150 Вт 180 200 300 СО2 лазерный источник питания Yongli HY ZYE MYJG co2

- Категория: >>>

- Поставщик: Pcs Equip Co. Ltd.Pcs Ltd.

Сохранить в закладки 1601013940471:

Описание и отзывы

Характеристики

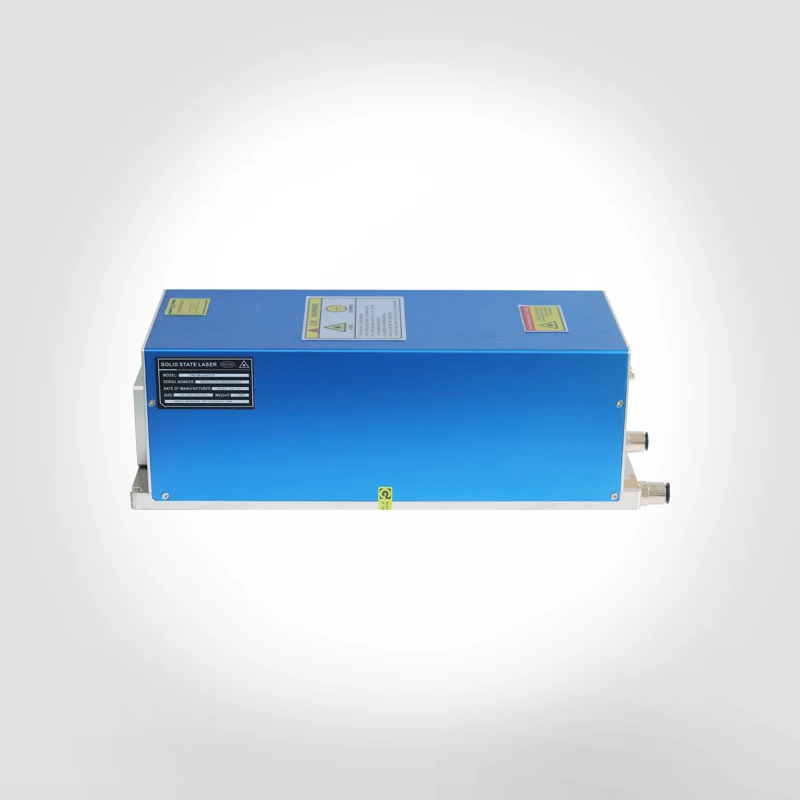

150W 180W 200W 300W Co2 LASER POWER SUPPLY Yongli HY ZYE MYJG CO2 LASER POWER SOURCE

YL-HSP200 CO2 Laser Power Supply, which perfectly compatible with DLT Series CO2 laser tube. YL-HSP200 is designed for Yongli’s patent product the Beam Combined Lasers, So the HSP-200 are not suggested to adapted to other brands of CO2 laser tubes.

Model No. | YL-HSP200 |

Compatible with | DLT-300, DLT-40Z,DLT-300P |

Input Voltage | AC220V or AC110V (Optional) |

AC Input Frequency | 47~440Hz |

Over Current Protection | Yes |

Open Circuit Protection | Yes (Within Certain Time) |

Cooling Method | Fan Cooling |

Operating Temperature | -30℃ ~ 65℃ |

Relative Humidity | 20-85%RH (Non-Consendate) |

Vibration Resistance | Amplitude:1mm /Frequency 30Hz / 2 Hours |

Ageing Time | Continuous over 4 hours / Pulse over Half Hour(Frequency 60Hz) |

Feature:

1.Easy Control: The start and stop of laser can be easily controlled by TTL level. And there are protection switch to test the external water, ventilation, et

2. Easy control of laser power: Both 0-5V analog signal and PWM signal can control the laser power.

3. The power supply has the function of open circuit protection: Under the condition of good protective in earth, the power supply can work in open-circuit condition for a short time, which could avoid the damage of laser power supply because of the bursting of laser tube, thereby enhancing the life of power supply.

