Заводская цена 1500 Вт лазерная сварочная машина Стабильная и прочная нержавеющая сталь батарея

- Категория: >>>

- Поставщик: Guangdong Xiaowei Intelligent Technology Co. Ltd.

Сохранить в закладки 1601076653875:

Описание и отзывы

Характеристики

Automatic Continuous Fiber Laser Welding Machine

Laser welding is one of the important aspects of laser material processing technology. The welding process belongs to the heat conduction type, the laser radiation heats the workpiece surface, and the heat on the surface diffuses through the heat transfer guide. By controlling the width, energy, peak power and repetition frequency of laser pulse, the workpiece is melted to form a specific molten pool.

Laser welding is a new type of welding method. Laser welding mainly aims at the welding of thin-walled materials and precision parts, which can realize spot welding, butt welding, stack welding, seal welding, etc.

Laser welding is a new type of welding method. Laser welding mainly aims at the welding of thin-walled materials and precision parts, which can realize spot welding, butt welding, stack welding, seal welding, etc.

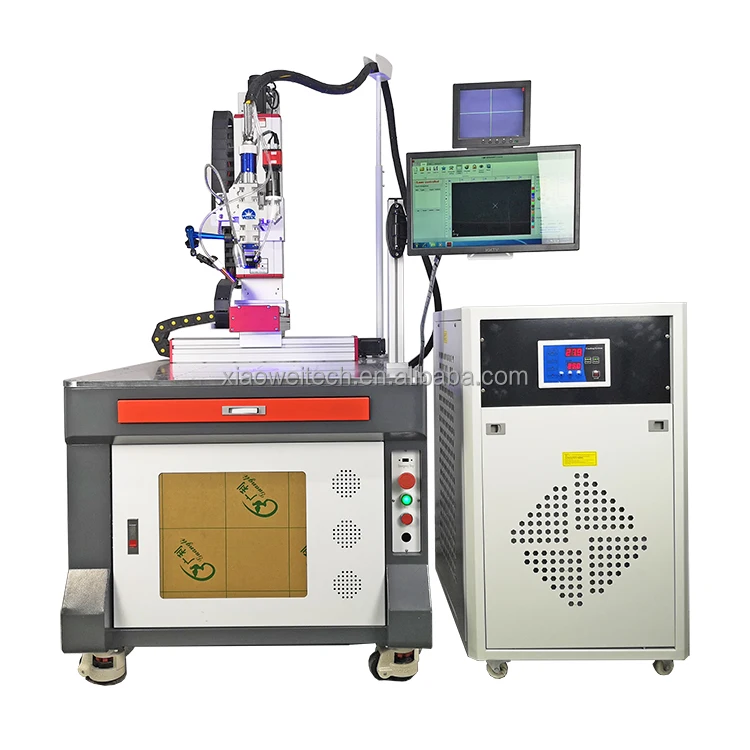

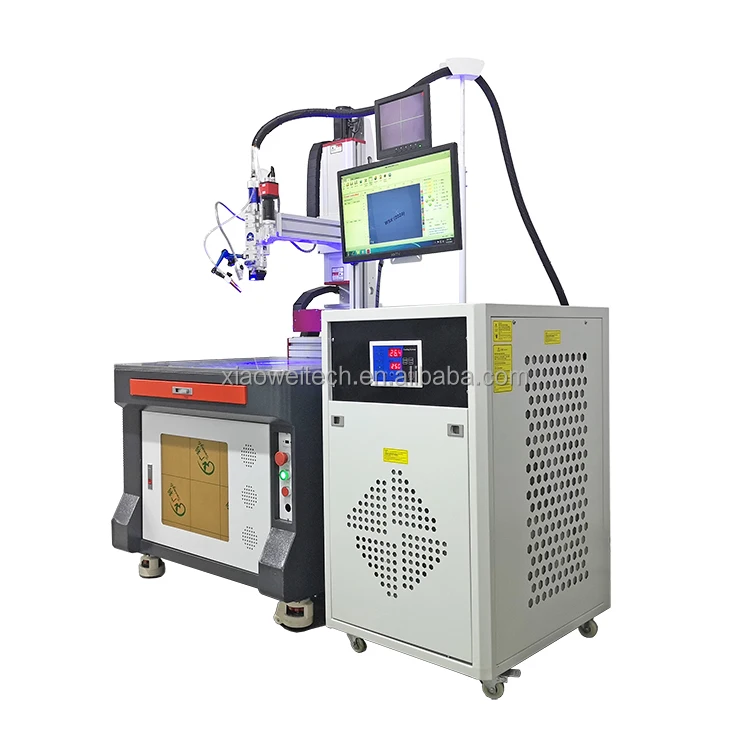

Automatic Continuous Fiber Laser Welding Machine

Left view

Right view

Features:

1) Equipped X/Y/Z three-axis motion platform, driven by servo motor, stroke can be customized, fast running speed and high precision;

2) HD CCD monitoring system, the welding condition is clearly visible to avoid outflow of defective products.

3) Professional control software, graphical operation interface, user-friendly, simple operation;

4) Can be welded in any shape, such as point, line, circle, square,custom shape, etc.;

2) HD CCD monitoring system, the welding condition is clearly visible to avoid outflow of defective products.

3) Professional control software, graphical operation interface, user-friendly, simple operation;

