Оборудование для производства бумажных изделий в Турции машина переработанной гофрированной бумаги

- Категория: >>>

- Поставщик: Zhengzhou Leizhan Technology Paper Machinery Co. Ltd.

Сохранить в закладки 1601038941817:

Описание и отзывы

Характеристики

Paper Product Making Machinery In Turkey Waste Paper Recycled Corrugated Fluting Paper Making Machine

Kraft carton paper machine brief introduction

Kraft carton paper machine is mainly used for making high grade kraft paper.

| Paper grade | Kraft carton paper |

| Trimmed width(mm) | 3600 |

| Gauge(mm) | 5100 |

| Basis weight(g/m2) | 80-200 |

| Operating speed(m/min) | 380 |

| Design speed(m/min) | 450 |

| Production capacity(t/d) | 200 |

| Drive type | AC frequency, Sectional drive |

Kraft carton paper making pulping line

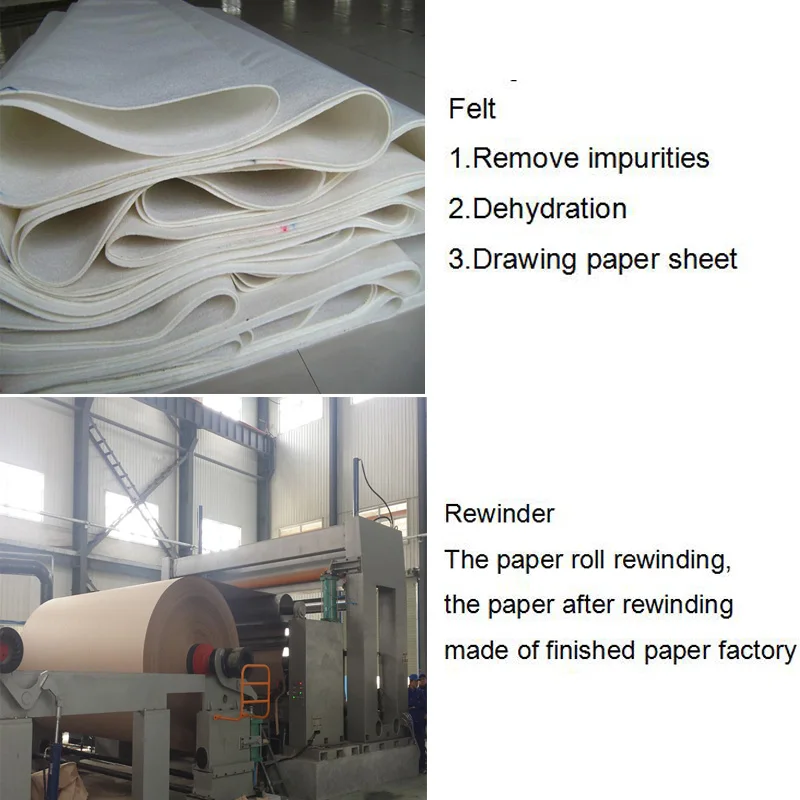

Raw materials (waste paper)——chain conveyor——bale breaker ——chain conveyor——pulper——hign density cleaner——cosrse pressure screen——light impurity separator——reject separator ——low density cleaner——fine pressure screen——inclined screen——inflow pressure screen——paper making machine——the big finished jumbo roll paper

Kraft carton paper machine main structure

Paper machine is consist of headbox, wire section, press section, front drying section, oblique surface sizing machine, back drying section, calender section, reel section.

1.Headbox : Two sets of open headbox, corresponding to top layer, bottom layer, and by controlling the gas pressure in the headbox to control and stabilize the sizing of the pulp.

2.Forming section : Double layer include top layer and bottom layer, The main components are consist of breast roll , forming board, dewatering board, vacuum box, composite roll, suction couch roll, wire drive roll, wire guiding roll and paper machine framework.Top layer and bottom layer are all equipped with one forming wire respectively .

3. Press section: including First press, second press.The first press is K-type composite press with vacuum suction roll, which also equipped with one rubber coated metal roller, one vacuum press roll and one stone roll. The second press is MG press with upper & lower rubber coated metal rolls and upper & lower felts. The two press are all equipped with wire guiding roll and felt suction box. These two press are pressurized by the hydraulic cylinder pressure.

4. Front drying section: Φ1500/Φ1800 dryer, drove in group and equipped with wire guiding roll , dry wire and closed gas hood.

5. Oblique surface sizing machine: one surface chrome-plated metal roller and one rubber coated metal roll. it is pressurized by corrugated gas tire pressure.

6. Back drying section: Φ1500/Φ1800 dryer drove by group and equipped with wire guiding roll ,dry wire and closed gas hood.

7. Calender section: Double roller calender, the upper and lower rollers are metal rollers, pressurized way is the corrugated gas tire pressure.

8. Reeling section: Pneumatic horizontal reel and pressurized way is cylinder pressure.

Kraft paper machine main spare parts

Kraft carton paper machine packaging and delivery

1. Export packing (Wooden case, carbon cast and pallet).

2. Container (as customer requirements)

3. It is suitable for long distance ocean transportation.

Leizhan service

2.Designing and fabricating targeted products according to the special requirements of clients.

3.Training periodically high qualified service technician.

1.Assisting our clients for foundation construction of equipment.

2.Dispatching engineers to install and debug equipment.

3.Training the first-line operators on site.

4.Regularly visit clients to solve production problem.

FAQ

What do you offer?

A: We can offer the whole pulp and paper production line. From factory design to machine installation and training, our company can supply for you all.

Are your a manufacturer?

A: Yes. Of course we are. We are spealized in pulp & paper equipment manufacturing in China for 44 years. There are about 50 paper mills near our factory and most of them are using our machines.So, welcome to visit our factory and I believe you will be satisfied with our products.

What's your advantages?

A: We have 44 years experience in the field of paper making machine industry. 20000 square meters

workshop with more than 200 staffs including 50 engineers. ISO9001:2000 and BV certification. Strict quality control of every procedure.

Why Choose Leizhan?

Похожие товары

Устройство для терапии воздушным давлением аппарат прессотерапии и дальним инфракрасным излучением лучше чем

Клапан управления направлением MP80 21gpm Bspp G1/2 порта 3 рычага моноблок гидравлический

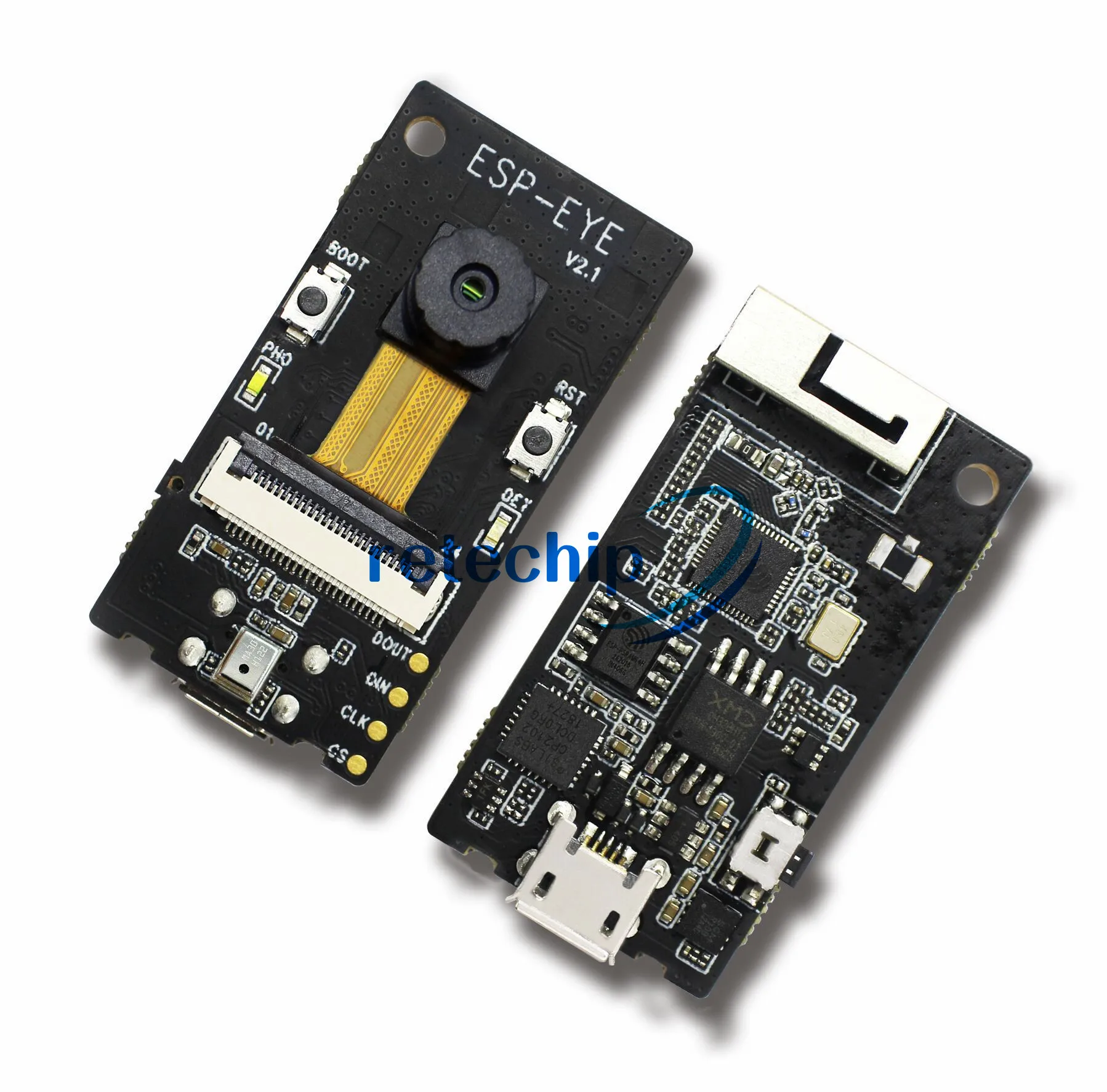

Оригинальная плата для развития распознавания изображений, Wi-Fi и Bluetooth, двухрежимные электронные компоненты, ESP-EYE ESP32

A7V A7V78 A7V78LV Серии Гидравлический поршневой насос высокого давления A7V-78LV1RPG00

Высокое качество макияж веганская основа частная Этикетка OEM оптовая торговля

FX-620 планер дрона с дистанционным управлением SU35 истребитель 2,4G с дистанционным управлением самолет электрический самолет модель игрушка с неподвижным крылом AB Glider модель горячей продажи

Sinotrug HOWO запчасти WD615.47 WD615.69 D12.42 двигатель для грузовика

Новые поступления

Новинки товаров от производителей по оптовым ценам