Станок для лазерной резки луча 30000 Вт ч

- Категория: >>>

- Поставщик: Jinan Pioneer CNC Technology Co. Ltd.

Сохранить в закладки 1601060333868:

Описание и отзывы

Характеристики

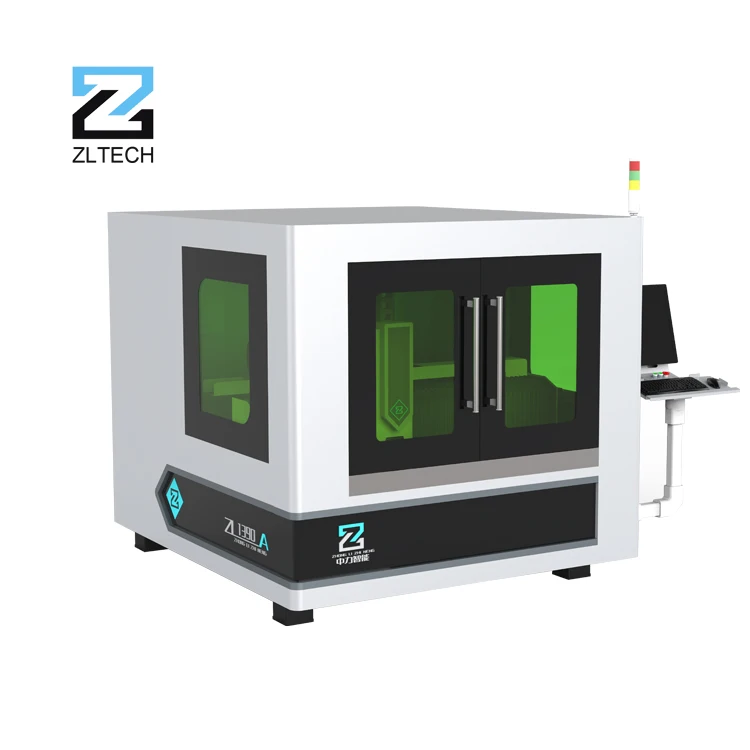

facilitating pre-sales and after-sales services. The high-speed Ether CAT bus is another advantage. As a key technology for the development of Industry 4.0 and domestic industrial automation, Ether CAT's high-speed real-time Ethernet communication can ensure the extremely short control cycle and environmental reliability of the PIONEER CNC system. In addition, With the powerful compatible modules of the PIONEER CNC system, the PIONEER CNC system can support a variety of Field buses, thereby meeting the system's openness needs to the greatest extent.

supports bevel cutting in various overlapping forms and supports TEKLA three-dimensional modeling data file cutting.

◆Floor area:

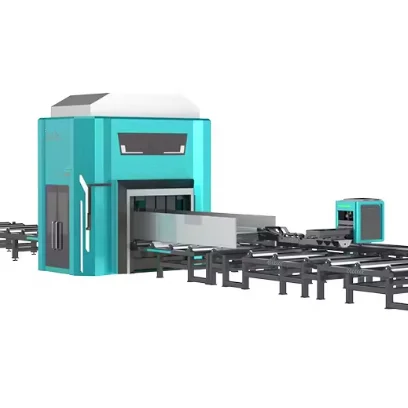

The entire equipment occupies an area of 30000mm×10000mm, of which the length of

the cutting station is 2000mm and the feeding conveyor roller is 14000mm, ensuring

that the maximum raw material to be cut is 12000mm.

transfer.

1.Manual crane loading

2.The steel moving machine feeds the material to the roller table

3.Side push positioning

4.Clamp clamping and feeding

5.Position the workpiece

6.Cutting room cutting

7.Unloading roller conveyor

8.Steel moving machine moves out

9.Manual crane unloading

The gas path of the fiber laser cutting machine is the cutting gas provided to the cutting head: clean and dry compressed air, nitrogen, and oxygen. Cutting gases are divided into three types: nitrogen, oxygen and air. Nitrogen, oxygen and air can enter the electronically controlled proportional valve respectively and be controlled by the system. The input and output of air pressure can be accurately controlled to ensure the consistency of cutting quality. The water system of the fiber laser cutting machine mainly consists of two parts: after the cooling water comes out of the chiller, it enters the laser in two ways, and one way enters the cutting head part of the laser machine to cool it; all the way it enters the interior of the fiber laser to cool it; Return to the chiller after the cycle.

Auto cutting & beveling

Marking support;

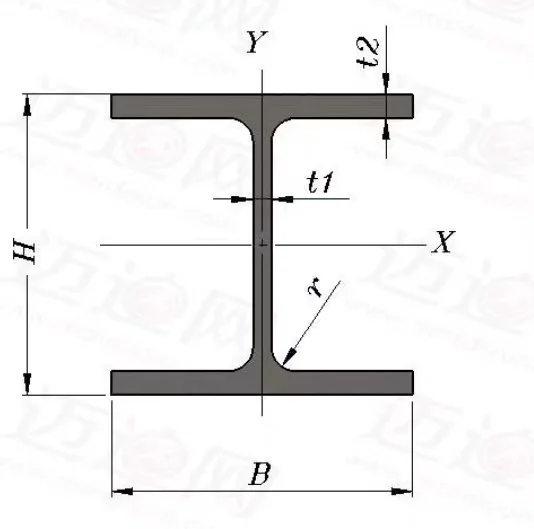

Suitable H/Angle/Channel Beam ;

Support customization

The discharging roller table is shown in the figure: After the component cutting process is completed, the component is

automatically transported out to the discharging roller table. The discharging roller table is powered by the roller table AC

motor driving each rack sprocket and chain drive. Ensure that the component can be completely removed from the cutting station. Power transmission: The motor drives the sprocket to rotate to provide power.

H Beam Fiber Laser Cutting Machine

It is mainly divided into 8 sets of moving machines for loading and unloading to form a material transfer system. Each set of independent frame structure is welded and assembled by channel steel and consists of a lifting mechanism slider, a transmission chain, an oil cylinder and a conveyor motor. The loading steel moving machine can cache at least 6 sections of steel, and the unloading steel moving machine can cache at least 5 sections of steel. Function: Functions such as profile storage and loading, and work piece output and storage after cutting. It is convenient to operate through remote operation buttons, reducing manual handling of turnover materials, storing multiple materials at one time, reducing frequent waiting operations in the workshop, optimizing the operation process and improving production efficiency.

laser cooling system | ||

Power | 220V/50HZ | |

Cooling medium | Distilled/deionized water | |

Water temperature control accuracy | ±0.1ºC | |

Normal temperature water setting | Standard 30 ºC (adjustable) | |

Chilled water settings | Standard 25 ºC (adjustable) | |

High temperature warning | 50ºC | |

Low temperature warning | -10ºC | |

Flow alarm | Standard | |

Water pressure alarm | Standard | |

Laser main parameters | ||||||

Laser type | fiber laser | |||||

Laser working method | CW,QCW | |||||

Transmission fiber diameter | ≥50μm | |||||

Maximum conditioning frequency | ≥50KHz | |||||

Cooling method | Water cooled | |||||

Output power stability | ±2% | |||||

Energy output regulation | 10%-100% | |||||

Central radiant wavelength | 1080nm | |||||

Power | 380-400VAC | |||||

Materials that can be cut | Stainless steel, carbon steel, aluminum, brass, copper, manganese, nickel | |||||

The headquarters of Jinan Pioineer CNC is located in Jinan, the spring city. It is a high-tech enterprise integrating R&D,

manufacturing, sales and service of intelligent CNC laser equipment. Focusing on the fields of intelligent manufacturing of

customized furniture and laser cutting of metal materials, respectively, we are committed to providing global customers with intelligent equipment and automation application solutions in two major areas. The group has a standardized intelligent equipment manufacturing base with a total area of more than 70,000 square meters, of which Qihe base covers an area of more than 60,000 square meters. It has built a high-level R&D center, a high-standard customer experience center, a business office building, and a staff restaurant. Standard machining center, the introduction of Japanese automatic welding robots, annealing heat treatment furnace, large shot blasting machine, CNC five-sided gantry milling, precision metal processing center and other CNC machining machines and high-precision testing equipment, to achieve 100% testing of key processes to ensure products Performance, quality and delivery time. The company has established a complete distribution and after-sales service network system at home and abroad, with more than 30 offices in the country, and exports to more than 60 countries and regions including Russia, North America, Turkey, Vietnam, and Malaysia. The group's laser cutting equipment products have achieved standardization and serialization, and serve global customers through domestic and overseas distribution service networks. In the future, Jinan Pioneer cnc will continue

to devote itself to creating a domestic first-class intelligent CNC laser equipment machinery manufacturing base and R&D base to provide global customers with better products and services.

world. We need your machines running in order to keep your business running.

Q: I am not sure if this machine suitable for my work?

A: Don't worry, just tell me your working materials, max working area and cutting thickness, then I will recommend you the

most suitable machine for you.

Q: Are you factory or trading company?

A: We are factory, which manufactures CNC cutting machines , with 10 years experience in CNC machine’s industry.

Q:How can i do if the machine goes wrong?

A:If confronted with such problems,online service is offered,you could contact our sales. Also,we offer engineer delivery

service.Please contact us asap and don’t try fix the machine by yourself or someone else.

We will response within 12 hours as quickas we can to solve it for you.After-sales service Guaranty

* Provide free upgraded for software

* One years global warranty ,within one year any parts broken by non -human factors will send to you at first time

* Professional after sale team , speak fluent English ,support installation and training online and at site

Похожие товары

Профессиональный LJ-F8025 прототип лазерной резки металла для ткани AI инструменты листового

Высококачественный козловой Yaskawa ABB робот рука автоматическая Робототехника Волоконно-Лазерная резка машина

1500 Вт 3000 Металлическое волокно лазерная резка 5 мм прецизионная углеродистая сталь латунь нержавеющая

Дешевые 3000 мм * 1500 листового металла алюминиевая нержавеющая сталь углеродистая трубка Волоконно-Лазерная резка машина

Высокоэффективный 3015 алюминиевый сплав титановый Магниевый 1500 Вт автоматический металлический волоконно-лазерный станок для резки

Прямая поставка с фабрики 3015 алюминиевый сплав титановый Магниевый 1500 Вт промышленная автоматическая машина для резки металла

Лидер продаж 1 кВт 5 2 3 6 мощный волоконный лазер мини-лазерный 6060 1390 волоконно-лазерный станок для резки металла серебряного золота

Новые поступления

Новинки товаров от производителей по оптовым ценам