Фрезерный станок с тисиновым

- Категория: >>>

- Поставщик: Chengdu Gyration Cnc Tool Co. Ltd.Chengdu Ltd.

Сохранить в закладки 1601035139009:

Описание и отзывы

Характеристики

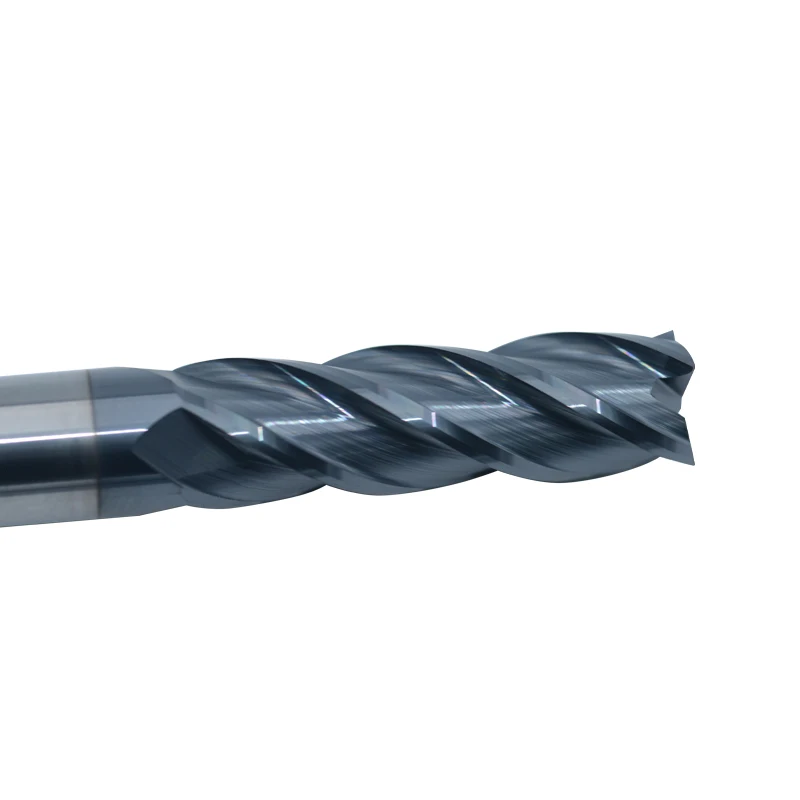

| Product Specifications | Basic Size (mm) | Number of teeth(T) | |||

| Blade Diameter (D) | Shank Diameter(b) | Blade Length(H) | Full Length(L) | ||

| GNC-D3-10-100-4T | 3.0 | 3 | 10 | 100 | 4T |

| GNC-D4-20-100-4T | 4.0 | 4 | 20 | 100 | 4T |

| GNC-D6-25-100-4T | 6.0 | 6 | 25 | 100 | 4T |

| GNC-D8-30-100-4T | 8.0 | 8 | 30 | 100 | 4T |

| GNC-D10-35-100-4T | 10.0 | 10 | 35 | 100 | 4T |

FAQ

Q1. Are you a trading company or manufacturer?

We are trading company of CNC tools.

Q2. How about samples charges?

Samples and express charges needs to be paid by buyer and we will refund the samples charges in normal order to buyers.

Q3. Do you provide after-sale service?

Yes. So if you find any problem after using our cutting tools, please do not hesitate to tell us, we’ll help you to solve it as soon as possible. Your any feedback to products is our way to improvement.

Q4. How do I pay for my purchase?

Escrow, Credit card, Western union, Paypal, MoneyGram, T/T, L/C, D/A, D/P are all accepted.

Q5.What’s your delivery time for our orders?

The delivery is about 48 hours for standard products and 30 days for OEM ODM products.

The delivery is about 48 hours for standard products and 30 days for OEM ODM products.

Q6. How do you handle the quality failure?

We can assure you of 100% refund you the money for quality problem.

We can assure you of 100% refund you the money for quality problem.

Q7. Can you provides special carbide tools?

Yes we can. Special tools according to your drawing and sample.

Product maintenance tips:

Before using our company's products, first ensure that the machine tool is operating normally in all aspects, and then conduct a test on our cutting tools. Only after passing the test can we use them to avoid danger and damage to the machine tool/mold. If the tool is used without being tested/verified to be qualified/normal, resulting in personal injury and damage to the machine tool/mold, one shall bear economic losses and legal responsibility on their own.

Maintenance of milling cutters:

For milling cutters, pay special attention to the protection of the cutting edge, and never touch or fall onto the ground. If not in use or after use, be sure to put it back into the box or put it on the tool management seat and place it separately.

ATTENTION TO:

In order to get better cutting surface and prolong tool life, please use high precision, high rigidity, dynamic balance and high speed tool shank!

1:Before using this tool, please measure the tool deflection, if the tool deflection accuracy is more than 0.01MM, please correct it before cutting.

2The shorter the length of the tool sticking out of the collet, the better, if the tool sticks out longer, please adjust down the speed, feed rate or cutting volume by yourself.

Before using our company's products, first ensure that the machine tool is operating normally in all aspects, and then conduct a test on our cutting tools. Only after passing the test can we use them to avoid danger and damage to the machine tool/mold. If the tool is used without being tested/verified to be qualified/normal, resulting in personal injury and damage to the machine tool/mold, one shall bear economic losses and legal responsibility on their own.

Maintenance of milling cutters:

For milling cutters, pay special attention to the protection of the cutting edge, and never touch or fall onto the ground. If not in use or after use, be sure to put it back into the box or put it on the tool management seat and place it separately.

ATTENTION TO:

In order to get better cutting surface and prolong tool life, please use high precision, high rigidity, dynamic balance and high speed tool shank!

1:Before using this tool, please measure the tool deflection, if the tool deflection accuracy is more than 0.01MM, please correct it before cutting.

2The shorter the length of the tool sticking out of the collet, the better, if the tool sticks out longer, please adjust down the speed, feed rate or cutting volume by yourself.

Похожие товары

WEIKE CNC фрезерный станок с высоким техническим содержанием для алюминиевого

188 170,02-193 255,69 ₽

ЧПУ фрезерный сверлильный станок алюминиевые автоматические оконные

1 767 272,41 ₽

65-градусный микро-путь 2-край шаровой головки глубокий паз глубокое отверстие глубокая полость обработка удлиненный фреза

381,43-457,72 ₽

Заводская поставка одноразовая медицинская маска для лица с петлей ушей 3ply BFE95 % EN14683 тип I Чистящая Гигиеничная нечувствительная

Домашняя Спальня Декоративные винтажные классические деревенские полимерные натяжные цепи буфетные настольные

4 322,83-5 467,11 ₽

Беспроводная Светодиодная настольная

2 263,13-2 479,27 ₽

Оптовая продажа хорошее качество керамический льняной оттенок нордическое украшение светодиодная настольная винтажная легкая фарфоровая лампа для спальни

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $