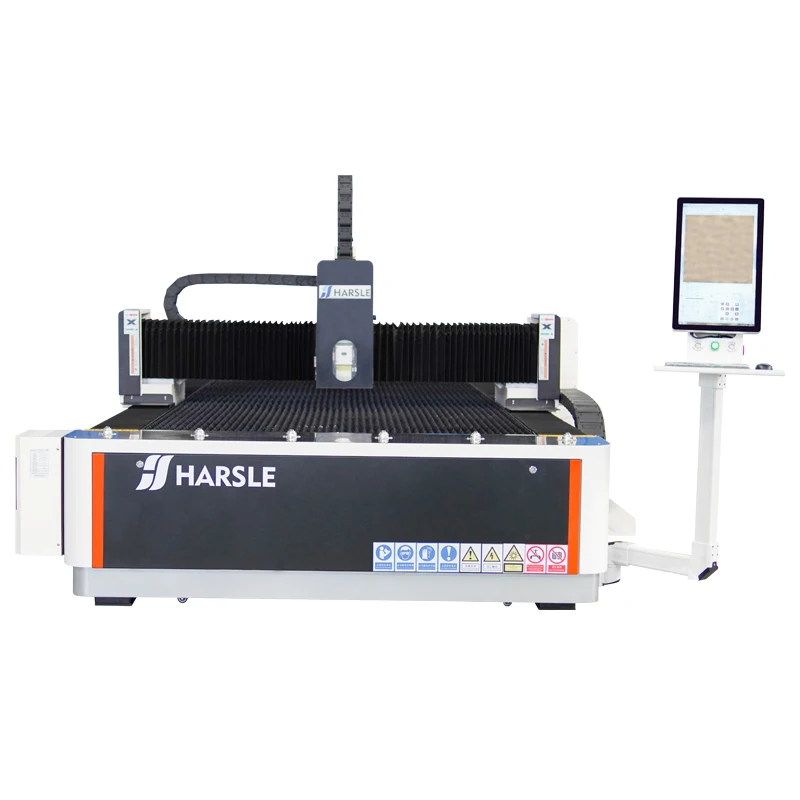

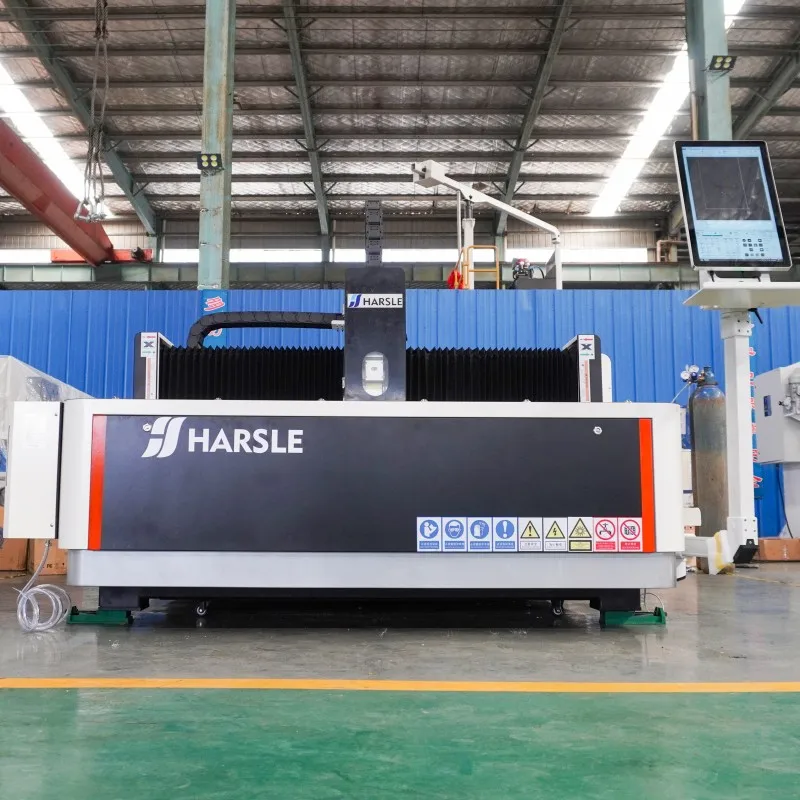

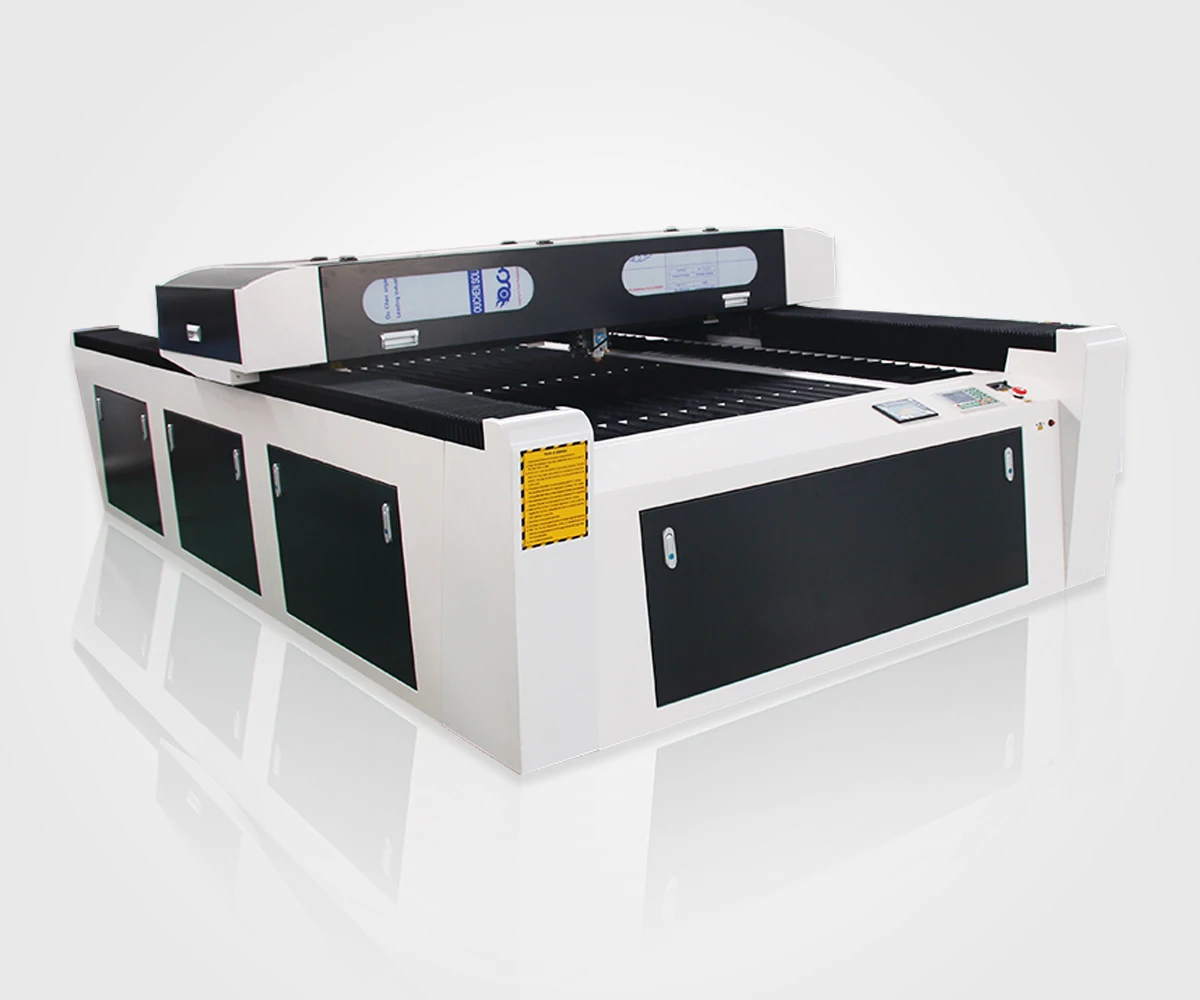

Оптовая Продажа с фабрики волокна 3000 Вт умная Лазерная резка для листового металла

- Категория: >>>

- Поставщик: Nanjing Harsle Machine Tool Co. Ltd.

Сохранить в закладки 1601055497743:

Описание и отзывы

Характеристики

Products Description

HARSLE HS CNC Fiber Laser Cutting Machine

The CNC fiber laser cutting machine has a stable performance and high precision, using a German brand reducer to ensure that the machine starts and stops ay high speed, and a double drive rack and pinion transmission system to guarantee performance. All electrical compoments and lasers are housed in the control cabinet, with excellent dust-proof design to enhance the life of the electrical components. The outside of the control cabinet is equipped with an air conditioner with automatic constant temperature to prevent damage to the components in summer.

Product Details

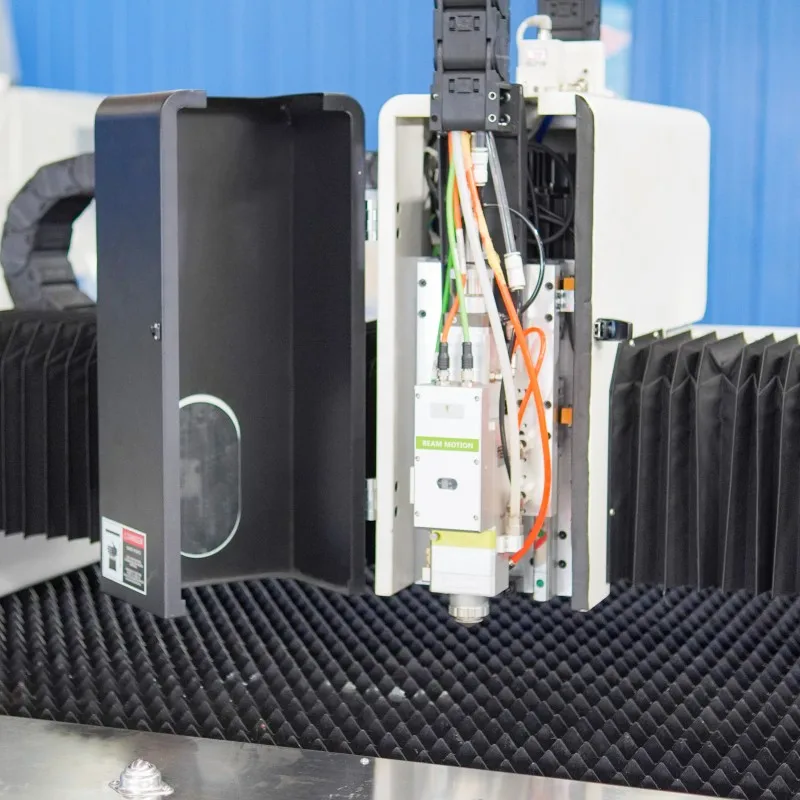

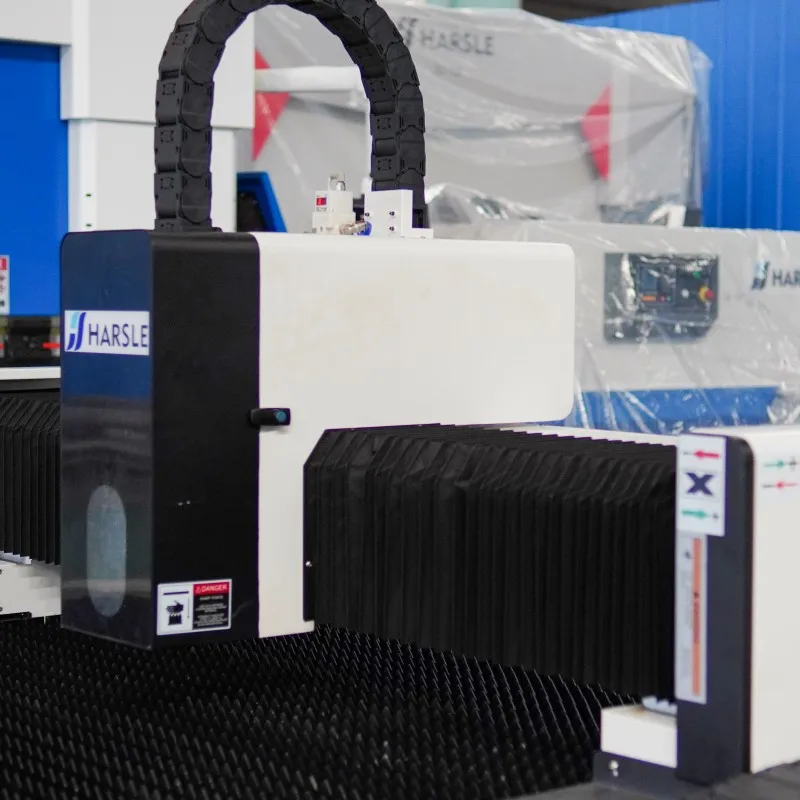

Switzerland RAYTOOLS Laser Head

Optimization of the optical configuration smooth and efficient air flow design rotary knob focus adjustment more easy and flexible.

France MOTOREDUCER

Satellite gears are double-supported an hardened and ground shafts with full-complement needle bearings increasing torsional stiffness.

Japan YASKAWA Servo Motor

The increased power demands of largeautomation components utilize the robust performance of SGM7G.

JAPAN NSK Bearings

These bearing housings have square flange which can be easily attached to a machine with four bolts.with its simple mounting face,this bearing unit is widely used.

Laser Source

We have two types of laser sources: MAXPHOTONICE and IPG, which can be supplied according to customer request.

Japan SMC Pneumatic Components

Stepless control of air pressure proportional to an electrical signal. Compact/lightweight (Integrated communication parts.)

France Schneider Electronic Component

Circuit protection against short-circuit currents,overload currents.

Auto Lubrication System

Electrical lubrication is a kind of gear pump with rational construction, great performance,complete functions.

Working Principle

1.Moving Direction

2.Auxiliary Gas

3.Nozzle

4.Nozzle Distance

5.Molten Material

6.Residues

7.Cutting Section

8.Heat Affected Zone

9.Joint-Cutting

Help You to Solve the Following Problems Easily

SAVE MAN POWER | ■ Save manpower cost |

■ Solve the problem- | |

High cost and difficult mangement of labor force | |

HIGH EFFICIENCY | ■ High speed, convenient operation |

■ Solve the problem- | |

Artificial or common mechanical processing with low speed, low efficiency | |

GOOD QUALITY | ■ High precision smooth section is convenient for welding processing or assembling |

■ Solve the problem- | |

Poor precision,coarse section,large slit | |

STANDARDIZATION | ■ Computer operation standardization production |

■ Solve the problem- | |

Batch job error | |

LOW COST | ■ Almost zero maintenance cost |

■ Solve the problem- | |

The equipment maintenance cost is high,the continuous investment | |

ENVIRONMENTAL PROTECTION | ■ High-eficiency laser source,dust and smoke treament device |

■ Solve the problem- | |

High energy consumption,serious pollution |

Fine Processing

Low cost in use | power consumption is only 20-30% of CO2 laser |

High speed | 2-3 time faster than yag or CO2 laser |

High accuracy | Fine laser beam,slim kerf |

Low maintenance | Almost zero maintenance cost |

■ Solve the problem- | |

Artificial or common mechanical processing with low speed, low efficiency |

Installation Instructions

1 | Machine tool body | 1 set | HARSLE |

2 | X、Y axis gear rack | 1 set | YYC -Taiwan |

3 | Linear guide rail | 1 set | HIWIN- Taiwan |

4 | Servo motor and driver | 4 sets | YASKAWA/Schneider |

5 | Reducer | 3 sets | Japan SHIMPO |

6 | Solenoid valve | 1 set | Japan SMC |

7 | Air cylinder | 1 set | Japan SMC |

8 | Proportional valve | 1 set | Japan SMC |

Certifications

Exhibition

India-BLECH INDIA

UAE-STEELFAB

Russia-METALLOOBROBOTKA

Thailand-METALEX

Manufacturing Technique

Cutting

Lathe

Milling

Drilling

Welding

Boring

Testimonial

Dominica

Belarus

South Korea

Thailand

USA

Malaysia

FAQ

What will be the payment method for the transaction?

We can accept T/T, Irrevocable Letter of credit(LC), Cash, Bank guarantee, Western Union and etc.

How is about the quality of HARSLE machines

We hare world-class R&D team to support the quality of our machines, our products have got CE, ISO and SGS certification to prove the advantages of HARSLE machines.

How can I visit HARSLE factory in China?

-Take high speed train from other city to Nanjing south railway station, HARSLE factory is around 40KM far from this station.

-Take plane to Nanjing Lukou international airport, HARSLE factory is around 20KM far from this airport.

-Take plane to Nanjing Lukou international airport, HARSLE factory is around 20KM far from this airport.

How can I get after-sales service from HARSLE?

You can contact HARSLE via phone or Email, HARSLE will certainly give you reply in 24 hours. You can show your questions or problems in the form of video or picture that would be better for both of us to solve your problems promptly. Customers can also contact our local agent directly, they will give you reply ASAP.

What is the warranty about HARSLE machine?

We will provide 3 years warranty for HARSLE machines, during the warranty period, customers can get thorough and timely service and HARSLE will send the spare parts for replacement of any broken parts on the machine for free.

Похожие товары

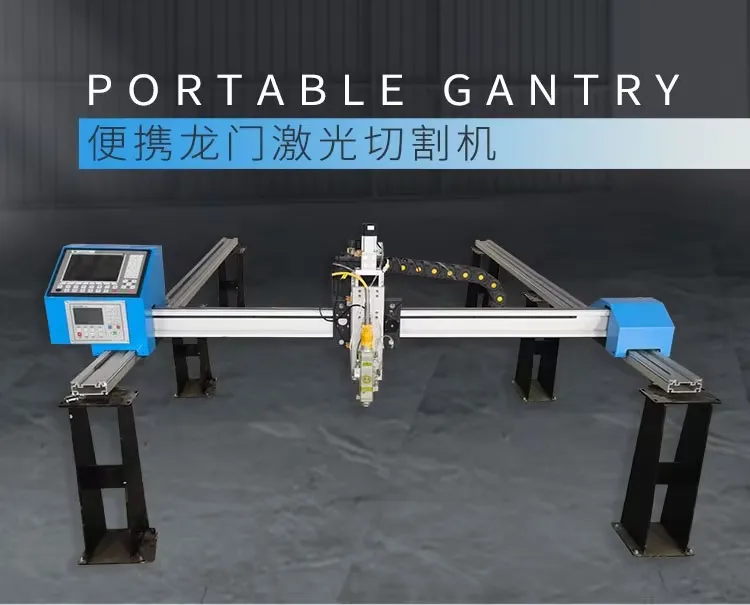

1500 Вт Портативный станок для лазерной резки волокна по лучшей цене от прямого завода

838 209,51 ₽

Углеродистая сталь нержавеющая сталь алюминий медное волокно Лазерная резка машина 6000 Вт 12 кВт 20 кВт

975 923,10 ₽

Используется на заводах-изготовителях, акрил, дерево, МДФ, нержавеющая сталь, железо, металл, хорошая цена, пластиковые режущие машины

Маленькие металлические лазерные резаки 300*300 мм рабочий размер 1000 Вт 1500 Вт 2000 Вт 3000 Вт волокна из нержавеющей стали лазерный станок

1 062 671,82 ₽

GLASSPLUS | Пикосекундные лазерные Режущие Машины для PI пленки/FPS/RPFC

2 385 589,80 ₽ - 2 494 025,70 ₽

1325 co2 лазерной резки 500-600 Вт акриловый лазерный гравировальный станок

563 866,68 ₽

Промышленное высокоточное программное обеспечение Cypcut для резки самолета, золотые, серебряные, латунные Углеродные листы, оборудование для лазерной резки Raycus

759 051,30 ₽ - 975 923,10 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $