Автоматическая экструдированная жареная пшеничная мука закуски Хрустящие черепашные Чипсы Закуски Гранулы жареные 3d гранулы линия по производству продуктов

- Категория: >>>

- Поставщик: Jinan Dayi Extrusion Machinery Co. Ltd.Jinan Ltd.

Сохранить в закладки 1601015459435:

Описание и отзывы

Характеристики

Product Description

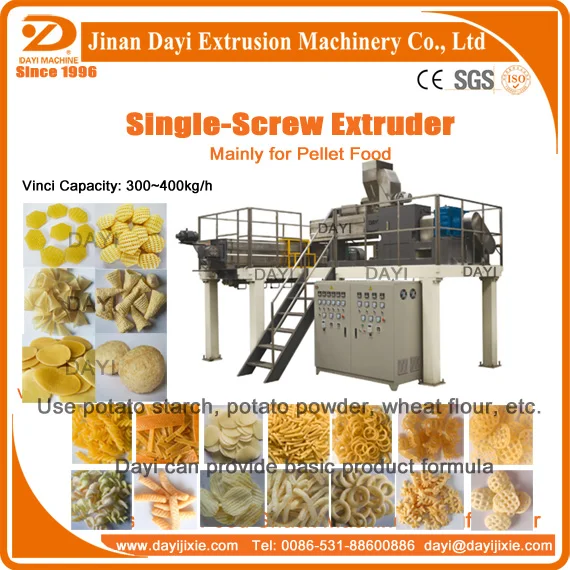

3D pellet process line is newly designed and produced with foreign advanced technology. It has reduced your cost on investment and production.Corn starch, wheart flour,potato flour and potato starch can be raw material to produce 3D Compound Pellet. 3D pellet process line is only one tenth of that of import equipment. It is the best investment choice for large or medium-sized enterprises.

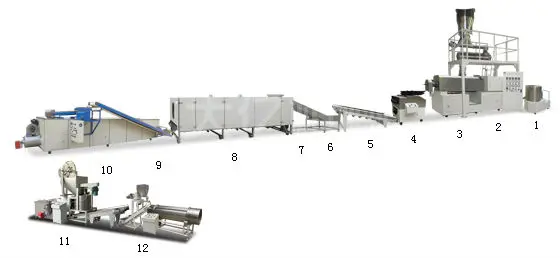

Technical parameters of 3D pellet production line

Model | Installed Power | Power Consumption | Capacity | Dimension |

Vinci | 132.2kw | 91.2kw | 300-350kg/h | 48000*4280*4550mm |

1) VINCI is combation of pre-cooking machine and shaper machine pefectly, replace the traditional twin screw extruder and single

screw extruder.

2) Save much more money and space for you.

3) Raw material can be wheat flour and Potato Cassava Powder and Starch.

4) 2D/3D Pellet Food shape and structure is the best.

screw extruder.

2) Save much more money and space for you.

3) Raw material can be wheat flour and Potato Cassava Powder and Starch.

4) 2D/3D Pellet Food shape and structure is the best.

Details Images

Name | Flour Mixe |

Model | BF-III |

Motor | 5kw |

Capacity | 100kg/batch |

Original: | Jinan,Shandong,China To Mix up the raw material like wheat flour, potato powder,oil. |

Name | Pellet Extruder |

Model | VINCI |

Motor | 350-400kg/h |

Capacity | 132kw |

Original | Jinan,Shandong,China Cook the raw material and form into different shapes. |

Name | Pattern Machine |

Model | YP |

Motor | 1.5kw |

Capacity | With extruder |

Original | Jinan,Shandong,China To make the pattern in the pellet. |

Name | 3d Compound Shape Machine |

Model | QF-III |

Motor | 1.5kw |

Capacity | With extruder |

Original | Jinan,Shandong,China To make the 3d compound shape. |

Name | Multi-layer Diesel/Gas Dryer |

Model | WHX |

Motor | 6kw |

Capacity | 300-400kg/h |

Original | Jinan,Shandong,China To dry out the extra moisture inside of pellet snack. |

Equipment Real Time Shooting

Company Introduction

Jinan Dayi Extrusion Machinery Co., Ltd. was established in 1996 and has always been a professional manufacturer and leader of advanced and efficient extrusion food machinery in this field in the world. The freshman company has gathered a team of experts with over 20 years of experience in the extrusion machinery industry, striving not only to continuously research extrusion technology, but also to explore food processing processes to benefit our customers who produce creative food.

A corner of the factory area

After years of exploration and research, our screw extrusion technology has been widely used in the production of the following products: casual snacks, breakfast cereal and corn flakes, fried flour food, granular food, bread crumbs, soy protein and vegetarian, pet food, etc. More than 20 production lines can be selected. We can also provide customized services for special requirements.

Customer testing

Many influential large food companies and agent have chosen us as and set up worthy fellowship with us over 20 years, especially Oishi Foods Company in Japan, Ai Nasim food industries Co.,LTD in Jordan, Pt mayora indah tbk in Indonesia, Kinh Do Corporation in Vietnam, Universal robina corporation in Philippines, and the many agents like Vs tecnologia industrial in Brazil, Pakistan etc. Meantime.

Customer Visit

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing&Shipping

Package

1.Wooden Case or Wooden Pallet

2.Fumigation wooden cases, which are well sealed and strong enough for long-term trip, and suitable for multi-times loading &

unloading by forklift.

Marketing Campaign

Our Advantages

We can keep product design in the same level with internationally advanced technology consistently.We can guarantee customers superior quality machines up to design requirements and perfect working state.

We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.We provide 1 year complete Guarantee and life-time maintenance service.

FAQ

1.Does your product support international transportation?

Answer: Yes, we support international transportation. Our products can be shipped globally. The transportation method and cost will depend on your order and destination. At checkout, you can choose the shipping option that suits you.

2. Does your product have quality assurance?

Answer: Yes, we have high requirements for the quality of our products and provide quality assurance to support pre factory inspection. You can click here to Contact Us.

3. What’s your Guarantee?

Answer:We provide 1 year complete Guarantee and life-time maintenance service

4. How about the installation?

Answer:We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Похожие товары

Полностью автоматическая машина для изготовления капкейков

4 900,00-5 100,00 $

Ying Machinery автоматическая машина для изготовления небольших печенья производственная линия электрическая мини-машина приготовления закусочные машины

13 800,00-14 500,00 $

Машина Для Производства Конфет

7 576,00-8 000,00 $

Автоматическое многофункциональное устройство для производства леденцов цена

9 600,00-12 800,00 $

Коммерческий Снэппер shaq тайваньский Shaq японский корейский шейкер для выпечки рыбы

153,00-175,00 $

Экструдер для детского питания

9 580,00-13 500,00 $

Лабораторная машина для обжига медных таблеток

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $