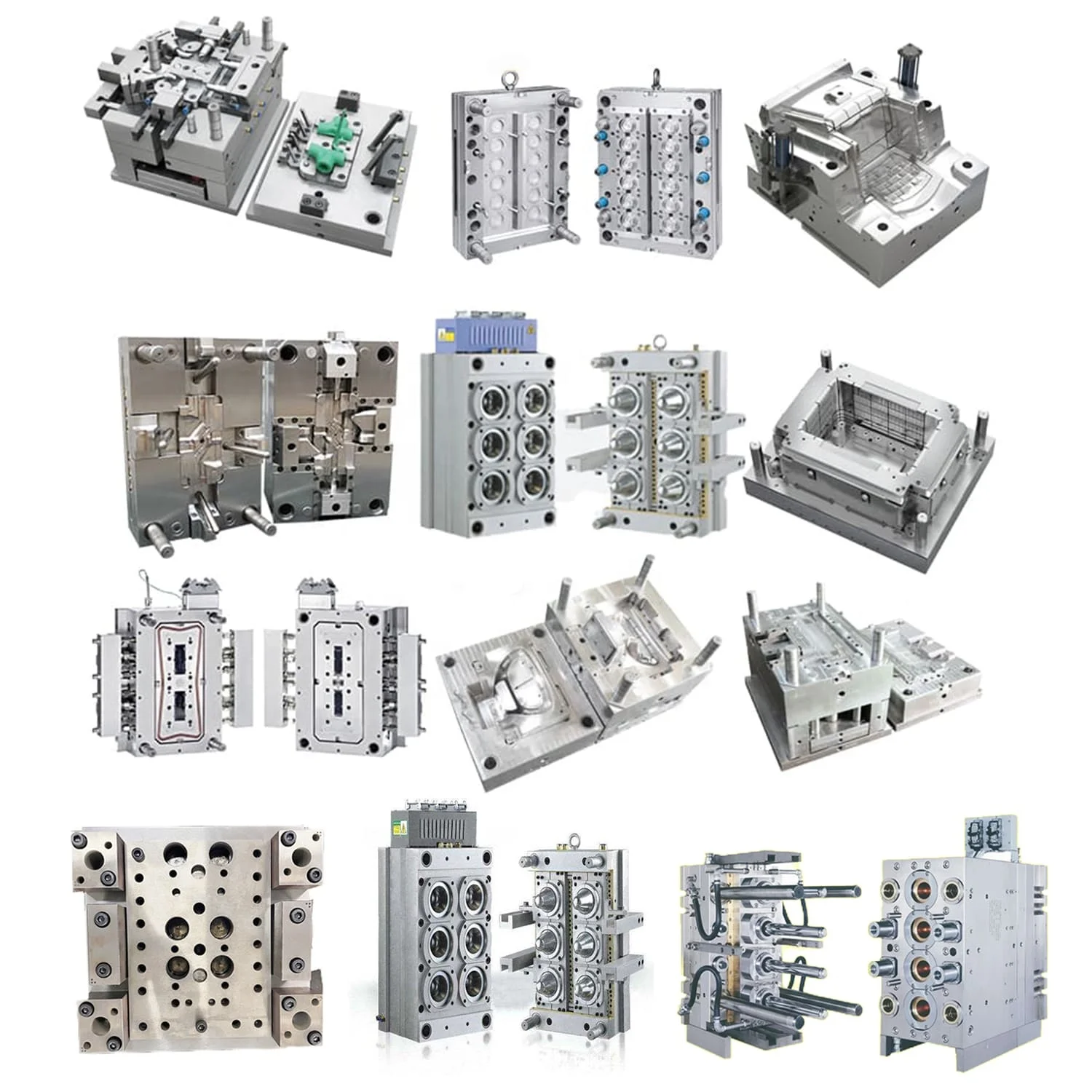

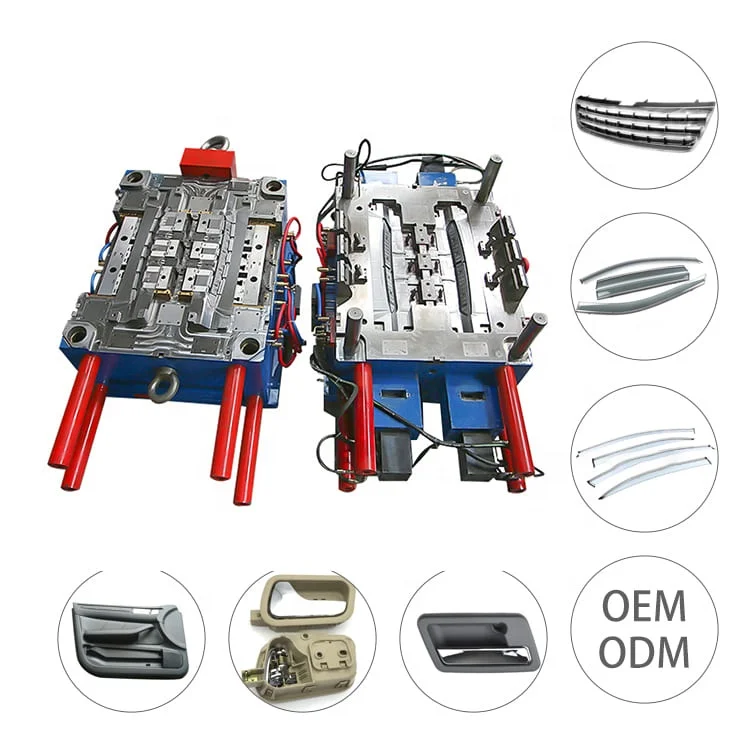

Высокоточная пресс форма для прессования OemInjection кабельный лоток Гидравлический Штамповочный Инструмент с отверстиями под заказ

- Категория: >>>

- Поставщик: Dongguan Longhuan Electronics Technology Co. Ltd.

Сохранить в закладки 1601093974873:

Описание и отзывы

Характеристики

HighPrecision OemInjection Molding Cable Tray Hydraulic Custom Hole Punching Press Tooling Cuttingprogressive Die Metal Stamping

CNC turning parts service

CNC Lathe 40 set

Daily output 250,000 pcs

Tolerance range: 0.005-0.01mm

Tolerance range: 0.005-0.01mm

5-axis CNC machining parts service

Rapid Prototyping

300,000 prototypes experiences

300,000 prototypes experiences

CNC milling parts service

CNC milling 110 set

Daily output: 20000 sets

Tolerance range: 0.005-0.01mm

Daily output: 20000 sets

Tolerance range: 0.005-0.01mm

Machines | CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting | ||||||

Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. | ||||||

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo,etc | |||||||

Brass: 260,C360,H59,H60,H62,H63,H65,H68,H70, Bronze, Copper | |||||||

Titanium Alloy:TC1, TC2, TC3,TC4, etc | |||||||

Plastic:POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |||||||

Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc | ||||||

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF, DWG),PDF etc. | ||||||

Quality Assurance | ISO9001, IATF 16949, SGS, ROHS, | ||||||

ABOUT US

Located in Dongguan, known as the world’s factory, with a factory area of 6000 m². We mainly engage in various types of hardware processing including CNC, stamping, and molds. 100 employees and an efficient factory system can guarantee sample production within 48 hours.

150 sets of equipment for rapid production and passed ISO9001:2005 & IATF 16949 & SGS & ROHS & VerpackG in order to ensure the quality.

150 sets of equipment for rapid production and passed ISO9001:2005 & IATF 16949 & SGS & ROHS & VerpackG in order to ensure the quality.

Baic Size Range | Fine | Medium | Coarse | Very Coarse |

0.5 up to 3 | ±0.05 | ± 0.1 | ± 0.2 | - |

over 3 up to 6 | ± 0.05 | ± 0.1 | ± 0.3 | ± 0.5 |

over 6 up to 30 | ± 0.1 | ± 0.2 | ± 0.5 | ± 1 |

over 30 up to 120 | ± 0.15 | ± 0.3 | ± 0.8 | ± 1.5 |

over 120 up to 400 | ± 0.2 | ± 0.5 | ± 1.2 | ± 2.5 |

over 400 up to 1000 | ± 0.3 | ± 0.8 | ± 2 | ± 4 |

over 1000 up to2000 | ± 0.5 | ± 1.2 | ± 3 | ± 6 |

over 2000 up to4000 | - | ± 2 | ± 4 | ± 8 |

QC Equipment

How can Ouroboros help you?

Have you been looking for a professional factory?

Since the establishment of Ouroboros, the range of aluminum alloy CNC machining parts has covered various industries, including auto parts, robot parts, new energy parts, medical product parts, biomedical equipment parts, automation parts, sports equipment parts, optics Equipment spare parts, communication equipment spare parts, drone parts, beauty device parts, electronic and electrical parts, etc.

What surface treatments are available for CNC machined parts?

General aluminum alloy CNC machining manufacturers focus on processing and are not professional in surface treatment. Once the surface treatment is improper, the entire product may not reach the ideal state, which consumes time and cost. The surface treatment of Ouroboros is very mature. The material types and uses of CNC machined parts are different, and the corresponding surface treatment will also be different.

Four Guarantees

Quality Assurance

Strictly implement the ISO9001:2015 and IATF16949 quality management system and pass ROHS raw material hazardous substance testing. There are at least 10 inspection procedures from raw materials to processing to shipment. No quality loopholes are missed, and the shipment pass rate reaches 99.98%!

Service Guarantee

Technical business personnel are online 24 hours a day, respond within 60 minutes, provide solutions within 4 hours, and resolve

them within 1 day; follow up the order status at any time.

them within 1 day; follow up the order status at any time.

Exhibition

Certificate

FAQ

Q1:Available for customized design drawings?

A1: Yes, DWG DXF, DXW, IGES, STEP, PDF etc.

Q2: Will my drawing be safe after you get it?

A2: Yes, we can sign a confidentiality agreement before you send the

drawings.

drawings.

Q3: What's the MOQ?

A3: Our minimum order quantity is 1 piece.

Q4: Do you provide samples?

A4: Yes, we will provide samples. Samples will be shipped within 48-72 hours after order is placed

Q5: How do you do quality control?

A5: (1)On-site material inspection.

(2) In the process of processing, our lPQC will check each product .

(3) The German Blue ray 3D scanner is used for detection, and the inspection accuracy reaches the top in the industry to ensure zero error of products.

(4) OQC will have 100% inspection before shipment .

Q6: What should we do if we receive unqualified products?

A6: lf you receive defective products, please send photos to us, we will

feedback to our engineers and quality control department as soon as

possible to solve the problem.

feedback to our engineers and quality control department as soon as

possible to solve the problem.

Q7: Mold service life range?

A7: The normal life of the mold can be 700,000-1 million times.

Похожие товары

Форма Huazhida для обуви

Китайские продукты дует формовочные, дуя прессформы

Высококачественные модульные резервуары для воды GRP/FRP резервуар для воды/GRP резервуар для воды

Алюминиевые детали для станков с ЧПУ

8 308,14 ₽ - 9 171,32 ₽

Ротоформовочная машина лодка пресс-форм и Rotomolded формы пластиковая лодка для продажи

269 744,50 ₽

Металлургическое оборудование для порошковой металлургии CNC Mim спеченные детали из нержавеющей стали для литья под давлением

539 489,00 ₽

Большая Стекловолоконная скульптура, формы для резиновой силиконовой садовой бетонной полимерной статуи Ангела, формы для продажи

129 477,36 ₽ - 139 943,45 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $