Изготовленные на заказ стандартные вставки Pcbn DCGW070202 наконечники DCGW для чугунной твердой стали

- Категория: >>>

- Поставщик: Henan Wegcl New Materials Co. Ltd.Henan Ltd.

Сохранить в закладки 1601010400945:

Описание и отзывы

Характеристики

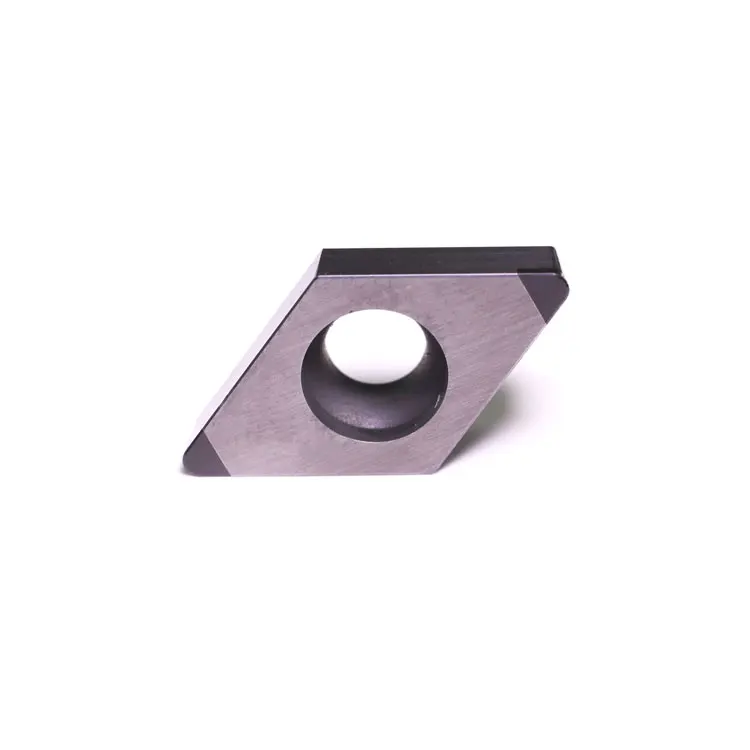

Custom ISO Standard Pcbn Inserts DCGW070202 Pcbn Inserts Pcbn Tips DCGW For Cast Iron Hard Steel

PRODUCTS DESCRIPTION

What is DCGW PCBN Inserts ?

DCGW is an 55-degree diamond-shaped insert with a 7-degree relief angle. It is made of PCBN composite sheet with excellent performance. It is a composite PCBN insert with a carbide base inlaid with a CBN tip. It is commonly used in finishing and semi-finishing cast iron and hardened steel. It is commonly used as boring inserts. Common used material grades are as follows:

SBH130 | SBH150 | SBH560 | |

Continuous Cutting For Finish | High-Performance Series | Excellent Cost-Effective Series | |

Machining hardened steel | SeriesContinuous Cutting~Light Interrupt Turning For semi-finish and finishing hardened steel | ||

SBH170 | SBH190 | SBH570 | |

Light Interrupt~Mid-Interrupt Cutting | High-Performance Series | Excellent Cost-Effective Series | |

Suitable For combined wear and impace resistance | Heavy Interrupt Turning For Heavy Interrupt Finishing Harded Steel | ||

PRODUCT RANGE

Tipped PCBN Inserts DCGW/DCGT

DCGW series inlaid composite PCBN inserts are often used as boring inserts, which can withstand continuous, intermittent and heavy interrupted machining conditions. There are different types of insert materials for cast iron and hardened steel parts, which can fully meet different customer needs.

DCGW compound PCBN inserts are conventional ISO standard triangular inserts. Commonly used models are DCGW0702,DCGW11T3, etc. Standard cutting edges are 2 tips, and radius can be 02,04,08, common chamfer is S01020, S01025, S01325,ect. Other non-standard cutting edges, radius and chamfer can be customized.

DCGW compound PCBN inserts are conventional ISO standard triangular inserts. Commonly used models are DCGW0702,DCGW11T3, etc. Standard cutting edges are 2 tips, and radius can be 02,04,08, common chamfer is S01020, S01025, S01325,ect. Other non-standard cutting edges, radius and chamfer can be customized.

CBN Inserts DCGW/DCGT | ||||||||||

Model | L(mm) | d(mm) | t(mm) | Φd(mm) | r(mm) | |||||

DCGW070202 | 7 | 6.35 | 2.38 | 2.8 | 0.2 | |||||

DCGW070204 | 7 | 6.35 | 2.38 | 2.8 | 0.4 | |||||

DCGW070208 | 7 | 6.35 | 2.38 | 2.8 | 0.8 | |||||

DCGW11T302 | 11 | 9.525 | 3.97 | 4.4 | 0.2 | |||||

DCGW11T304 | 11 | 9.525 | 3.97 | 4.4 | 0.4 | |||||

DCGW11T308 | 11 | 9.525 | 3.97 | 4.4 | 0.8 | |||||

CBN INSERTS CHARACTERISTICS

The performance characteristics of CBN tools mainly include the following aspects

1. High hardness: CBN tools have a hardness second only to diamond, reaching above 5500HV, which gives them extremely high wear resistance and tensile strength, allowing them to work under high loads and speeds.

In summary, CBN tools have the advantages of high efficiency, precision, stability, wear resistance, and high temperature resistance, making them an indispensable cutting tool in modern industrial production

2. High thermal stability: CBN tools have good high-temperature stability and high-temperature hardness, and can work under high temperature, speed, and load, greatly improving cutting efficiency.

3. Excellent wear resistance: CBN tools have higher wear resistance than traditional hard alloy and ceramic tools, with longer service life, which can be several times or even more than that of hard alloy and ceramic tools.

4. Small cutting force: CBN tools can complete machining tasks with smaller cutting force, reducing workpiece deformation and loss.

5. Processing high hardness materials: CBN tools can process high hardness materials, such as quenched steel, hot-worked hardened steel, thermal spraying materials, and high hardness cast iron.

6. High-speed cutting: CBN tools can achieve high-speed cutting, thereby improving production efficiency and reducing production costs.

3. Excellent wear resistance: CBN tools have higher wear resistance than traditional hard alloy and ceramic tools, with longer service life, which can be several times or even more than that of hard alloy and ceramic tools.

4. Small cutting force: CBN tools can complete machining tasks with smaller cutting force, reducing workpiece deformation and loss.

5. Processing high hardness materials: CBN tools can process high hardness materials, such as quenched steel, hot-worked hardened steel, thermal spraying materials, and high hardness cast iron.

6. High-speed cutting: CBN tools can achieve high-speed cutting, thereby improving production efficiency and reducing production costs.

In summary, CBN tools have the advantages of high efficiency, precision, stability, wear resistance, and high temperature resistance, making them an indispensable cutting tool in modern industrial production

APPLICATION INDUSTRY

INSERTS TIPS DETAILS

Self-sufficiency from raw materials to production , material properties are uniform, high temperature and high pressure synthesis make the product dense and uniform, and achieve stable and long life.

Ultra-precision high-end welding equipment ensures that the blade welded firmly and has a more stable tool life.

Imported peripheral grinding machine has higher precision and more stable cutting edge size, which achieves excellent stability and maintains surface roughness for a longer period of time.

Henan WEGCL New Materials Co., Ltd. (Named SCBN TOOLS), originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China), focusing on the research and development and production of superhard materials, is committed to providing the best cutting solutions and tools for global customers, and is regarded by customers as a reliable supplier of superhard material tools.

After several years of rapid development, SCBN TOOLS has formed an industrial pattern based on the advantages of raw materials and turning tools, and has realized the self-sufficiency of the whole industry chain. In the application technology and material research and development of superhard materials, it is at the leading level in China, and has passed the IOS9001 quality system certification.

The main products are: Solid CBN inserts, Tipped PCBN Inserts and other precision machine cutting tools, etc. Solid CBN Grade SBN800,SBN850, have unique advantages on cast iron materials. It has an absolute cost-effective advantage in the processing of typical parts brake discs and brake drums.

Products are widely used in gears, bearings, automobiles, iron and steel metallurgy and aerospace and other industries, has reached cooperation with many well-known enterprises around the world, and our products are exported to Germany, Italy, South Africa, South Korea and other countries in Southeast Asia.

After several years of rapid development, SCBN TOOLS has formed an industrial pattern based on the advantages of raw materials and turning tools, and has realized the self-sufficiency of the whole industry chain. In the application technology and material research and development of superhard materials, it is at the leading level in China, and has passed the IOS9001 quality system certification.

The main products are: Solid CBN inserts, Tipped PCBN Inserts and other precision machine cutting tools, etc. Solid CBN Grade SBN800,SBN850, have unique advantages on cast iron materials. It has an absolute cost-effective advantage in the processing of typical parts brake discs and brake drums.

Products are widely used in gears, bearings, automobiles, iron and steel metallurgy and aerospace and other industries, has reached cooperation with many well-known enterprises around the world, and our products are exported to Germany, Italy, South Africa, South Korea and other countries in Southeast Asia.

Why Choose Us

01 Technical support: We have a professional technical team that provides comprehensive technical support and consultation services. Please contact us at any time when you have any problems and we will provide timely solutions.

02 Quality guarantee: All SCBN TOOLS products undergo strict quality control and testing to ensure they meet ISO standards. If there are any quality issues, please contact us and we will handle them promptly. We are committed to providing our customers with high-quality products and services.

03 Fast response service: We promise to respond within 24 hours of receiving your feedback, and provide you with a solution in the shortest possible time.

04 Fast shipping: We promise to arrange delivery as soon as possible after receiving your order and choose the fastest express delivery method to ensure you receive the product as soon as possible. (DHL, FedEx, UPS, TNT)

FAQ

1 Who Are We?

SCBN TOOLS are based in Zhengzhou,Henan,China,originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China).

2 How Can We Guarantee Quality?

Always a pre-production sample before mass production;

Always multiple quality inspection steps in the production and final inspection before shipment;

3 What Can You Buy From Us?

Solid cbn inserts,tipped pcbn inserts,coating pcbn inserts,wiper pcbn inserts,CBN Grooving Inserts,Chipbreaker PCBN Inserts and any other customized CBN Inserts.

4 Why Should You Buy From Us Not From Other Suppliers?

1) Integrating R&D, production and sales.

2) Formerly known as Henan Advanced Materials Research Institute, located in China's Superhard material Base.

3) Known for "SCBN TOOLS" Brand and have exported our products to various countries.

5 What Services Can We Provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,German,Russian,Korean

SCBN TOOLS are based in Zhengzhou,Henan,China,originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China).

2 How Can We Guarantee Quality?

Always a pre-production sample before mass production;

Always multiple quality inspection steps in the production and final inspection before shipment;

3 What Can You Buy From Us?

Solid cbn inserts,tipped pcbn inserts,coating pcbn inserts,wiper pcbn inserts,CBN Grooving Inserts,Chipbreaker PCBN Inserts and any other customized CBN Inserts.

4 Why Should You Buy From Us Not From Other Suppliers?

1) Integrating R&D, production and sales.

2) Formerly known as Henan Advanced Materials Research Institute, located in China's Superhard material Base.

3) Known for "SCBN TOOLS" Brand and have exported our products to various countries.

5 What Services Can We Provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,German,Russian,Korean

Похожие товары

Твердосплавные вставки T5K10 T15K6 снеппа 110408 PNUM110408 в продаже

0,80-0,90 $

APMT1135PDER/APMT1604PDER TG6275 APMT1605PDER/APMT1604PDER TG6325 токарный станок с ЧПУ карбидные фрезерные вставки режущие лезвия инструменты

Высокоскоростная твердосплавная вставка BMS-9 высокой скорости 2D/3D/4D U дрель

1,00 $

ZHUZHOU WCMX Tungsten Carbide Drill Bit Insert WCMX030208R-53 YBG202

2,00 $

Фрезерные Инструменты серии TMR круглый носик Т-слот Фрезерный инструмент

TNMG160402/04 MS KC5010 TNMG160402 MP KENNAMETALS полный диапазон можно заказать

7,00-10,00 $

Токарный станок с ЧПУ для лазерной резки инструмент MGEHL2020-3 режущие канавки держатель токарного инструмента MGMN300 карбидная вставка

Новые поступления

Новинки товаров от производителей по оптовым ценам

Специальные продажи экстремальное бездорожье Unimog Merce-des-Benz U530

6 000 $

Запасные части для мотоциклов сила 1 импульсная

Беспроводной велосипедный Спидометр Одометр ЖК-Смарт-подсветка

6,40-6,80 $

Вакуумный выключатель против сифон обратный клапан с

Оптовая продажа мужские футболки оверсайз с графическим рисунком 100% футболка премиум-класса хлопковая Футболка логотипом принтом на заказ без рисунка

4,85-7,10 $

2025 новый солнцезащитный крем SPF50 ++ водонепроницаемый Стойкий УФ Отбеливающее масло контроль OEM Private Label

Оптовая продажа натуральное исцеление хрустальные черепахи ручной работы смешанный материал черепаха для украшения дома подарок

3,50-4 $