Рентабельная дробилка и Миксер Для древесного угля Chancador De Mandibula

- Категория: >>>

- Поставщик: Shanghai Zenith Mineral Co. Ltd.

Сохранить в закладки 1601050822832:

Описание и отзывы

Характеристики

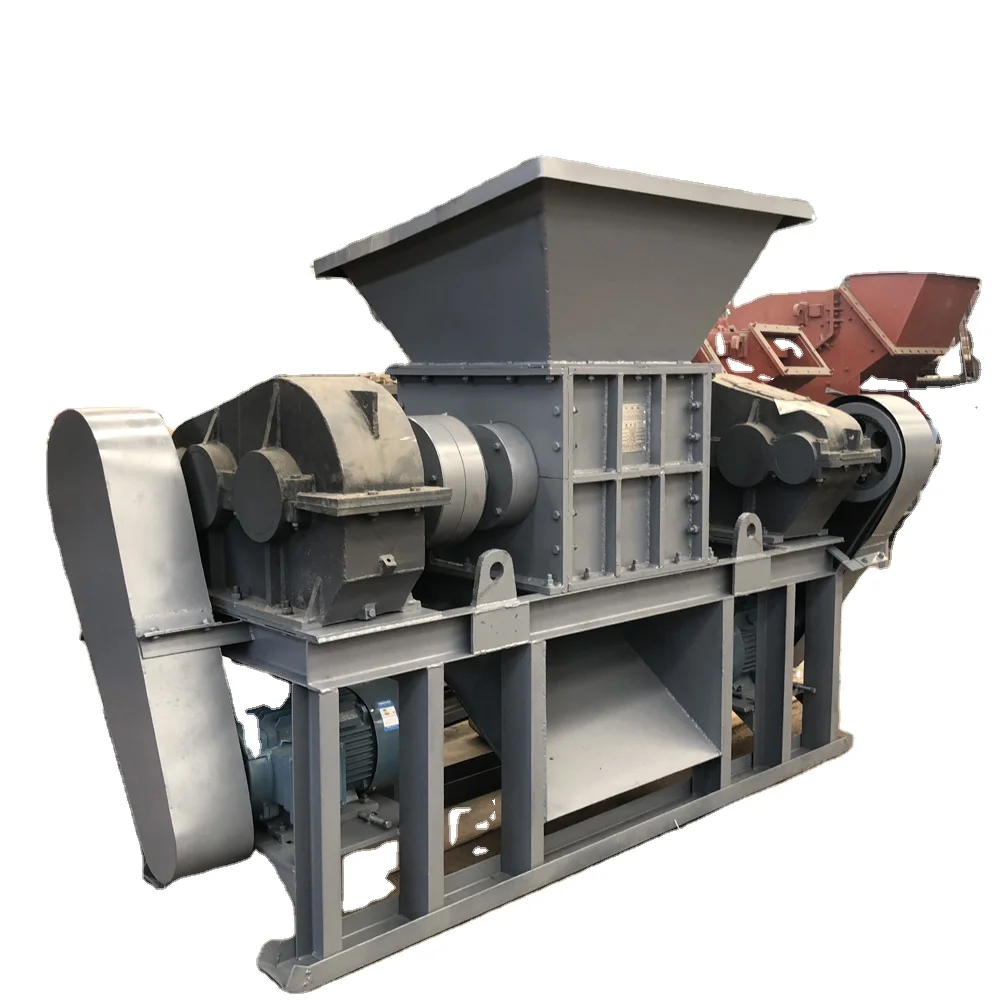

Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer

El chancador de mandíbula es una máquina versátil para la trituración primaria de rocas y minerales. Funciona por compresión para reducir grandes piedras en materiales de tamaño uniforme.

Está construido con una estructura robusta de acero refuerzo y placas de mandíbula resistentes. Posee una cavidad de mandíbula profunda y tiene la función reversible, permitiendo la alimentación continua aun con interrupciones de energía.

Tiene la capacidad de triturar más de 50-800 toneladas por hora. Sus configuraciones estandar permiten ajustar el tamaño final de la salida entre 3/8 a 3 pulgadas, cumpliendo con los requerimientos de producir agregados para concreto.

Es una herramienta confiable para proyectos de minería, canteras y plantas de agregados. Su servicio es respaldado por ingenieros expertos, ofreciendo máxima producción y disponibilidad incluso en condiciones exigentes.

El chancador de mandíbula es una solución rentable para la trituración primaria de rocas de toda índole.

| Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer

Product Features: Inheritance of century-old classics, simple structure, stable working performances

|

Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer introduction:

Classic Inheritance, Simplicity & Reliability

| "Power Failure" Safety Device Effectively Responds To Overload

|

Shorter Downtime &Longer Service Life - Super-Strong High-Manganese Steel Casting

| Precise Processing, Craftsmanship Spirit

|

Various Models To Satisfy More Demands

| Sufficient Supply Of Spare Parts, Worry-Free Operation

|

Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer working principle:

The PE Jaw Crusher is powered by the motor. Through the motor pulley, the eccentric shaft is driven by the V-belt and the sheave, so that the movable jaw reciprocates along the predetermined tracks to crush materials inside the crushing cavity. Materials, after being processed and reaching the standard, would be discharged from the lower discharge opening.

Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer:

Cost-Effective Chancador De Mandibula Charcoal Crusher And Mixer parameters:

| Model | Feed opening (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity (t/h) | Speed (r/min) | Power (kw) | Overall dimension (mm) |

| PE500×750 | 500×750 | 425 | 50-100 | 45-100 | 275 | 55 | 1890×1916×1870 |

| PE600×900 | 600×900 | 500 | 65-160 | 70-120 | 250 | 75 | 2520×1840×2303 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 130-260 | 250 | 90 | 2620×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 130 | 3789×2826×3025 |

| PE1000×1200 | 1000×1200 | 850 | 195-265 | 230-380 | 200 | 130 | 3889×2826×3025 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 200 | 4930×3150×3700 |

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that ZENITH may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, Z keeps the right to explain all data involved in this website.

Project Background:

Raw Material: Kenya Phonolite

Location:Isiolo

Capacity: 100-120TPH (8 hours per day)

Input sizes: 0-500mm

Final output sizes: 0-6mm, 6-10mm, 10-14mm, 14-20mm.

Installation Time: Jun, 2016

Foundation Type: Steel Structure Foundation

Customer Feedback:

“My friend introduced me to ZENITH. With their professional advice, I start to prepare the land, license and look for partner. I place the order even without visiting their China factory as they have local office here and a lot of customers in Kenya. Against the inspection opportunity, I visited their headquarters and factory in Shanghai and was quite impressed on their strength. I am very happy I choose the right company to work together and I catch the early developing train in my hometown.’’

Pre-sales Service: The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site. To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

|

After-sales Service: Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also. |

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Shanghai Zenith Mineral Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Zenith Factory

Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city.

Exhibition

Zenith participate in various exhibitions frequently,such as Bauma China,China Import and Export Fair , Asia-pacific's International Mining Exhibition, Bauma Africa, CONEXPO Latin America , etc.

If you are interested with our products, please don't hesitate to contact us now!

You can tell me the following questions, Then I can send you accurate quotation, including additional discount!

1. Which machine do you need? like stone crusher, grinding mill or beneficiation machine, etc.

2. what is your raw material plan to process? like limestone, granite or inron ore, etc.

3. The capacity you need. Like 100 tones per hour or 2000 tones per day.

4. Your contact information. Both Email and phone number are essential, we can contact you easier.

Now,please click the following contact to send us email or chat online!

Похожие товары

Двухосевая Большая пластиковая листовая машина материал измельчитель отходов бытовая дробилка простая и долговечная

Низкопотребляемая машина для измельчения железа щековая дробилка Экваториальной Гвинеи

Лидер продаж 2023 машина для дробления камня онлайн-поддержка Филиппины Индонезия

Новая технология дробилка карьерный молотковый завод с дизельным двигателем для цеолита

Мельница горизонтальная Die роликовая дробилка для удобрений

Мобильная дробильная станция гусеничного типа 150 Tph конусная дробилка с вибрационным экраном

Гусеничный мобильный сверхмощный скрининговый завод станции для продажи ST833 емкость 60-300 т/ч отслеживаемый Вибрационный экран цена

Новые поступления

Новинки товаров от производителей по оптовым ценам