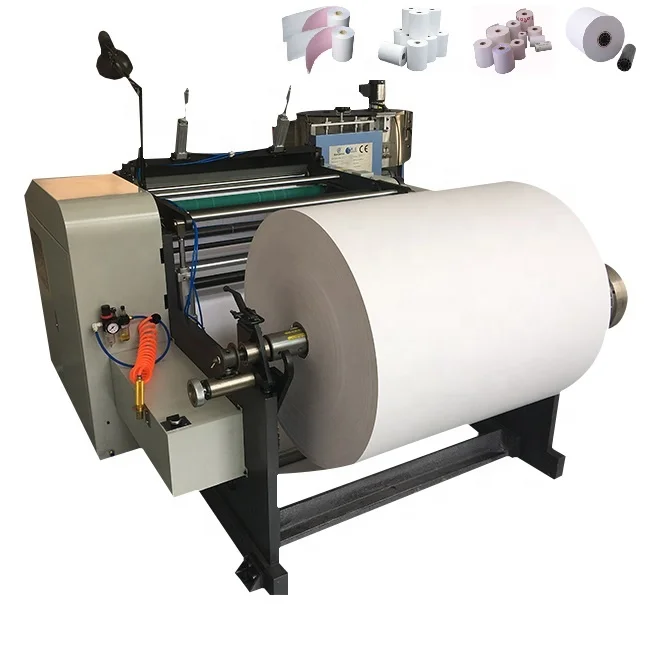

Усовершенствованная машина для резки термобумаги ATM эффективного производства рулонных пластов

- Категория: >>>

- Поставщик: Hangzhou Havesino Import And Export Co. Ltd.

Сохранить в закладки 1601089176757:

Описание и отзывы

Характеристики

Advanced ATM Thermal Paper Slitting Machine for Efficient Roll Production Jumbo Roll Slitter

Introduction:

Efficient Roll Production Jumbo Roll Slitter CP-S900C is a very versatile and professional slitter rewinding machine which could handle a wide range of paper widths and thicnesses. This machine can slit the thermal paper jumbo roll into smaller specific width and then rewind them into small paper rolls with certain size like 57mm,79mm,80mm and other hot selling thermal paper roll sizes on the market.

Main Configurations:

- This NCR ECG CTG Paper Computer Bill Slitter equipped with Panasonic PLC and Weinview touch screen,all the parameter are display on the monitor.

- Auto Tension Control System for unwinding tension.

- Meter Counter,the data displayed on the screen.

- Synchronic Belt,used to avoid the over lap problem.

- Frequency Inverter for main inverter motor driving, the speed can be displayed on the operation panel.

- All the transmission rollers have been dynamic/static treated.

- Emergency switch.

Our Thermal ATM POS rolls slitting machine boasts incredible performance, customization capabilities, and impressive production capacity. Here are some of the features and advantages that make it a top choice for any business looking to optimize their production process.

1. Its high-speed performance allows for an unparalleled level of productivity. Running at a remarkable speed of 200m/min, our thermal paper roll slitting machine ensures fast and seamless production, meeting strict deadlines and optimizing efficiency.

2. Its customizable width cutting, making it easy to slit thermal paper rolls into any desired size. This cash register roll cutting machine excels at cutting commonly used 57mm ,79mm and 80mm widths, making it highly versatile and able to fulfill different client needs.

3. Its impressive production capacity is due to its robust design and advanced mechanisms. This thermal bond paper roll slitting rewinder can handle up to two tons of thermal paper rolls per day, facilitating large-scale production and enabling you to effectively meet the growing demands of the market.

4. Competitive price. We understand that cost-effectiveness is a crucial factor in today's business environment. Our thermal receipt paper slitting rewinding machine provides excellent quality and affordability, giving you a competitive edge while ensuring a high return on investment.

5. Wide range of applications. Our ATM POS ECG paper roll slitting machine is used in various industries and sectors such as supermarkets, retail shops, restaurants, printing shops, cash registers, medical facilities, and engineering CAD industries. It is an indispensable tool for any business operation.

6. Humanity design. Its intuitive interface and straightforward operation make it suitable for operators with different skill levels, further increasing its usability.

By investing in our thermal paper roll slitting rewinding machine, you can enjoy an unparalleled level of productivity, flexibility, and production capacity to take your business to the next level. With its impressive features and advantages, it is sure to be a valuable asset to any business looking to stay ahead of the competition.

So, do not hesitate to consider our thermal jumbo roll slitter for your business. It is a favorable solution that you have been looking for to increase efficiency and productivity while meeting the demands of your clients. Let our thermal paper roll slitting machine be the driving force behind your business success.

Applications:

CP-900C is a very precise and cost effective Slitting Rewinder for Thermal paper rolls,Lotery rolls, POS rolls, Cash register rolls, Medical paper rolls, Gas pump paper rolls, Plotter rolls, ECG paper rolls and so on. It's a cheap but very smart thermal paper slitting and rewinding machine.

- EASY SETTING ON THE TOUCH SCREEN

![1.png]()

- EASY TENSION SET

![2.png]()

- WITH END MARK ROLLERS TO MAKE END MARK ON THE INSIDE OF THE ROLLS

![3.png]()

- WITH METER COUNTER WHEEL,TO MAKE SURE THE MACHINE CAN STOP AUTOMATICALLY AT SETTING METER

![4.png]()

Basic specification:

| Model | CP-S900C |

| SLITTING LAYER | SINGLELAYER |

| SLITTING WIDTH | 900MM |

| SLITTING THICKNESS | 40-120GR/M2 |

| UNWINDING DIAMETER | 1200MM |

| UNWINDING TYPE | AIR SHAFT |

| UNWINDING CORE SIZE | 3 INCH |

| UNWINDING BRAKE TYPE | MAGNETIC POWDER BRAKE |

| REWINDING WIDTH | 20MM(MIN) |

| REWINDING DIAMETER | 250MM(MAX) |

| REWINDING SHAFT | 8-50MM |

| SLITTING UNIT | 10PCS CIRCLE BLADE |

| WALL THICKNESS | 30MM |

| MECHANICAL SPEED | 200M/MIN (MAX) |

| WORKING SPEED | 180M/MIN (MAX) |

| POWER SUPPLY | 380V,3PHASES, 50Hz, 2.2KW |

| AIR POWER SUPPLY | 0.8 Mpa (MINI) |

| N.W | 1500 KG |

| MACHINE SIZE | 1800MM*1700MM*1450MM |

| WOODEN BOX SIZE | G.W. | N.W. | H.S CODE |

| 215*186*160CM | 1600KGS | 1550KGS | 8441100000 |

1. ONE YEAR GURANTEE FOR THE KEY PARTS OF THE MACHINE, THE PARTS ARE AS FOLLOWING:

MOTOR, PLC, TOUCH SCREEN,MAGNETIC POWDER CLUTCH

2. MACHINE INSTALLING AND WORKER TRAINNING SERVICE.

A. ENGINEER AVAILABEL ON YOUR FACTORY TRAINNING AND INSTALLING

IF YOU PAY THE VISA COST, AIR TICKET, FOOD, HOTEL AND SUBSIDY.

B. TRAINNING YOUR WORKER AT OUR FACTORY SERVICE IS AVAILABEL

YOU ONLY NEED TO PAY THE HOTEL COST.

3. WHOLE LIFE TECHNICAL SUPPORT, 24 HOURS BY 7 DAYS CALLING-SERVICE.

WE GUARANTEE FULLY TEST AND CHECK BEFORE SHIPMENT TO ENSURE THE QUALITY.

A.:We pay much attention to quality control from the very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Hangzhou,China.You can fly to Hangzhou airport directly or take fast train from Shanghai. We will arrange to pick you up from train station or airport.

Q.:What’s service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service; Free technical support whole life; Material support

Q: Will it take long time to receive the machine?

A: The lead time will be 7 days after the pre-payment has been issued. We will help to deliver the machine at the earliest.

Q:Why do I choose your machine?

A: Our machine is cost-effective and lifetime technical support. We have random complaints from the older order client. The goal of our company is to offer the client the most valuable products and make a win-win result.

Q. Without professional technicians, do not know how to choose a machine?

A: Our staff is all professional, if you don't know how to choose a machine, we can help you select the most proper machine for you.

Q. Do not find the right machine structure to match your current demand?

A: You can tell us what's your requirements about the machine, we support customization for you to meet your demand and we will provide full sets of solutions for you. We guarantee to solve all your needs, all you need to do is trust us and tell us your needs.

Q.Don't have a professional operator to run the lines?

A: We shipped our machine as a whole, and it is very easy to everybody to operate it, we send all manuals and videos and 7*24 hours service to you. Everybody will learn it in 2 hours.

Похожие товары

Многофункциональная Автоматическая макаронная машина для изготовления макарон

Строительная техника VR тренировочный 3d-симулятор для

Суперникелевая бесшовная трубка permalloy из сплава 80 1j79 для электронной авиационной ядерной энергетики

Реле аккумулятора 08088-30000 BR262 4255762 0808830000 релейный переключатель аккумулятора

K5V200DPHA11AR-OE11 шариковая направляющая для стопорного башмака K5V200DPH

Оригинальные Panasonic ET-LAEF100 лампой PT-EW550 PT-EW650

Предохранительный клапан PCV подходит для VW 022 103 765 A 022103765A

Новые поступления

Новинки товаров от производителей по оптовым ценам