Mjf 3d печать поставщик/HP Multi jet fusion нейлон PA12 сервис с Wayne

- Категория: >>>

- Поставщик: Anqing Wayne Hand Model Technology Co. Ltd.Anqing Ltd.

Сохранить в закладки 1601032002546:

Описание и отзывы

Характеристики

What is MJF?

Multi Jet Fusion (MJF) is HP’s proprietary 3D printing process. HP Multi Jet Fusion (MJF) is a powerful 3D printing technology that produces highly accurate and durable parts at fast speeds, especially compared to other powder bed fusion technologies like selective laser sintering (SLS) or direct metal laser sintering (DMLS).

Due to their affordability, speed, and high resolution, multi jet fusion technology can be used for end-use, low-volume production, rapid prototyping, or as a bridge process to injection molding. MJF allows engineers to get a feel for how parts will perform with minimal upfront costs.

Materials

Nylon 12 is a robust thermoplastic with all-around excellent physical properties and chemical resistance, ideal for functional prototypes and end-use applications.

Glass-filled nylon is reinforced with glass bead and creates parts with higher stiffness and thermal stability than standard nylon.

| Material Name | Description | Shore Hardness | Elongation at Break (XY, ZX %) | Elongation at Break (XY, ZX %) |

| Nylon 11 | HP 3D High Reusability PA 11 | 80D | 55%, 40% | 6 kJ/m², 5 kJ/m² |

| Nylon 12 | HP 3D High Reusability PA 12 | 80D | 20%,15% | 3.6 kJ/m², 3.5 kJ/m² |

| Nylon 12 Glass Filled | HP 3D High Reusability PA 12 Glass Beads (40% GB) | 82D | 10% | 3 kJ/m² |

Size and Tolerance

From prototyping to small-batch production, our global network of certified MJF 3D printing facilities will allow you to produce highly accurate parts with quality comparable to injection molding.

| Capabilities | Description |

| Maximum build size | 380 x 285 x 380 mm (14.9'' x 11.2'' x 14.9'') |

| Standard lead time | 3 days |

| Dimensional accuracy | ± 0.3% with a lower limit on ± 0.3 mm (0.012'') |

| Layer thickness | 80 μm |

Surface Treatment

Available surface finishes for MJF 3D printing

Additional post processes can be applied to improve the appearance or mechanical properties of parts produced with MJF.

MJF parts with a wall thickness greater than 4 mm are watertight up to 20 bar without additional finishing.

Ideal MJF Applications

Advantages of MJF 3D Printing Process

Advantages of MJF 3D Printing Process While there are many benefits to MJF printing, a few truly stand out. For starters, the standard build parameters are optimized for the best density. The result is that Multi Jet Fusion parts are watertight.

If you like SLS but want to produce higher quantities for small-batch production runs, Multi Jet Fusion is the way to go. MJF printers have the ability to print multiple parts simultaneously across the entire build volume means you can print parts at rates up to 10X faster than SLS or other 3D printing processes. Also, Multi Jet Fusion delivers more balanced mechanical properties across the X, Y, and Z axes compared to SLS.

If you’re interested in injection molding for your project, it’s always a good idea to get a 3D printed “test” part before making the investment in metal molds.

Company Profile

WAYNE PROTOTYPE

Wayne Prototype is a specialists at design and engineering company who support you from the concept stage to prototyping and fabrication of the completed product with plastic injection molding. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop manufacturer for accurate, precise, custom 3D printed parts at an affordable price. We print everything from single prototypes to thousands of production-grade parts.

We use the latest additive manufacturing technology to build affordable functional parts in over 20 metals and plastics. WayNe Prototype offers four high-quality 3D printing processes including stereolithography (SLA), direct metal laser sintering(DMLS), HP Multi Jet Fusion (MJF) and selective laser sintering(SLS). Our main goal is to help companies to turn their dream projects into reality. We work very closely with our clients and strive to give them the best services at all times., We use industrial-grade printers such as hp printer, Union-Tech SLA printer, EOS printer and DMLS and more.

We make all projects possible and get your idea valued, designed, tested, prototyped and manufactured in a fast, reliable, easy and supportive way.

You think it, we make it !

Certificates

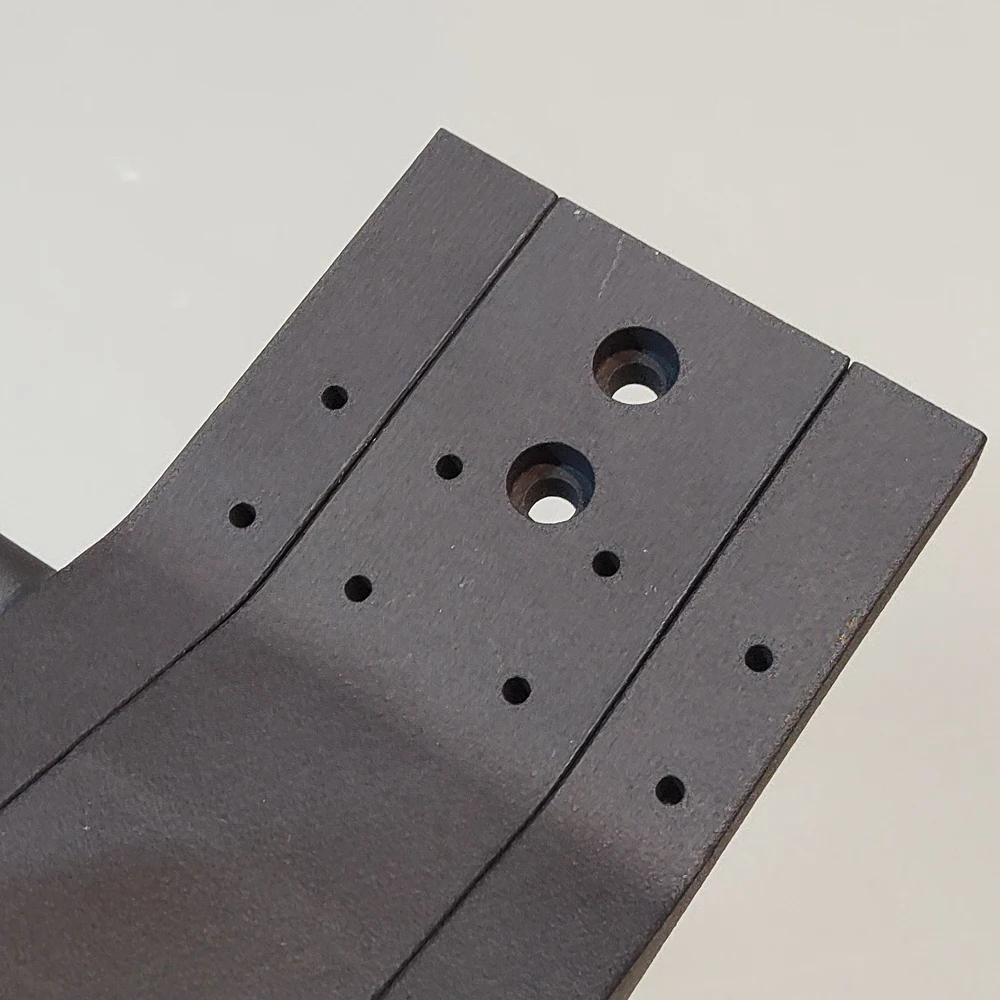

Customer Photos

Question & Answer

Q:What kind of production service do you provide?

A:Rapid prototyping, 3d printing service(SLA/MJF/SLM/FDM), Vacuum casting, CNC machining/milling/turning, Plastic/Rubber injection molding, Reverse engineering service.

Q:How about the lead time?

A:abs or nylon 3d printed parts: 3-4 days.

Metal 3d printed parts: 4-5 days.

Injection mold: 4 weeks.

Mass production: About 10 days.

Q:How about your product quality?

A:· Our management and production executed strictly according to ISO9001:2008 quality System.

· We will 100% inspect the products before shipment.

· If there is quality problem, we will supply the replacement by our shipping cost.

Q:How long should we take for a quotation?

A:After receiving detail information we will quote within 2 days.

Q:What is your quotation element?

A:Drawing or Sample, Material, finish and Quantity.

Q:What is your payment term?

A:· Mould:30% prepaid, 40% after the mould finish, balance after sample approval.

· Goods:30% prepaid, balance T/T before shipment.

Похожие товары

Дешевая Массовая памятная индивидуальная металлическая штамповочная аркадная монета под заказ латунная пустая

[CSUSTOM] CNC обработка древесных бамбуковых деталей производственные услуги

Новый дизайн хорошее качество детали для обработки с ЧПУ и штамповки из листового металла по индивидуальному заказу комплект переоборудования фургона спринтера

Детали для станков с ЧПУ

Прямая поставка с завода CNC изготовленная на заказ цинк клюшка для гольфа правой и левой руки взрослых

Пользовательские высокоточные гальванические алюминиевые фиксированные детали CNC Услуги обработки

Cnc фрезерование анодированного алюминия rc cnc мотоцикл механические детали анодированный алюминий автозапчасти

Новые поступления

Новинки товаров от производителей по оптовым ценам