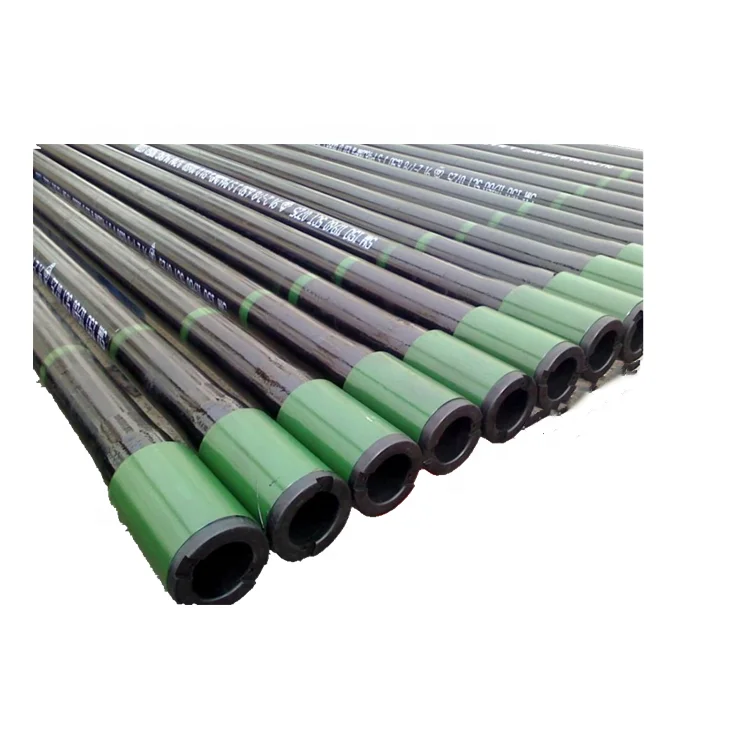

Бесшовная труба для труб API 5CT K55 J55 L80 N80 P110

- Категория: >>>

- Поставщик: Dongying Kangya Petroleum Equipment Co. Ltd.

Сохранить в закладки 1601080236119:

Описание и отзывы

Характеристики

Product Application

Tubing is a relatively small-diameter pipe that is run into a well to serve as a conduit for the passage of oil and gas to the

field surface facilities for processing. Tubing must be adequately strong to resist loads and deformations associated with

production and workovers. Further, tubing must be sized to support the expected rates of production of oil and gas.

Tubing Specifications:

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.

Tubing comes with non-upset (NUE) and external upset (EUE) ends. EUE tubing is more common, because of the benefit that cutting threads into the tubing ends does not reduce the body strength.

NB: for ESP applications, if power cable clearance between the tubing and casing becomes an issue, NUE tubing should be considered.

Internal diameter (ID): is a result of the OD and the wall thickness, and it is used to calculate pressure losses and velocities.

The drift diameter: is the diameter of a 42” long mandrel that passes through tubing joint. It is a foremost parameter as it gives the maximum OD of any equipment to run through the tubing string.

Maximum outside diameter: it depends on the nominal diameter and the connection type. It is critical as it determines the strings size that we can run in a given casing.

Nominal size: is the outside diameter of the pipe body. The most used sizes are: 2-⅜”, 2-⅞”, 3-½” and 4-½”.

The tubing joint length: is the length of tubing joint including the coupling and excluding the pin thread. It is classified into

two length range: range I: from 20 ft to 24 ft (6.1 to 7.32 m) long, or range II: from 28 ft to 32 ft (8.53 to 9.75 m) long. The

length range must be chosen with care. It must be compatible with the hoisting and storage capacity of the mast of the rig used when running in hole the equipment during completion as well as later on during workover operations.

Package : Steel bundle ,Protector on both end .hexagonal bundles of max. 2000kgs with several steel strips , two tags on each bundle , wrapped in waterproof paper , PVC sleeve and sackcloth with several steel strips .

Heat treatment : Normalized , Quencher+Temper

Test : Chemical Component Analysis , Mechanical Properties (Ultimate tensile strenth ,Yield strenth ,Elongation )

Technical Properties ( Flattening test , flaring test , bending test , hardness test , blow test , impact test etc )

Exterior size inspection , Nondestructive test ( Ultrasonic flaw detector , eddy curent flaw detector ) Hydrostatic test .

Mill Test Certificate : EN10204/3.1B and EN10204/3.2 Certificat .

Third Party Inspection : SGS , BV ,LLoyds etc

Product Name | Tubing Pipe |

Standard | API 5CT |

Grade | K55 J55 N80 L80 P110 |

Thread | EUE NUE & Premium Connection |

Length | R1 R2 R3 |

Size (in) | 1.315"~4 1/2" |

Dongying Kangya Petroleum Equipment Co.,Ltd.is a professional manufacturer and supplier of all types of petroleum equipment.The company is located in Dongying, the beautiful petroleum city at Yellow River Delta, covers an area of more than 330 million square meters.

And we have many years of history in the petroleum equipment industry.Our main products include drilling equipment,oil production equipment,wellhead equipment,well control equipment,downhole tools,OCTG pipe,\tvavle & pipe fitting and oilfield tools.

Currently,our products is already exported to America, Middle East, Australia,Africa and 20 other countries and regions.

Our company has always focused on research, development and innovation.Kangyapetro will initiate the second phase of our development strategy.Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T and Western Union are the most usual ways we are using.

3) What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25days if we don't have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.

Похожие товары

API обсадные/трубные протектор резьбы, стальная буровая труба для бурения скважин для бурильной промышленности, инструмент для защиты труб, продажа

Бесшовная труба для труб API 5CT N80 L80 J55 K55 P110

Трубка кожух щенка соединения для продажи

Заводская Продажа API 5Ct L80 бесшовная стальная/нефтегазовая обсадная буровая труба/P110 N80 бесшовная труба из углеродистой стали

Озеро API 5CT черная стальная труба BTC Бурильная труба обсадная труба

PDC сверло 102 мм API 2 3/8 Reg алмазное Композитное трехкрылое Угловое сверло без сердечника

Части износа ударной дробилки с высоким содержанием хрома с керамическими вставками

Новые поступления

Новинки товаров от производителей по оптовым ценам