Законченный продукт инспекционные Запчасти для мотоциклов производитель индонезий запчасти нажмите 125I аксессуары

- Категория: >>>

- Поставщик: Chengdu Jingbang Technology Co. Ltd.

Сохранить в закладки 1601009321563:

Описание и отзывы

Характеристики

Welcome to Chengdu Jingbang Technology,

your trusted partner in CNC machining.

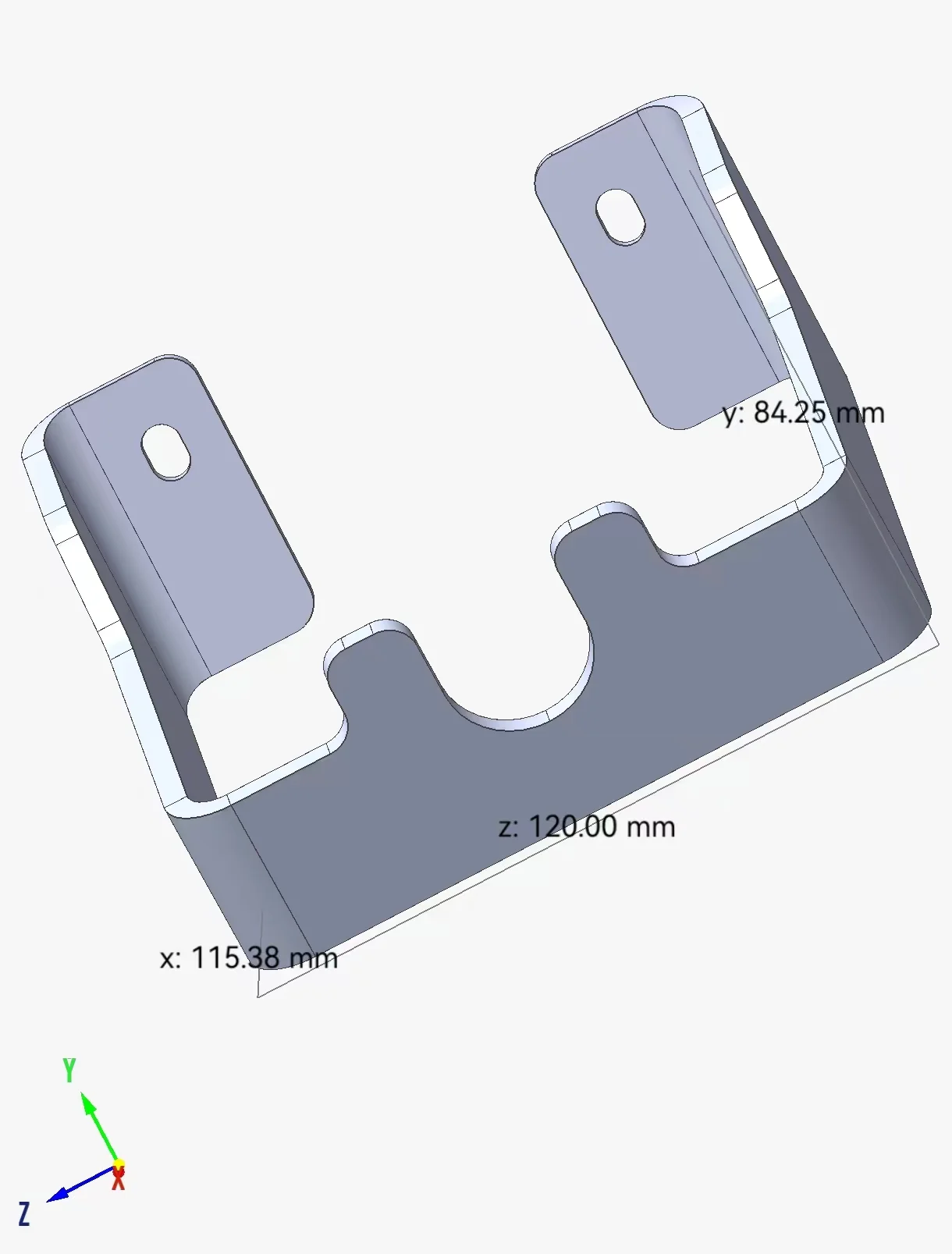

Upload me your drawings CAD files to get an instant online fabrication quote !

| Customzied Service | ||

|  |  |

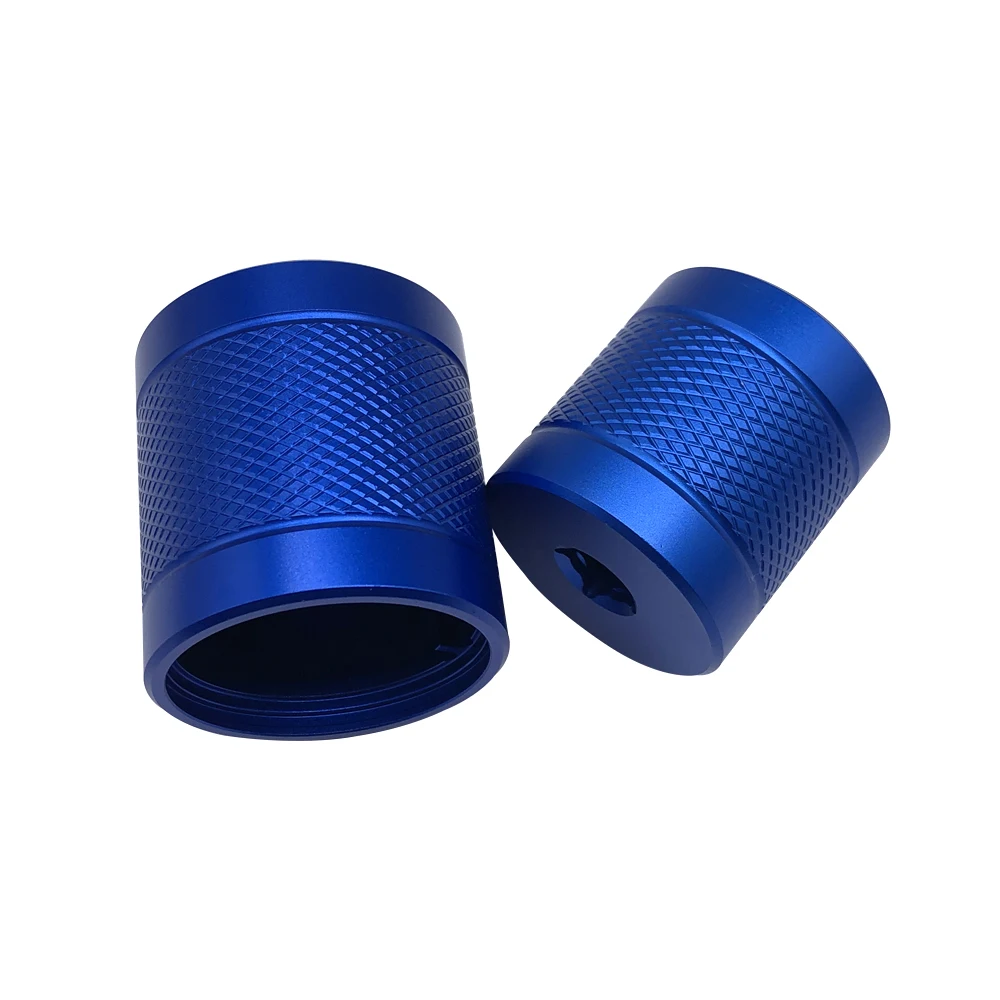

| CNC Stainless Steel Parts | CNC Aluminum Parts | CNC Stainless Steel Parts |

| Stainless steel is a common material used in various industries due to its strength, durability, and affordability. With other elements present in smaller quantities. CNC milling allows for precise and accurate machining of stainless steel parts, ensuring tight tolerances and high-quality finishes. | Aluminum CNC milling parts refer to components or parts made from aluminum using the CNC milling process. CNC milling is a subtractive manufacturing method that utilizes computer numerical control (CNC) machines to remove material from a workpiece using rotating cutting tools. | Brass CNC machining parts are components or parts made from brass using the CNC machining process. CNC machining is a subtractive manufacturing method that utilizes computer numerical control (CNC) machines to remove material from a workpiece using various cutting tools.

