Wondery лучшие новые профессиональные продукты алюминиевая медная плавник штамповочная машина для штамповки ребер

- Категория: >>>

- Поставщик: Wuxi Wondery Industry Equipment Co. Ltd.

Сохранить в закладки 1601033310108:

Описание и отзывы

Характеристики

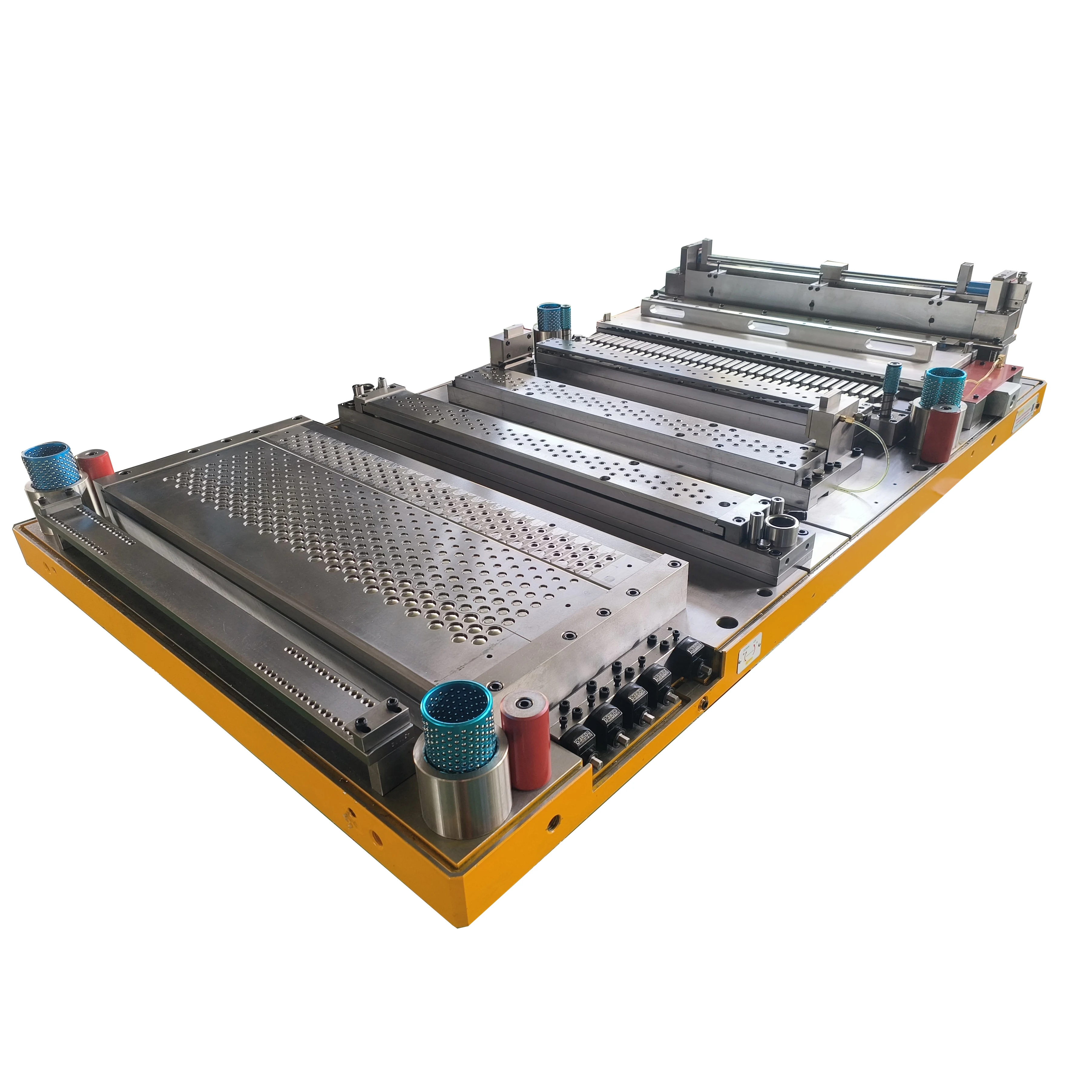

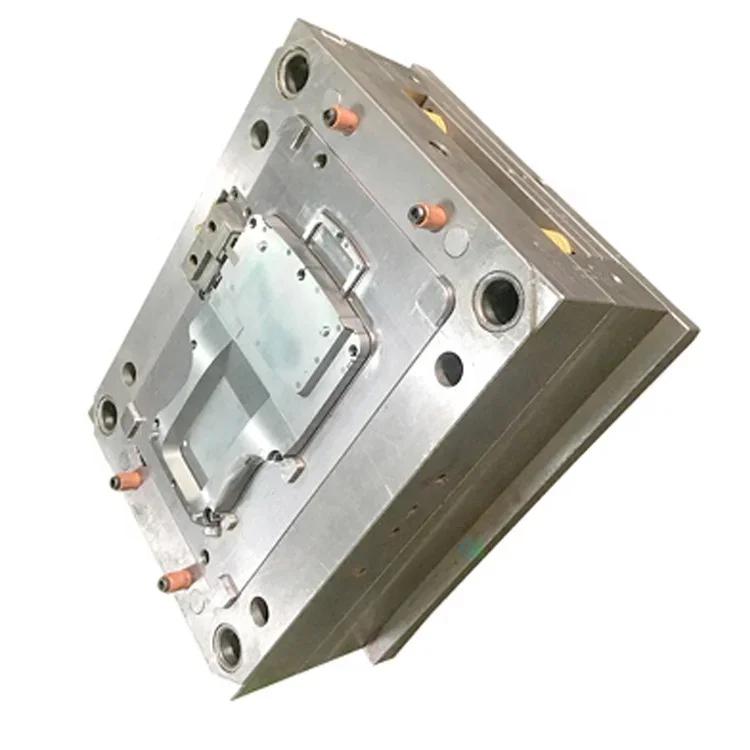

Wondery Best New Professional Products Aluminum Copper Fin Die for Fin Stamping Punching Machine

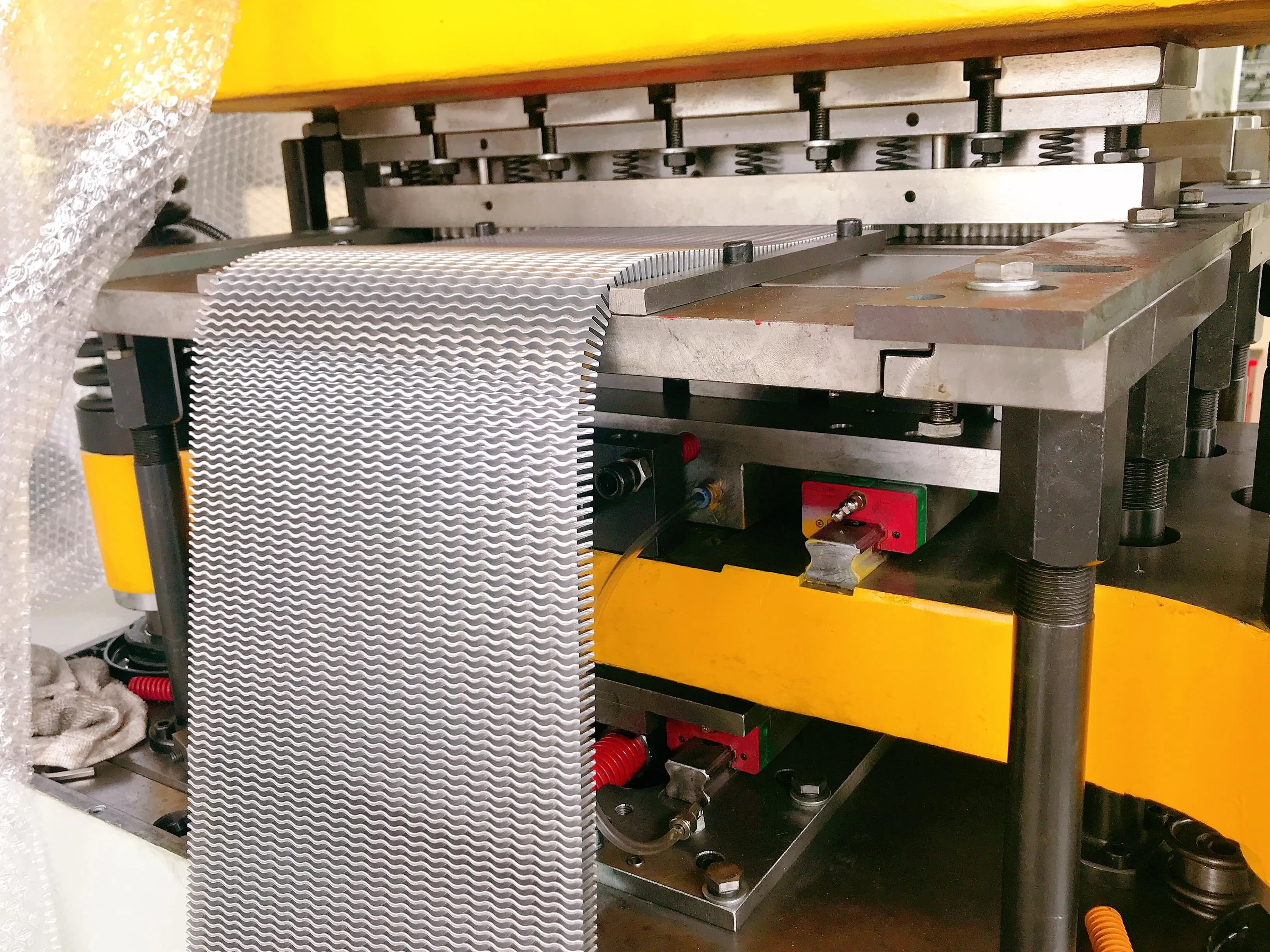

Product Application

Aluminum fin stamping machine is used to produce the following fins: straight and flat fins,serrated fins, perforated fins, wavy fins, louvered fins and others. The aluminum fin stamping machine is also called as aluminum fin stamping machine, aluminum fin machine, fin press machine, fin press line, aluminum fin punching machine, aluminum fins press, aluminum fin press line.

Item | Parameter |

Nominal force | 450KN; Open Type |

pressing time | 120-200 pressing per mins; |

Slide block stroke | 40mm |

Throat depth | 330mm |

Die height | 210-270mm |

Fin collection height | 650mm |

Fin collection length | 1200mm |

Aluminum coil width | ≦ 330mm |

Aluminum coil ID*OD | Φ75mm*Φ850mm |

Main motor power | 7.5KW |

Power supply | AC380V, 50HZ, 3P, 5-wire |

Fin die lubrication | Manual |

Waste blowing device | Oil mist waste blowing |

Variable ways | Electric adjustable die |

SPECIFICATIONS FOR Aluminum Fin Stamping Machine | ||||||

Technical Parameters | Power supply | customized 3P 5 wire power supply | ||||

Model Number | mm | CPJ8.5*10, CPJ14*10, CPJ16*10,CPJ19*10,CPJ24*10mm | ||||

Punching force | kg | 4200 | ||||

Fin Size | Fin Width | mm | max 450 | |||

Fin Size | mm | customized | ||||

Fin height accuracy | mm | +/-0.01-0.05mm | ||||

Fin height | mm | 1mm- 45mm | ||||

Overall Size | L,W,H | mm | 1500*900*1700 | |||

Total Weight | kg | 1500 | ||||

Fin Type | lanced offset fin, straighte flat top fin, louvered fin, wavy fin, etc | |||||

