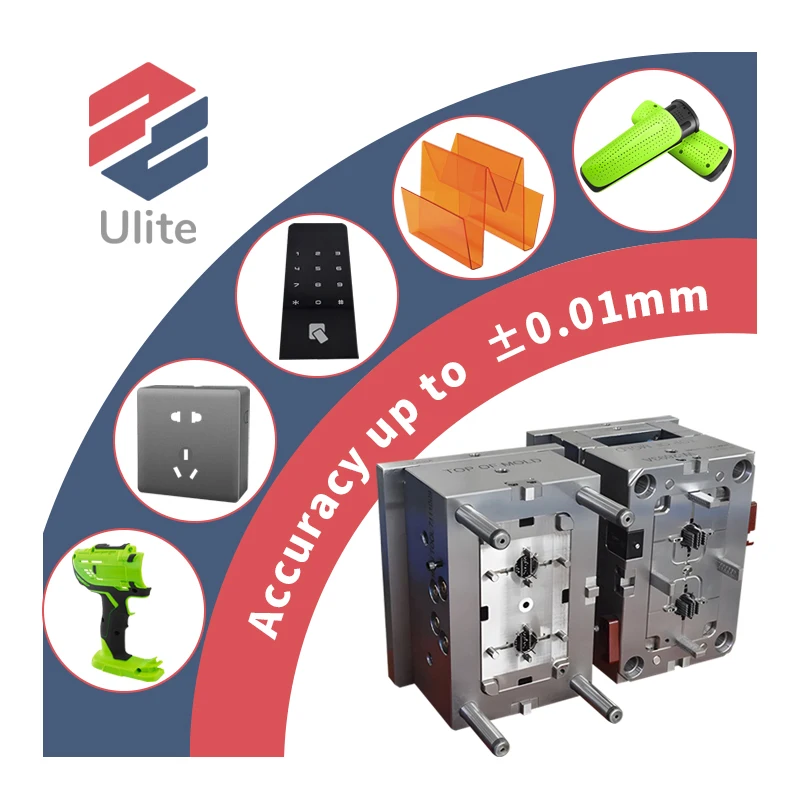

Высококачественная Пластиковая форма для литья под давлением

- Категория: >>>

- Поставщик: Shenzhen Ulite Precision Tech LimitedShenzhen Limited

Сохранить в закладки 1601094195502:

Описание и отзывы

Характеристики

Our Service

One-stop Injection Mold Manufacturing and Plastic Parts Production Assembly

1. Prepare pictures or 3D drawings,

2. Materials for the required products,

3. Quantity of each order and estimate the annual demand.

☞ >Click on Send Inquiry or Chat Now

We will quickly provide you with professional advice to save mold costs and maintain high quality.

Mold Description

Mould Details -

Name | Plastic Injecition Mold |

Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

Mould base | LKM, HASCO, DME or upon customer's requirement |

Type of plastic mold | 3-plate mold,2-plate mold |

Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

Runner | Hot/cold type |

Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

Mould life | 300,000-1,000,000 shots |

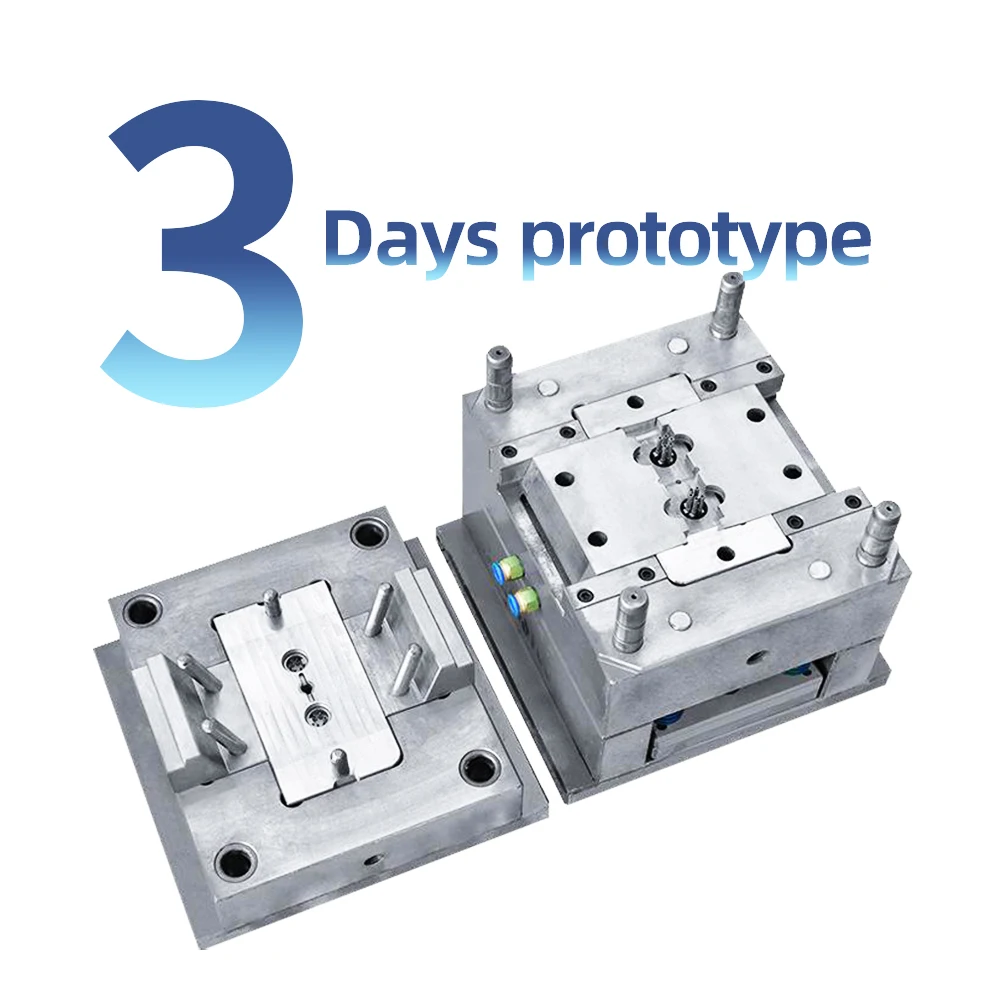

Lead time | 15-35days after deposit received |

Specification | Follow the 3D final drawing |

Packaging details | covering with film for anti rust and packed with wooden Case |

Parts Production Details -

Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

MOQ | 500 PCS |

Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

Shipping | By sea or by air as customer requirement |

Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

Typical Used For | Housings, containers, caps, fittings,including as below Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Plastic Applications

FAQ

Q1: What is injection molding?

A1: Injection molding is a widely used manufacturing process for producing plastic parts in large quantities. The process involves using an injection molding machine to melt the material, inject it into a mold under pressure, and produce components of the desired shape after cooling.

A2: Yes, We can provide one-stop service for mold making and plastic parts production and assembly

Q3: Is injection moulding expensive?

A3.: The start-up costs for a large run can be expensive, but the price for the project becomes better and better as you continue to produce. If you're looking at price per unit, plastic injection molding is one of the cheapest, most cost-efficient forms of

manufacturing.

Q4. What are the basics of molding?

A4. The basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold.

Q5. What is custom injection molding?

A5. Custom injection molding refers to the process of manufacturing plastic parts using injection molding technology, where the molds are specifically designed and fabricated to produce parts according to the unique requirements of a customer or project. In other words, custom injection molding involves the production of plastic components tailored to the specific needs, dimensions, and specifications provided by the customer.

Q6: What are the 4 stages of injection moulding?

A6: These four stages—clamping, injection, cooling, and ejection—are repeated for each cycle of the injection molding process, with the mold closing, injection of plastic, cooling, ejection of the part, and then reopening of the mold for the next cycle. Proper control and optimization of each stage are essential to ensure high-quality, consistent production of plastic parts.

Похожие товары

Большие силиконовые формы для эпоксидной смолы

127,15-152,58 ₽

Высококачественные небольшие партии акриловые литья под давлением Pp пластиковые детали для инъекций служат

1,28-12,72 ₽

Креативный дизайн треугольная позвоночная антиволинная Каменная форма шаблон для скрученного Королевского блока индивидуальная обработка

Изготовитель из Китая изготовленный на заказ пластиковый прессформа для впрыска ABS/PP/PC стальные формы

Oem дизайн мини-пластиковые литьевые детали для литья под давлением китайские производители

1,28-12,72 ₽

OEM 32 ампер на заказ латунный мужской и женский контактный пластиковый налитой разъем для зарядки производство

2 873,41-3 127,70 ₽

Литье под давлением пластиковая крышка для бутылок пресс-форма ABS PP PC CNC стальные резиновые материалы

546 710,17-635 709,50 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $