам