Пищевой 635 сетчатый Ультразвуковой вибрационный экран роторный просеиватель для мелкодисперсного порошка глинозема

- Категория: >>>

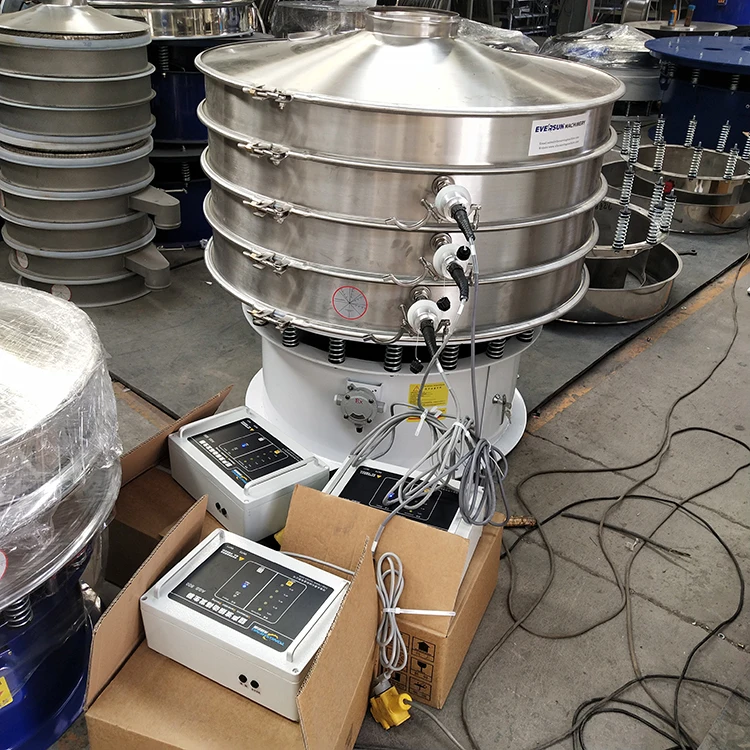

- Поставщик: Eversun Machinery (henan) Co. Ltd.

Сохранить в закладки 1601014052394:

Описание и отзывы

Характеристики

Food grade 635 mesh ultrasonic vibration screen rotary vibrating screen sifter for fine alumina powder

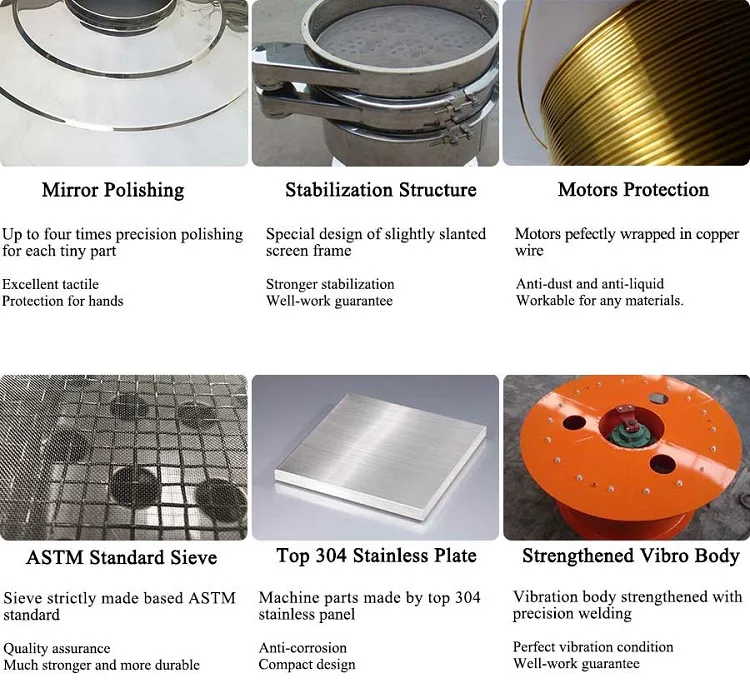

ultrasonic vibrating sieve for powder processing is composed of ultrasonic vibration system and vibro sieving machine. With unique technology, the VSM ultrasonic system will transmit high-frequency micro vibration to the mesh. Plus the original vibro of machine, the sieving output, quality and capacity can be dramatically increased. Also mesh can do perfect self-cleaning to reduce the downtime for our clients.

