12000 Вт 20000 30000 12 кВт 20 профиль стальной h лучевой волоконный лазерный робот

- Категория: >>>

- Поставщик: Jinan Pioneer CNC Technology Co. Ltd.Jinan Ltd.

Сохранить в закладки 1601064756057:

Описание и отзывы

Характеристики

12000W 20000W 30000W 12KW 20KW 30KW Channel beam I U C H beam hbeam h-beam fiber laser cutting machine line

12000W 20000W 30000W 12KW 20KW 30KW Channel beam I U C H beam hbeam h-beam fiber laser cutting machine line

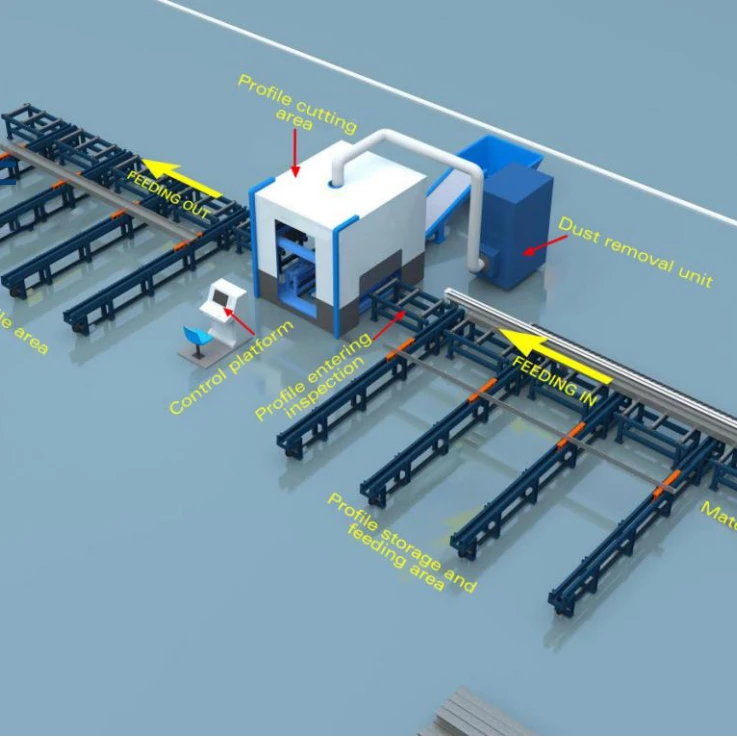

- Profile Storage and Feeding Area 1 Set

- Feeding Into[Roller Conveyor] 1 Set

- Hydraulic Clamp Feeding Trolley 1 Set

- Cutting Station Unit 1 Set

- Feeding Out[Roller Conveyor] 1 Set

- Laser Cutting System[Control Platform] 1 Set

- Finished Profile Area 1 Set

- Dust Removal Unit 1 Set

- Model:H-Beam 1250mm, Length 120000mm, Pierce cutting thickness 40mm

- Name:Robot Profile cutting line

- Application:Robot profile cutting line is consisted of Cutting Unit, Roller frame[Feeding In & Feeding Out], Clamp Feeding Trolley and Rail, Storage & Finished Profile Traversion Conveyor Station, etc. It is a hot cutting processing equipment for H beam, I beam, Channel steel, Angle steel and their intersection shape.

- Dimension:The whole cutting machine is 30000mm length, 10000mm width, of which cutting unit length is 2000mm, Feeding In Conveyor Unit is 14000mm, Feeding Out Conveyor Unit is 12000mm, the max cutting materials is 12000mm.

- Applicable materials:Carbon structural steel, stainless steel

Channel beam I U C H beam hbeam h-beam fiber laser cutting machine line Technical Parameters

Item | Name | Parameters |

1 | H/I beam[Web/Flange] | 100~1250mm x 100~600mm; |

Channel/ U/C Beam | 100x48~400x200mm | |

Beam Length | 12000mm | |

2 | Cutting method | Fiber Laser Cutting |

3 | Laser source | 12000W 20000W 30000W Max or Racyus |

4 | Laser cutting thickness | Pierce cutting thickness 1-30~40mm |

5 | Workpiece Cutting Shape | Fixed-length straight cutting, fixed-length beveling cutting, and end socket-related cutting functions, and marking, etc. |

6 | Effective cutting length | 12000mm or customized |

7 | Position precision in X, Y axis direction | ±0.1mm/m |

Repeat Position Precision in X , Y axis direction | ±0.05mm | |

8 | Cutting Shape | According to confirmed drawing(offered when signing technical contract) |

9 | Robot axis | X1 &X2 Axis: True bilateral synchronization axis (the axis of the cutting torch moving forward and backward) |

Y Axis:the cutting torch movement left and right axis | ||

Z Axis:the cutting torch up and down | ||

A Axis: The cutting torch rotation axis | ||

C Axis: The cutting torch swing axis | ||

U Axis: External workpiece axial direction horizontal feeding axis | ||

10 | Cutting speed | 500.0~30,000.0mm/min |

11 | Moving speed | 33000mm/min |

12 | Maximum profile weight to be cut | Note:Can customized according to offered max weight Standard support weight is 20,000.0Kgs. |

13 | Beveling cutting | ±45 degree |

14 | Makring | yes |

15 | Profile cutting form | Fixed length straight cut, fixed length oblique cut and end socket function |

16 | Cutting accuracy execution standard | ISO9013-2002\\ISO8206-1991\\ JB/T10045.4-1999JB |

Main equipment configuration

No. | Commodity | Brand/Model | Note[Origin] |

1 | Laser steel cutting host | Pioneer CNC | China |

2 | Laser Cutting Head | PORAD | China |

3 | Height Controller &Adjuster | HYD THC | China |

4 | High precision disc reducer | Motovario | France |

5 | High precision helical rack | YYC/TAIWEN | Taiwan |

6 | Linear Guides | HIWIN | Taiwan |

7 | Fiber-optic laser power | Max or Raycus | China |

8 | Host servo drive and motor | INOVANCE | China |

9 | CNC System | BECKHOFF | Germany |

10 | Electronically controlled proportional valve | Aventics | Germany |

11 | Laser water chiller | S&A | China |

12 | Auxiliary loading machine | PIONEER CNC | China |

13 | Auxiliary blanking machine | PIONEER CNC | China |

14 | Nesting software | PIONEER CNC | China |

15 | Smoke and dust removal system | PIONEER CNC(Option) | China |

16 | Regulator power supply | Option | China |

Note: Due to supply cycle/technical upgrades and other reasons, the manufacturer[PIONEER CNC] reserves the right to replace the same brand. | |||

1. The composition, main configuration and working principle of the Control System

- The Beam profile fiber laser cutting production line is mainly composed of two parts: the laser cutting station control system bus and the automatic beam profile loading and unloading. The actions of each execution unit are completed through program instruction transmission.

- The laser cutting master station control system mainly consists of Germany Beckhoff industrial computer, I/O module, HYD Torch Height Controller, 6 Sets of absolute encoder Inovance Servo motor and External Sensors. The cutting program is completed through PIONEER CNC BEAM CUTTING Control Software download to complete multi-axis linkage control to achieve various cutting processes at the end of the beam profile.

- The automatic up and down control part of the beam profile is mainly composed of a Hydraulic Control System, AC motor and External sensors. It completes the logical control of the execution units of each part to satisfy the requirements of the on-site environment and facilitate the operator to load and unload the beam profile. It is equipped with a wireless manual control box externally.

- Introduction to PIONEER CNC Control System

- The PIONEER CNC system is an industrial computer developed based on the Windows system. It uses a dual-core processor with fast running speed. The core processing speed of motion control and HMI can reach up to 0.5ms. When the controller performance meets the requirements, the equipment can be upgraded. , such as increasing the number of servo axes and controlling the number of I/Os, without changing any main control system, which is very convenient for equipment expansion.

![7-6.PNG]()

Not only that, the modular linking method of PIONEER CNC has a simple structure and convenient wiring, saving debugging time and facilitating pre-sales and after-sales services. The high-speed EtherCAT bus is another advantage. As a key technology for the development of Industry 4.0 and domestic industrial automation, EtherCAT's high-speed real-time Ethernet communication can ensure the extremely short control cycle and environmental reliability of the PIONEER CNC system. In addition, PIONEER CNC system's powerful compatible modules, PIONEER CNC system can support a variety of field buses, thereby meeting the system's openness needs to the greatest extent.

![8-7.PNG]()

Software operation and equipment operation method

![Software.png]()

Nesting software and system features

(1) The interface is friendly, easy to learn, and easy to operate. The CNC program it uses is easy to edit and has strong readability.

(2) Equipped with a cutting process parameter database, the cutting parameters can be adjusted in real time during the cutting process to achieve the best cutting quality.

(3) The cutting system has functions such as laser energy power control and multi-axis synchronous control.

(4) With status display and current location display functions.

(5) Advantages of intelligence, integration, high speed and high precision.

(6) Modular structure, world-class performance.

(7) Remote diagnosis function, digital servo system.

(8) Using embedded installation panel, the operation is convenient and fast.

(9) No special control card is needed. It completely adopts standard PC products and is independent of hardware suppliers.

(10) The entire system has only one CPU (PC) to complete all data calculations (NC, CNC, PLC) to avoid system performance loss caused by communication cooperation between multiple CPUs in the traditional structure.

(11) High-speed real-time communication ensures extremely short control cycle and environmental reliability.

(12) The Ethernet communication interface can communicate directly with the computer and transfer part program files.

A. PIONEER CNC CNC System Advantages

(1) BECKHOFF TwinCAT CNC three-dimensional five-axis function

(2) Mature and complete RTCP function

(3) Profile surface height tracking control (two-axis follow-up function)

(4) Clamp retraction function

(5) Automatic edge finding function

(6) Common edge cutting and other functions

(7) Direct perforation, progressive perforation, multi-level perforation, blast perforation and other perforation methods, etc.

(8) Fast cutting mode, standard cutting function, etc.

(9) According to the thickness of different plates, select different thickness process libraries to achieve fast cutting.

(10) The Ethernet communication interface can communicate directly with the computer and transfer part program files.

(11) Various cutting auxiliary gases can be converted easily and quickly through the CNC system.

(12) It has the function of displaying the cutting status and current position in real time.

B. Nesting software

(1) Multiple parts import methods

(2) Fast conversion and file batch processing

(3) Efficient automatic typesetting function

(4) Supports contour inspection and complex graphics repair functions

(5) Automatically optimize cutting path

(6) Perfect automatic process and flexible manual process

(7) Professional process display interface

(8) Support common edge cutting

(9) The software is easy to install and has stable functions.

(10) Introduction to other functions:

l Support marking

l Support splitting and loop nesting

(11) Support TEKLA steel structure deepening software 3D modeling data file cutting, sat and other formats

Customers’ site[Sample display]

Canada Successful Case

United States Successful Case

If you are interested in these related amchine, sincerely invite you to come and visit our machine in China or in client factory. All are well and okay!

Jinan Pioneer CNC is the earliest professional group company engaged in cross-border supply chain management in China's welding and cutting&Drilling steel structures field. Its headquarters is located in Jinan, China. It also has product experience centers and manufacturing bases in Shanghai, Zhengzhou, Dezhou, Jinan, Wuxi, and other places. We set up suppliers and customers at home and abroad. Establish a complete cross-border supply chain ecosystem, gather a large number of cross-international and cross-industry related enterprises, rely on the professional brand operation team of PIONEER CNC to carry out systematic cross-border supply chain management, and provide specialized services for customers and distributors at home and abroad in procurement, logistics, warehousing management, and supply chain finance and other integrated projects.

Похожие товары

1810 130 Вт 150 заказной Co2 лазерная гравировка гравер Mdf резиновый деревянный кристалл акриловый 1612 лазерный резак Lightburn

Аппарат для лазерной резки А4 защиты экрана мобильного телефона

Станок для лазерной резки волокон металла

Высокоуровневый лазерный резак 1500 Вт промышленная легкая в эксплуатации система управления для резки листового металла

Заводская цена 5 мм 10 20 стальной алюминиевый двухсторонний волоконно-лазерный станок для резки

Скидка 500 Вт 1000 1500 2000 4000 6000 металлическая листовая труба CNC Волоконно-Лазерная режущая машина

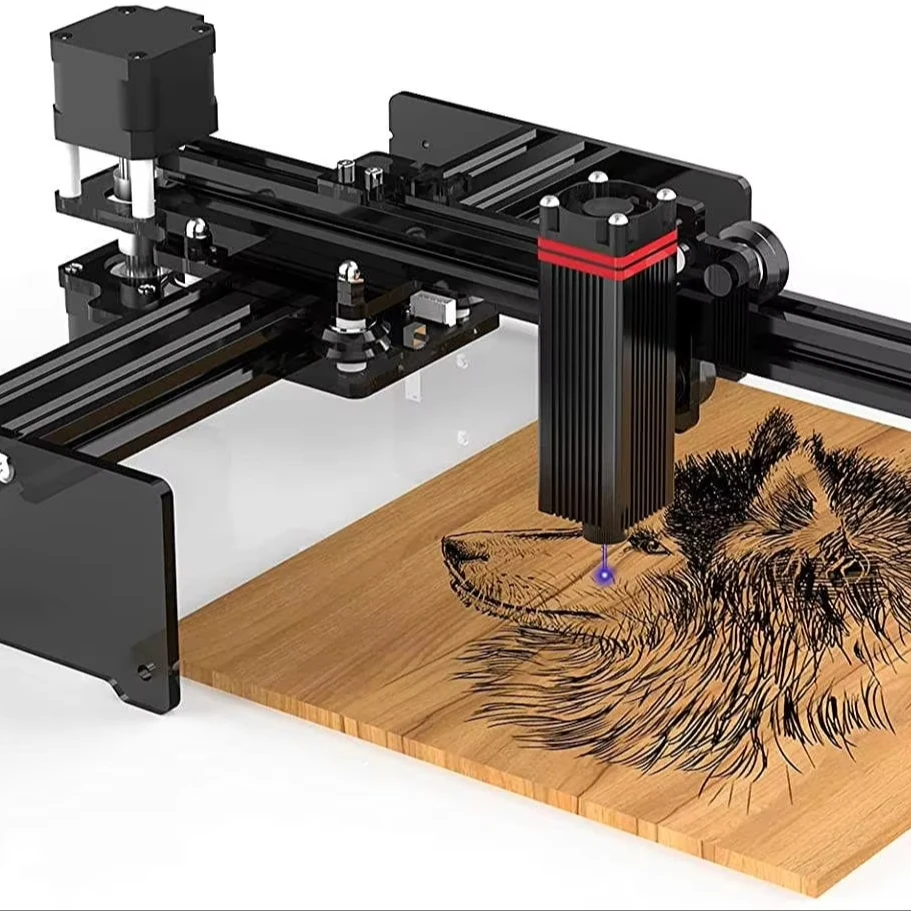

Портативный 20 Вт диодный лазерный станок для резки и 170*170 мм шины QR-код логотип маркировочный гравировальный

Новые поступления

Новинки товаров от производителей по оптовым ценам