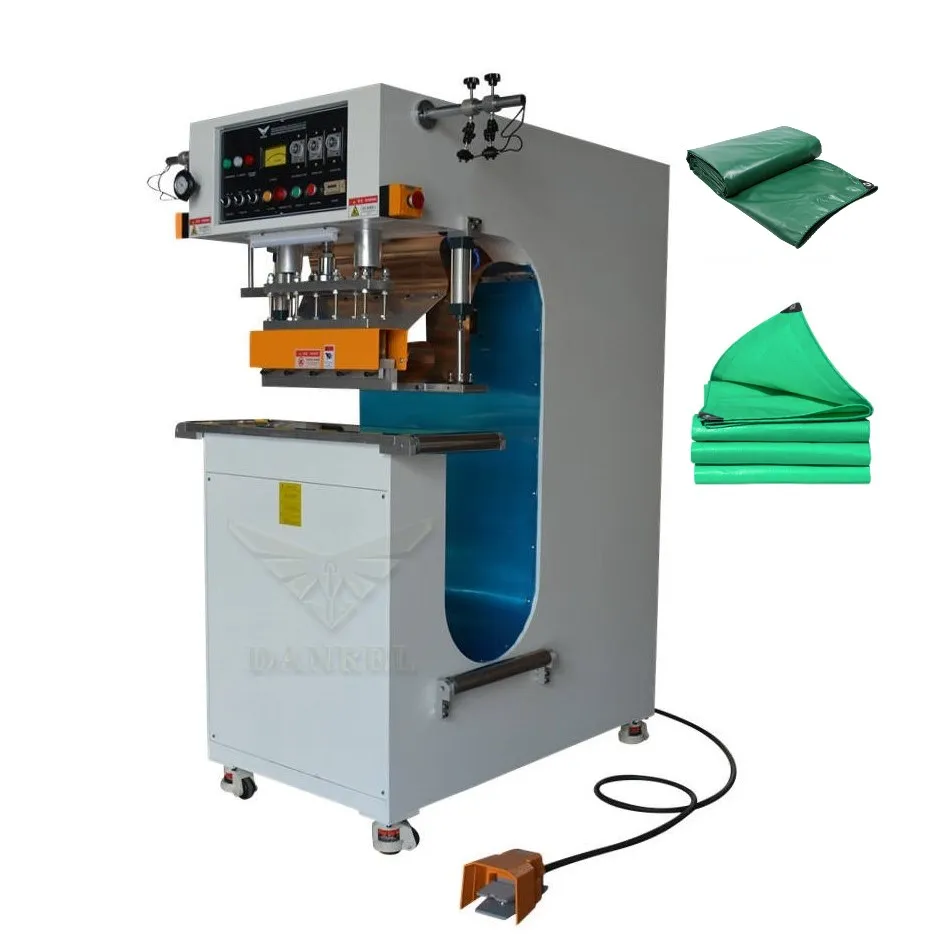

Горячая Распродажа DR T5 F1 полуавтоматический 5 кВт высокочастотный ПВХ брезент тент сварочный аппарат

- Категория: >>>

- Поставщик: Shenzhen Danrel Industrial Co. Limited

Сохранить в закладки 1601076348917:

Описание и отзывы

Характеристики

DANREL HIGH FREQUENCY CANVAS WELDING MACHINE

High Frequency PVC Tarpaulin Welding Machine only works with thermoplastics that have a high dielectric constant. In this process, an electric field is generated near the joint, the direction of which is alternated approximately twenty-seven million times a second. Every time the electric field changes, the dipole molecules of the polymer attempt to flip around to realign themselves to the new field orientation. Because this movement is impaired by inertia and friction, the molecules do not flip in unison. This constant relative movement of the molecules results in inter molecular friction which results in heat and, subsequently, melting. Radio Frequency welding typically has weld cycle times from two to five seconds and can handle parts from approximately one-thousandths inches thick to fifty-thousandths inches thick.

Main Features:

1. HF Power ranges from 5-35KW to meet any welding bar size.

2. RF emission protection design.

3. Deep trough creating ample space behind the electrode for easy material handling.

4. The Welding bar length & width & shape can be customized, fast changeover capable.

5. European-model square high frequency vibration cavity, more reliable and stable in output

6. Single line or two lines continue welding, welding length can be ordered as special need.

7. Easier material placement and better visualization of weld with built in LED illumination

8. Customized work table dimensions, electrode holder dimensions

9. Laser Guide Projectors–laser lines (easy for operator's eyes) for quick material guidance on the work table

10. High sensitive anti-spark tube to protect the welding bar and welding products.

Похожие товары

Новый productsTR-5S 5KW двойной головкой высокой частоты и ВЧ натяжной потолок ПВХ кожа потолочный сварочный аппарат машина для тиснения

5 кВт с двойной головкой HF сварщик высокочастотный Натяжной потолочный сварочный аппарат

ПЛК управление работой eva стелька высокочастотный сварочный аппарат 12 кВт для тапочек

Высокая частота ПВХ ткань сварочный аппарат для холст тент и брезент

Машина для изготовления пакетов из ПЭТ ПВХ на молнии сварочный аппарат пластиковых сумок

Настраиваемый дизайн ПВХ Брезентовая сварочная машина сварочный аппарат горячим воздухом для

110-220 В дополнительная зарядка портативные новые пластиковые фитинги для сварки палочек

Новые поступления

Новинки товаров от производителей по оптовым ценам