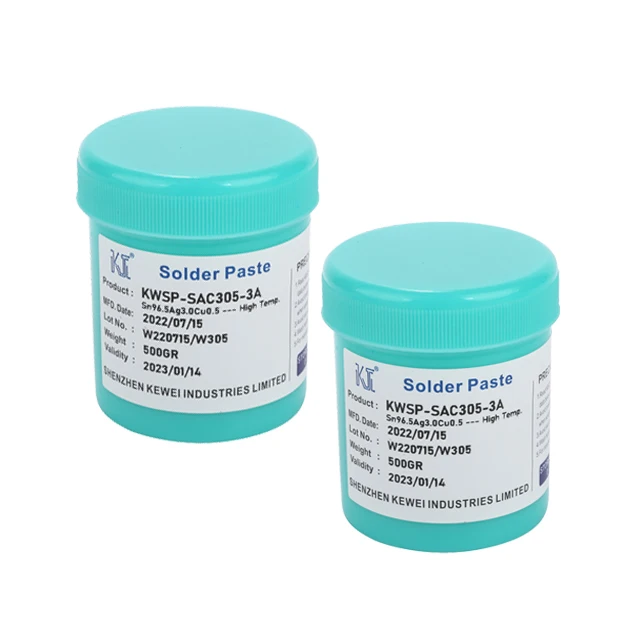

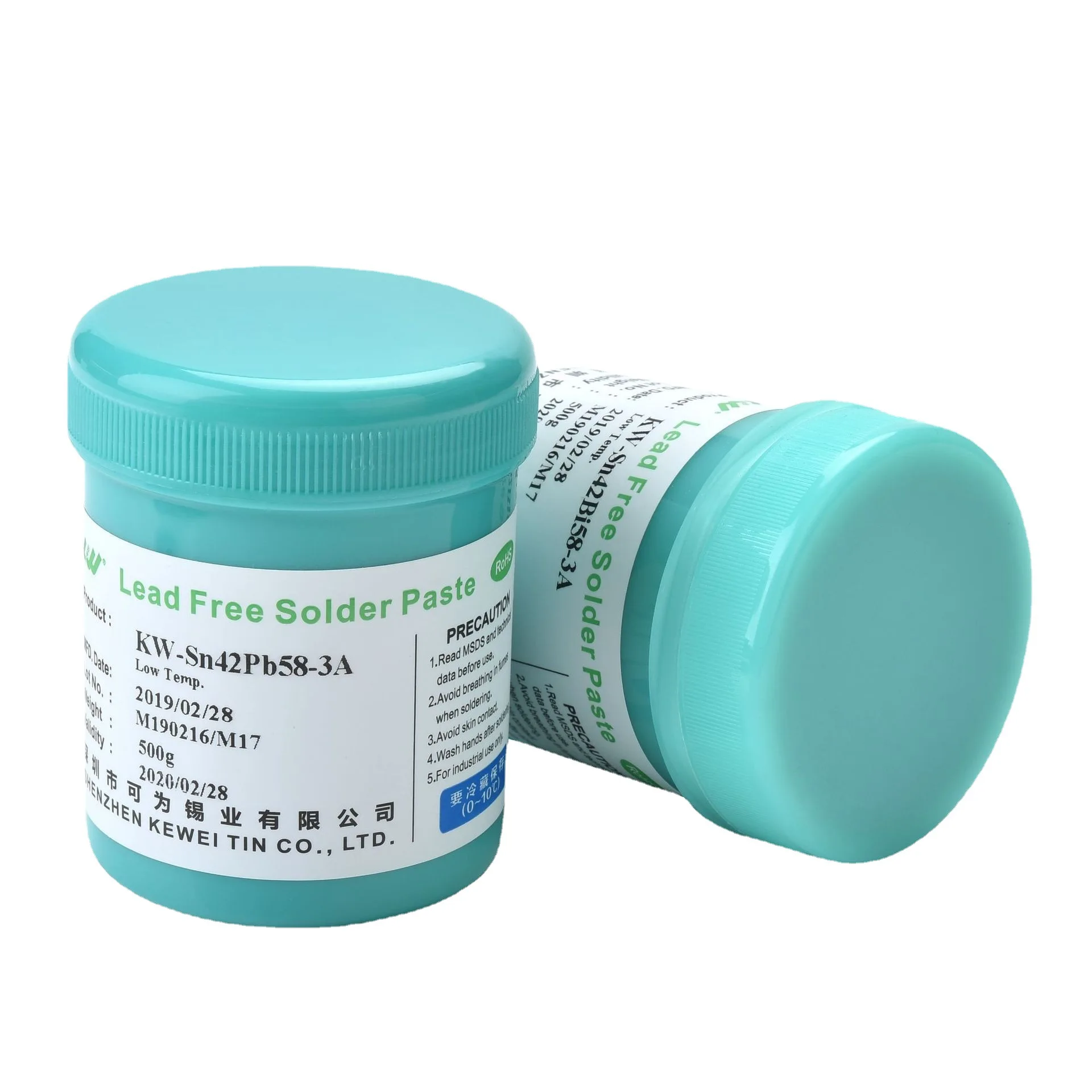

Высококачественная Бессвинцовая паяльная паста SAC305 для трафаретной печати SMT электронной пайки

- Категория: >>>

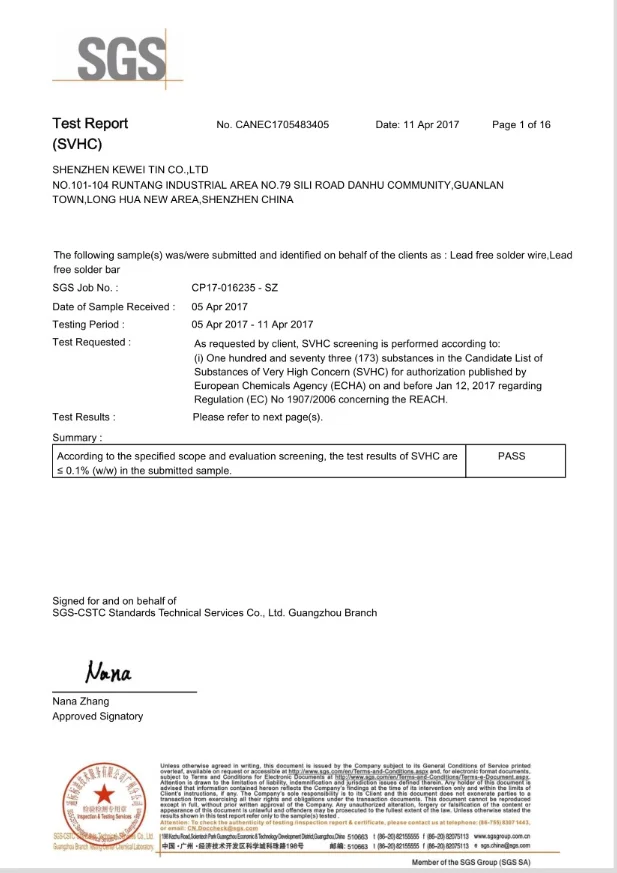

- Поставщик: Shenzhen Kewei Industries LimitedShenzhen Limited

Сохранить в закладки 1601060902688:

Описание и отзывы

Характеристики

Specifications | ||

Alloy Composition | Sn96.5Ag3.0Cu0.5 | |

Halogen (W/F) | Halogen Free | |

Metal Content % | 90±0.5 % | |

Powder Size | Type 3, Type 4 (Optional) | |

Flux Type | No-Clean | |

Viscosity Range | 175 ± 30Pa/s | |

Expansion Rate | > 80% | |

Tin Bead Test | <3 | |

Melting Point | 217-227℃ | |

2. The computer-controlled atomization process ensures the consistency and stability of various process indicators of the tin powder atomization atmosphere.

3. Strictly control the oxidation rate of tin powder, so that the total oxygen content is controlled within the range of Japanese Industrial Standards, and the oxygen content is low, which is less than 200 PPM.

4. Narrow particle size distribution, powder particle size diameter is small, good sphericity. Type 3, type 4, type 5 is available.

Advantage 1

Less Residue, higher insulation resistance

No-clean flux solder paste, after soldering, there is no residue at the surface of the stencil printing. It can keep a transparent appearance and high insulation resistance.

Advantage 2

Suitable viscosity, no collapse and excursion

By using our own formulated and lead-free soldering flux, our solder paste can keep very good thixotropic behavior and stable viscosity. Our solder paste also has excellent thermal collapse protection, it will provide quality guarantee for production.

Advantage 3

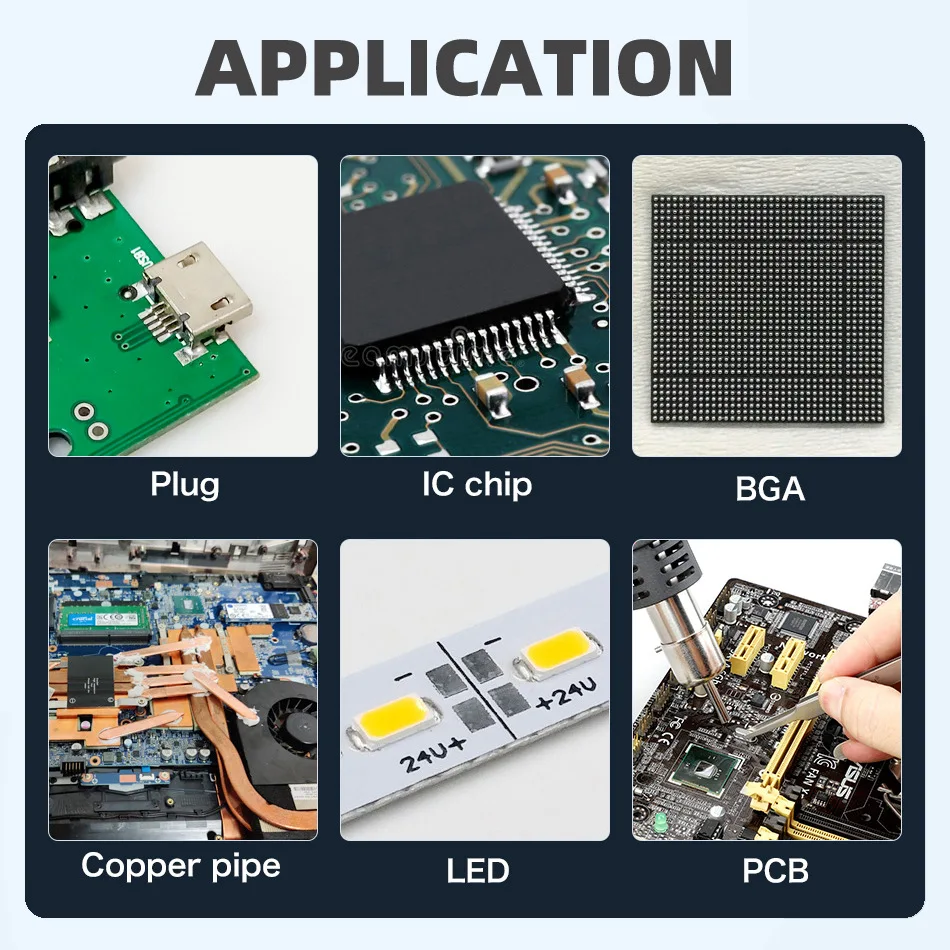

Excellent wettability, high tin climbing performance

The wettability and tin climbing properties will determine the soldering quality.

We have a powerful grinding machine, it can product different size of solder powder. Type 3, type 4, type 5 is available in different production requirements.

Advantage 4

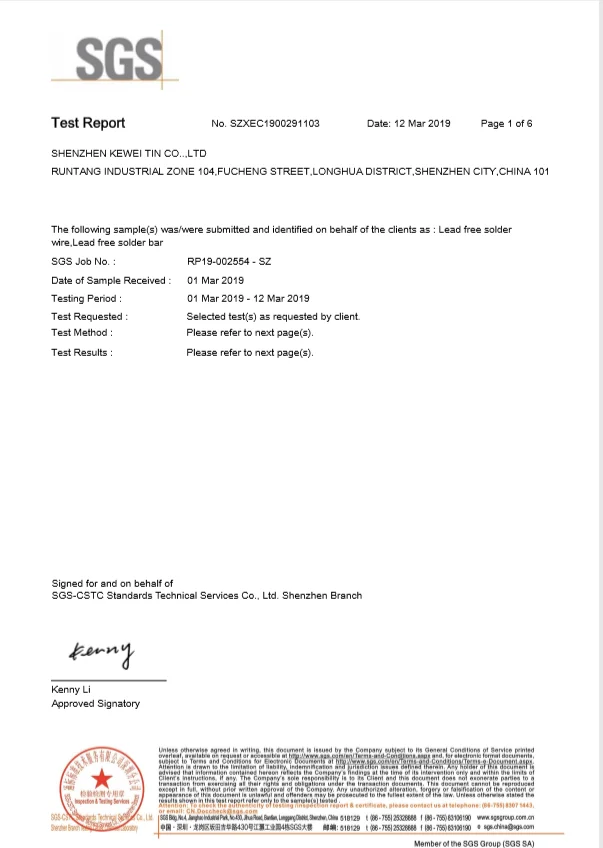

Manufacture direct and dust-free plant

Our factory located in Shenzhen, China. We have our own factory to manufacturing solder wire, solder bar, and a separate solder paste plant which with dust-free working room. To make sure the products are pure and clean.

We have a cooperated biggest mine field provider in China, to ensure our stable and fresh raw material supply.

Похожие товары

Бессвинцовая паста Pcb высокотемпературный огнестойкий паяльный флюс

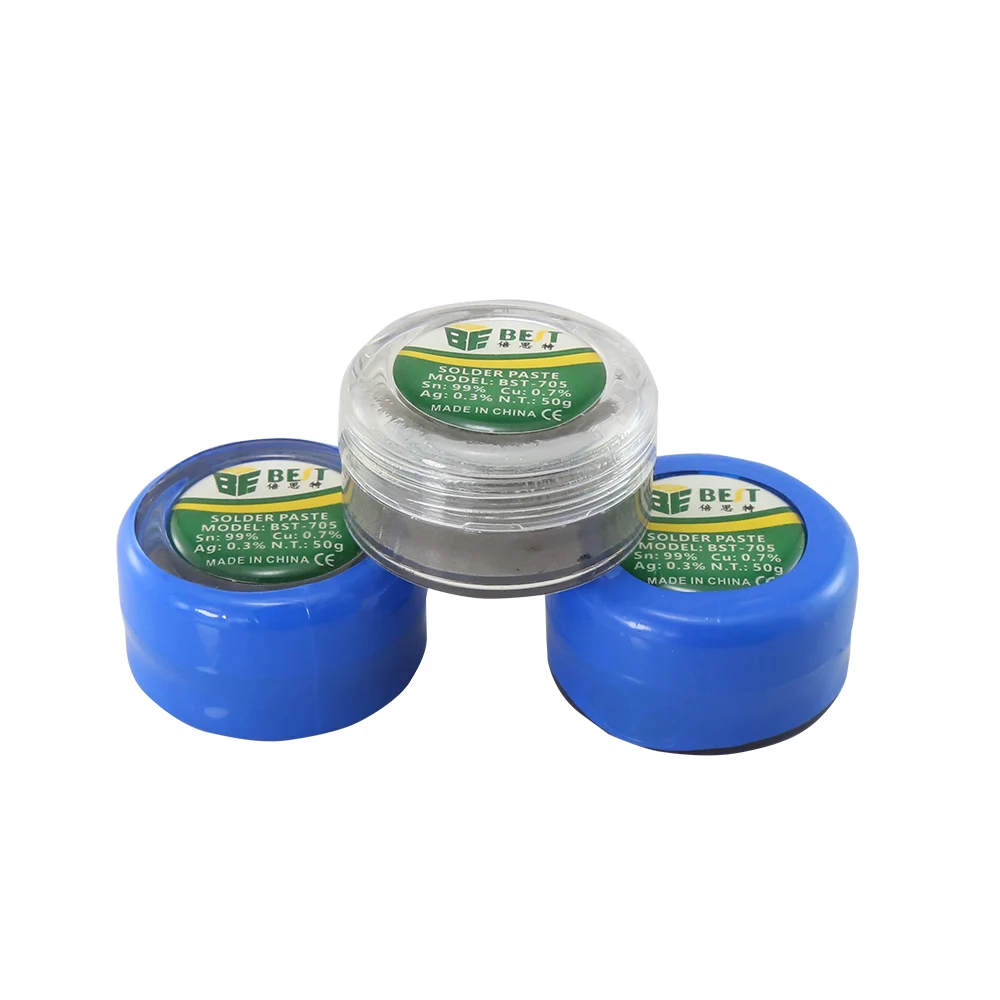

Лучшая 705 Бессвинцовая Серебристая Оловянно-свинцовая паяльная паста

Шприц комплект привести средней температуре и низкой temperature138/183 с иглой пуш-ап для нанесения паяльной пасты на печатные

Игольчатая паяльная паста Sn99 Ag0.3 Cu0.7 бессвинцовая Экологически чистая Оловянная высокоцентральная низкая температура

Экзотермический сварочный материал для заземления

Уточните 2022 бестселлер экзотермический сварочный порошок и медный Железный для сварки заземления

JCD паста для пайки

Новые поступления

Новинки товаров от производителей по оптовым ценам