Fin material | stainless steel, aluminum, copper, steel | |||||

Main Features

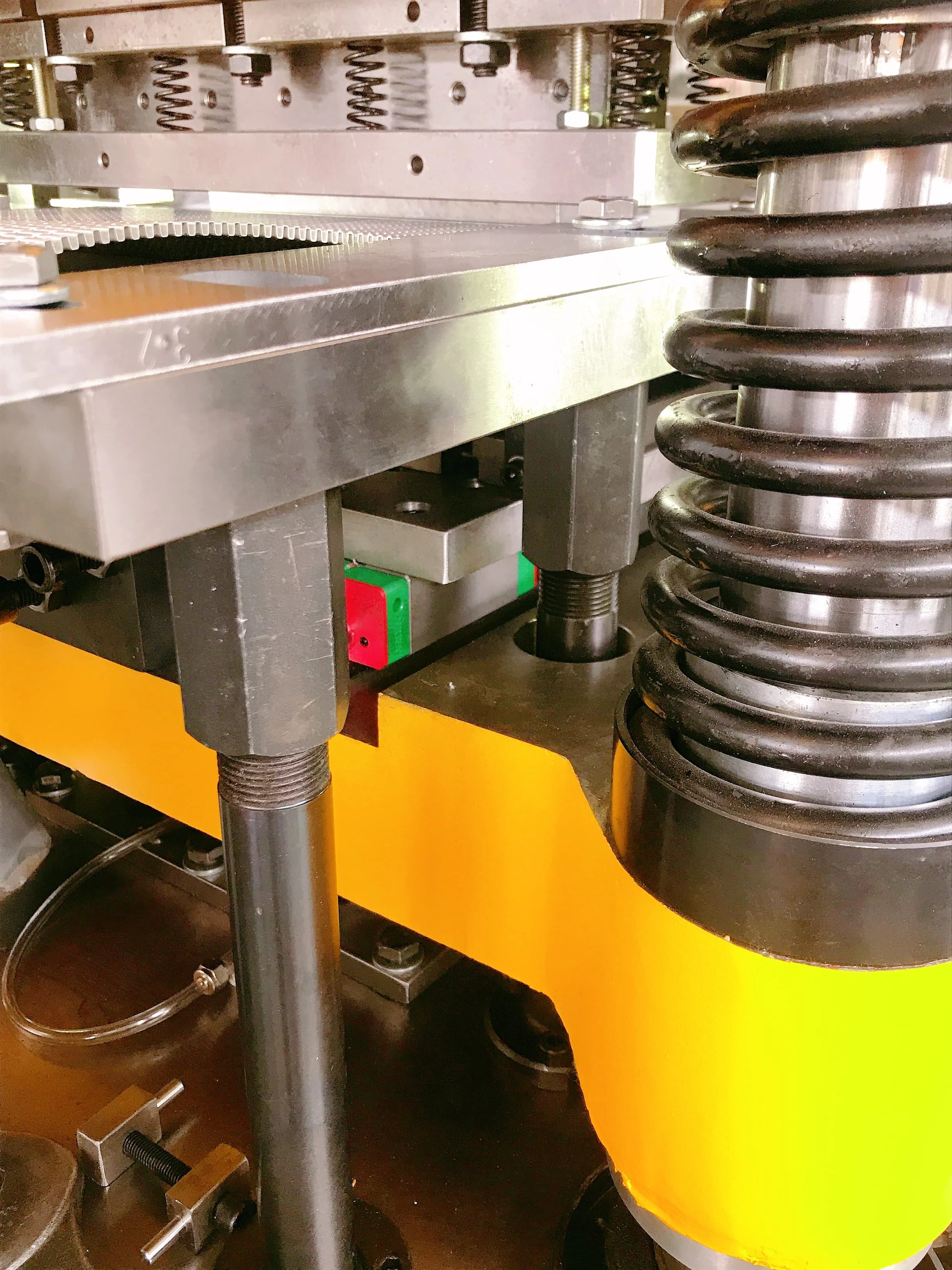

1) The column bushing is made of high-strength imported wear resistant material. It has a service life of more than 1 million times.

2 ) The slide of the die is of rolling ball structure which has less wear and tear and a longer service life.3 )The tension control device can keep the feeding speed matching with the cutting speed.

4 )The touch screen allows the operator to set the parameters directly.

5 )The decoiler of the aluminum fin stamping machine is an auxiliary to the fin punching machine. It is equipped with proximity switch and control delay switch so as to control the decoiling speed.

6) The fin punching machine is already installed with one set of die for producing fin of one specific specification.

The aluminum fin stamping machine is also called as aluminum fin stamping machine, aluminum fin machine, fin press machine, fin press line, aluminum fin punching machine, aluminum fins press, aluminum fin press line.

Wuxi Wondery Industry Equipment Co., Ltd. is a professional supplier of industrial machines. Currently the company mainly supplies the equipment for the automobile industry, household air conditioner industry, engineering vehicle industry, power generation plant industry, train industry, ship industry, etc. Our main products are: radiator making machines, aluminum fin machine, aluminum radiator core builder machine, aluminum radiator plastic tank clinching machine, aluminum radiator brazing furnace, aluminum header pipe punching machine, aluminum flat tube straightening and cutting machine, high speed fin press machine, aluminum/copper pipe straightening and cutting machine, tube expander machine, automatic bending machine, progressive fin die, metal punching die, etc. Established in year 2008, the company has gained rich experiences in development and design, quality control, and after-sales service. The company aims to serve every customer with quality products and excellent service. The company provides thoughtful services like technical consultation, installation and test-running, technical training, and maintenance. Our company is also able to design non-standard products as per customers' requests.

1. What is the power supply of the heat exchanger making machines?

The power supply of heat exchanger making machines is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer or of the customer's voltage directly so that the melting furnace is ready for use at the end user's site.

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 30-60 days after receipt of down payment.

Похожие товары

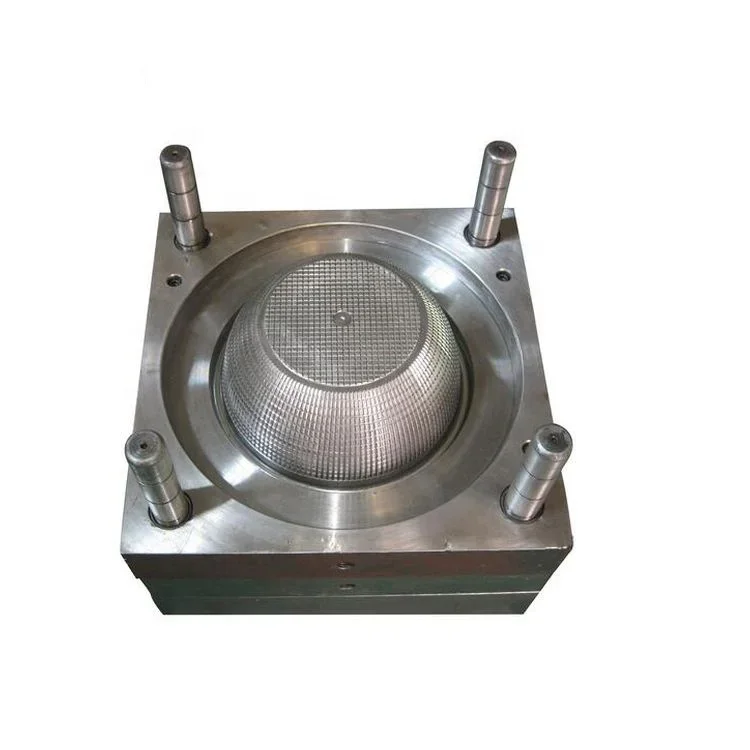

Профессиональные инженерные услуги для промышленного продукта, дизайн, литьевая форма для металла, сталь, новый пластиковый материал, резина

5 400,31 ₽

Изготовленная на заказ Высококачественная пластиковая форма для литья под давлением, Пластиковая форма для литья под давлением 2K, производство 17 лет на заводе

5 400,31 ₽ - 17 281,00 ₽

Китайская технология, более чем 17-летний опыт производства Pmma, пресс-форма для литья под давлением из водопроводного крана

5 400,31 ₽ - 17 281,00 ₽

Производитель пластиковых форм для литья под давлением

5 400,31 ₽ - 17 281,00 ₽

Прецизионная литьевая оснастка с 17-летним опытом массового производства пластика

5 400,31 ₽ - 17 281,00 ₽

Защитная крышка для объектива камеры iPhone 12 13promax 14 14promax 8 8P X XR XSmax

Карнизные формы для бетона, поставщики в Китае, самая дешевая гипсовая линия для формования кровельных карнизов, пресс-форма для пластиковой цементной опалубки

885,66 ₽ - 1 069,27 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $