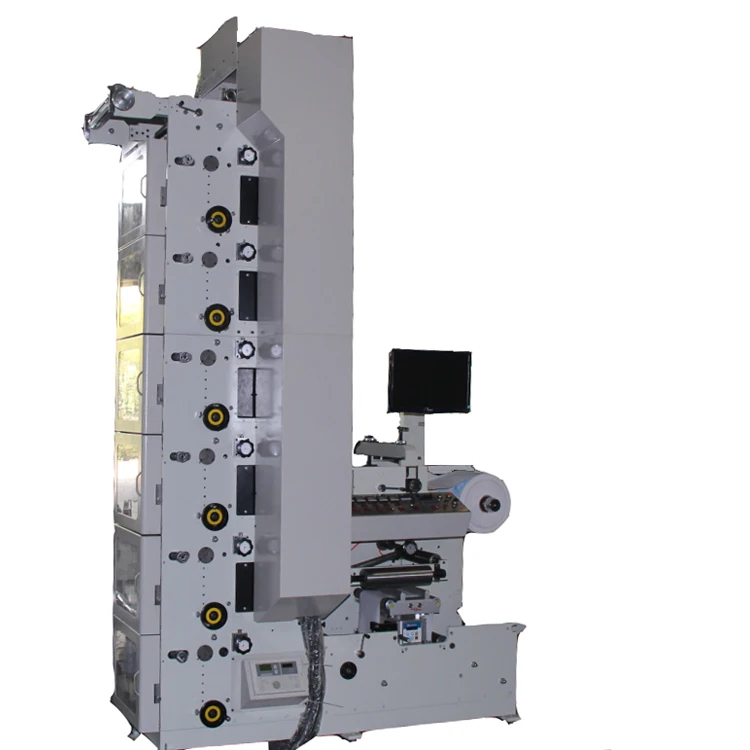

Полностью Автоматическая флексографическая маленькая этикетка 8 цветов 320 мм ширина наклейка флексографская печатная машина

- Категория: >>>

- Поставщик: Shanghai Shiyu Machinery Co. Ltd.

Сохранить в закладки 1601018033775:

Описание и отзывы

Характеристики

Characters:

1. From thedischarge to the receipt of the short

2. Theceramic stick is equipped with a scraper, which is printed and moist, and has a clear color.

3. Repeatedly printing the circumference of 190.5-635MM, filling the blank of the cascading flexographicprinting machine, the slanting trademark printing machine, the petal printing machine and the printing

4. Theuse of gear color to solve the 360-degree coloring device gap, assembly, wear, affecting the color accuracy and printing instability.

5. From left to right: coil feeding, printing, UV curing,film cutting, laminating, slitting,winding a coherent completion .

6. Water-based inkprinting, pollution-free, environmentally friendly, printing speed varies according to the network cable, the speed is also different, the fastest speed of printing labels is 90 meters per

7. Printingbills, labels, cardboard, high-grade stickers, clothing tags,

1. From thedischarge to the receipt of the short

2. Theceramic stick is equipped with a scraper, which is printed and moist, and has a clear color.

3. Repeatedly printing the circumference of 190.5-635MM, filling the blank of the cascading flexographicprinting machine, the slanting trademark printing machine, the petal printing machine and the printing

4. Theuse of gear color to solve the 360-degree coloring device gap, assembly, wear, affecting the color accuracy and printing instability.

5. From left to right: coil feeding, printing, UV curing,film cutting, laminating, slitting,winding a coherent completion .

6. Water-based inkprinting, pollution-free, environmentally friendly, printing speed varies according to the network cable, the speed is also different, the fastest speed of printing labels is 90 meters per

7. Printingbills, labels, cardboard, high-grade stickers, clothing tags,

8. Printingmaterials: paper 20~250g/m2 self-adhesive soft coil and other

Printing speed: | 10m/min-70m/min |

Maximum paper width | 330mm |

Maximum printing width | 320mm |

Repetition length of printing plate | 175 ~ 450 mm |

Maximum unwinding diameter | 700mm |

Maximum recovery diameter | 700mm |

Registration accuracy | 0.1 mm |

Gear specification | 1/8cp |

Plate thickness | 1.7mm |

Thickness of pasting tape | 0.38mm |

Printable materials | 30-300gsm |

Total power of the whole machine: | 65kw |

Drying heat source: | Electric heating |

Machine weight: | 4000kg |

Dimensions : | 7.5(L) x 1.5 (W) x 2.6(H)m |

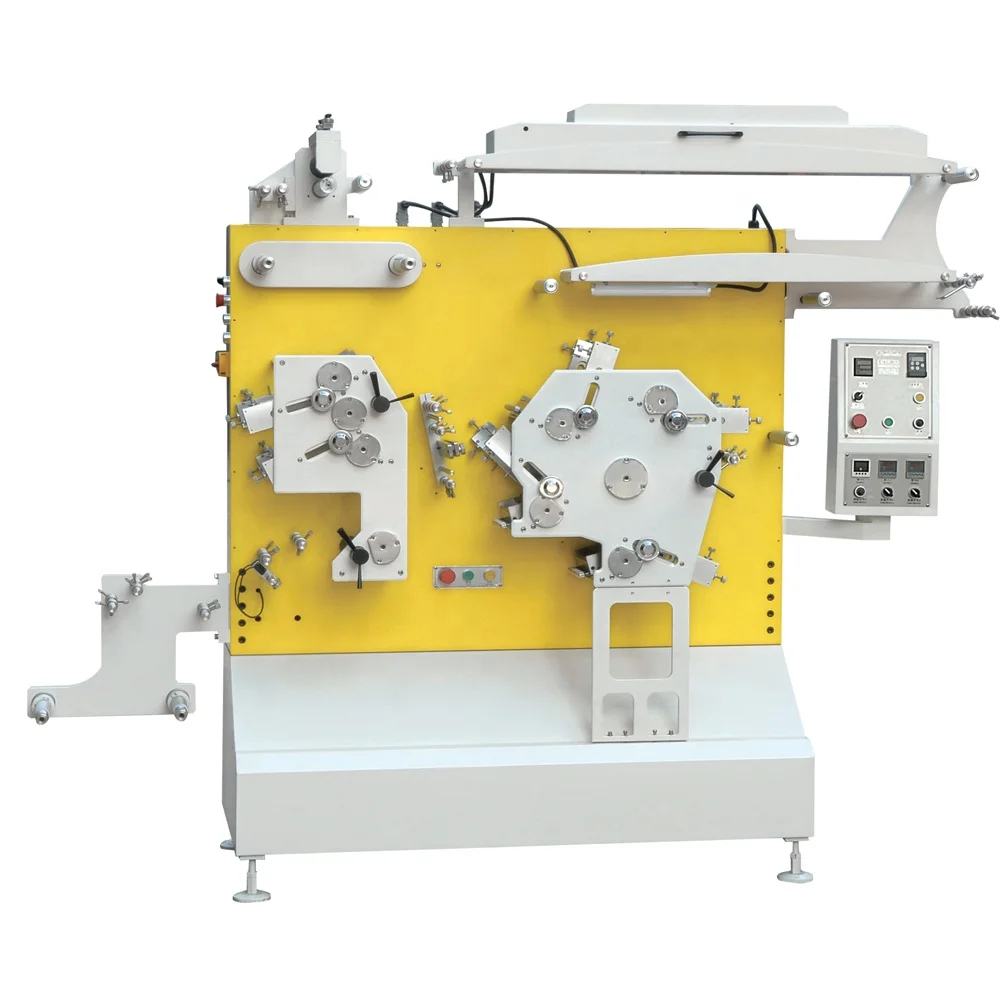

Printing Unit

Printing station comes with ink rubber roller, ceramic anilox cylinder, printing plate cylinder, scrapper blade and ink

container.helical gear

container.helical gear

Video system

It is used to check the printing quality in real time while the machine is working. The main purposes are to reduce waste,maximize productivity and improve printing quality

UV Oven group

During printing, the printing ink temperature becomes very high due to UV curing, so it is equipped with a water-cooled roller to reduce the surface temperature of the material, eliminate the deformation of the printing material,reduce the friction between the layout and the surface of the printing material, and increase the number of flexographic printing.

Water cooling curing

Water cooling enables printing to instantly cure the printing ink after printing, and the printed products are

environment-friendly, bright in color, strong in adhesion and strong in durability.

environment-friendly, bright in color, strong in adhesion and strong in durability.

