Бетонная цементная водопропускная труба Формовочная установка

- Категория: >>>

- Поставщик: Zhengzhou Xinyu Machine Manufacture Co. Ltd.

Сохранить в закладки 1601017678466:

Описание и отзывы

Характеристики

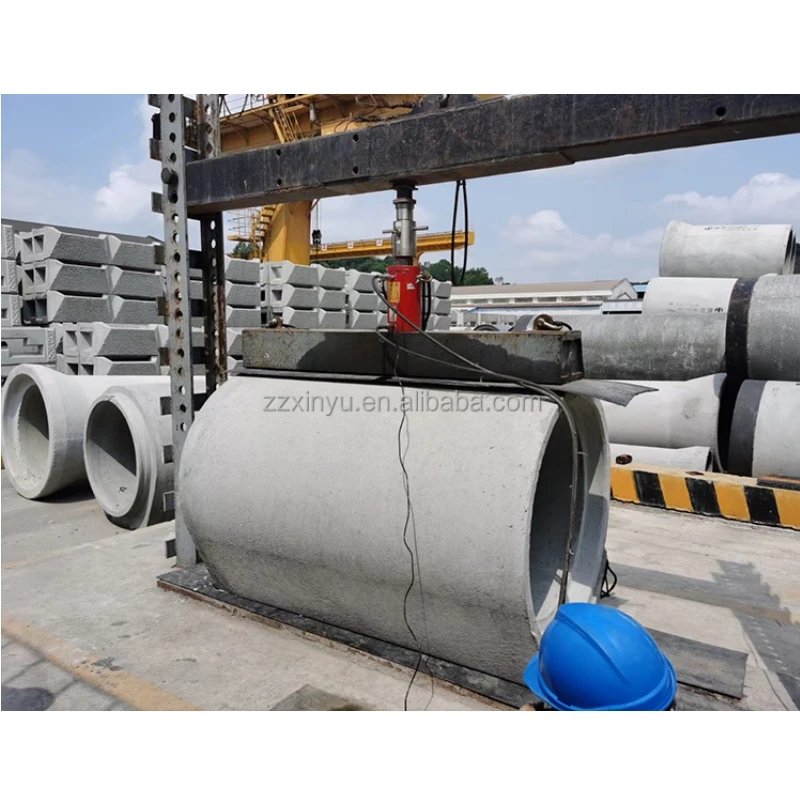

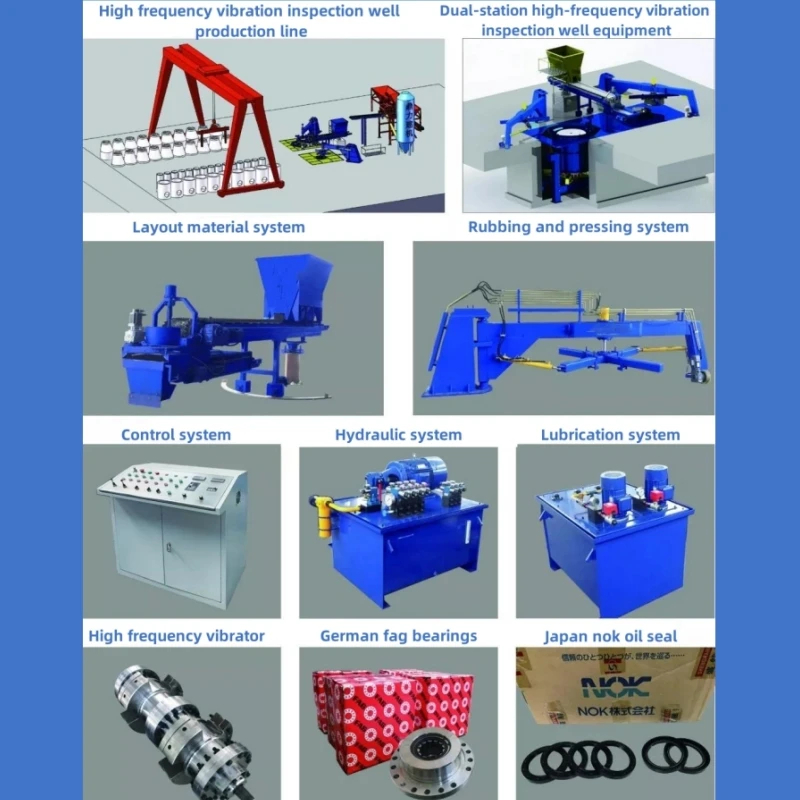

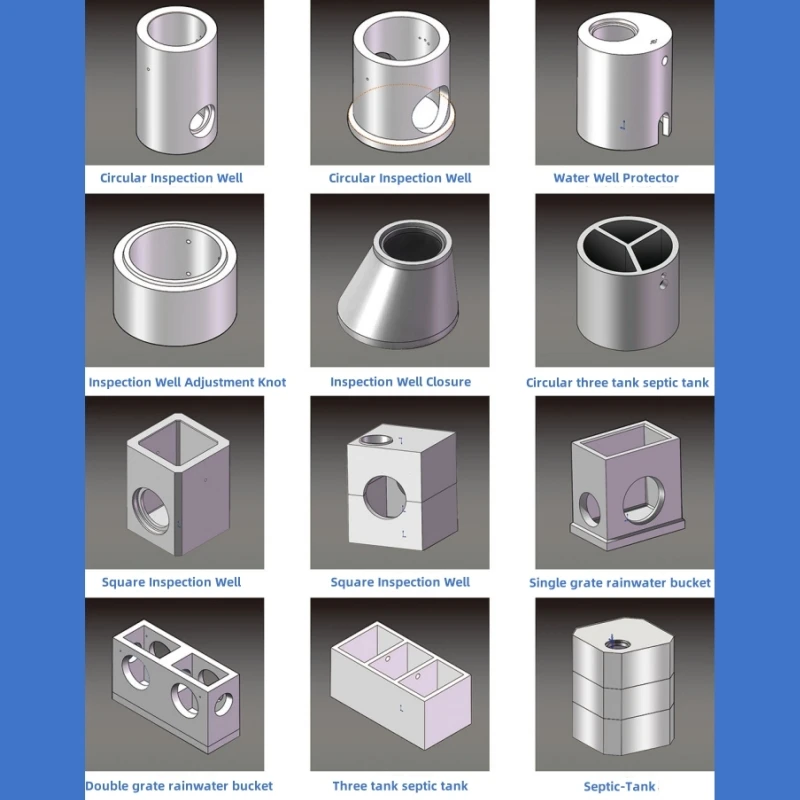

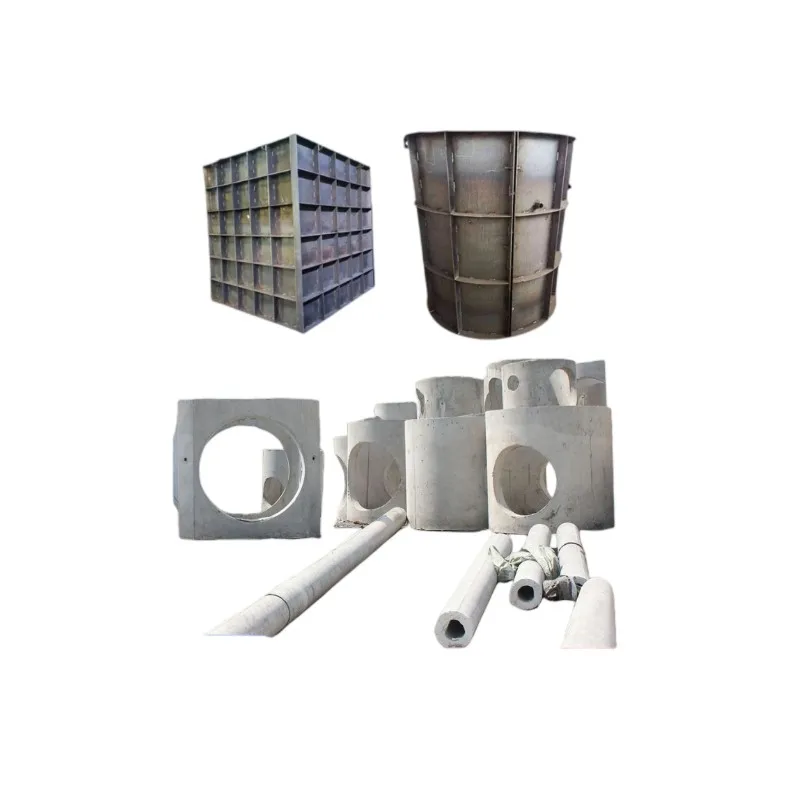

The high-frequency vibration inspection well is a new type of prefabricated concrete inspection well equipment developed and manufactured by our company. It is our company's patented invention product. This equipment has the advantages of high universality and can produce various cement components such as square wells, circular wells, rectangular wells, septic tanks, cement pipes, etc. It is versatile and helps customers solve multiple investment problems.

Characteristics of new high-frequency vibration inspection well equipment:

1. High frequency vibration (5000-6000rpm) is applied to dry and hard concrete through the high excitation force generated by high-frequency oscillators, achieving steam free curing, immediate demolding, energy conservation and environmental protection;

2. The wellbore and bottom are formed in one go, with the bottom facing upwards during production, solving the problem of traditional secondary molding techniques;

3. Due to the use of a high-frequency vibration table (5000-6000rpm) for vibration in this process, longitudinal vibration is generated on the entire component, resulting in uniform vibration of the entire wellbore and bottom, high compactness of the component, and basically no pores on the surface;

4. After vibration molding, the mold is automatically flipped using the axial eccentric force of the mold, and the bottom of the well is demolded downwards. There will be no collapse, cracking, or water seepage at the bottom of the well; Improve production efficiency;

5. The equipment is easy to operate and has high universality in technology. It can be used to make various cement components such as circular inspection wells, rectangular inspection wells, U-shaped grooves, cement pipes, etc;

6. The high-frequency vibration table adopts high-performance spring vibration reduction, with good amplitude transmission effect in the upper part and good vibration reduction effect in the lower part.

The water absorption rate experiment is 1.15%

Concrete position | Weight after drying (kg) | Weight after water absorption (kg)

| Water content (kg) | Water absorption (%) |

| On concrete | 4.595 | 4.620 | 0.025 | 0.5 |

| Under concrete | 4.505 | 4.550 | 0.045 | 1.0 |

| In concrete | 4.695 | 4.800 | 0.105 | 2.2 |

| Concrete | 4.53 | 4.570 | 0.040 | 0.9 |

Zhengzhou Xinyu Machine Manufacture Co., Ltd is the specialized corporation which produces large and medium construction equipment products. We specialize in the production of concrete mixing plant, asphalt mixing station, JS series twin shaft concrete mixer, concrete block making machine amd tower crane.

With nearly 20 years of development, successfully completed the original accumulation of capital. Our company covers an area of 126,000 square meters, with 78 million yuan in fixed assets and the employees are more than 1000. We have abundant economic strength, strong technical force, huge sales network and perfect after-sales service.

Use the technical strength, advanced technology, continuous product upgrades to make the quality of the products more perfect, more applicable. We not only have good sales in the domestic market, but also exported to Russia, Kazakhstan, Mongolia, and Viet Nam and other countries.

|  |  |

Q:Do you have set up an independent factory?

A:We have our own factory. Has the specialized cement machinery product equipment factory, also has the large-scale cement drain pipe production factory.

Q:What can you do for us?

A:1. Before sales can be targeted to give some constructive Suggestions.

2.Make a specific plan for your needs.

3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us?

A: Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.

Q:Can your engineers train our workers in our factories?

A:Yes, we have a very large engineering installation team that can train and instruct your workers to operate the installation equipment.

Q:If we provide the parameter requirements, can we make it to order?

A:We provide customized services as long as you provide the appropriate drawings and product requirements.

Q:How long is your lead time?

A:Our delivery time varies according to the quantity of the order, usually around 15 days.

Похожие товары

Китайский производитель бетонных труб, пресс-формы для бетонных люков, предварительно напряженные бетонные цилиндрические трубы, литейные формы

Бетонная форма для дренажной трубы

Сборная машина для производства крышек люков для проверки бетона

Производство Китай, передвижная машина для изготовления люков, сборные водопропускные бетонные трубы, машина для производства люков

Бетонная полая труба литейная форма цемента

Сборный бетон для осмотра колодца стальная форма

Сборный бетон/цементные инспекционные стальные формы, формы для люков

Новые поступления

Новинки товаров от производителей по оптовым ценам