Оборудование из Китая для малого бизнеса оборудование производства гипсовых блоков

- Категория: >>>

- Поставщик: Yantai City Hede Machinery Equipment Co. Ltd.

Сохранить в закладки 1601025961520:

Описание и отзывы

Характеристики

Gypsum block Making Machine

If you are interested, click Start Query to learn more

Equipment parameters | Description |

Capacity | 4~52cavities per mould!! The largest, most advanced technology in China. |

Automatic degree | mannual, semi- automatic; high automatic |

Raw material | gypsum powder and water |

Finished products | meeting China national standard (JC/T698-1998) |

Block length | 333/500/666/800/1000, adjustable |

Block width | 400/500±2, adjustable |

Block thickness | 80/100/120/150/180/200±0.5, adjustable |

Gypsum/Plaster Block making machine working process

Fully automatic gypsum block machine is used to make block with gypsum and water. The machine is composed of gypsum weighing machine, water weighing machine, mixer, shaper, hydraulic station, grip, hydraulic station, control panel, etc.

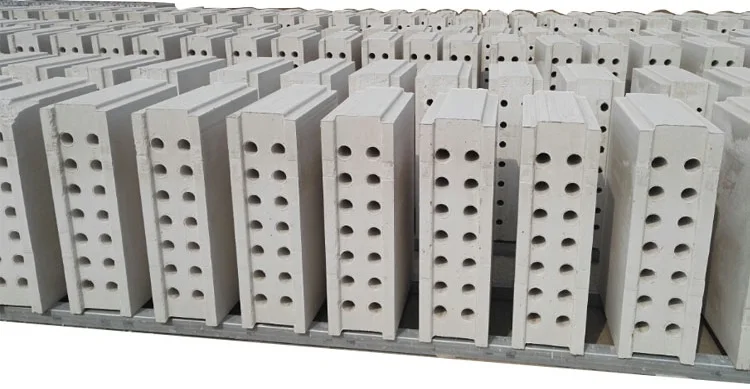

The raw material is stirred by water and poured into shape. After drying, a new lightweight partition product - hollow gypsum bfock is made. The utility model is mainly used for frame structures and other non load bearing walls, and is generally used as an inner partition board.

If you are interested, click Start Query to learn more

1. Dosing system

Consisting of water metering device, powder metering device, compressed air systems and chassis and other components.

2: Screw convey feeding system

Advantage :With discharge balance device ,Open the butterfly valve can be uniform discharge material, will not form blocks during the mixing)

3. Mixer

Consisting of the mixer rack, stainless steel mixing tank, stainless steel openable top cover, the water pipe installed on the roof, stirrer and pouring cylinder which are equiped with with motor, etc.

If you are interested, click Start Query to learn more

4. Forming machine

Consisting of the mixer rack, stainless steel mixing tank, stainless steel openable top cover, the water pipe installed on the roof, stirrer and pouring cylinder which are equiped with with motor, etc.

If you are interested, click Start Query to learn more

5. Central hydraulic station

Including high and low pressure oil pump and drive motor, fuel tank (with oiler, liquid level indicator, hook, etc.), electromagnetic valve, one-way throttle valve,etc.

6. Pneumatic flexible fixture

Pneumatic flexible fixture-on-rails: install fixturing trolley with wheels on two rails. The trolley can move at high or low speed, advance and retreat, and has the functions of brake positioning.

7. Automatic control system

The system uses programmable logic controller (PLC), and is composed of a button box, an electric control cabinet and other devices near the operators.

If you are interested, click Start Query to learn more

Characteristics of Gypsum/Plaster Block making machine

1. Development and application of the new high-speed mixer. High speed strring aimed at shortening the gypsum slurry time (mix average within 10 seconds), helps to make full use of gypsum slurry liquidity, so don't have to add the retarder.

2. Discharge using reverse discharging, flip to speed up the pulp out of discharge, and gypsum can be full flow in the mold. The appearance of gypsum block size precision, ensure the product quality and accuracy.

3. Easy to form a complete equipment. Control the quality in strict accordance with the ISO9001. The key electronic components use the Siemens brand.

4. The scale of production and the area of the automatic gypsum block production line (iso+ce) from china is moderate and match the automation and the mechanization of the production line.

Advantages over cement block

flat surface, plaster can be applied to the gypsum block directly. Light to handle for the construction workers. High installation efficiency.

If you are interested, click Start Query to learn more

Gypsum block product overview

Advantages | Experience |

Our experience | over 300projects in China, all over the world!! |

Formula | we will provide a unique formula, can save your much cost |

Cavity quantity | 4~52cavities per mould!! The largest, most advanced technology in China. |

Different sizes | can be organized into only one mould!!! No factory can achieve such level! |

Mixer | no need power, our unique design!!! save your electricity much!!! |

What we provide | for your project |

Free design | we will provide free design for you, including plant layout; machinery diagram, equipmentlist, ect. |

Labor shifts | arrangement suggestions |

Raw material supports | we supply all surports for raw material supplier information |

Installation | our process/ installation/ electricity engineers will stay at your plant until your workers know how to produce good products. |

Testing | after installation, we will test your production, and sign agreement with your workers after succesfully testing. |

After-sale service | we will be here for 24hours. When you need any help, just contact us! |

Похожие товары

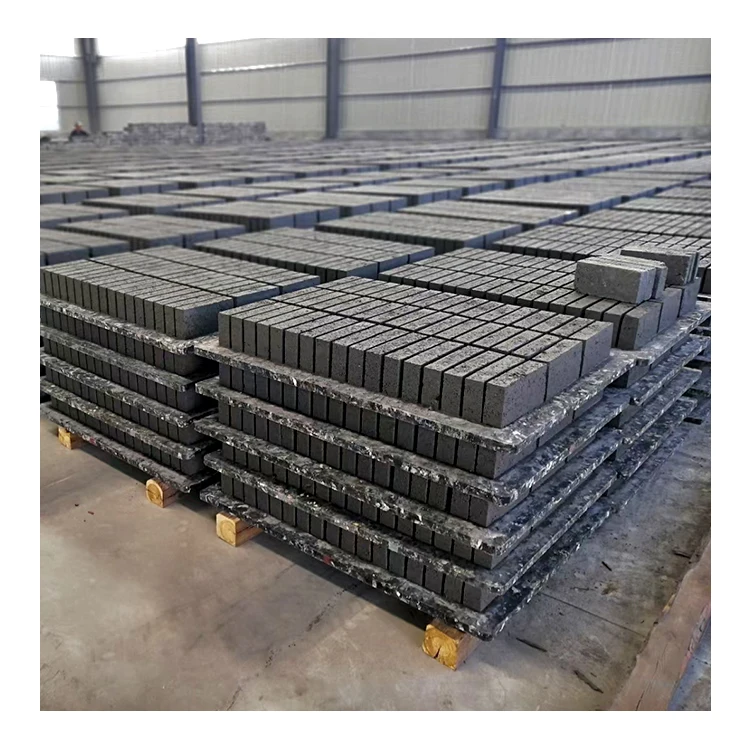

Машина для производства тротуарных блоков QT8-15 гидравлический пресс

QT4-30 машина для изготовления блоков самая продаваемая продукция в Африке лучшее оборудование автомобильных цехов

Низкая стоимость строительного оборудования QMY2-45 небольшой мобильный блок машины для домашнего бизнеса

Прямая поставка с завода высокое качество полая глина изготовление гидравлической средней автоматической кирпичной машины по низкой цене

Портативный небольшой кирпич делая машину блок формовочная машина

Ручной работы машина для производства кирпича в Африке небольшие мобильные портативные цементные кирпичи электрические ручные машины

GMT поддон прочный блок машина пластиковый 20%-80% стекловолокно поддоны для кирпича

Новые поступления

Новинки товаров от производителей по оптовым ценам