4) Can be welded in any shape, such as point, line, circle, square,custom shape, etc.;

5) Optional swing welding head, welding in the form of a circle, to meet higher welding process requirements.

6) It can customize special automatic fixture to realize mass production of products

6) It can customize special automatic fixture to realize mass production of products

No | Item | XW-BW1000W | XW-BW1500W | XW-BW2000W | XW-BW3000W | |||

1 | Laser Power | 1000W | 1500W | 2000W | 3000W | |||

2 | Voltage | Single phase 220V/50Hz 3-phase 380V/50Hz | ||||||

3 | Control Method | Control card and computer | ||||||

4 | XY Travel | Customizable, Max 700*500mm | ||||||

5 | Z Travel | Customizable, Max 400mm | ||||||

6 | R Axis | Optional, 360° rotation | ||||||

7 | Laser Source Brand | RAYCUS/JPT | ||||||

8 | Position Accuracy | ±0.02mm | ||||||

9 | Repeatability Accuracy | ±0.01mm | ||||||

10 | Motion Source | Servo motor | ||||||

11 | Max Speed | 500mm/s | ||||||

12 | Welding Penetration | 0.1-3.0mm | ||||||

13 | Cooling Method | Water cooling 1P-3P | ||||||

14 | Laser Wavelength | 1080nm | ||||||

15 | Observation System | Red light and CCD system | ||||||

16 | Consumables | Protection lens, purified water, protection gas | ||||||

17 | Weight | About 450kg | ||||||

High-performance Laser Generator & Industrial Control Computer

The JPT is China famous brand of laser generator.

JPT’s single-mode continuous fiber laser is an optimized combination of optical, mechanical, electrical, and soft. Through the control interface and Jept’s standard software, the laser’s operating status can be monitored and alarmed in real time. Collect and record operating data. The laser adopts water-cooled heat dissipation and rack-mounted chassis design. It has many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, flexible fiber optic transmission output, and easy integration for customers. It is industrial laser cutting, welding and other Ideal light source for application.

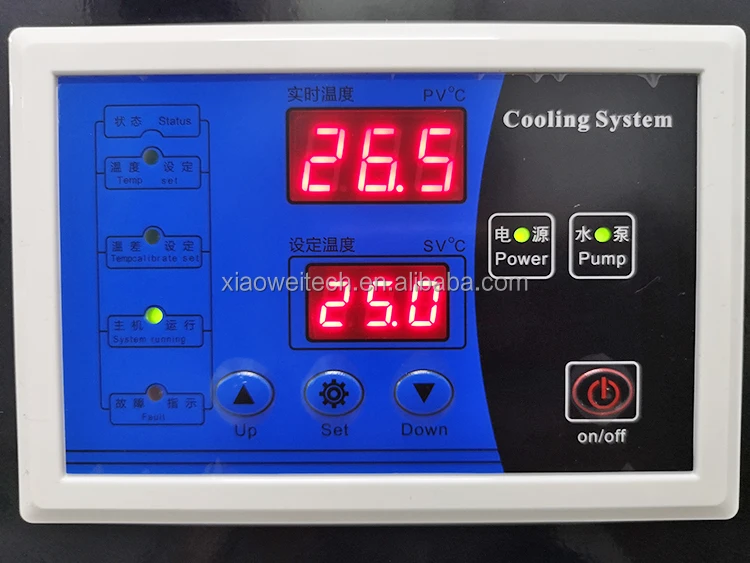

Chiller Controller

It is very important to match a suitable chiller for the laser welding machine. The cooling performance and temperature control accuracy of the chiller are closely related to the stability of the laser output.

Compressed Air & Protect Gas

Compressed air is used to protect the lens of the laser welding head, and protect gas is used to protect the workpiece to be welded from oxidation

Buttons

The welding machine have Emergency Stop button, Start button, and Stop button for fast operation.

Battery Welding Samples

Laser welding is widely used in the welding of batteries, especially the welding of prismatic battery packs.With the following characteristics:

1. It has high aspect ratio, small weld width, small heat affected zone, small deformation and fast welding speed;

2. The weld is flat and beautiful, and there is no need to deal with or only simple process after welding;

3. The weld has high quality and no porosity, which can reduce and optimize the impurities in the base metal. the microstructure can be refined after welding. The strength and toughness of the weld are at least equivalent to exceed the base metal;

4. It can be precisely controlled, the focus light point is small, it can be positioned with high precision, and it is easy to realize automation;

5. Welding between some different materials is possible.

1. It has high aspect ratio, small weld width, small heat affected zone, small deformation and fast welding speed;

2. The weld is flat and beautiful, and there is no need to deal with or only simple process after welding;

3. The weld has high quality and no porosity, which can reduce and optimize the impurities in the base metal. the microstructure can be refined after welding. The strength and toughness of the weld are at least equivalent to exceed the base metal;

4. It can be precisely controlled, the focus light point is small, it can be positioned with high precision, and it is easy to realize automation;

5. Welding between some different materials is possible.

XIAOWEI after-sales service policy

1. One year guarantee, one Year spare parts free if the machine parts damage, whole life technician support.

2. With professional engineers, you can go to the world for on-site mechanical maintenance

3. Operation Manual, Operation or repair Video,

4. 24-hours Email technical support, we will do our best to help the clients solve any question or problems.

5. Available to send our engineer to clients factory, to install the machines, train the workers, repair the machines.

3. Operation Manual, Operation or repair Video,

4. 24-hours Email technical support, we will do our best to help the clients solve any question or problems.

5. Available to send our engineer to clients factory, to install the machines, train the workers, repair the machines.

Похожие товары

Ручной лазерный сварочный аппарат с воздушным охлаждением 1500 Вт волоконно-лазерный для сварки алюминиевой меди

311 291,81 ₽ - 383 769,40 ₽

Лазерный сварочный аппарат ручной лазерный цена портативный 1000 Вт 1 5 кВт

442 595,77 ₽ - 491 773,08 ₽

Мини-портативный лазерный сварочный аппарат с воздушным охлаждением для лазерной резки алюминия из нержавеющей стали 1500 Вт

2000 Вт сварочный лазер для сварки металла подходит ресторанов гостиниц рекламных компаний

Портативный алюминиевый лазерный сварочный аппарат soldadora лазерная резка гибочная сварка сборка обработка

471 488,12 ₽

Ручной лазерный сварочный аппарат 1500 Вт автоматический

328 725,91 ₽ - 328 945,20 ₽

Высокоскоростная сварочная лазерная машина YHS Высокая точность автоматическая сварочный лазер для металла

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $