Высокоточный широкоформатный ЖК экран/телевизор/подсветка

- Категория: >>>

- Поставщик: Wuhan Sunic Photoelectricity Equipment Manufacture Co. Ltd.

Сохранить в закладки 1601047975781:

Описание и отзывы

Характеристики

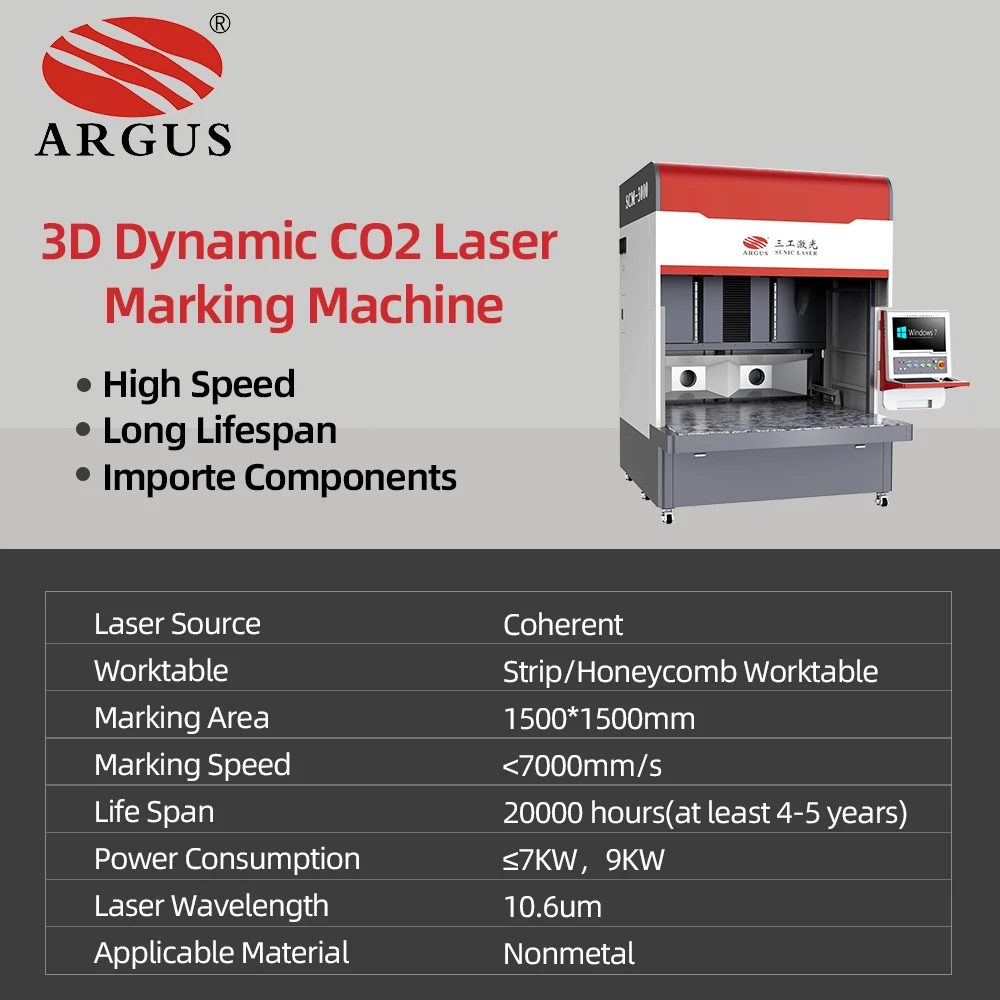

Model | SCM3000 | ||||||

Working Area | 1500*1500mm | ||||||

Worktable | Marble worktable | ||||||

Laser Source | Coherent CO2 Metal R.F. Laser Source (USA) | ||||||

Laser Power | 250W/350W | ||||||

Laser repetition rate | 1kHz~100kHz | ||||||

Life Span | 20,000 hrs (at least 4~5 years) | ||||||

Scanning System | Gantry model | ||||||

Repeat accuracy | +-0.01mm | ||||||

Marking Speed | <10,000mm/s | ||||||

Power Consumption | ≤7KW | ||||||

Control Software | Sunic Laser self developed professional control software | ||||||

File Formats Support | PLT, DXP, BMP, JPG, AI etc | ||||||

Cooling Way | Circulation of water cooling | ||||||

Including | Host Machine, Water Chiller, Exhausting System, Computer, Control Cards and Software | ||||||

Equipment size | 1.65m*1.81m*2.4m | ||||||

Equipment weight | About 1100 KG | ||||||

Top 1 LED Panel Light LGP Laser Dotting Machine in China

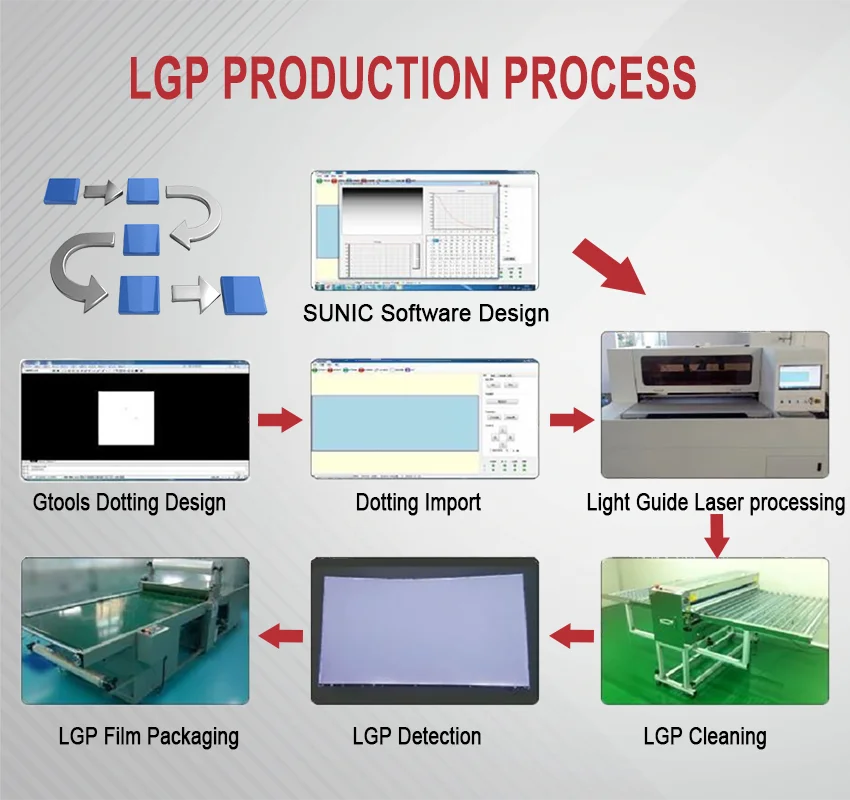

The SCM3000 LGP Laser Dotting Machine is specialized designed for LGP Laser Dotting Application, which is widely used in the LED panel light producing, and it is also the most popular model in the market.It is the outcomes of SUNIC Laser’s technical expertise and experience in marking and engraving PMMA sheets for Backlight applications exploiting proprietary laser technology to produce micro- points by light guide plate (LGP) on PMMA panels up to 1500×1500 mm working size. This process is much more productive in comparison to other traditional technologies and other lasers, even with the maximum quality.

Main Features

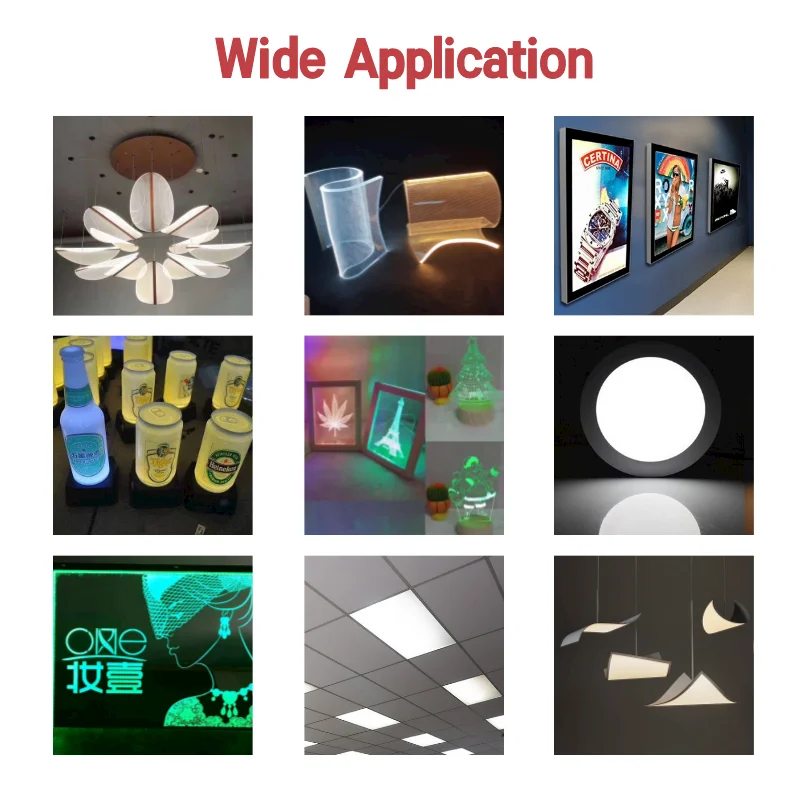

The Light guiding plate (LGP) processed by Laser dotting display the excellent features of super thinner&brighter, uniform light guiding, energy saving and green, no dark areas, long time lasting, no yellowing, convenient and easy maintenance:

1. Thinner acrylic materials are viable, to save raw cost

2. Higher lighting efficiency

3. Both dots and marking lines are generated by reasonable arrangement (sparse in edges and intensive in middle ) processed by professional optical designing software, to maximize the uniformity of lighting efficiency of at least 90%.

4. Longtime lasting, and no yellowing features to ensure an indoor lifetime of 8 years’ normal use

5. No affects by water or humidity, while by which the LGP processed by screen printing can be easily affected and bleak.

6. Simple process as well as higher flexibility with LGP production. It’s supportive with various LGP shapes according to customers’ designs. Faster marking, lower cost, and avoid the shortcomings of complexity processing, poor durability in screen printing craft.

7. Much Lower requirement with plate flatness. The laser dotting machine is capable to bear a deviation of 5mm in flatness with few affect, which is totally unacceptable in screen printing industry.

1. Thinner acrylic materials are viable, to save raw cost

2. Higher lighting efficiency

3. Both dots and marking lines are generated by reasonable arrangement (sparse in edges and intensive in middle ) processed by professional optical designing software, to maximize the uniformity of lighting efficiency of at least 90%.

4. Longtime lasting, and no yellowing features to ensure an indoor lifetime of 8 years’ normal use

5. No affects by water or humidity, while by which the LGP processed by screen printing can be easily affected and bleak.

6. Simple process as well as higher flexibility with LGP production. It’s supportive with various LGP shapes according to customers’ designs. Faster marking, lower cost, and avoid the shortcomings of complexity processing, poor durability in screen printing craft.

7. Much Lower requirement with plate flatness. The laser dotting machine is capable to bear a deviation of 5mm in flatness with few affect, which is totally unacceptable in screen printing industry.

Похожие товары

20 кг металлическая гравировальная машина портативная Вт 30 50 Mopa золотая умная цветная волоконно-лазерная маркировочная

DAJA S4 машина для маркировки оптического волокна 30 Вт ручная лазерная гравировка поддержка AI графический формат

Автоматическая машина для лазерной маркировки маркировочная металлических визитных карточек и табличек

Лазерная маркировочная машина ручной маркер логотипа 20 Вт 30 50

170 717,31 ₽ - 241 362,75 ₽

Лидер продаж волоконно-лазерная маркировочная машина Wuhan Ротационная Машина RAYCUS JPT 20 Вт-60 Вт мини-гравировальная для металла ключевой компонент лазерного источника

122 885,60 ₽ - 140 519,41 ₽

50 Вт Автоматическая Стыковочная настольная волоконно-лазерная маркировочная машина и волоконно-лазерный маркер для металла неметаллический Настольный лазерный гравер

195 845,49 ₽ - 231 333,52 ₽

2024 новый дизайн 15% выключен! 20 Вт/30 Вт/60 Вт 80 JPT MOPA цветная волоконно-лазерная маркировочная машина с компьютером для металла

88 169,04 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $