JD440E автоматический и высокоскоростной роторный цифровой струйный принтер для книг газет

- Категория: >>>

- Поставщик: Weifang Huatian Precision Machinery Co. Ltd.Weifang Ltd.

Сохранить в закладки 1601090719008:

Описание и отзывы

Характеристики

JD440E Rotary digital inkjet printer

Characteristics:

JingDian Color Inkjet Rotary Digital Printing Machine, black and white/ color/single and double-side sheetfed inkjet digital printing machine are produced by Huatian Precision machinery. Founded in 2003, Huatian Precision has been specialized in the production of sheetfed paper, single-color, multi-color, single and double-side offset printing machines, water-based flexo graphic printing machines, packaging equipment and other precision machines for 20 years. With the large database and rich experience in designing and manufacturing, through independent design and independent production of parts, the company has manufactured a variety of inkjet digital printing machines.The machine has a compact design, small footprint, complete functions and high configuration, which is a very cost-effective product.

Mechanical part:

1. The machine is composed of unwinding unit, front printing, back printing, hot air plus IR dryer unit, paper storage unit, cutting unit and paper delivering unit.

2. The unwinding unit is equipped with: paper roll automatic lifting mechanism, paper roll automatic tension control mechanism, paper automatic correction mechanism, paper automatic powder removal, static removal mechanism. In order to ensure the high-precision printing quality and prevent changing the accuracy of the machine when transportation and handling, the printing unit adopts the overall base and the overall wall plate design and manufacturing, the guide roller uses small bearings, high-precision manufacturing, to ensure the operation accuracy unchanged , and the paper transportation is more stable. Due to the deformation of paper printing after drying, this machine adopts unique design of post-constant tension mechanism, so different thickness of paper and different ink absorption after drying by printing, the post-tension is constant, and the front and back printing accuracy is higher.

3. The drying mechanism of the front and back side is independent and parallel to the printing unit, the temperature of each drying unit can be set according to the amount of ink on the front and back side, effectively preventing the paper deformation caused by high temperature, and the drying mechanism parallel to the printing unit avoids the blockage of the nozzle caused by the upward discharge of heat.

4. The independent paper storage unit can ensure the normal operation of cutting, shifting and delivery stations when the machine prints at high speed.

5. The cutting unit adopts flying knife type and small diameter knife cutting device, with small power, fast speed and stable performance; the cutter has a long service life, equipped with a vertical cutter mechanism, and micro adjustment of the left and right cutting size without stopping machine. and the shift division function, which is convenient for the postpress process; The automatic non-stop paper delivery function can meet the working mode of one person and two machines.

6. The whole machine control system adopts imported PLC , which has stable performance and long service life. Touch screen operation mode of man-machine interface, artificial intelligence; Multi-axis linkage servo motor, driven by motion controller, high precision and stable performance. The whole machine control system is completely independently developed and designed. Parts production, assembly, adjustment are carefully selected, the materials are appropriate, the manufacturing is fine, the precision is high, and the life is long, which provides an effective basic guarantee for high-precision printing.

Printing part:

1. The nozzle adopts Epson i3200, the resolution is 1200*600/1200*900dpi/2bit, and the four-channel on-demand piezoelectric nozzle makes the printing quality more delicate.

2. The ink supply system adopts advanced negative pressure control device, and the ink supply is more stable.

3. Intelligent digital file processing, imposition, RIP, variable data, color management, set file standardization and other functions in one of the prepress document process, fast/efficient and convenient , truly realize intelligence, digitalization and informatization.

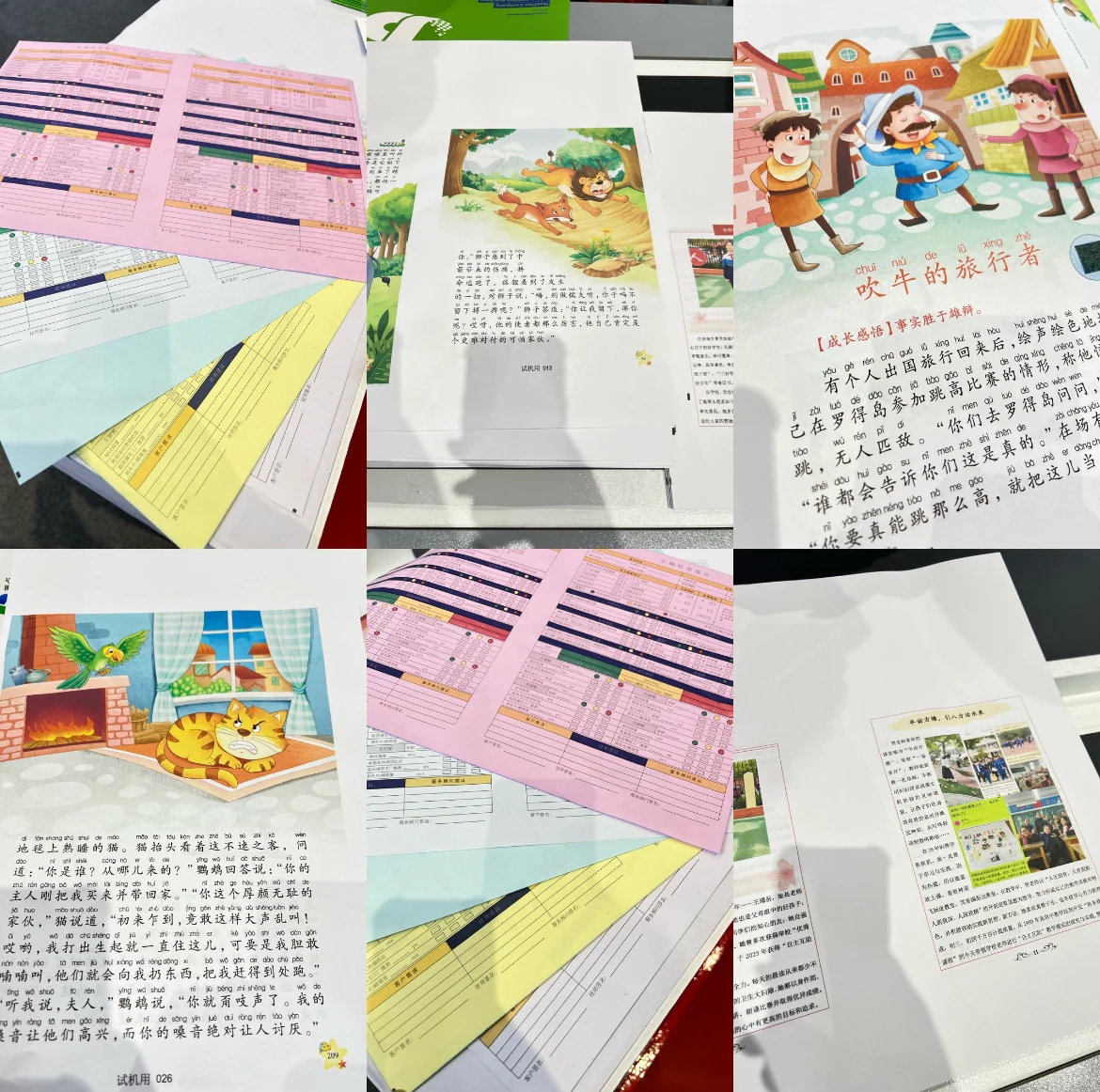

4. Advanced printing software control system, fast document processing process, industrial-grade piezoelectric four-color nozzle, four-color domestic ink, which make the printing text is clear, the graphic pattern saturation is high, the flat screen and gradient color are good, and the printing quality is high.

5. Low carbon and environmental protection, saving paper, ink and electric energy, low cost of use, easy to operate and maintain, high efficiency, high production capacity, high added value, it is a new products of technology revolution .

Parameter :

Control software |

Inkjet digital printing control and drive system |

Process software |

RIP, imposition, variable data |

Nozzle |

Epson i3200:1200x600 dpi/1200x1200 dpi |

ink |

ECO water-based pigment four-color ink |

Speed |

75m/min color |

Print width |

32.8mm/each head |

Paper type |

Digital printing paper, woodfree-paper, newspaper print |

Paper thickness |

45-165g/m2 |

Max roll diameter |

1270mm |

Automatic deviation correction |

Standard |

Static elimination |

Standard |

Drying system |

Hot air and IR dryer |

Cutting size | 140mm/170mm----640mm |

Shift sub-function |

standard |

Delivery height | 260mm |

Machine size | 7600x1400x2100mm(LXWXH) |

Machine power | 380V/50HZX50KW |

Working temperature and humidity | 20-25℃ 40-60% RH |

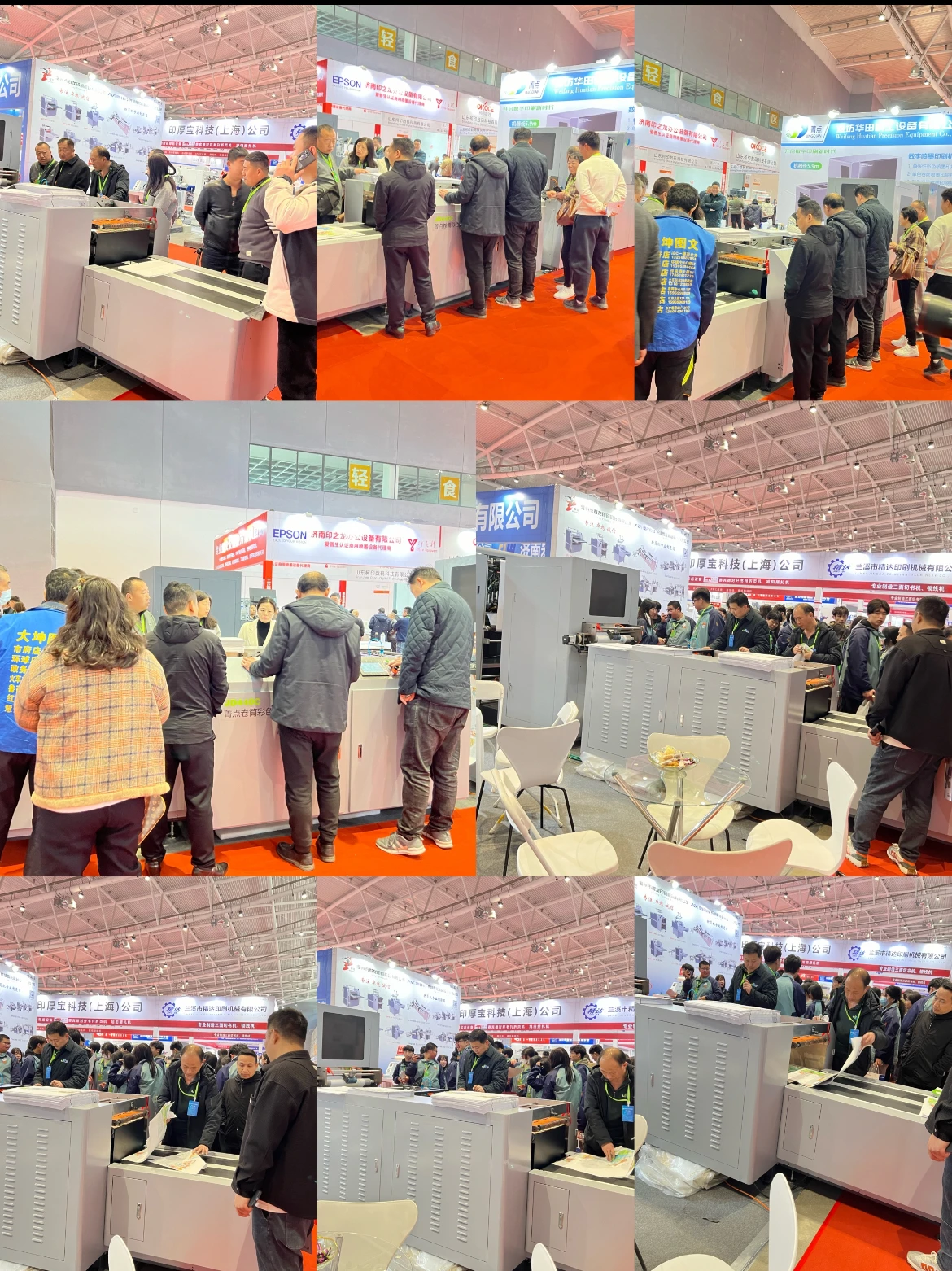

Exhibition

Похожие товары

D100 16 точек печатная машина для ткани текстильная ДД струйный принтер на строительных материалах

Новый дизайн хорошее качество промышленная печатная машина tij высокоскоростной струйный принтер G300

Хорошая производительность широкоформатная рекламная бумага 1 6 м ~ 3 2 Открытый цифровой струйный принтер

Высокое качество Pro9500 Pro Графический струйный принтер

360 градусов цифровой печатной машины продукт

Сверхмощный промышленный широкоформатный цифровой рулонный текстильный принтеры для сублимации

Многофункциональная печатная машина X-Roland промышленный плоттер струйный принтер печатающая головка Струйные большие принтеры цветная печать

Новые поступления

Новинки товаров от производителей по оптовым ценам