The EVERSUN ultrasonic vibro sieving machine changes the damage caused by the conventional screening method to the powder, especially ultra-fine powders and highly viscous materials, and the sieving throughput are increased efficiently. Also the abrasion of sieves will be reduced sharply so that the maintenance cost and downtime will get lower.

Features & Benefits of ultrasonic vibrating sieve for powder processing

Dramatic increase of capacity——the processing volume is 2-10 times than that of ordinary screening machines

Ultra fine grading available——the sieving size can reach up to 600mesh(0.023mm)

Efficient for hard-to-screen materials——the materials like silicon carbide micro-powder, hard alloy micro-powder, coffee powder,etc can be screened efficiently

Reduce frequency of cleaning sieve——low blocking and high throughput rate of sieve

Low maintenance cost——reduce the damage rate of sieve and no need to repair and replace the mesh always

Wide application——almost all kinds of sieving machines can use this system

Detailed data of ultrasonic vibrating sieve for powder processing

Other products of ultrasonic vibrating sieve for powder processing

Q:How to choose the suitable machine?

A:The proper selection of the vibrating screen depends on the material, number of layers, every mesh size, capacity, material moisture, viscous and corrosive etc:

Name and feature of the raw material?

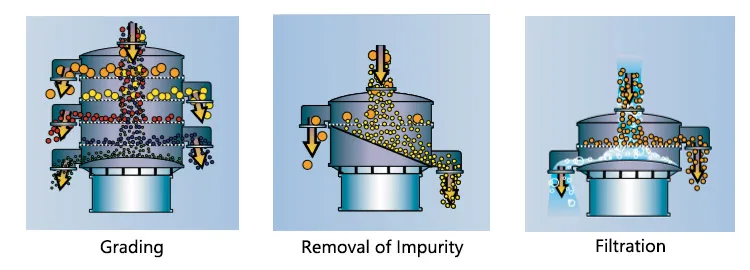

Aim of using: get rid of impurity, filtration, grading

Handling capacity: kg /h, L/h

The raw material size: (mesh or mm)

How many final materials you want, or how many layer you need?

Local power supply (voltage and frequency)

Note: You had better send us the relevant pictures about the details.

Q:Is it special requirement available?

A:Yes, the equipment could be designed according to customer's using aim or special requirements.

Q: How long will my order take?

A: Normal delivery is about 7 working days. Ending delivery schedule depends on the quantity and items you ordered.

With more than 30 years of development and technology precipitation, Our company, Henan Yongsheng Vibro Sieving Machine Co.,Ltd, has become one professional international manufacturer for sieving machines, vibro sifter machines, ultrasonic sieving clearing systems, separators, vibrating screen machines, conveying equipment, filtration equipment, crushing equipment and so on.

As one of the largest OEM factories in China, each year we supply around 5000 sets machines to serve more than 150 distributors, manufacturers and traders, providing all kinds of reliable customized equipment to help our clients build their brands.

Different from those small factories, which only produce several parts for one machine, our factory have one complete modernized production line of sieving machines, producing all the parts of products. By this way, we can monitor every aspect of production and do the customized goods for different industries.

Right now, our factory have 12,000sqm of production area and more than 100 skillful workers, including 30 highly-trained engineers. Our engineers can provide the most suitable sieving solutions to meet the needs of different industries, from fine materials, such as food, chemical, medicine to rough materials, such as mineral,fertilizer, garbage.

Package of ultrasonic vibrating sieve for powder processing

2020 Factory best selling ultrasonic vibrating sieve for powder processing with 400~2000mm diameter

Product details

| Unique advantage | All parts can be customized |

| Material | Carbon Steel, Stainless Steel 304/316L |

| Function | Screening, separation, sorting, sieving, grading |

| Layer(s) | 1-5 Layers |

| Screen Mesh | 2-500 Mesh |

| Customized | Acceptable |

| Capacity | 100Kg-10Tons/hour |

| Cleaning system | Bouncing Ball,Ultrasonic System |

| Motor | Vertical Vibrating Motor |

| Product Keywords | powder ultrasonic vibrating sieve separator |

Похожие товары

CSB-600 ультразвуковой роторный вибрационный сито из нержавеющей стали для порошкового покрытия и скрининга зерна

Индивидуальный промышленный 3-слойный Круглый вибрационный просеиватель для просеивания черных солдат

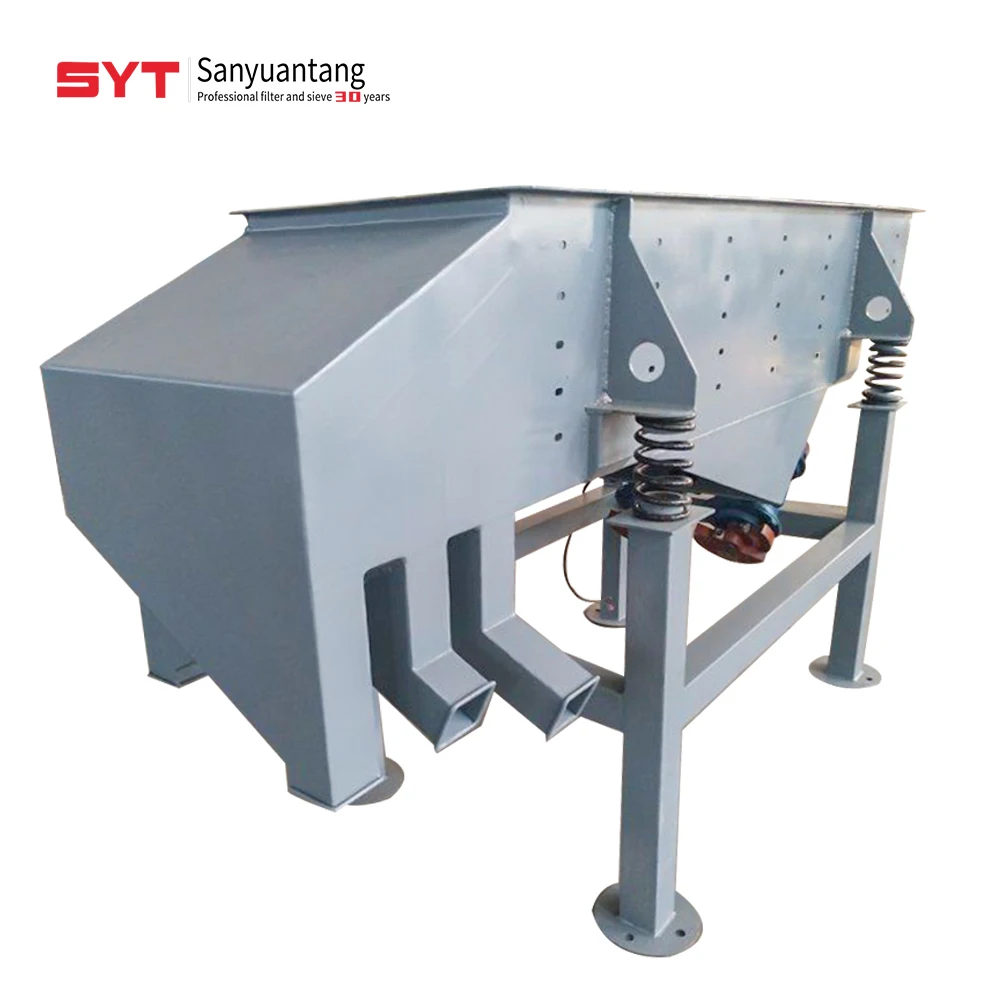

Лидер продаж каменный вибратор наклонный вибрационный сито двухосевой эллиптический горизонтальный экран серии ES

Вибрационные фидеры для песчаной мельницы большие кормушки горного камня вибрационный фидер

Порошковый измельчитель для мелкой древесной стружки сепаратор минеральной обработки xxnx горячее линейное Вибрационное Оборудование

Хит ХХХ для крахмала графитовый порошок гризли мелкая древесная щепа минеральная обработка сепаратор линейный вибрационный экран

Тумблер-экран для кварцевого песка слюды карбоната кальция нитрида кремния циркония свинцового сульфида литаржа

Новые поступления

Новинки товаров от производителей по оптовым ценам