Низкая стоимость оптовая продажа нейлон Пластиковые детали для литья под давлением пластиковое сырье

- Категория: >>>

- Поставщик: Anqing Wayne Hand Model Technology Co. Ltd.Anqing Ltd.

Сохранить в закладки 1601032028588:

Описание и отзывы

Характеристики

What is Injection molding?

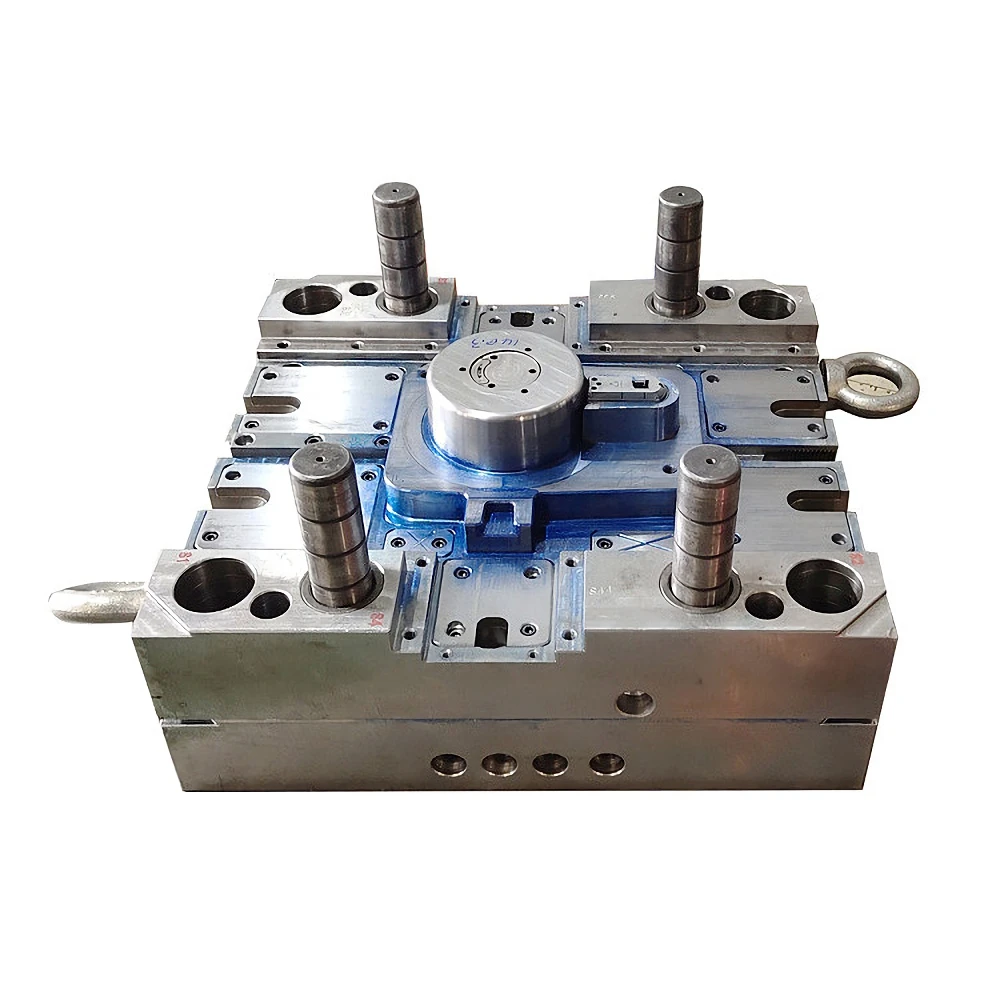

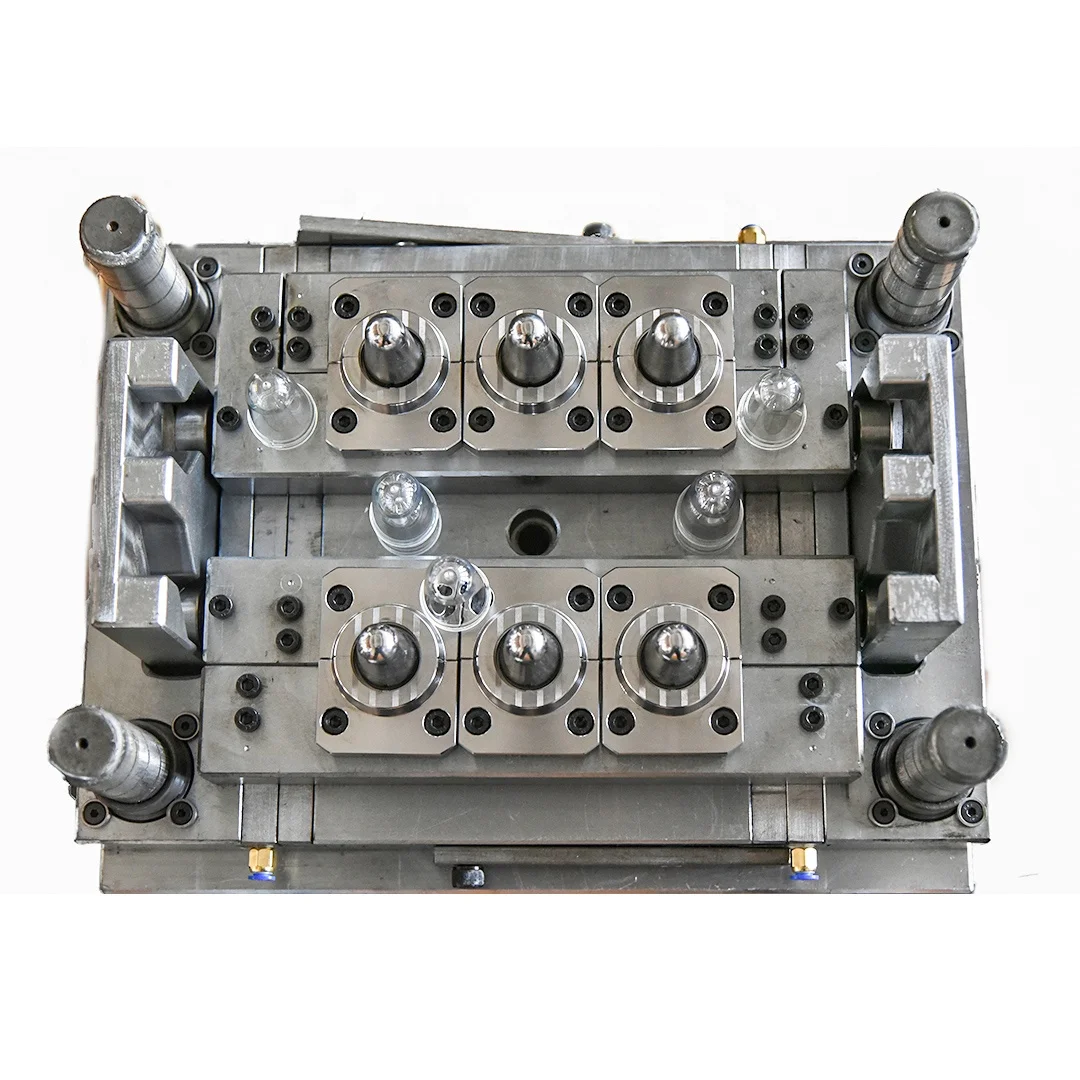

Injection molding is the most cost-effective way to make a plastic part at scale. The injection molding process involves injecting molten plastic into a mold tool, then ejecting the solidified part.

This process quickly repeats hundreds or thousands of times, amortizing the cost of the mold tool and driving down the cost of each unit to a few dollars or less. Since the injection molding process uses the same mold tool for each part, it offers consistent quality across every part.

Injection molding also has the highest variety of materials, colors, cosmetics, polishes, and surface textures when compared to CNC machining or even 3D printing.

Materials

Plastic Injection Molding Materials

PMMA acrylic | ABS acrylonitrile butadiene styrene | PA nylon polyamide | PC polycarbonate | PE polyethyelene |

POM polyoxymethylene | PP polypropylene | PS polystyrene | TPE thermoplastic elastomer | TPU thermoplastic polyurethane |

Finishes

| Injection Molding Finishes | |

| Standard Finish | Moldmaker's choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined. |

| SPI Finishes | Range of Society of Plastics Industry (SPI) finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3 |

| Other Textures - VDI | VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard set by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. This is mainly processed by EDM machining, producing fine to coarse matte finishes. |

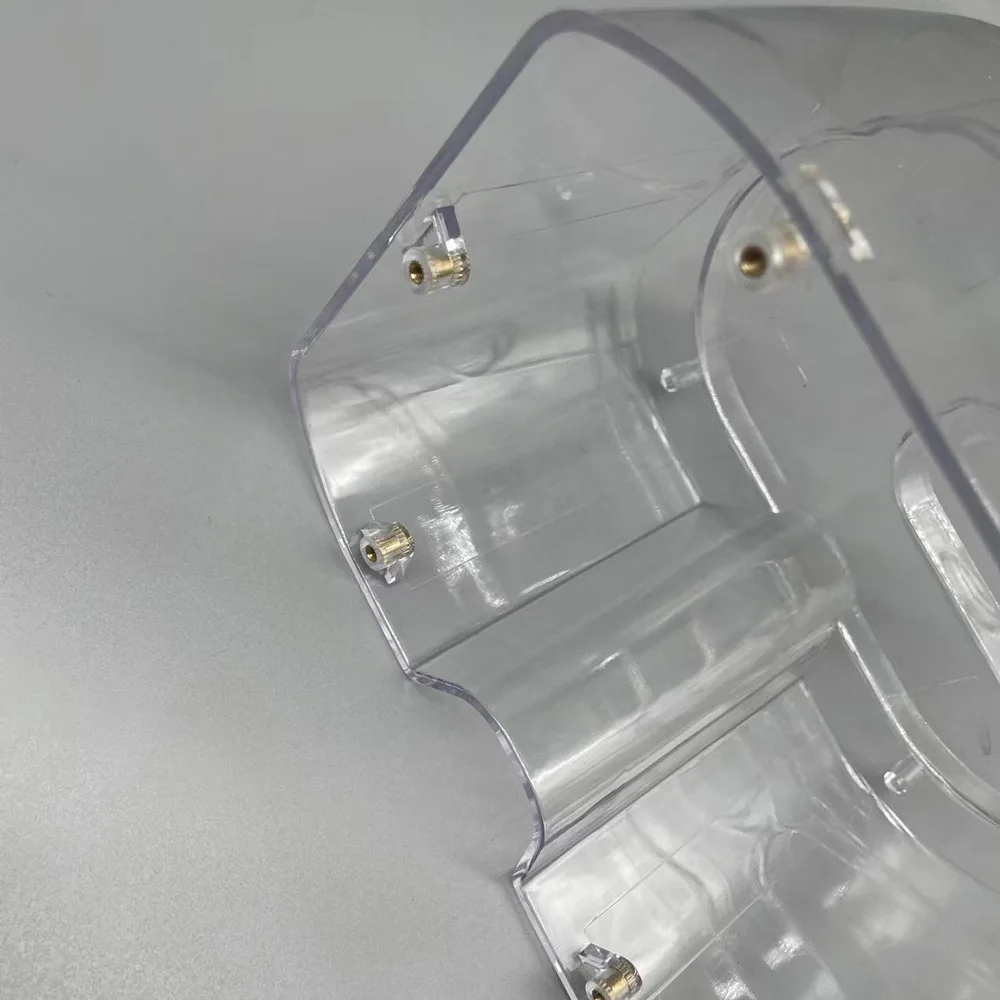

| Threaded Inserts | We can install most commonly used standard inserts in UNF and metric sizes. |

| Silk Screen | For logo |

| Laser Engraving | Engrave part numbers, logos, and more onto your parts. |

| Assembly | We can do the assembly work for you and custom package. |

Design Suggestion

| Injection Molding Design Guidelines | |

| Undercuts | Reduce undercuts, which will increase the complexity and cost of the tool ejection mechanisms, by adding in pass-thru coring. |

| Wall Thickness | Prevent wall sink and voids by maintaining an even wall thickness. Thinner walls reduce cycle time and reduce costs. |

| Drafts | Ensure parts are designed with a minimum draft angle of 0.5°, or up to 5°, for faces with medium textures. |

| Ribs/Gussets | Ribs should be 40-60% the thickness of outer walls and should still maintain draft. |

| Bosses | Bosses should be designed at a depth of 30% the wall thickness and with a 30% edge groove. Attach them to side walls or ribs for structural integrity. |

Applications of Injection Molding

The Top 6 Industrial Applications for Injection Molding

For most industries, it only makes sense to find the lowest cost yet most durable materials to produce the products they need. As a versatile manufacturing technique, injection molding plays a crucial role in developing and creating many modern products, from consumer toys to airplane components. This article will look at the top 6 industrial applications for injection molding and how manufacturers can improve existing systems.

Food and Beverage

When it comes to injection molding, the food and beverage industry relies heavily on plastic materials to create product packaging and containers. Since this industry must adhere to strict sanitization and safety regulations, plastic injection molding is an obvious fit to ensure various specifications are achieved, including BPA-free, FDA-certified, non-toxic and GMA-safe regulations. From components as small as bottle caps to the trays used in TV dinners, injection molding provides a one-stop-shop for all the food and beverage industry’s packaging and container needs.

Automotive Parts

Many of the parts found on modern automobiles require a broad range of intricately designed features to function correctly. For this reason, many of the leaders of the automotive industry have turned to plastic injection molding to develop, plan, and manufacture the parts they need. Typical injected molded elements include bumpers, dashboards, and smaller pieces, such as cup holders and mirror housings.

Medical & Pharmaceuticals

As many medical products must be shatter-proof, non-porous, and perfect in shape, plastic injection molding is critical for medical and pharmaceutical production. As a high volume producer, the medical industry can benefit from injection molding’s decreased production times and affordable production materials while still achieving high-quality medical-grade products. Medical and pharmaceutical parts created with injection molding can range from pill bottles to x-ray components.

Household Products

With just a simple trip to your kitchen, there is a good chance that you will find an injection molded product or part. From Tupperware to building materials used in the construction, there is no denying that this industry would not be where it is today without injection molding. Like other industries, household products can be made more affordable by investing in large production runs for shipping to retail locations worldwide.

Agriculture

Historically, it was typical for the agriculture industry to invest in metal-made components simply because they provided a durable solution. Now, reinforced plastic options have gained favor due to new plastic material characteristics like UV-resistance, impact-resistance, humidity resistance, and much more. The ability to create durable agriculture products that stand up to the elements on a farm makes plastic injection molding an obvious fit for the agriculture industry, from feeding troughs to specialized harvesting components.

Electronics

Although many people see electronic components as a predominately metal piece of machinery that uses electricity to function, enhancing system longevity with corrosion-resistant plastic housings improves overall performance. As you may have guessed, manufacturing housings through the plastic injection molding processes is preferred. The computer mouse you may be using right now, to the television in your living room, likely have some components created using plastic injection molding.

Company Profile

WAYNE PROTOTYPE

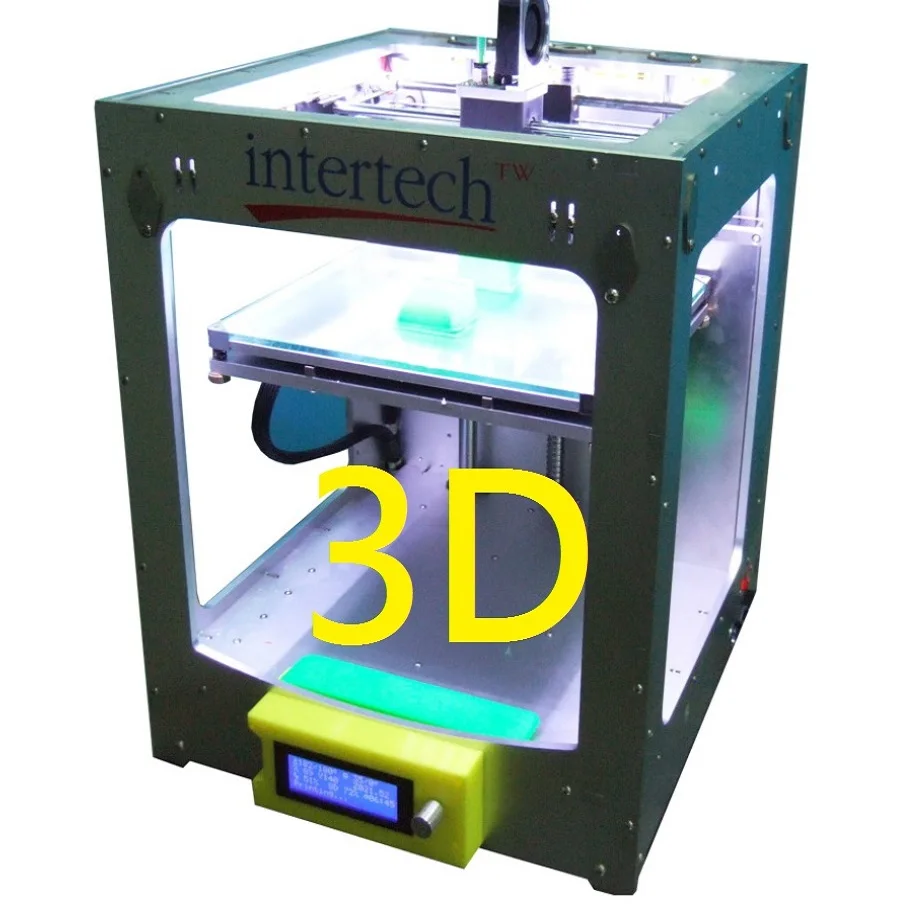

Wayne Prototype is a specialists at design and engineering company who support you from the concept stage to prototyping and fabrication of the completed product with plastic injection molding. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop manufacturer for accurate, precise, custom 3D printed parts at an affordable price. We print everything from single prototypes to thousands of production-grade parts.

We use the latest additive manufacturing technology to build affordable functional parts in over 20 metals and plastics. WayNe Prototype offers four high-quality 3D printing processes including stereolithography (SLA), direct metal laser sintering(DMLS), HP Multi Jet Fusion (MJF) and selective laser sintering(SLS). Our main goal is to help companies to turn their dream projects into reality. We work very closely with our clients and strive to give them the best services at all times., We use industrial-grade printers such as hp printer, Union-Tech SLA printer, EOS printer and DMLS and more.

We make all projects possible and get your idea valued, designed, tested, prototyped and manufactured in a fast, reliable, easy and supportive way.

You think it, we make it !

Our Services

Certificates

Customer Reviews

Question & Answer

Q:What kind of production service do you provide?

A:Rapid prototyping, 3d printing service(SLA/MJF/SLM/FDM), Vacuum casting, CNC machining/milling/turning, Plastic/Rubber injection molding, Reverse engineering service.

Q:How about the lead time?

A:abs or nylon 3d printed parts: 3-4 days.

Metal 3d printed parts: 4-5 days.

Injection mold: 4 weeks.

Mass production: About 10 days.

Q:How about your product quality?

A:· Our management and production executed strictly according to ISO9001:2008 quality System.

· We will 100% inspect the products before shipment.

· If there is quality problem, we will supply the replacement by our shipping cost.

Q:How long should we take for a quotation?

A:After receiving detail information we will quote within 2 days.

Q:What is your quotation element?

A:Drawing or Sample, Material, finish and Quantity.

Q:What is your payment term?

A:· Mould:30% prepaid, 40% after the mould finish, balance after sample approval.

· Goods:30% prepaid, balance T/T before shipment.

Похожие товары

Устойчивые к высоким температурам OEM продукты из углеродного волокна

Аппаратная обработка одной части индивидуальная независимая направляющая стойка втулка квадратная Mi Simi стандартная часть c

Прецизионная форма для литья под давлением и производство Пластиковая заказ Смарт-часы CN;FUJ

Дешевые пользовательские инъекции плесень abs пластиковые формы на заказ

Заводская цена 246 PA66 + GF GB автомобильный жгут проводов соединительный корпус для автоматических предохранителей

Пластиковые детали для инструментов 3D-принтер OEM услуги литья под давлением

Пластиковая форма с 32 полостями

Новые поступления

Новинки товаров от производителей по оптовым ценам