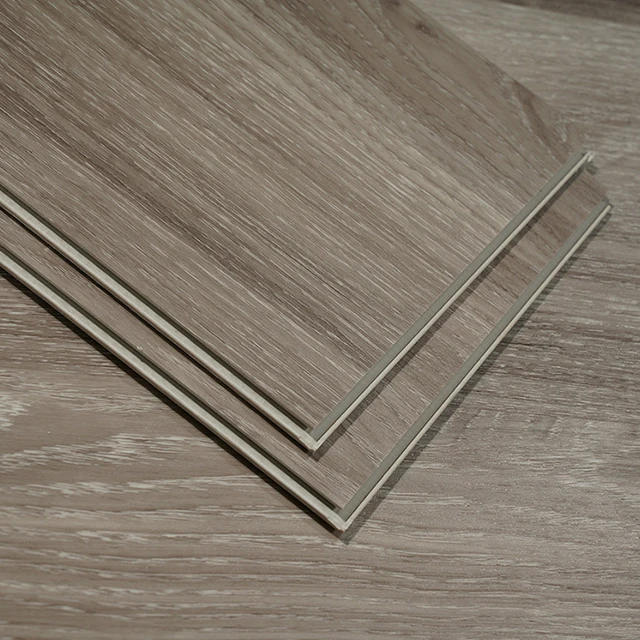

Огнеупорные пластиковые полы Лидер продаж 4 мм lvt для отеля

- Категория: >>>

- Поставщик: Shandong Longzheng Wood Industry Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601003973286:

Описание и отзывы

Характеристики

Fireproof plastic flooring hot selling items 4mm lvt flooring for hotel

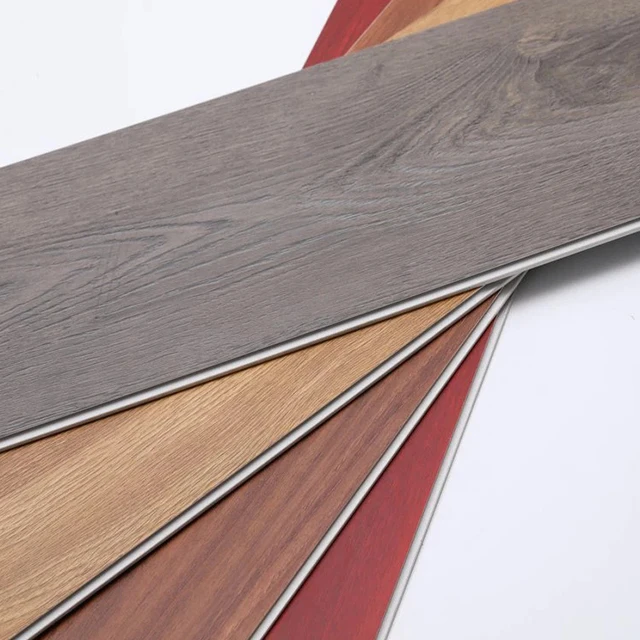

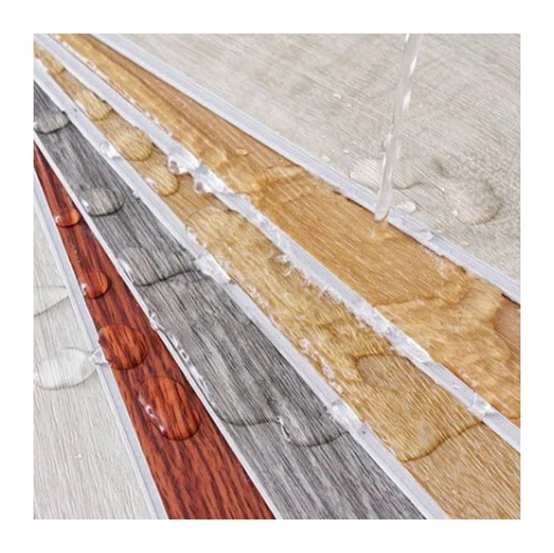

SPC flooring is a product made of a PVC base material extruded by an EXTRUDER extruder. A four-roller calendering unit is used to press and paste the PVC color film + PVC wear-resistant layer + PVC base film in one go. The process is simple and easy to apply. Sealing is done by heat and does not contain glue.SPC flooring is a new type of energy-saving floor that has the characteristics of zero formaldehyde, mildew removal, water-proof, fire-proof safety, waterproofing, and easy installation and operation. Vinyl flooring uses an extruder combined with a T-shaped die to extrude PVC sheets. A three-roller or four-roller calender is used to separately heat and emboss the PVC wear-resistant layer, PVC color film and PVC sheet at one time. The processing technology of our products is simple and relies on heat generation, without the need for strong glue.

SPC flooring materials use environmentally friendly formulas, do not contain heavy metals, phthalates, formaldehyde and other harmful substances, and comply with EN 14372, EN 649-2011, IEC 62321, GB 4085-83 standards.

SPC floor density: 1.9~2 tons/cubic meter; SPC floor shrinkage: ≤1‰ (after tempering treatment): ≤2.5‰ (without tempering treatment) (shrinkage test standard: 80℃, 6 hours standard )

| Product name | Fireproof plastic flooring hot selling items 4mm lvt flooring for hotel | |

| Key words | plastic flooring1 | |

| Item | Standard | Result |

| Dimensiontal Stability after exposure to heat | EN ISO 24342 | X Direction:<0.1%Y Direction:<0.05% |

| Curing after exposure to heat | EN 434 | <0.1mm |

| Castor Chair | ISO 4918 | After 25000 cycles,no visible damage |

| Slip Resistance | EN 13893 | Class DS |

| Fire Resistance | EN13501-1 | Bfl-S1 |

| Abrasion Resistance | EN 660 | Group T |

| Stain &Chemical Resistance | EN ISO 26987 | Class 0 |

| Formaldehyde Emission | EN 717-3 | Class 0 |

Похожие товары

Лидер продаж экологически чистые ПВХ напольные самоклеющиеся виниловые полы

Бразильское Розовое Дерево Антистатическая виниловая плитка SPC напольное покрытие экспортируется в США

Противоскользящая износостойкая Водонепроницаемая виниловая доска из ПВХ 4/5/8 мм

Доска рыболовная 4 мм 5 6

Плитка 30*30 см 12 'x 12' напольные наклейки ПВХ линолеум пол самоклеящиеся SXP роскошные виниловые полы

Morden мраморный виниловый пол самоклеящийся покрытие и палка ПВХ камень плитка 30x60 см для ванной кухни

Коммерческое использование 4 мм клик Lvt Lvp девственный материал водонепроницаемый ПВХ композитный пластик пол Spc гибридная Виниловая Плитка

Новые поступления

Новинки товаров от производителей по оптовым ценам