Песочный насос Deshi для бурения и шлама морской земснаряд погружной твердых частиц каменный гравийный G GH

- Категория: >>>

- Поставщик: Shijiazhuang Deshi Pump Company LimitedShijiazhuang Limited

Сохранить в закладки 1601089866211:

Описание и отзывы

Характеристики

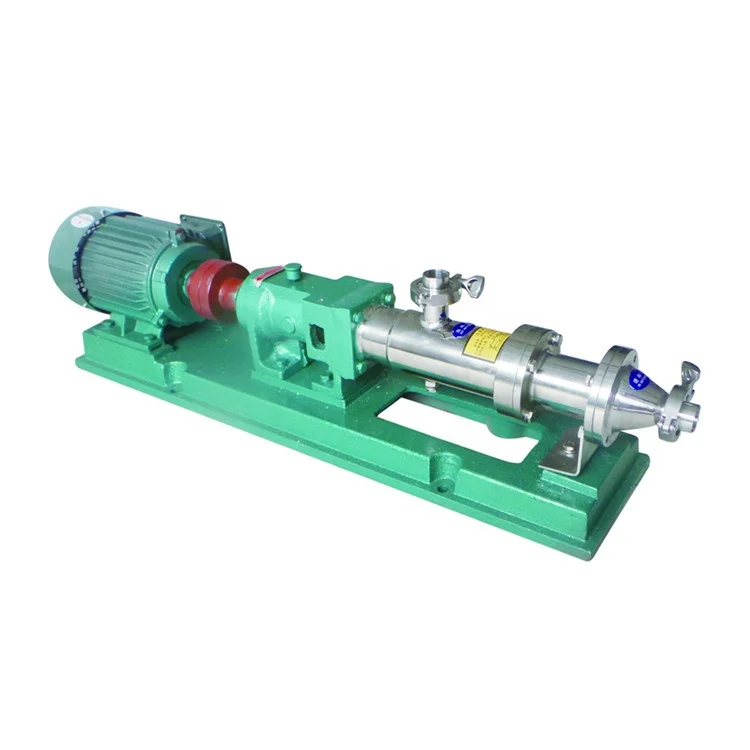

G and GH type sand gravel pump cutter suction dredger mud slurry pump for bigger passage.

Introduction:

Type G and GH pumps are single-stage, single-suction, cantilevered, horizontal, centrifugal slurry pump .They are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by common pumps. They are suitable for delivering slurries in mining, explosive sludge in metal melting, dredging in dredger and course of rivers, and other filed. This series of pump especially suitable for the high flow, high concentration and high head working condition, good performance of NPSH and high abrasion- resistant, can be widely used in high temperature and strong abrasive slurry transportation.

The wet parts are made of wear resistant high-Chrome alloys to ensure long service life. It has superior performance than common pumps in dredging, sand mining, barge loading and mineral processing etc.

GH gravel pump has achieved extra high head for special working conditions.

Overview:

Pump Diameter: 4"~18"

Max flow rate up to: 5600m3/hr

Head to: 82m

Handling solids: 0~254 mm

Slurry Concentration: 0%-70%

Drive type: electric motor or diesel engine.

Pump casings: high chrome alloy

Impeller, liner, throatbush: high-chrome alloy, Stainless steel, etc

Submersible type can be costomized.

Typical Application:

• Mineral processing | • Mining | • Coal Washery | • Cyclone feeds |

• Aggregate | • Chemical slurry | • Tailing | • Mill grinding |

• Ash handing | • Metallurgy | • Waste sludge | • Coarse sand |

• Sand | • Phosphoric acid | • Dredging | • Sewage |

• Quarry | • Power Plant | • Fertilizer | • Tunnel |

• Iron ore sand | • Copper Concentration | • Gold mine | •Molybdenum |

Bentonite | Construction | Island Reclaiming | Alumina Industry |

Design Features:

1. Gravel Sand pump (dredge pump) is designed as single casing connected by means of clamp bands and wide wet-passage.

2. The wearing parts are made of ultra chromium abrasion-resistance alloys, long service life and very low failure rate.

3. The pumps are designed for continuously transferring strong corrosive big-solid -contained slurry which the common

slurry pump cannot transfer. They are widely used in dredging, sand excavation; mining, explosive-sludge in metal melting, etc..

4. DG series gravel pump is often installed on cutter suction dredger or barge.

5. Gravel pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

6. The discharge direction of pump can be oriented in any direction of 360°

Wear Parts

Shaft Seal Arrangement:

Horizontal Sand/Gravel Pumps Performance Parameters

Outline Dimensions

Please contact us for the detailed outline drawings if needed.

Motor Drive Type:

Assembly Workshop

Packaging & Shipping:

Applications Case:

Our main products:

Note: The displayed prices are for reference only, and the final price should be subject to mutual negotiation.

Welcome to contact us any time for more details.

Your inquiry or advice will get our prompt attention and response !

Похожие товары

CQB-G высокотемпературный Магнитный приводной насос

LFY-YKSKF-G поверхностный плавающий лодочный легкий ТИП небольшой водяной бензиновый насос

Распродажа роторные винтовые насосы и Статоры для бетона тип g моно эксцентриковый винтовой насос ротор sta

Переключатель давления воды для водяного насоса

Регулятор давления воды механический переключатель для насосов

Реле давления насоса установки 220v-240v/ 110-120v

Испытательный насос 15000 Psi для труб/труб

Новые поступления

Новинки товаров от производителей по оптовым ценам