Электрическая проводящая ткань из углеродного волокна или Нетканая углеродная

- Категория: >>>

- Поставщик: Suzhou Dasen Electronics Material Co. Ltd.

Сохранить в закладки 1601062110404:

Описание и отзывы

Характеристики

Product Description

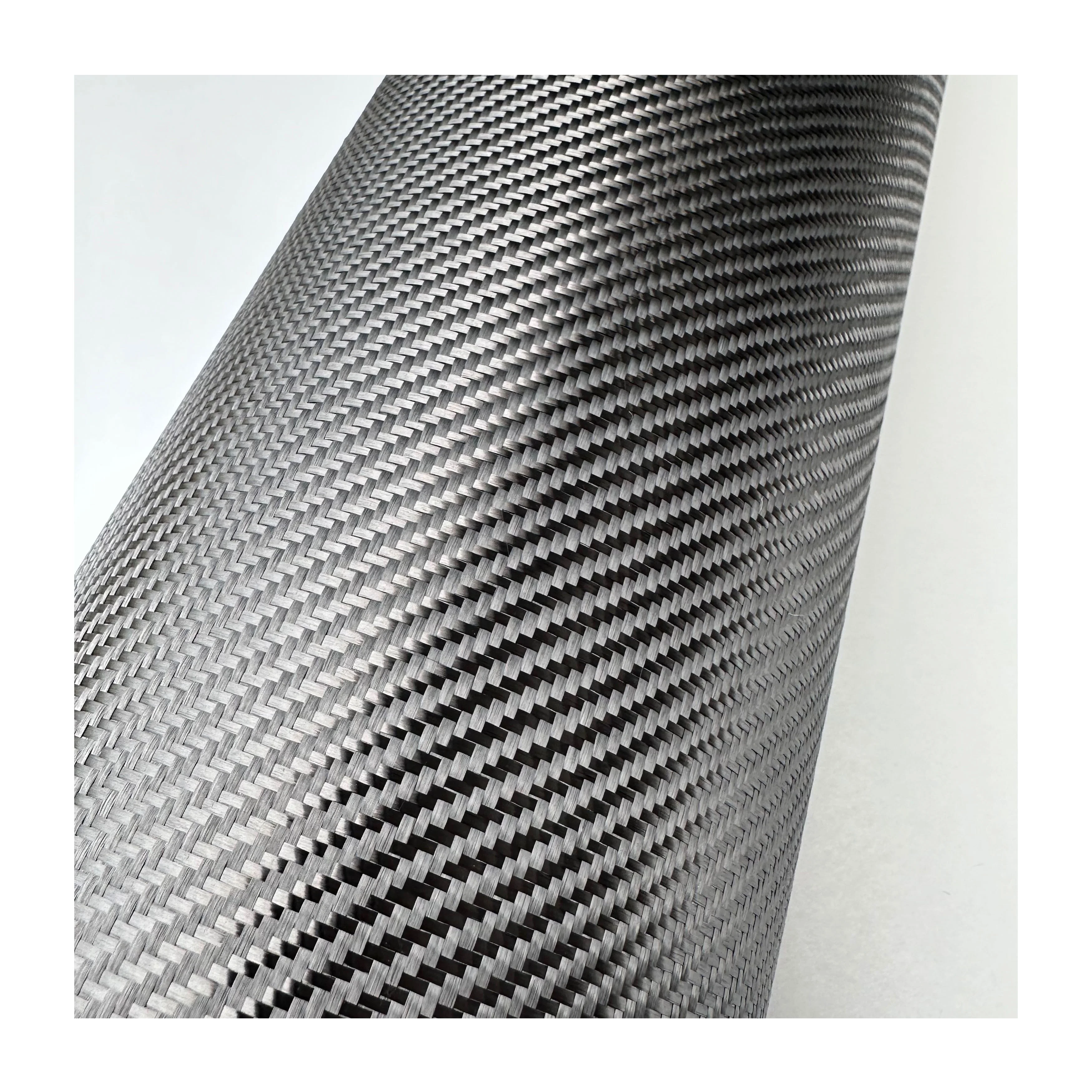

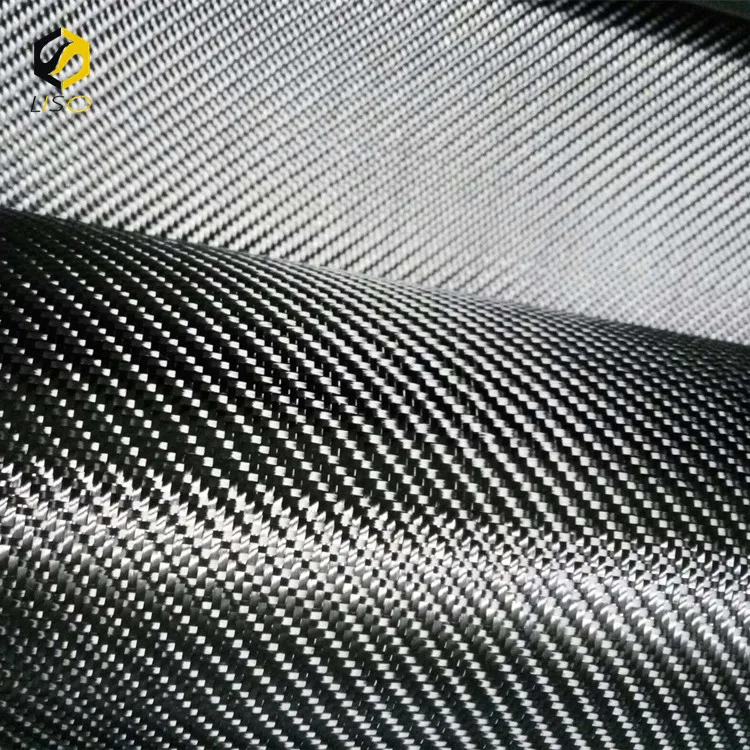

A new composite material choice for the 21st century--UD Carbon Fiber Fabric

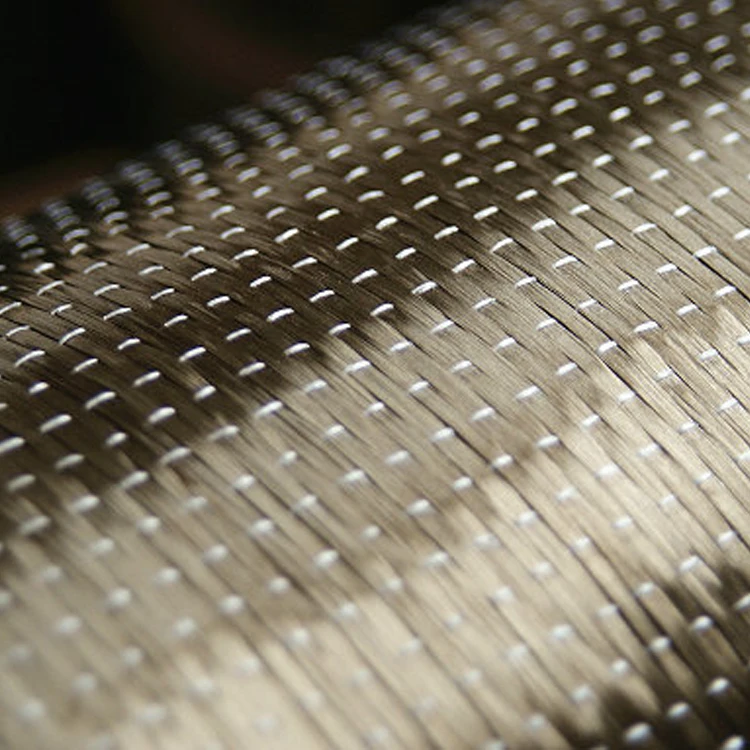

Carbon fiber reinforcement fabric is a unidirectional carbon fiber reinforcement product, usually woven with 12K carbon fiber filament.

Available in two thicknesses: 0.111mm (200g) and 0.167mm (300g). Various widths: 100mm, 150mm, 200mm, 300mm, 500mm, 1000mm and special widths. With the continuous development of the carbon fiber cloth industry, more and more industries and enterprises use the carbon fiber cloth, and there are also departments of enterprises into the carbon fiber cloth industry and development.

Available in two thicknesses: 0.111mm (200g) and 0.167mm (300g). Various widths: 100mm, 150mm, 200mm, 300mm, 500mm, 1000mm and special widths. With the continuous development of the carbon fiber cloth industry, more and more industries and enterprises use the carbon fiber cloth, and there are also departments of enterprises into the carbon fiber cloth industry and development.

Feature

1. Carbon fiber material itself is relatively strong and light, basically no change in the dimensions of the original structure after reinforcement construction, and at the same time basically does not increase the weight of the original structure itself;

2. Carbon fiber cloth reinforcement construction process is simple, short construction period, high efficiency.

3. Carbon fiber material itself has high modulus of elasticity, the structure is reinforced to temperature cracks, rust expansion cracks and other small deformation control effect is better.

4. Carbon fiber cloth reinforcement basically does not need external pressure, the original structure of the concrete is basically not destroyed.

5. After choosing carbon fiber cloth reinforcement method of reinforcement construction, decorative construction without the need to deal with the interface, only in the carbon fiber sheet project construction of the latter process of sand paste can be sprinkled.

6. Carbon fiber cloth reinforcement double or triple paste, because of its own thin thickness is relatively thin, basically no increase in shear moment due to the thin thickness of the impact, so the structural reinforcement effect is better.

7. Carbon fiber reinforcing material because of its own flexibility, coiled nature, the effect of structural reinforcement of narrow work surface reinforcement construction is unique.

8. Carbon fiber cloth reinforcement can reduce many unnecessary human and material resources and financial resources, but also can save a lot of construction time.

2. Carbon fiber cloth reinforcement construction process is simple, short construction period, high efficiency.

3. Carbon fiber material itself has high modulus of elasticity, the structure is reinforced to temperature cracks, rust expansion cracks and other small deformation control effect is better.

4. Carbon fiber cloth reinforcement basically does not need external pressure, the original structure of the concrete is basically not destroyed.

5. After choosing carbon fiber cloth reinforcement method of reinforcement construction, decorative construction without the need to deal with the interface, only in the carbon fiber sheet project construction of the latter process of sand paste can be sprinkled.

6. Carbon fiber cloth reinforcement double or triple paste, because of its own thin thickness is relatively thin, basically no increase in shear moment due to the thin thickness of the impact, so the structural reinforcement effect is better.

7. Carbon fiber reinforcing material because of its own flexibility, coiled nature, the effect of structural reinforcement of narrow work surface reinforcement construction is unique.

8. Carbon fiber cloth reinforcement can reduce many unnecessary human and material resources and financial resources, but also can save a lot of construction time.

Specification

Production Line

Application

Carbon fiber cloth/Fabric

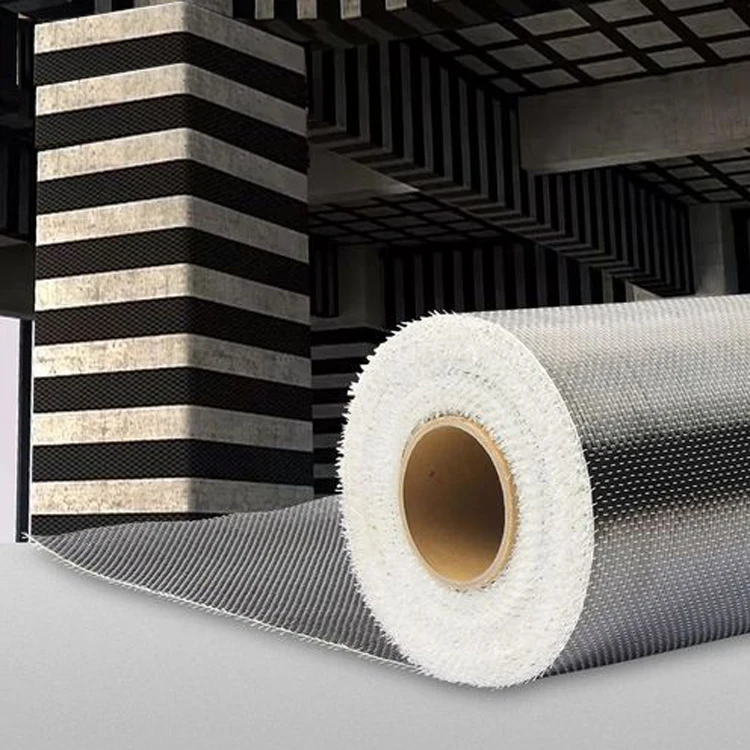

Carbon fiber cloth is used for tensile, shear and seismic reinforcement of structural components, the material and supporting impregnation resin used together to become a carbon fiber composite material, can constitute a complete carbon fiber cloth sheet reinforcement system, suitable for dealing with the use of the building load increase, change in the use of the project function, aging of the material, the concrete strength level is lower than the design value, the structural crack treatment, the harsh environment service component repair, protection of the reinforcement project. The system is suitable for dealing with the increase of building load, change of project use function, aging of material, concrete strength grade below design, structural crack treatment, repair and protection of service components in harsh environment.

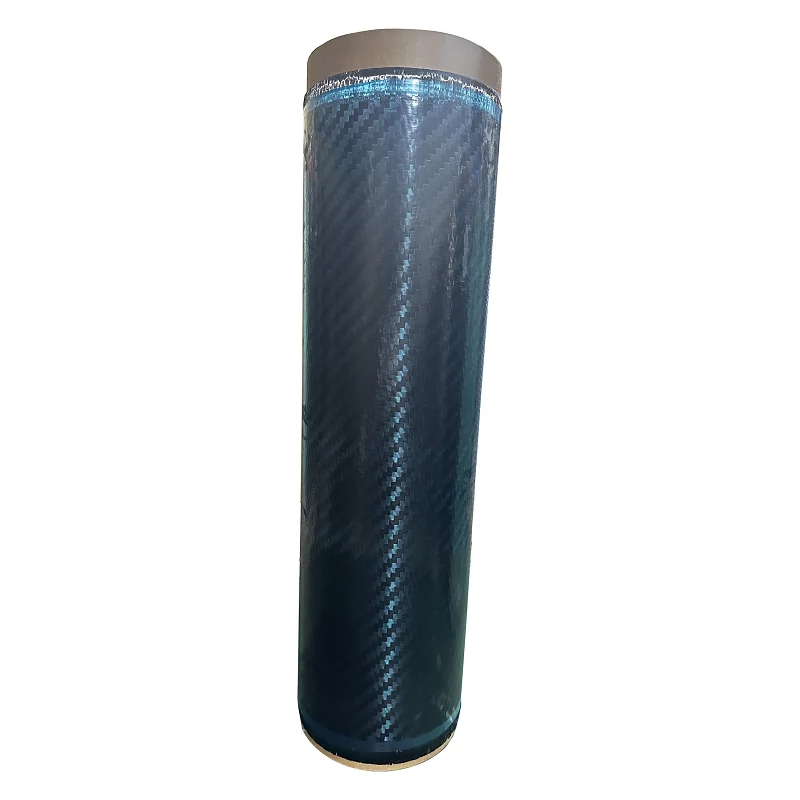

Packing & Delivery

Packed with plastic bag and cartons/pallets.

The prepreg requires storage at temperatures below -18℃.

Our factory support package, logo customization when more than 600 Square meters.

The prepreg requires storage at temperatures below -18℃.

Our factory support package, logo customization when more than 600 Square meters.

Company Profile

DASEN Group was founded in 2011 and headquartered in Suzhou. It is a high-tech enterprise mainly engaged in the research and development, production, and sales of high thermal conductivity graphite materials, carbon fiber prepregs, and composite material products. DASEN has passed ISO9001 International Quality Management System, ISO14001 International Environmental Management System, and QC080000 Hazardous Substance Process Management System. DASEN has production, research and development bases in Jiangxi, Dongguan, and Vietnam, as well as offices in Suzhou, South Korea, Shenzhen, and the United States. DASEN can provide professional and convenient thermal management and carbon fiber lightweight application solutions to global customers. DSN has always been committed to becoming an excellent supplier of material solutions!

Related Products

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7-10 days, mass production time needs 4 weeks If need a big quantity.

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 7 days to arrive.

Airline and sea shipping also optional,need to consult the freight forwarder by address/ port.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q5. Is it OK to print my logo on carton?

A: Yes. Please inform us formally before our production and confirm the design.

Q6: What is your terms of payment ?

A: Payment<=10000 USD , 100% in advance.

Payment>=10000 USD , 50% T/T in advance ,balance before shipping.

If you have another question, please feel free to contact us !

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7-10 days, mass production time needs 4 weeks If need a big quantity.

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 7 days to arrive.

Airline and sea shipping also optional,need to consult the freight forwarder by address/ port.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q5. Is it OK to print my logo on carton?

A: Yes. Please inform us formally before our production and confirm the design.

Q6: What is your terms of payment ?

A: Payment<=10000 USD , 100% in advance.

Payment>=10000 USD , 50% T/T in advance ,balance before shipping.

If you have another question, please feel free to contact us !

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Высокое качество и дешевая цена 100% 80 г 240 200 12k углеродного волокна ткань углерод

1 873,60 ₽ - 2 204,23 ₽

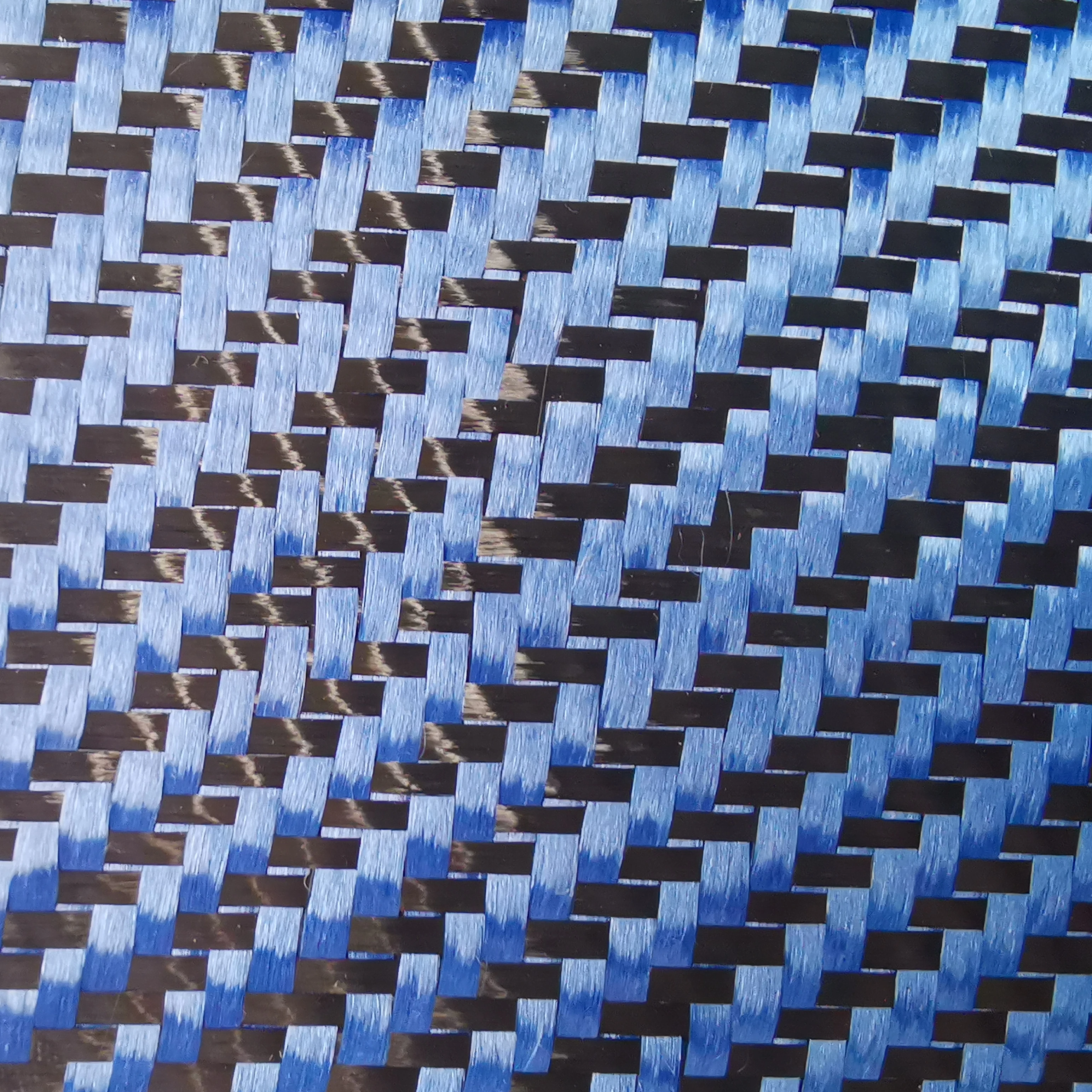

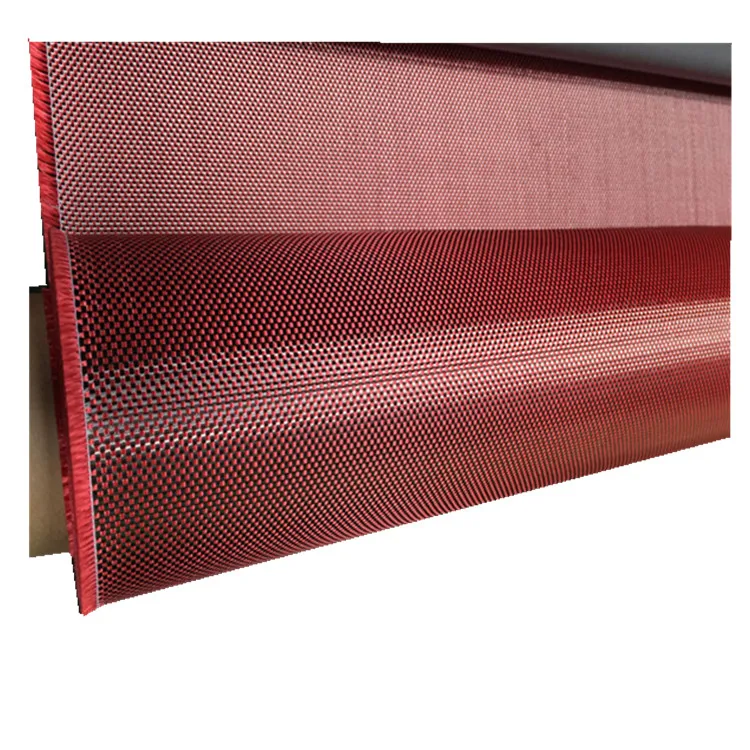

Оптовая продажа один рулон голубая ткань из углеродного волокна кевларовая ширина 1 м

1 607,99 ₽ - 2 010,26 ₽

Высокое качество и дешевая цена 100% 240 г 200 3k углеродного волокна ткань углерода

Лучшее качество ткань для воздушного фильтра с активированным углем

2,21 ₽ - 3,31 ₽

Оптовая продажа 400gsm препрег углеродная ткань 12K twl или простая полностью

Новый бренд 3k тканевый волоконный материал углеродный тканый ровинг по отличной цене

200 г высокопроизводительная ткань из арамидного волокна

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $