Нигерийский литиевый завод по переработке минерального сырья 1000 ТПД сподуменная флотационная машина оборудование для добычи лития

- Категория: >>>

- Поставщик: Jiangxi Province County Mining Machinery Factory

Сохранить в закладки 1601049109611:

Описание и отзывы

Характеристики

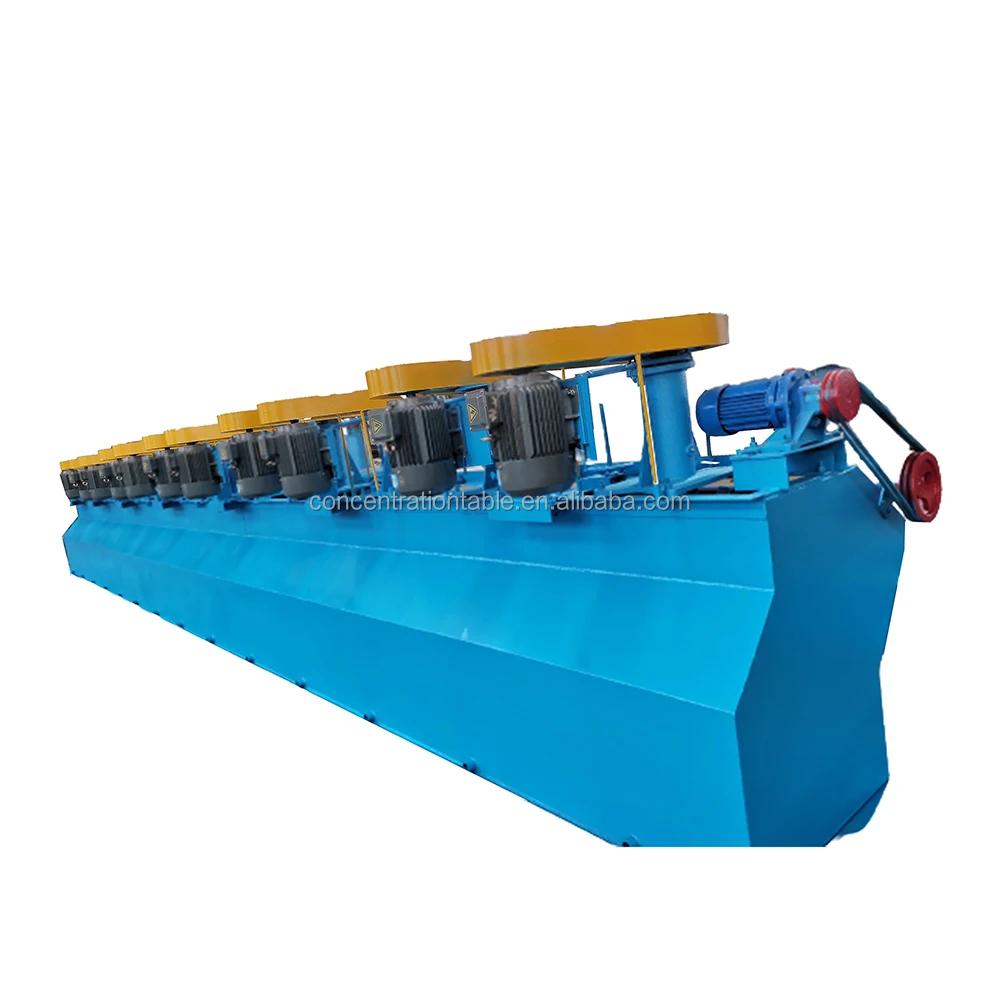

Introduction of Flotation Machine

Flotation machine, in the ore dressing, mainly used for separating copper, zinc, lead, nickel, gold and other Non-ferrous metal, can also be used for Ferrous, non-metallic crude and selected.

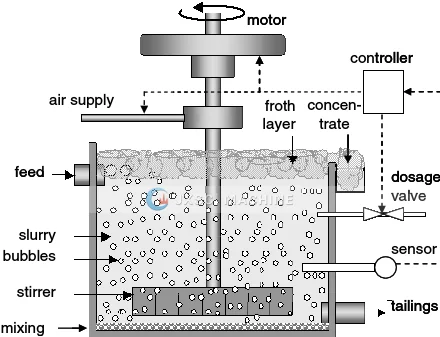

After mixing the crushed ore with water and flotation reagent, the ore is mixed into a slurry tank, which is filled with air to form a large number of air bubbles. Some mineral particles which are not easily wet by water attach to the air bubbles and float to the surface of the pulp together with the air bubbles The formation of mineralized bubble layer, some easy to be water wet, hydrophilic mineral particles not attached to the bubble, and stay in the pulp, will contain specific minerals mineralized bubble discharge, so as to achieve the goal of mineral processing.

Features of Lead Zinc Separation Equipment Flotation Machine

1. High flotation efficiency and low energy consumption.

2. Long Service Life of wearing parts.

3. The flotation machine is equipped with high self-configuration, and has the functions of suction, Pulp Suction, and flotation, and does not need any auxiliary equipment.

4. Mechanical Mixing, easy to operate and adjust.

5. It can combine with other mineral equipment, sand making machine, sand washing machine to separate ore, the effect is better.

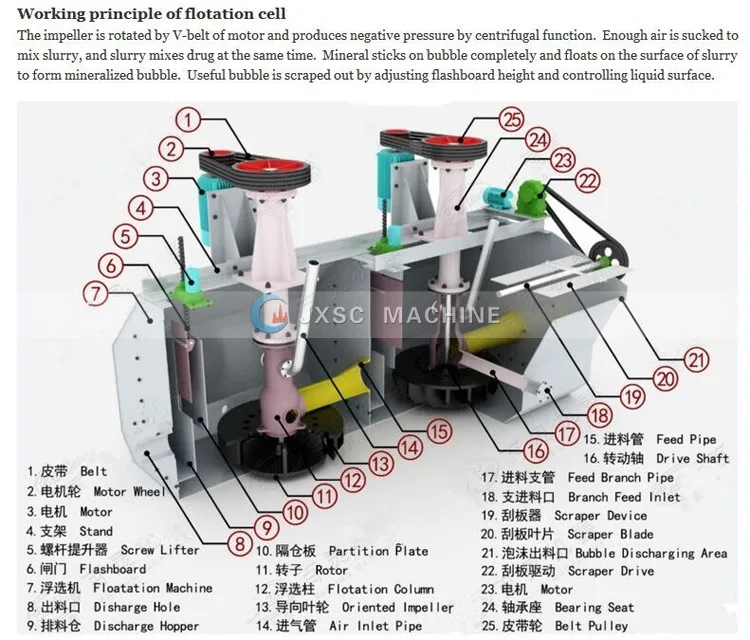

Product Structure of Lead Zinc Separation Equipment Flotation Machine

The metallurgist flotation mainly made up of slurry-supporting Trough, mixing device, aeration device, mineralized bubble discharging device and motor. Flotation cell is mainly used to select nonferrous metals such as copper, zinc, lead, nickel, gold, etc., and also be used for coarse selection and selection of black metal and nonmetal.

With the poor, fine, hybridized primary mineral resources and the increasing complexity of mineral processing technology, energy consumption and production costs, it is necessary to strengthen the research of flotation equipment in the following aspects. JXSC, focus on the mineral equipment business since 1985, CE, SGS certified.

Technical Parameters of Lead Zinc Separation Equipment Flotation Machine

we can choose the model according processing capacity and mineral particle size. The best feeding size is 200 mesh account for 80% or more.

Model | Volume | Cell size | Impeller Dia. | Impeller speed | Capacity | Power | Singe cell weight |

Unit | m3 | mm | mm | r/min | m3/min | kw | kg |

XJK-3A | 0.35 | 700×700×700 | 300 | 483 | 0.18-0.4 | 2.2/0.55 | 430 |

XJK-4A | 0.62 | 820×900×850 | 350 | 400 | 0.3-0.9 | 3/1.1 | 755 |

XJK-5A | 1.1 | 1100×1100×1000 | 500 | 330 | 0.6-1.6 | 5.5/1.1 | 1416 |

XJK-6A | 2.8 | 1750×1600×1100 | 600 | 280 | 1.5-3.5 | 11/1.1 | 2113 |

XJK-7A | 5.8 | 2200×2200×1200 | 750 | 240 | 3–7 | 22/1.5 | 3400 |

SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9828 |

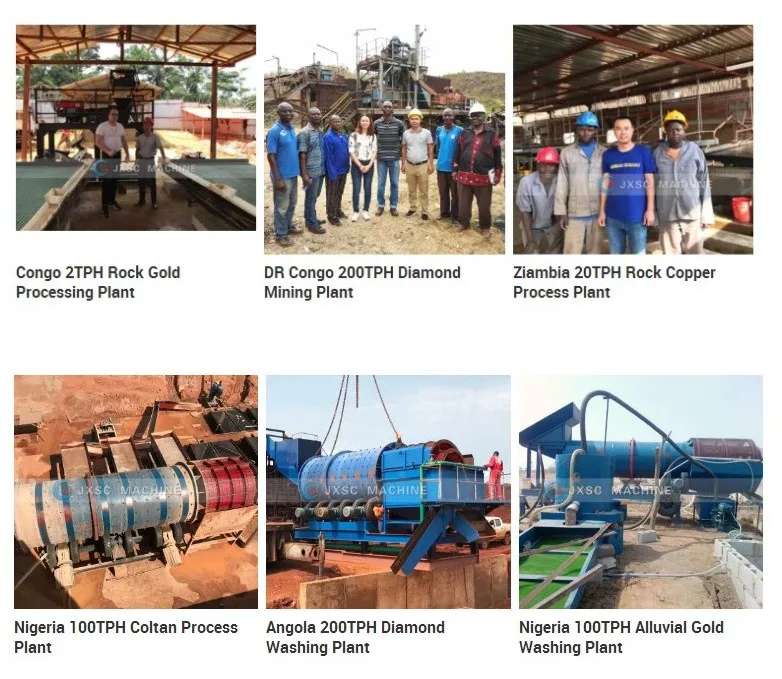

JXSC has proveded many mineral plant cases. Except for manufacturing of the mining equipment, JXSC also can provide engineering consultation, mineral processing experiments, mine design, installation and commissioning, personal training, track service, management of dressing plant, etc one package service. Make customer worriless whole-process, shorten construction period and get profit earlier.

We JXSC can design the whole processing line according to clients mineral info & requirement. In China, there are full of Tin, Tungsten ore. Many clients use flotation processing way for concentration.

Except gold, tin, tungsten plant, we can also provide many other mineral processing plant.

Here above is Angola 200 tons per hour Clay diamond wash Plant

The process for your reference first here. Kindly contact for more details.

Process: First use vibration feeder to feeding material to trommel scrubber, After trommel scrubber for washing clean, and separator big size out, then to vibration screen. Vibration screen also for separator different size.

Jiangxi Province County Mining Machinery Factory is a leading mining machinery manufacturer with over 34 years experiences, providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore /Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore/Cobalt ore/Antimony ore, ect. As well as complete set small laboratory mining machines.

Main product including: trommel screen, trommel scrubber, shaker table, spiral chute separator, jig machine, centrifugal concentrator, sluice box, vibration screen, melting furnace, jaw crusher, hammer crusher ,ball mill, flotation machine, spiral classifier, as well complete set small laboratory mining equipment.

Jiangxi Province County Mining Machinery Factory mainly manufactures shaking table, flotation equipment, crushing(powder)equipment, magnetic separation equipment, screening equipment, ore washer classifying equipment, agitation equipment, spiral chute equipment, gravity separation jig, feeding equipment, milling equipment. Also we can custom-manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Below some hot selling machines for your reference. We can customize the related mineral processing machine based on your requirement.

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.How about your guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 40% deposit, 60% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Похожие товары

Водонепроницаемый класс защиты NIJ уровень iiia 3a тактические пуленепробиваемый пуленепробиваемые Броня

Напрямую с фабрики larrex 6x24 водонепроницаемый 1500 м Охота гольф GPS Long Range Finder на оптовая продажа

HY 2001 Hi-Fi 12V Мини Автомобильный стерео усилитель 2 канальный Авто Аудио Цифровой

Торговый автомат для еды и Напитков Автомат для закусок

Запчасти для грузовиков Drag Link 81466106840 81466106841 81466106812 81466116138 для M-A-N грузовик

Автомобильный стартер арматура двигателя 12 В 2 кВт 1004011074 1004011087 1004011219 Im2114 61-27556-W для сиденья Vw Audi

Стоматологический Ультразвуковой скалер с наконечником

Новые поступления

Новинки товаров от производителей по оптовым ценам