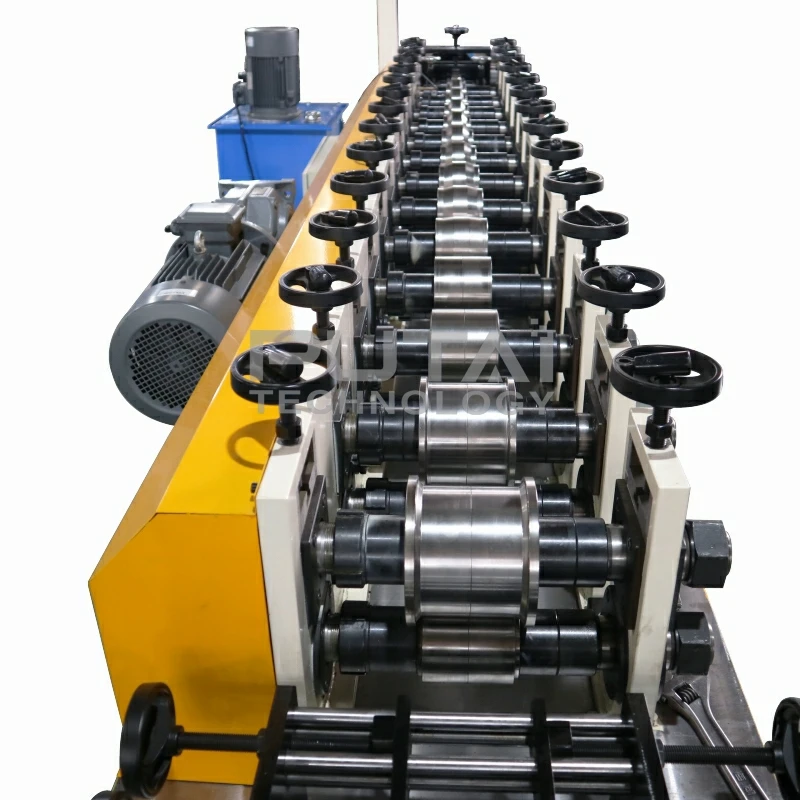

Станок для изготовления металлических штифтов из гипсокартона световой манометр шпилька гусеница канальный стальной рулон формовочная машина

- Категория: >>>

- Поставщик: Bazhou Chenglang Keel Equipment Co. Ltd

Сохранить в закладки 1601039843733:

Описание и отзывы

Характеристики

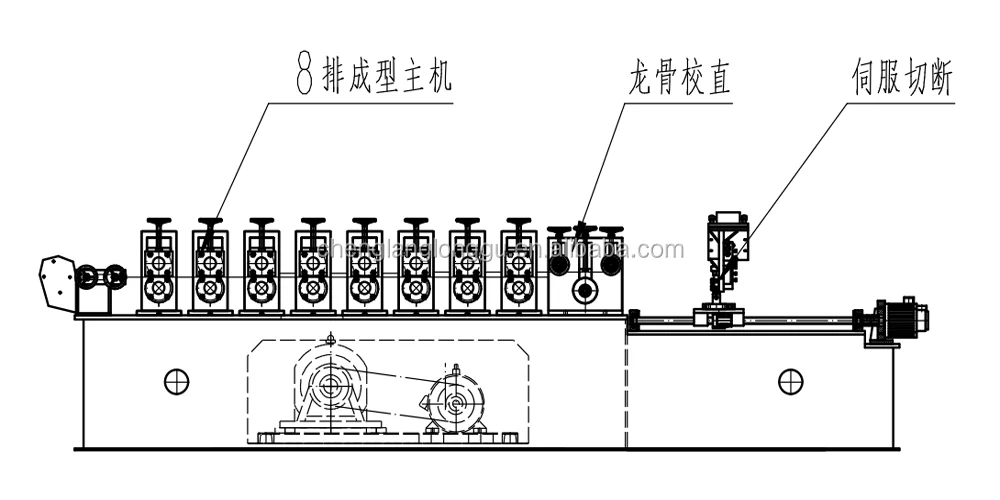

Drywall Metal Stud Cu Making Machine Light Gauge Keel Stud Track Cu Channel Steel Roll Forming Machine

Specification of T runner main tee making machine | ||||||

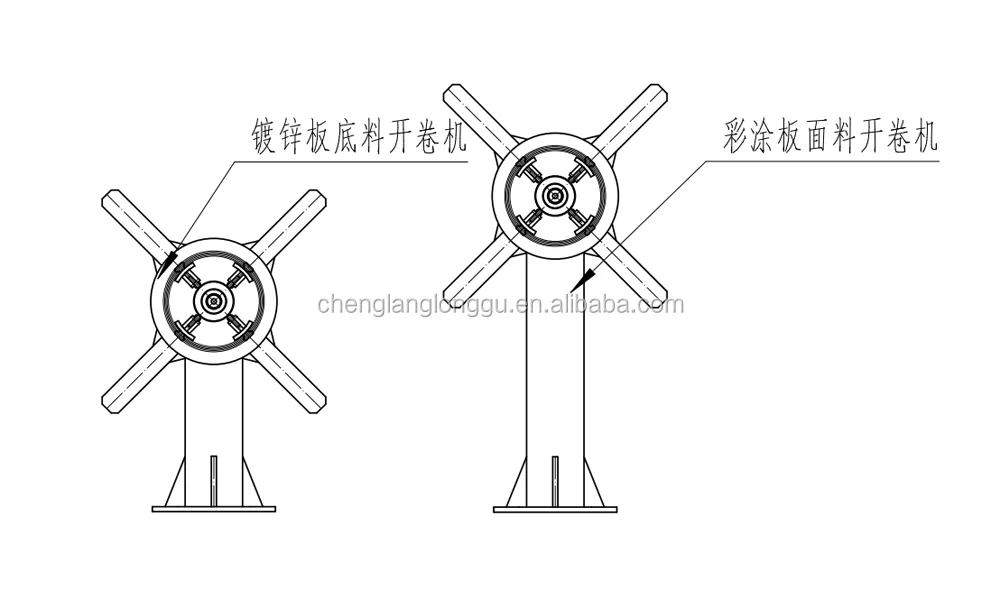

Decoiler | Weight | 150kg | ||||

Steel coil ID | 450-550(mm) | |||||

Steel coil OD | 1500(mm) | |||||

Roll forming machine | 14-18 Rows Material:Cr12 roller inner diameter:Φ40mm, roller outer diameter:minΦ90 heat treatment hardness:HRC58-62 | |||||

Transmission | The main drive uses chain drive, roll between the use of gear transmission | |||||

Middle Plate | Thickness 25mm, grinding six-sided, high-precision boring from processing | |||||

Hydraulic system | Motor Power | 7.5kw | ||||

Cutting system | Cutting System | Servo tracking system | ||||

Mold | Mold Material | SKD11 | ||||

Roll Forming Machine

1.Stitching: section of four-wheel really bite, easy to replace.

2.Side panel: thickness of 25 mm, six surface grinding, precision boring.

3. main axis:Main shaft material is 45 # steel, finishing with mo bed after machining and tempering heat treatment.

4.Feed positioning: manually positioning, flexible adjustment on both ends.

5.Electrical control system: PLC programmable controller, touch screen automatic control system.

6.Die: material is SKD11, heat treatment hardness HRC58-62, template fine grinding, wire of high precision.

1) Engineer avaialble to go abroad to installte machines and try machine.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Full automatic production line and semi-automatic production line for customer choose

4) Running in a high automatization and intellectualization,no pollution

5) With fewer molds, high production speed .

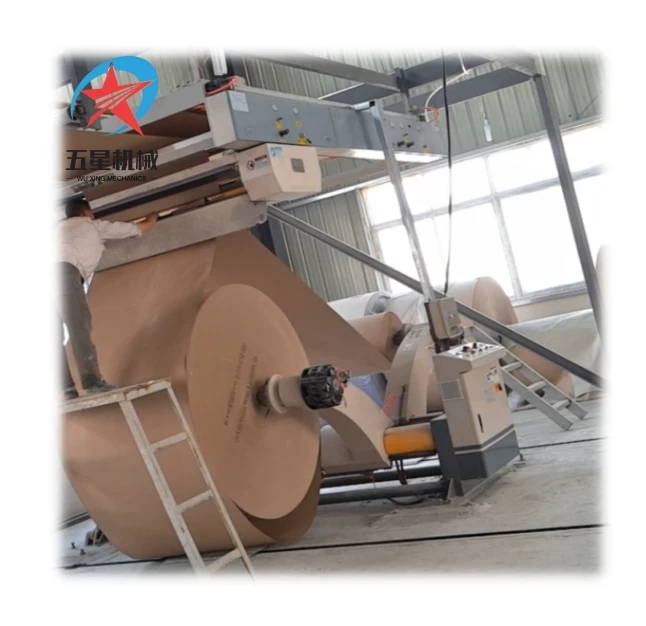

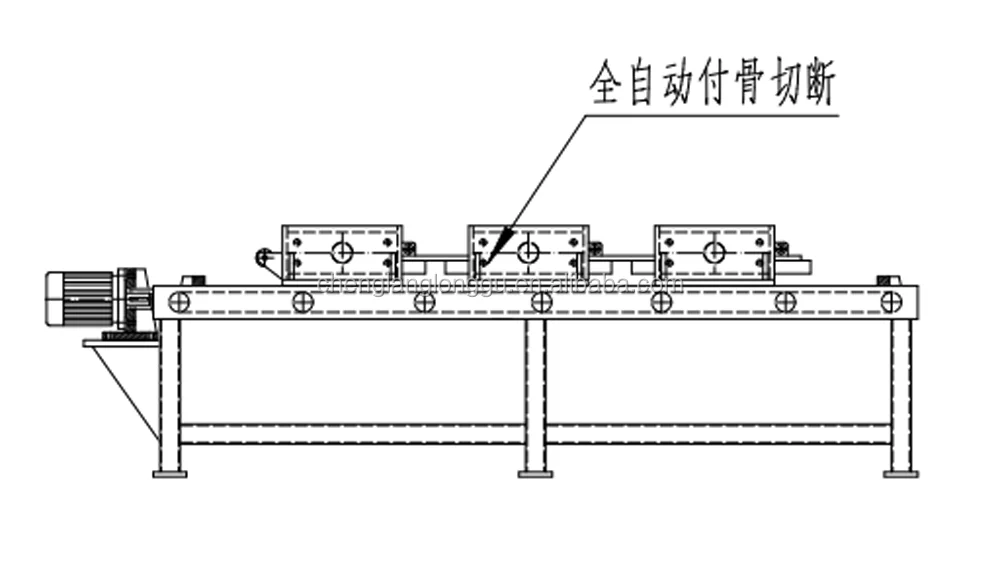

Production Flow

Tianjin Putai Technology full automatic good quality and low price metal profile steel structure stud roll forming machine

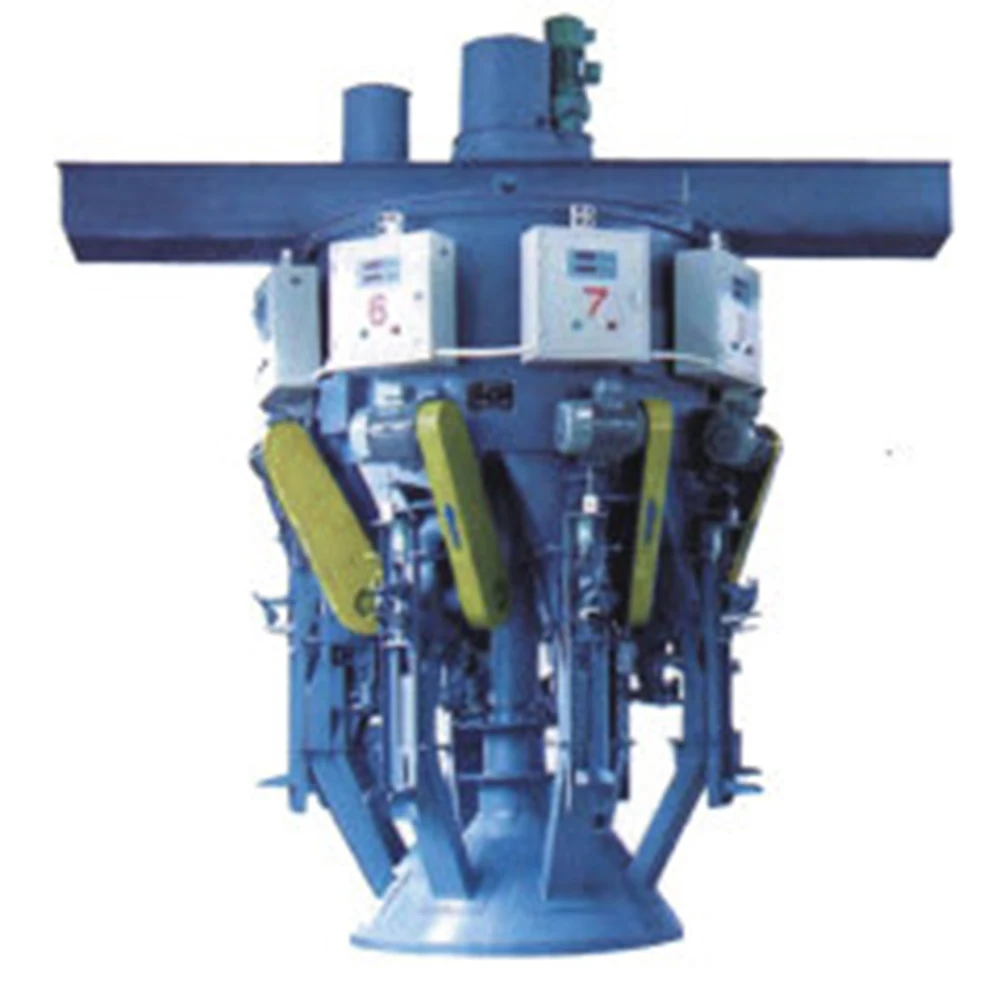

Name: Full automatic main T grid punching machine

Brand: Chenglang

Original: He bei, China

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits , convenient for operation. Function: To punch the dots on the T grid and punching lock on two sides end.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Machine trial before shippment

Packaging | ||

Size | 5450 (L) *780 (W) *1200 (D)mm | |

Weight | 1.5 T | |

Packaging Details | packed with water-proof plastic film | |

Packaging | ||

Size | 123 (L) * 456 (W) * 789 (D) | |

Weight | 1.2 T | |

Packaging Details | 1). Tighten to container with steel wire rope and welded machine with container by angel iron 2). Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic) 3). PLC contral system and motor pump are packed in box with water proof paper coverage | |

stud and track channel keel roll forming machine

91.8% Response Rate

1)Q: What is stud and track?

A: Structural Studs and Tracks are the basic "foundational" parts of steel frame technology. The "U" shaped channel runners

(tracks) are used as the top and bottom tracks to secure wall studs or end support closures for floor joist framings.

2) Q:Are studs and tracks the same?

A: Metal studs are also available in a range of lengths and thicknesses ranging from 25 to 16 gauge, the smaller the number the

thicker the steel. Steel track is the u-shaped channel used to attach steel studs to the floor and ceiling.

3)Q: How does your factory do regarding quality control?

A: Quality is a priority. we always attach great importance to quality control from the very beginning to the end of the

production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers' specifications, using top-brand name components

5) Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are

going to book with us

6)Q: How can we be assured that you will deliver us a quality machine with spare parts?

A:1. Customers to send the technical people to our factory to check the quality.

2. We can send the technicians to the buyer`s factory for the installation of the machine.

3. Good aftersales service, it's free of charge during the warranty period.

7)Q: What can you do if the machine is broken?

A: Our machine's warranty period is 12 months, if the broken parts can't be repaired, we can send the new parts to replace the

broken parts free, but you need to pay the express cost yourself. if after the warranty period, we can look at negotiation to

solve the problems, and we supply the technical support for the whole life of the equipment.

8:How to play order?

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit ---then OK

9:How to visit our company?

Fly to Tianjin airport, we will pick up you at the airport.

If any questions,you can call my mobile phone at any times:0086 18522898438

whatsapp/wechat/imo/mob: 0086 18522898438

Похожие товары

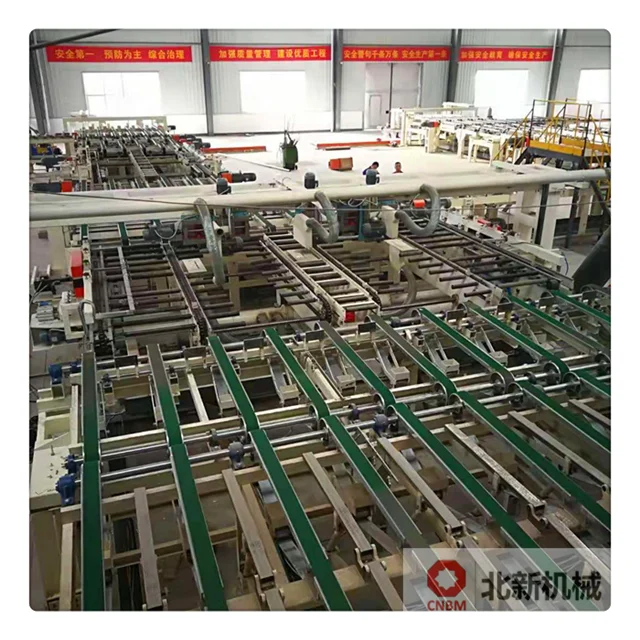

Высококачественная передовая технология Высокоэффективная полностью автоматическая производственная линия для производства гипсокартона

Оборудование для производства гипсокартона

CNBM производственная линия гипсокартона/машина для изготовления гипсокартона высокого качества автоматическая

Гипсокартон производственная линия делая машину гипсокартон машина

Оборудование для производства гипсокартона

Высокое качество автоматический клапан роторный цемент 8 рот упаковочное оборудование для наполнения цемента

HPB 70 гидравлический рулон грубая круглая гибочная машина

Новые поступления

Новинки товаров от производителей по оптовым ценам