|

|  | |

| Sheet Metal Parts | Metal Enclosures | Injection Moulded Parts |

| Sheet metal stamping housings are enclosures or casings that are manufactured using the sheet metal stamping process. These housings are commonly used in various industries to protect and enclose electronic components, machinery, equipment, and other devices. | Explore our range of fully finished precision enclosures and sheet metal parts, including brackets, plates, frames, arms, bus bars, fixtures, and more. | Two-plate mold / three-plate mold / hot runner mold / right-angle injection mold. We has "one-stop" supporting professional manufacturers of engineering technology, project management, injection mold design and manufacturing, injection molding, printing, testing, testing and assembly. |

Material Available | Stainless steel: 201SS, 301SS, 304SS, 316SS, etc. |

| Aluminum: AL6061, AL6063, AL6082, AL7075, AL5052, etc. | |

| Steel: carbon steel, alloy steel, stainless steel, | |

| Brass: C37700, C28000, C11000, C36000, etc. | |

| Plastics: PTFE, PEEK, POM, PA, UHMW, NYLON, etc. |

Our CNC Machining Capabilities

| 5-Axis CNC Machining: Utilizing advanced technology to produce complex geometries with micron-level precision. This capability is crucial for aerospace, automotive, and medical industries, where stringent requirements demand utmost accuracy and reliability. |

| Prototyping and Production: We have a team of 50+ engineers capable of delivering rapid responses and providing fast feedback. From initial prototypes to full-scale production runs, design for manufacture, based on customer requirements, will discuss with the customer to provide constructive suggestions from the perspective of structure, material selection, surface treatment, etc. |  |

| Custom Machining Process: Specializing in bespoke machining solutions, we cater to specific project requirements with meticulous attention to detail and rigorous quality standards.OEM & ODM design are welcomed. |

Our experienced team excels in advanced design capabilities, recently completing projects for Canada automotive companies, delivering intricate engine components that meet stringent specifications and deadlines. Additionally, we offer comprehensive services including CNC turning, milling, drilling, and tapping, ensuring all machining needs are met with precision.

| Production Process | CNC Machining, Casting, Sheet Metal Fabrication, Laser Cutting, Welding. |

| Drawing Format | PDF, DWG, STP, STEP, IGS, Etc |

| Material | Aluminum, Steel, Stainless Steel, Brass, Copper, Titanium |

| Tolerance | General tolerance ± 0.2 mm, The min tolerance is ± 0.005mm |

| Surface roughness | Min Ra0.2μm |

| Radian Internal Angle Radian | 0.05 mm |

| Packing | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton |

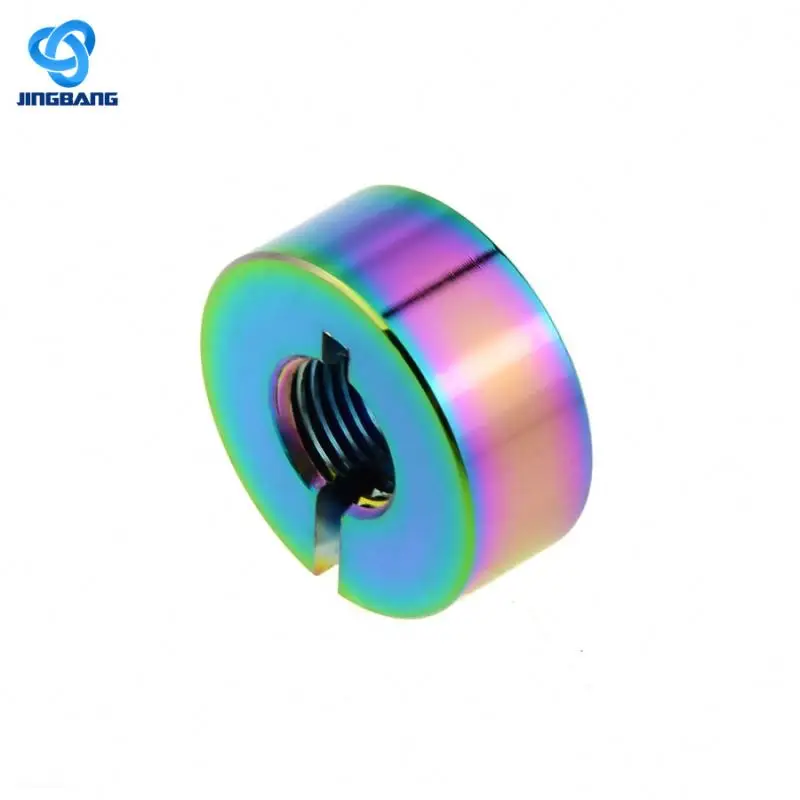

| Finish | As Machined, Sandblasting, Anodized, Zinc Plated, Black Oxide, Brushed, Polished, PVD |

Factory Show:

Quality Assurance:

Quality is the cornerstone of our operations at Jingbang Technology. We uphold ISO9001 Certification to maintain robust quality management systems that adhere to international standards. Our commitment to excellence is further underscored by NQA Certification, validating our environmental sustainability and operational excellence. Membership in LEKO signifies our adherence to industry-leading best practices, while IAF Certification assures compliance with global accreditation standards, ensuring the reliability and quality of our products and services.

In addition to certifications, Jingbang Technology holds patents for innovative solutions such as the anti-theft bolt and nut, demonstrating our commitment to innovation and tailored client solutions. These patents highlight our rigorous quality control processes, crucial in securing long-term contracts with major aerospace clients and delivering precision components for critical applications.

Quality Testing and Inspection:

Our commitment to quality extends to comprehensive testing and inspection protocols. We employ advanced quality inspection methods such as CMM (Coordinate Measuring Machine) and optical comparators to verify dimensional accuracy and ensure conformity to specifications. Each component undergoes meticulous scrutiny before shipment, guaranteeing that only products meeting our stringent standards reach our clients.

Customer-Centric Approach:

Our diverse and skilled sales team provides personalized attention and technical expertise, fostering lasting relationships with clients. A recent testimonial from a Sichuan medical device manufacturer underscores our team’s responsiveness and proficiency in facilitating successful product launches. We offer value-added services including assembly, finishing, and packaging, ensuring a seamless manufacturing experience from concept to delivery. Our commitment extends beyond delivery, providing ongoing support and partnership.

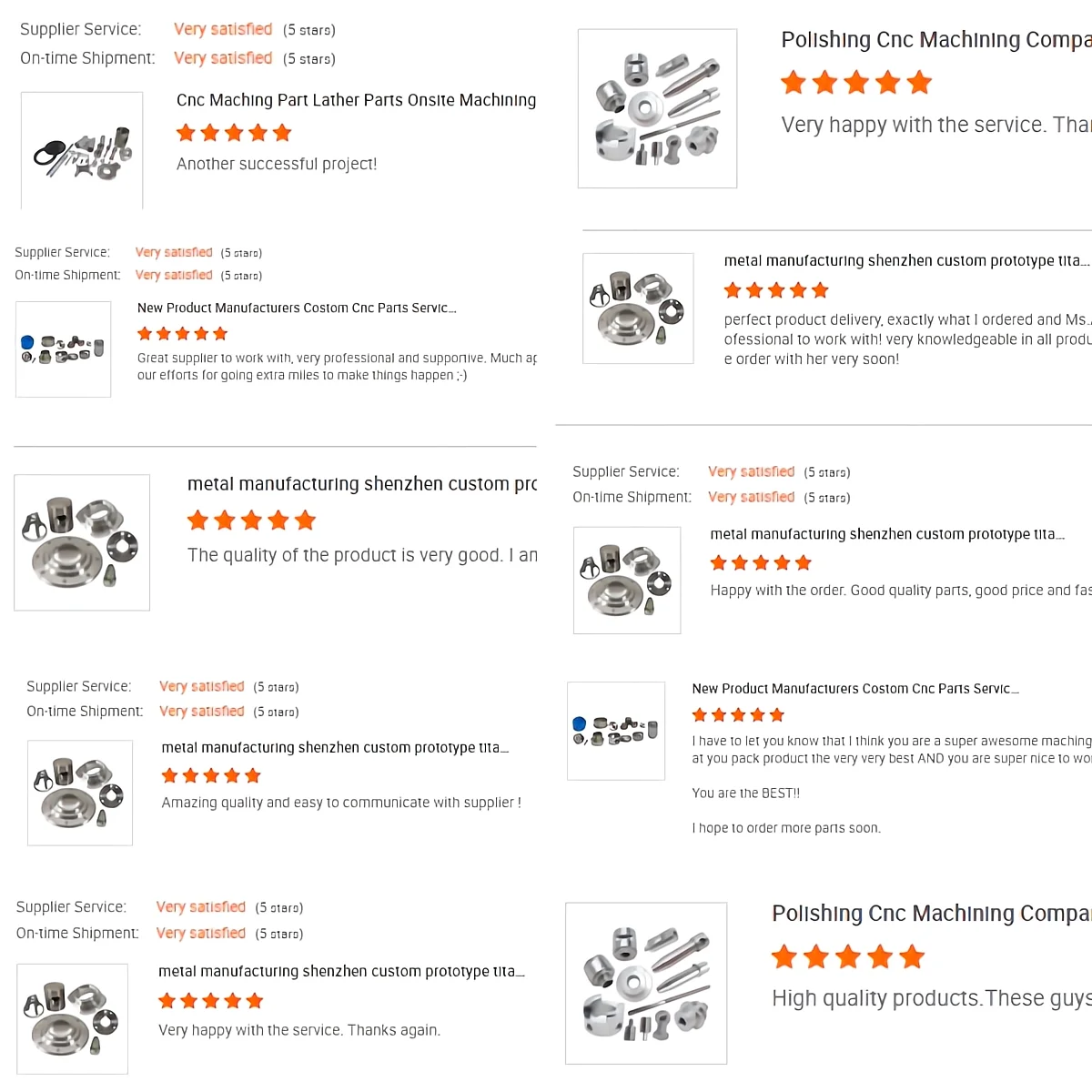

Customer Feedback:

We are factory established in 2011, located in ChengDu, SiChuan Province.

2. MOQ ?

For customized samples, MOQ is 200 pieces. For stock, MOQ is 30 pieces.

3. What materials are supported ?

.Aluminum alloy: 6061-T6, 6063-T6, 7075,2024,etc

. Stainless steel 303,304,316,201,etc

. Steel: Y15Pb, 45#, 20#, 65Mn steel, 4140,etc

. Brass: H57,H58,H59,H62,C3604BD,C2600,C3604,etc

.Plastic / Nylon / POM

4. Surface Treatment ?

Anodized, Oxide, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving Zn-plating, Ni-plating,Cr-plating, Tin-plating,copper-plating, the wreath oxygen resin spraying, the heat disposing,hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated,rust preventive oil, titanium alloy galvanized,silver plating, plastic, electroplating, anodizing etc.

5. How To Customize?

Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don't have a professional drawing, you can contact us and we will customize it for you according to your requirements.

Похожие товары

Высококачественные детали для обработки ЧПУ Liangyin экструзионный алюминиевый спиртовой профиль в промышленности

Индивидуальная механическая обработка винтовых зубчатых колес может производиться

OEM Заводская изготовленная на заказ установка уплотнения вала шестерни Магнитная

Автомобильные педали

Китай OEM ODM изготовление на заказ услуги по изготовлению листового металла детали для глубокого вытягивания

Оптовая продажа пластиковые детали 3D-печать углеродные микрофибры нейлоновые усиленные резьбовые стержни

Индивидуальные металлические прядильные формовочные автоматические термообрабатывающие промышленные изделия с ЧПУ

Новые поступления

Новинки товаров от производителей по оптовым ценам