Китай автоматическая машина для производства гофрированной проволочной сетки производитель металлическая изготовления электрической сварной

- Категория: >>>

- Поставщик: Hebei Zonghang Machinery Manufacturing Co. Ltd.

Сохранить в закладки 1601000826645:

Описание и отзывы

Характеристики

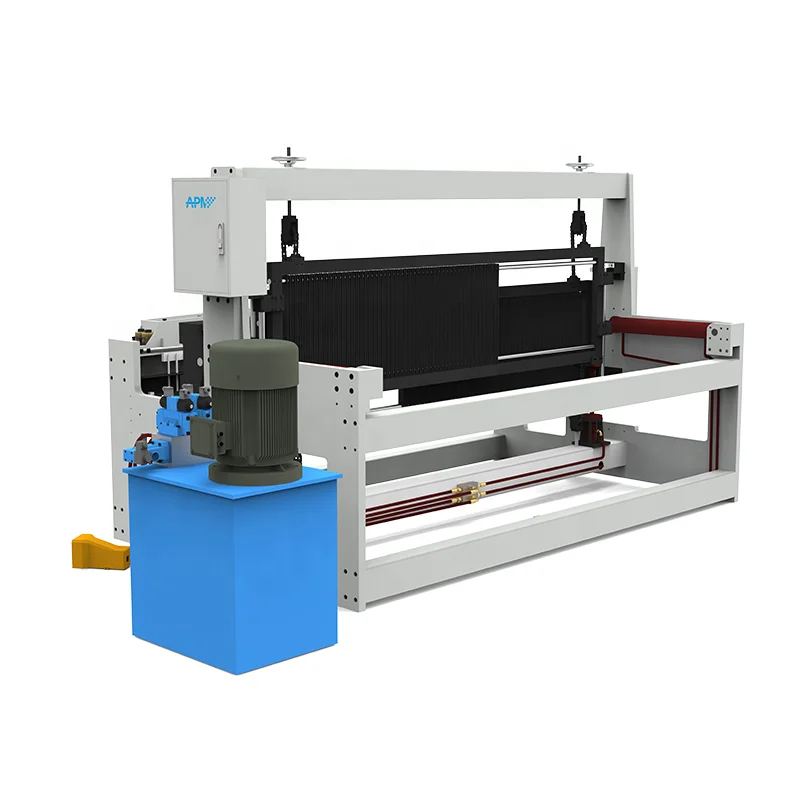

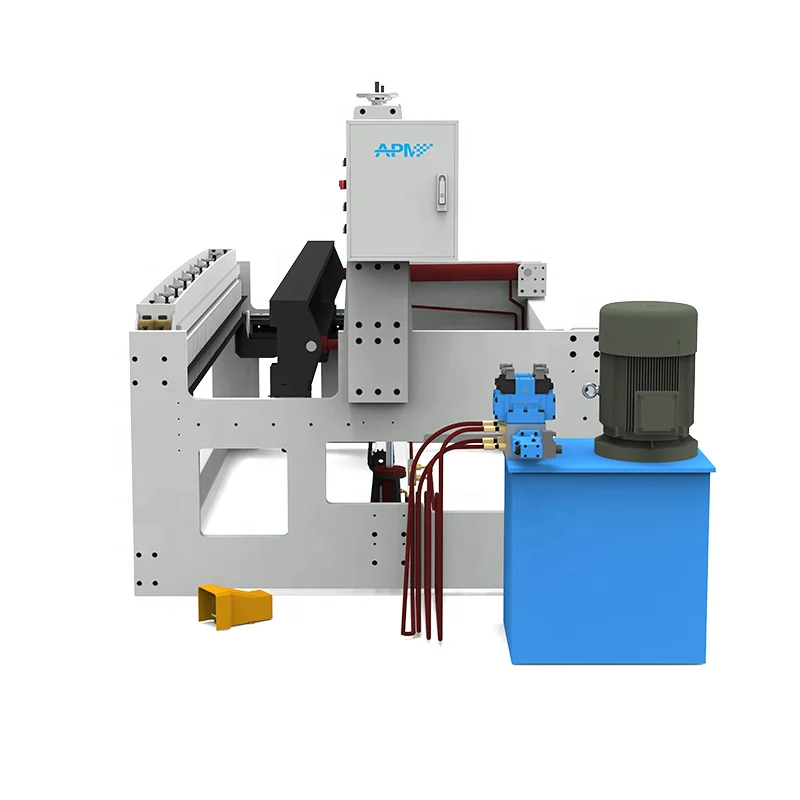

APM-CM-H101 screen assembly machines are for the production of heavy sieve screens with manual weft insertion.The 2 heddle frames have very strong power to lift the high spring steel wire. It can weave square crimped mesh screen and locked crimped screen.This type machine is specially good at mine sieve screen weaving.The wire material could be high carbon steel,stainless steel,galvanized iron,etc.

Technical Parameter

Machine Type | H101 |

Weaving Width | 2000mm,2500mm,or customized |

Opening size | 9-100mm |

Wire Diameter Range | 5.0-12mm,or 8-16mm |

Heddle Frame | 2 pcs |

Weft Insertion | By hand |

Customers

Customers

1, Maintenance period: one year

We can send our technicist to the buyers’ place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

2, The debugging fees: free

3, The training fees:free.

If buyers need the technicians,we will assign the technical staff to your company. And the fees such as round-trip tickets,accommodation etc, are all in buyers’ account.And a training fee is required.

4, The numbers of technical persons: one technical person per machines at most.

5, During the maintenance period: the parts damaged non-artificially will be provided free of charge.

6, After the maintenance period: If buyers need the machine parts, we will provide it as our cost.

Information provided by customer

1.Wire material

2.Wire diameters

3.Aperture size(mesh count per inch)

4.Weaving width

5.Weaving type.

Cooperation Procedure

1.Customer provides above information

2.We recommend or design the machines.

3.APM team explains the machine to customer

4.If customer confirm, APM offers the quotation ;

If customer not confirm, APM modifies the drawing

5.When the quotation confirmed, APM issues the contract

6.When the contract be signed, customer arranges the deposit

7.When deposit received, APM arranges the production

8.When production finished, customer or APM arranges quality inspection

9.When inspection passes, customer arranges balance and customer or APM books the shipment.

10.When balance received, APM arranges export

11.When machinery received, customer arranges assembling and APM offers trainning support

12.whenever technique support needed, APM will be around with you.

Похожие товары

Вентилятор охлаждения процессора для HP Pavilion 14-bk (bk000 bk100) 14-bp (bp000 bp100) 14-bk061st 14-bk154sa 14-bp103tx 14-bp111tx 927918-001

Тележка-тележка на 30 тонн для переноса батареи с вращающимися

JYMT-60 110V/220V/380V Автоматическая коммерческая машина для приготовления лапши быстрого приготовления процесса

NESQUIK без сахара добавил шоколадный какао-порошок от Nestle r, 16 Oz. Ванна | Шоколадный молочный порошок Лучшая оптовая цена

Подставка-ароматизатор для йоги, ароматерапии, дома

Универсальный диагностический инструмент V309 OBDII считывающая карта кода ELM327 V309 OBD 2 OBDII Автомобильный диагностический инструмент сканер интерфейса

Вьетнам, оптовая продажа, конкурентоспособная цена, переработанные поликарбонатные гранулы

Новые поступления

Новинки товаров от производителей по оптовым ценам