4. The power supply can take feedback interface which can be used in closed-loop control and testing the working current of laser.

5. Aging testing 500 times starting and stopping in 30 ℃ and 12 hours circumstance.

6. Application: CO2 laser power supply are mainly applied in engraving & cutting machine, laser marking machines and medical laser machine.

Technical parameters

Input Voltage

| AC220V or AC110V(to be specified when placing order) |

AC Input Frequency

| 47~440Hz |

Efficiency

| 91%(Full loading) |

MTBF | ≥10000hrs |

Speed of Response | ≤1ms |

Input-output, input-chassis: AC1500V 10mA 60s; The output negative pole is connected to the chassis. | |

Cooling Way | Fan cooling |

Working Temperature

| -30℃~65℃ |

Relative Humidity

| 20~85%RH(no condensation) |

Vibration Resistance

| Amplitude: 1mm frequency 30Hz Two hours |

Aging Time | Continuous>4 hours Pulse>Half an hour(frequency 60Hz) |

Product Details

1. The power supply output end shall not be open.It should be connected with laser electrode in correct way according to instruction.

1.Connection of laser tube, the high voltage (HV+) of the laser power supply shall be connected to the anode (full reflection terminal) of CO2 laser tube.

The current circuit of the laser power supply is connected to the cathode (laser output terminal) of CO2 laser tube through an ammeter (or directly).

2. Connection of control signal:Control signal shall be reliably connected to control terminal of the power supply.

3. Input of control signal: After connecting the output signal and TTL signal of external computer with the power supply, the laser tube shall work as expected.

Cautions:

1. Ensure that laser power should be place is well ventilated, it is strictly prohibited that the louver of laser power close to machine (the distance would better more than 3 cm).

2. HV output terminal shall not adopt open circuit! (HV output terminals shall be properly connected to the anode and cathode of the laser tube), High voltage connector and wire connection joint should not to be stressed and pulled etc.

3. Discharge resistance has been equipped inside the power supply and the residual voltage will be fully discharged 2s later after power off. Attentions should be given to avoid any electric shock! (Both output terminals of the high voltage shall ensure the isolation safety of the overhead 40KV.)

4. Three-poles socket with earth contacts shall be used to laser power supply. The enclosure should be well grounded to avoid electric shock.

5. Pay attention to the maintenance of the laser power, please cleaning the dust of power supply and cooling fan regularly

6. Ensure the laser power integrity. it is strictly prohibited to destroy the high voltage connector, the cable and labels, etc.

Packaging

Laser tube has obtained 50 patents, 6 software copyrights, and has successfully passed European CE certification, RoHS certification, FCC certification, REACH certification, MSDS certification, US Food and Drug Administration Certification, TUV Rheinland certification, Swiss SGS testing certification, and ISO9001 quality management system certification.

PCS Equip Co., Ltd. specialized in producing and exporting different kinds of Laser marking machine, Fiber welding machine; Sewing textile machinery and Laser machine spare parts, such as: Co2 Laser Tube, Laser Power Supply, Power Meter, Chiller, Laser mirror, Focus lens and so on.

PCS Equip Co., Ltd. specialized in producing and exporting different kinds of Laser marking machine, Fiber welding machine; Sewing textile machinery and Laser machine spare parts, such as: Co2 Laser Tube, Laser Power Supply, Power Meter, Chiller, Laser mirror, Focus lens and so on.

Products are widely applied in many kinds of fields such as Apparel, Textiles, Auto part & accessories, Hardware, Advertising industry, medical industry etc.

Currently, we have exported over 63 countries and regions, we have passed the CE, ROHS, REACH, FCC, FAD certification, at the meantime, have continuously improved after-sales service system and a good quality control team.

Currently, we have exported over 63 countries and regions, we have passed the CE, ROHS, REACH, FCC, FAD certification, at the meantime, have continuously improved after-sales service system and a good quality control team.

We are adhering to timely response, superior service and premier quality.

The aim is willing to provide the highest integrity customer service and the best after sales support in these industries.

We sincerely wish to have you join us in providing the ultimate user with the best available for mutual development and benefits.

PERFECT REPLACEMENT LASER TUBE FOR ALL CUTTING ENGRAVING MACHINE

This laser tube is made of the boron silicate glass that is also applied on the solar tubes. It is resistant to high temperature and high pressure. We packed and ship with a great amount of care and effort to ensure tubes arrive on time and in one piece!

We offer both before and after sale product services and technical support to our OEM and system integration partners worldwide.

Pre-sale service Material testing for free

Provide material testing with our laser tubes in different laser powers and configurations for specific industry. Upon returning your processed samples, we also will provide a detailed report that is for your specific industry and application.

Technical Consultation

Provide customers with professional technical, application and price consultation (via Email, Phone, WhatsApp, WeChat, Skype, etc.). Quickly respond to any questions that customers concern about, such as: laser processing in differences on the application of different materials, laser processing speed, etc.

After Sales Service

* Customers need to provide feedback and relevant photos and videos if the issue has arisen during their use of the CO2 laser tube and related products.

* The issue information will be conveyed to our technicians within 24 hours, and they will then work quickly to determine the cause of the problem.

* Customers will be informed of problem causes, and a solution, within 48 hours. If the Laser tube needs to be replaced within the period of warranty, no charge will be taken

We are adhering to timely response, superior service and premier quality.

The aim is willing to provide the highest integrity customer service and the best after sales support in these industries.

Have any quality problem, we could judge by a video and photo, donot need return the laser tube and power supply to factory more. We will arrange new shipment free. Save your expense and time.

Q:How to maintain the laser power supply during daily use

A:Pay attention to the machine and laser power supply strictly grounded,

The laser power supply should be placed in a well-ventilated place conducive to heat dissipation

Clean the dust accumulation on the laser power supply that blocks the ventilation opening in time.

Always check whether the cooling fan inside the laser power supply is running normally and whether the air outlet on the power supply case is blocked? Is the laser power supply overheating etc.

Q: Power Supply can used for RECI , EFR , SPT Co2 laser tube?

A: The HSP200 Laser power suppy is 'negative voltage' not for regular power supply, Yongli designed only for DLT series laser tube.

Q: My machine was grounded, power supply need extra connect earth wire?

A: The enclosure should be well grounded to avoid electric shock.

Q: How to insulate the high-voltage end of power supply and laser tube?

A: After putting on the silicone tube, pour some glues inside. Wrap a few more turns with electrical tape.

Q:Can you tell us the advantages your company, why we choose you?

A: We can integrate factory advantages to meet customers' multi-style needs,

Our team with rich foreign trade export experience, the export operation is more professional, ordering execution and shipping process is simpler than factory, reduce business risk.

Похожие товары

Qdlaser 60 Вт CO2 лазерный источник электропитания для лазерная гравировка машина HY-T60

Hy-T35 машина для резки Co2 35 Вт 40

Горячая распродажа однодырочные лазерные проточные трубки полостные фильтры из кварцевого стекла с легированным оксидом Самария

Промышленный Мощный фиолетовый 100 Вт диод LDI волоконно-оптический лазерный модуль 405 нм для УФ-экспозиции и медицины

SPT CO2 лазерная трубка 40 Вт ~ 150 co2 Лазерная ваттная для акриловой резки MDF медицинская

1064 нм 4 в 1 лазерная сварочная головка SUP21T с SUP-AFM-A проволокой питатель система набор для волоконно-сварочного аппарата

Gainlaser Ультрафиолетовый лазерный источник 3 Вт 5 10 355 нм станок аксессуары для водяного охлаждения

Новые поступления

Новинки товаров от производителей по оптовым ценам