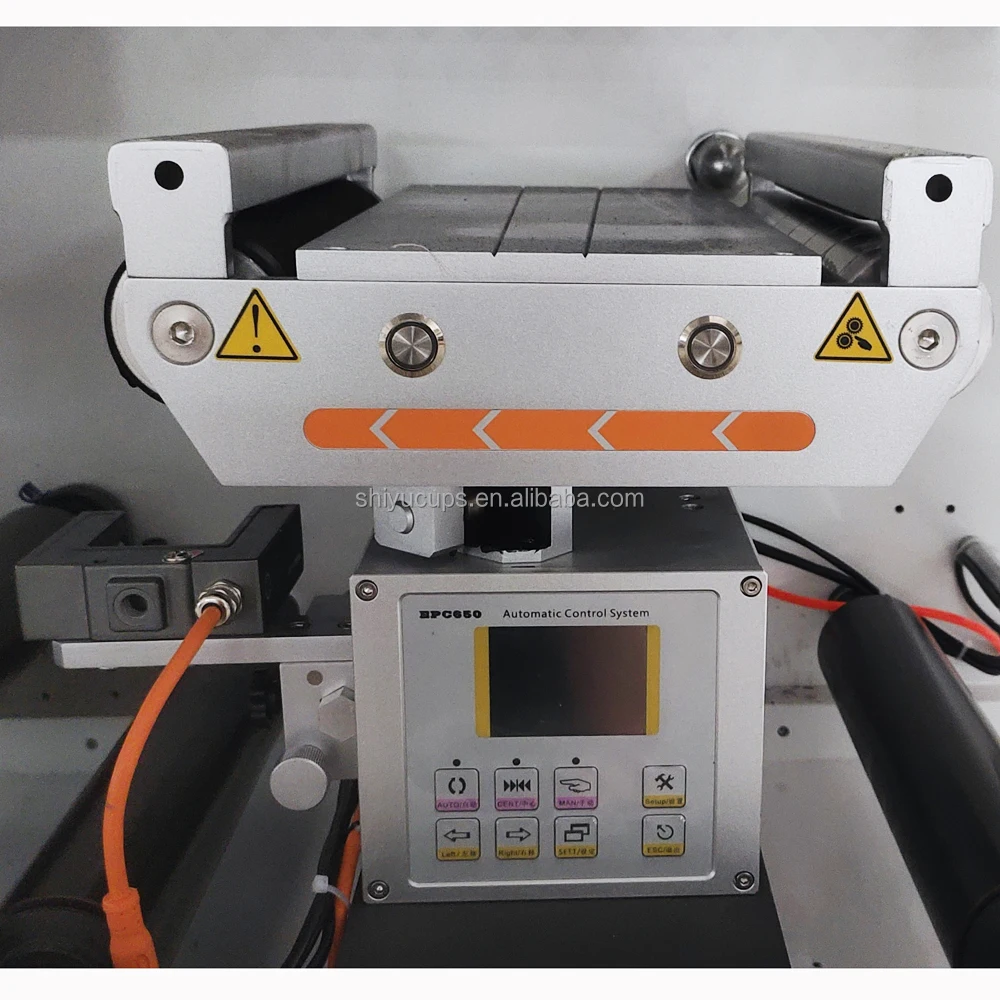

Control Panel

Power supply, stop button, start button,emergency stop

Web Guide System

Control paper move straightly.

Похожие товары

Автоматический принтер для бумажных стаканчиков с УФ-сушильной системой

4 406 652,96 ₽ - 4 417 453,58 ₽

Высокоскоростная маленькая бумажная наклейка этикетка Flex 4 5 цветов флексографская печатная машина для продажи

1 134 065,10 ₽

WJRB-320 рулон, холодная штамповка/ламинирование, штамповка, штамповка, продольная цветная этикетка, флексографская печатная машина

2 160 124,00 ₽

Легкая в использовании машина для печати на бумажных коробках для пиццы, высокоскоростная машина для печати на джутовых пакетах

108 006,20 ₽ - 216 012,40 ₽

JR-1542, 4 цвета, лента

1 242 071,30 ₽ - 1 350 077,50 ₽

Высокоскоростная двойная Размотка и перемотка 2/4/6/8 видов цветов флексографская печатная машина

2 030 516,56 ₽ - 2 106 120,90 ₽

4/6 цветная машина для флексографской печати конвертов

2 440 940,12 ₽ - 2 548 946,32 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Оригинальные oem-носки простые грелки для ног женские вязаные

5,25-6,25 $

Мужские Нескользящие Утепленные ботинки для

19,80-25,50 $

Автоматические компоненты 16B универсальный шаровой упаковочный конвейер модульный китайский поставщик система передачи

1-1,50 $

Хромированная стальная мебель ножки стола металлическая основа журнального столика

Лучшее качество 2000 Вт портативная электростанция солнечный генератор сертифицированный LiFePO4 чистый синусоидальный инвертор фонарик

Changan 4*2 Электрический небольшой моющий грузовик высокого давления для продажи от производителя

3 890-4 890 $

45-тонный экологически чистый контейнерный штабелер SANY SRSC45C30 ISO сертифицированный кран

35 700-53 550 $

CL0126 304 U-образная металлическая плитка внутренняя отделка для плитки из нержавеющей стали Декоративная полоса

0,68-2,88 $