Заводская цена ss316 корпус фильтра для различных средних фильтров

- Категория: >>>

- Поставщик: Haian Jci Technology Co. Ltd.Haian Ltd.

Сохранить в закладки 1601088647021:

Описание и отзывы

Характеристики

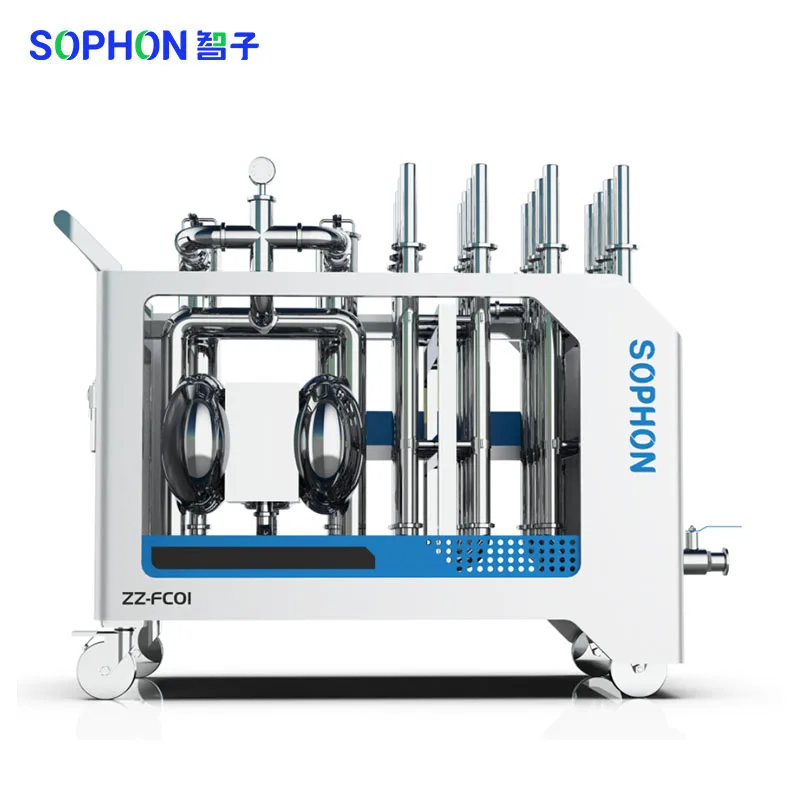

Products Description

BT series bag filter (BT filter for short), this filter uses a filter bag as the filter element. The filter bag is supported by a

metal mesh basket, which is suitable for liquid precision filtration to remove traces of fine impurities. This filter has the

outstanding advantages of simple structure, quick and flexible operation, economical consumables, and is equipped with a variety of high-performance filter bags, which can meet most of the requirements of precision filtration.

BT filter is a pressure type filter device, mainly composed of filter cylinder, upper cover, quick opening device, support basket and other components. The liquid flows in from the inlet of the equipment, and flows out from the outlet after being filtered by the filter bag. The impurities are intercepted in the filter bag. Only the filter bag needs to be replaced during maintenance.

BT filter can meet various filtering requirements in all aspects, subdivided into 4 sub-series:

* BTT series, single-bag top-in filter, with very good sealing effect, suitable for small flow and high precision occasions.

* BTS series, single-bag side-entry filter is suitable for small flow and general precision field.z

* BTF series, quick-opening multi-bag filter, which can be opened and closed in 20 seconds, suitable for occasions with large flow and frequent replacement of filter bags.

* BTM series, multi-bag filter, suitable for large flow and occasions where the filter bag does not need to be replaced

frequently.

metal mesh basket, which is suitable for liquid precision filtration to remove traces of fine impurities. This filter has the

outstanding advantages of simple structure, quick and flexible operation, economical consumables, and is equipped with a variety of high-performance filter bags, which can meet most of the requirements of precision filtration.

BT filter is a pressure type filter device, mainly composed of filter cylinder, upper cover, quick opening device, support basket and other components. The liquid flows in from the inlet of the equipment, and flows out from the outlet after being filtered by the filter bag. The impurities are intercepted in the filter bag. Only the filter bag needs to be replaced during maintenance.

BT filter can meet various filtering requirements in all aspects, subdivided into 4 sub-series:

* BTT series, single-bag top-in filter, with very good sealing effect, suitable for small flow and high precision occasions.

* BTS series, single-bag side-entry filter is suitable for small flow and general precision field.z

* BTF series, quick-opening multi-bag filter, which can be opened and closed in 20 seconds, suitable for occasions with large flow and frequent replacement of filter bags.

* BTM series, multi-bag filter, suitable for large flow and occasions where the filter bag does not need to be replaced

frequently.

Specification

Model No. | BT Series | ||||

Optional filter bags | PP/PE/NO/ etc. | ||||

Single filter rate | 1-1,000m³/h | ||||

Design pressure | 0.6-1.0MPa(Higher pressure can be customized.) | ||||

Single filtering area | 0.1-24㎡ | ||||

Filter accuracy | 0.5-1,250μm | ||||

Number of stand-alone filter bag | 1-24 | ||||

Applicable viscosity | 1-20,000cp | ||||

Housing material | 304/316L/CS | ||||

Working principle

Application

* Applicable industry: Water treatment, papermaking, fine chemicals, automobile industry, mechanical processing, petrochemical,coatings, electronics, etc.

* Applicable liquid type: The applicability is very wide, all kinds of liquids containing trace impurities are mainly filtered to

remove particles of various sizes, purify the liquid, and protect key equipment.

* Filter type: Particle filtration, using disposable filter materials to filter, manual regular replacement.

* Applicable liquid type: The applicability is very wide, all kinds of liquids containing trace impurities are mainly filtered to

remove particles of various sizes, purify the liquid, and protect key equipment.

* Filter type: Particle filtration, using disposable filter materials to filter, manual regular replacement.

Production Process

Our Advantages

1. The probability of side leakage of the filter bag is small, which effectively guarantees the filtering quality.

2. The filter can bear greater working pressure, with small pressure loss, low operating cost, and obvious energy saving effect.

3. The filter has large processing capacity, small volume and large dirt holding capacity.

4. The filter has a wide range of applications, flexible use and various installation methods.

5. The bag filter has a compact structure and a reasonable size. Installation and operation are simple, convenient, and occupy a small area.

6. Bag serise liquid filter has high filtration accuracy, suitable for any fine particles or suspended matter, and the filtration

range can be from 0.5 to 200 microns.

7. The processing flow per unit filtration area is large, the filtration resistance is small, and the filtration efficiency is

high. The filtering capacity of a filter bag is equivalent to 5-10 times that of the filter element, which can greatly reduce the

cost; the design flow can meet the requirements of 1~500m³/h, and the cost is low.

8. Bag type liquid filter has a wide range of uses, which can be used for coarse filtration, intermediate filtration or fine

filtration; in the case of achieving the same filtration effect, compared with the plate and frame fine filter, filter element

filter and other equipment, the equipment investment cost and filtration cost is lower.

9. High filtration precision, large filtration processing capacity, low cost and high efficiency.

10. Based on the working principle and structure of the bag filter system, it is convenient and quick to replace the filter bag,Most of the filter bag is free of cleaning, and the replacement of the liquid filter bag can be completed within 30 seconds, which

is convenient and fast, saving labor and time.Nylon filter bag can be used repeatedly after cleaning, saving cost.

11. The liquid bag filter has a complete range of specifications, including low-pressure, side-entry, top-entry, multi-bag, and

horizontal.

2. The filter can bear greater working pressure, with small pressure loss, low operating cost, and obvious energy saving effect.

3. The filter has large processing capacity, small volume and large dirt holding capacity.

4. The filter has a wide range of applications, flexible use and various installation methods.

5. The bag filter has a compact structure and a reasonable size. Installation and operation are simple, convenient, and occupy a small area.

6. Bag serise liquid filter has high filtration accuracy, suitable for any fine particles or suspended matter, and the filtration

range can be from 0.5 to 200 microns.

7. The processing flow per unit filtration area is large, the filtration resistance is small, and the filtration efficiency is

high. The filtering capacity of a filter bag is equivalent to 5-10 times that of the filter element, which can greatly reduce the

cost; the design flow can meet the requirements of 1~500m³/h, and the cost is low.

8. Bag type liquid filter has a wide range of uses, which can be used for coarse filtration, intermediate filtration or fine

filtration; in the case of achieving the same filtration effect, compared with the plate and frame fine filter, filter element

filter and other equipment, the equipment investment cost and filtration cost is lower.

9. High filtration precision, large filtration processing capacity, low cost and high efficiency.

10. Based on the working principle and structure of the bag filter system, it is convenient and quick to replace the filter bag,Most of the filter bag is free of cleaning, and the replacement of the liquid filter bag can be completed within 30 seconds, which

is convenient and fast, saving labor and time.Nylon filter bag can be used repeatedly after cleaning, saving cost.

11. The liquid bag filter has a complete range of specifications, including low-pressure, side-entry, top-entry, multi-bag, and

horizontal.

Related Products

Company Information

Shanghai JCI is a leading design and manufacturing company in the filtration industry, specializing in high-performance filtration equipment, especially in the field of self-cleaning filtration occupies an important position.Founded in 2014, the company is headquartered in Shanghai, with two production bases in Hai 'an, Jiangsu Province and Taiwan,China, and agents in Russia, the United States, Singapore, South Korea and other places. In March 2021, the company signed an investment and investment agreement with Jiangsu Haian City Government, and officially moved the factory to Nantong Haian in August of the same year. At present, the company has more than 5000 plants, the company currently has more than 40 patents, more than 2 invention patents, of which the company's self-developed self-cleaning and drying slag system fundamentally solves the pain points that have plagued the filtration industry for many years, and has been widely recognized by many customers and the industry.With excellent technical strength, exquisite product quality and excellent service system, JCI has won the trust and praise of many customers. At present, JCI has served more than 25 of the world's top 500 enterprises. In the future, Jiu Cheng will, as always, provide customers with better quality products and services to repay the support and trust of customers.

Похожие товары

Погрузчики погрузчики и другое механическое оборудование гидравлический фильтр инструменты Гидравлический масляный всасывающий TYL670-9

551,04-1 033,20 ₽

Серводвигатель миниатюрный фильтр для корпуса клапана дисковый складной A67999-065 A67999-100 A67999-2000

574,00-918,40 ₽

Переработка пластиковых Коротких Волокон обработки нержавеющей стали расплава свечи фильтр-картридж

2 181,20 ₽

HPQ300779L20-25MB25 микрон Стекловолоконный фильтр-картридж для промышленного фильтрующего оборудования

1 722,00-2 869,99 ₽

Нержавеющая сталь 316L перфорированный металлический и проволочный сетчатый ковшовый фильтр/корзина

9 757,97-11 365,17 ₽

Картридж с плиссированным фильтром для стерильной фильтрации буферов и биологических жидкостей 0 22 мкм 1 20 дюймов

9 787,82-9 902,62 ₽

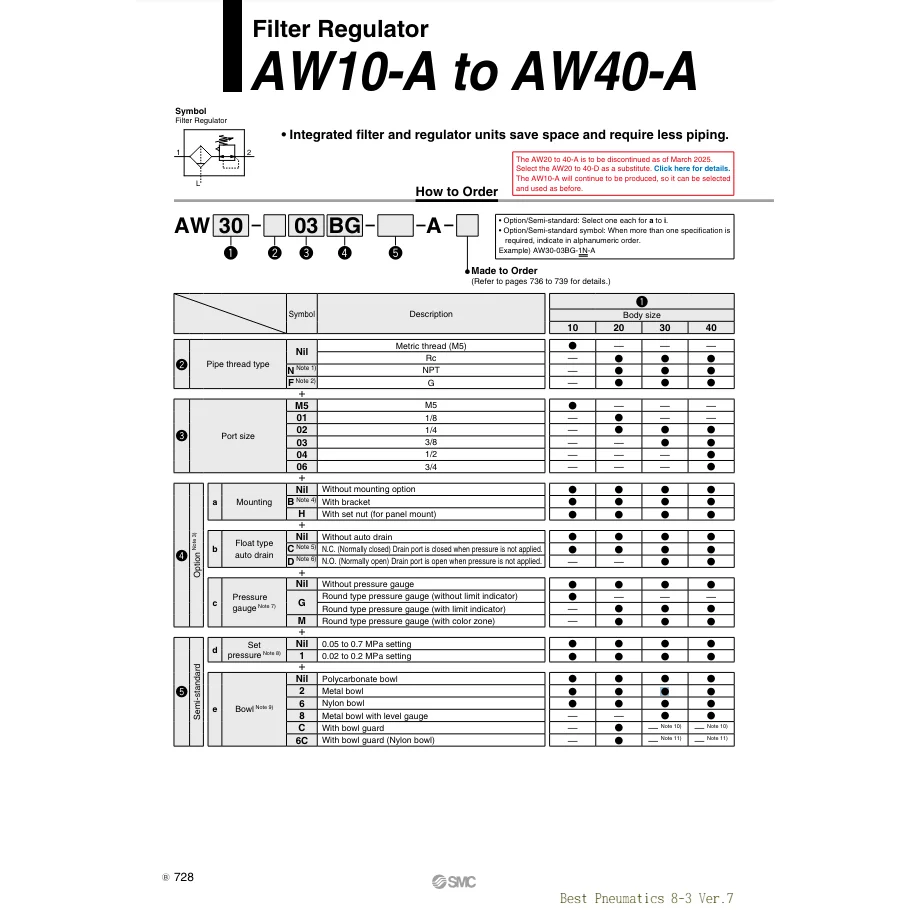

AW30-N02BDG-2R-A регулятора фильтра [SMC Pneumatics]

5 969,58 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $