Высококачественный керамический фильтр из карбида кремния для резки под заказ фильтрации медного сплава огнеупорных материалов

- Категория: >>>

- Поставщик: Taiyuan Simis Investment Casting Co. Ltd.Taiyuan Ltd.

Сохранить в закладки 1601095876241:

Описание и отзывы

Характеристики

Monthly output of filters is 3 million pieces

Over 20 years of ceramic foam filters' experience Physical/thermal properties tested and certified with SGS

Company quality system conform ISO9001:2015

Product Description

Ceramic foam filters have revolutionized the metal casting industry, offering a highly effective and efficient solution for filtering molten metal. These filters are made from a unique ceramic material that offers exceptional porosity and strength, making them ideal for use in a wide range of metal casting applications.

The primary function of a ceramic foam filter is to remove impurities and inclusions from molten metal before it is poured into a mold. These impurities, such as oxides, slag, and gas bubbles, can cause defects and porosity in the final casting, affecting its mechanical properties and durability. By filtering out these contaminants, ceramic foam filters ensure that the resulting casting is cleaner and stronger.

The primary function of a ceramic foam filter is to remove impurities and inclusions from molten metal before it is poured into a mold. These impurities, such as oxides, slag, and gas bubbles, can cause defects and porosity in the final casting, affecting its mechanical properties and durability. By filtering out these contaminants, ceramic foam filters ensure that the resulting casting is cleaner and stronger.

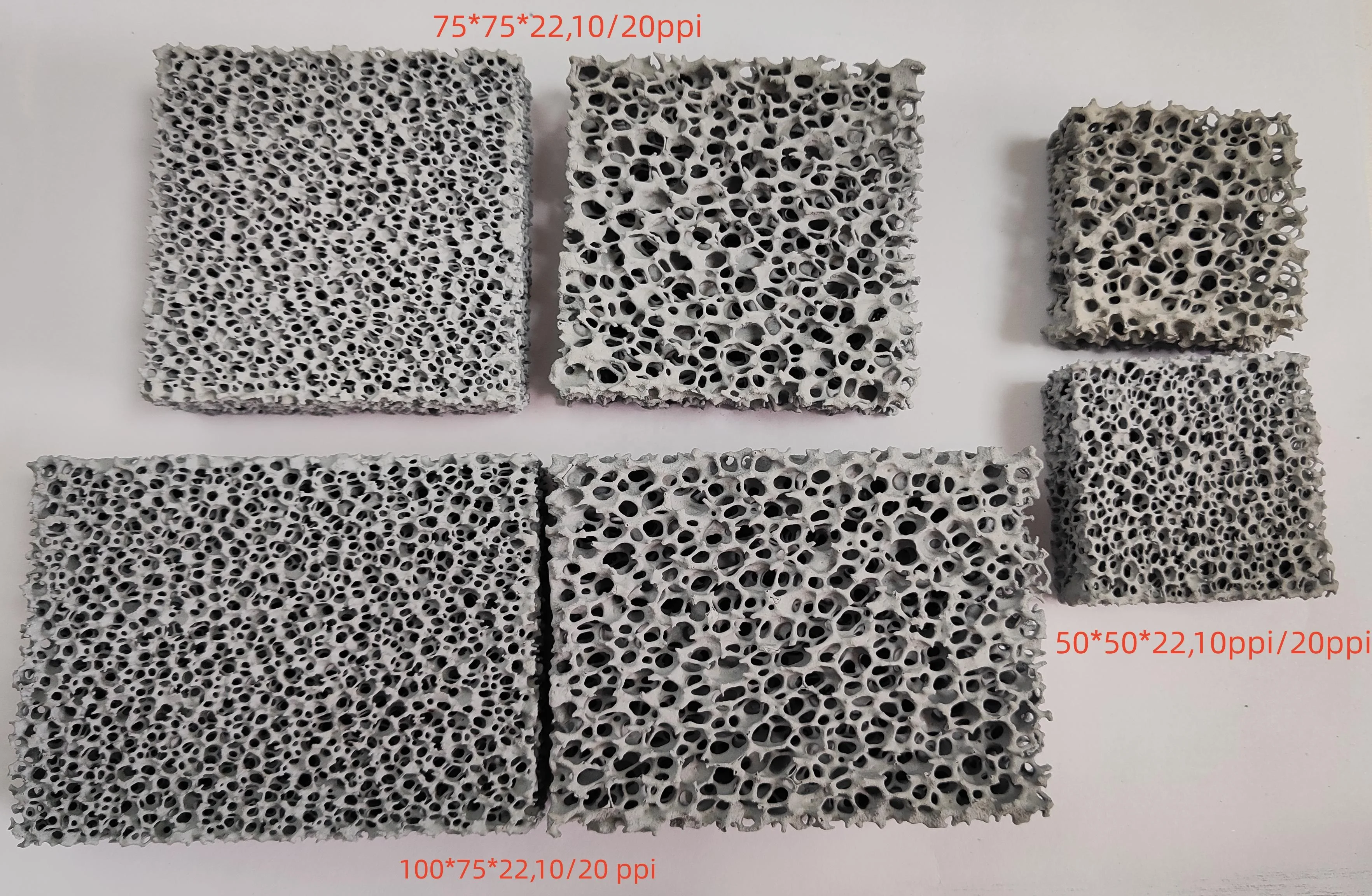

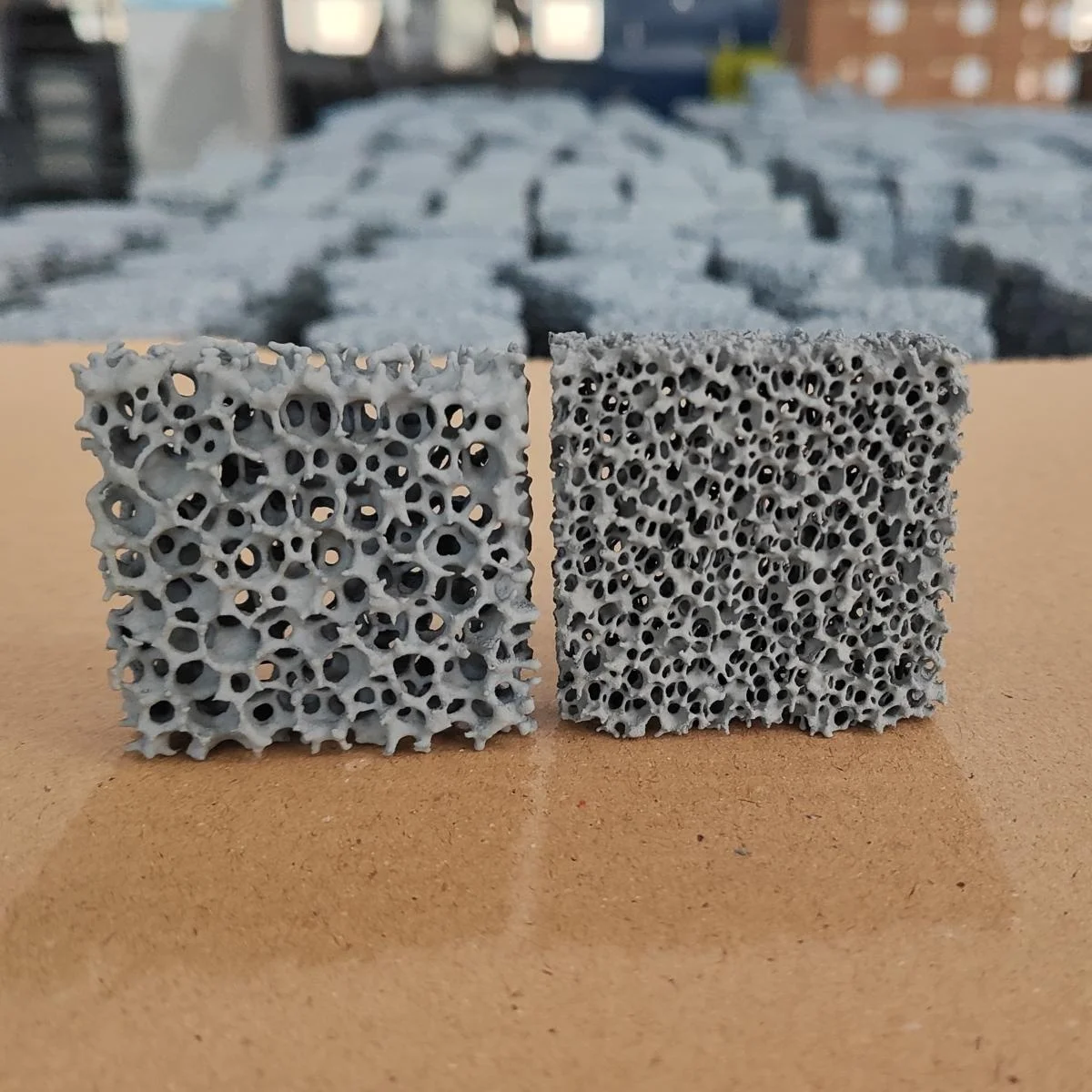

Silicon carbide ceramic foam filter (SIC ceramic foam filter)

* Color: Dark Grey

* PPI: 10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature: ≤1500℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>0.9Mpa

* Porosity: ≥80%

* Sample: Support

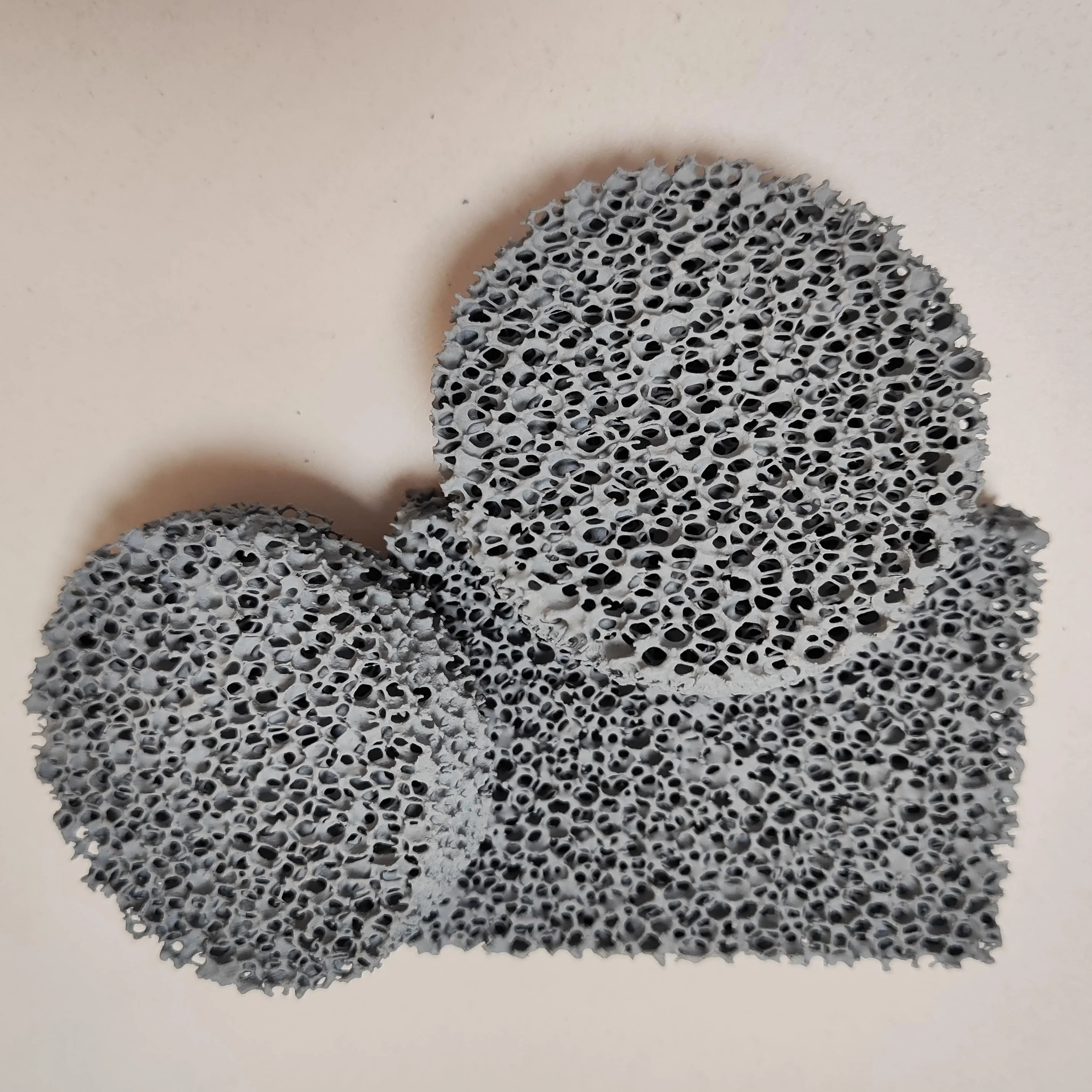

* Customization: Sizes and shapes

* Application:Ductile Cast Iron, Malleable Cast Iron, Gray iron, and other Cast Iron.

* PPI: 10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature: ≤1500℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>0.9Mpa

* Porosity: ≥80%

* Sample: Support

* Customization: Sizes and shapes

* Application:Ductile Cast Iron, Malleable Cast Iron, Gray iron, and other Cast Iron.

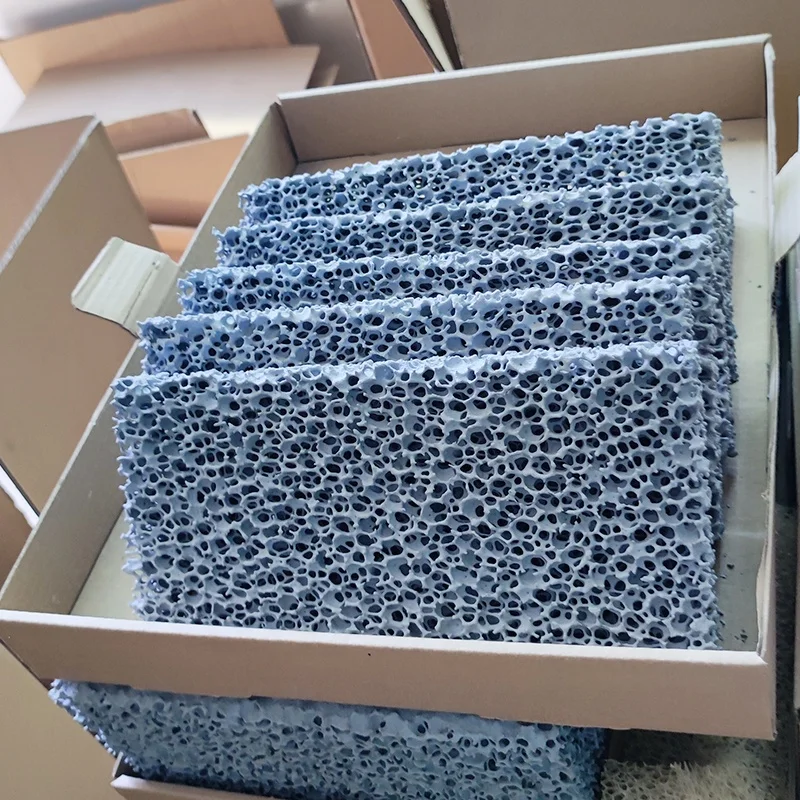

Alumina ceramic foam filter

* Color: White

* PPI: 10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature:≤1100℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>0.8Mpa

* Porosity: ≥80%

* Sample: Support

* Customization: Sizes and shapes

* Application:Aluminium Aluminium alloys and other Non-ferrous alloys.

* PPI: 10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature:≤1100℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>0.8Mpa

* Porosity: ≥80%

* Sample: Support

* Customization: Sizes and shapes

* Application:Aluminium Aluminium alloys and other Non-ferrous alloys.

* Color: Yellow

* PPI:10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature:≤1700℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>1.2Mpa

* Porosity: ≥80%

* Sample: Support

* Customization: Sizes and shapes

* Application:High melting point metal alloys like Steel, Alloy Steel, and Stainless Steel.

* PPI:10ppi, 20ppi, 30ppi, 40ppi, 50ppi

* Working Temperature:≤1700℃

* Thermal shock resistance(1100℃):≥2

* Compressive strength:>1.2Mpa

* Porosity: ≥80%

* Sample: Support

* Customization: Sizes and shapes

* Application:High melting point metal alloys like Steel, Alloy Steel, and Stainless Steel.

Product Paramenters

Size (mm) | 10ppi | 20ppi | 30ppi | ||||||||||

Capacity (kg) | Flow Rate (Kg/s) | Capacity (kg) | Flow Rate (kg/s) | Capacity (kg) | Flow Rate (kg/s) | ||||||||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | Grey Iron | Grey Iron | Grey Iron | Grey Iron | ||||||

40×40×15 | 64 | 32 | 4 | 3 | 50 | 3 | 42 | 2 | |||||

40×40×22 | 64 | 32 | 4 | 3 | 50 | 3 | 42 | 2 | |||||

50×30×22 | 60 | 30 | 4 | 3 | 47 | 3 | 40 | 2 | |||||

50×50×15 | 100 | 50 | 6 | 4 | 78 | 3.5 | 66 | 3 | |||||

50×50×22 | 100 | 50 | 6 | 4 | 78 | 3.5 | 66 | 3 | |||||

60×60×15 | 144 | 72 | 9 | 6 | 112 | 6 | 95 | 5 | |||||

75×50×22 | 150 | 75 | 9 | 6 | 116 | 6 | 99 | 5 | |||||

75×75×22 | 220 | 110 | 14 | 9 | 175 | 10 | 149 | 8 | |||||

100×50×22 | 200 | 100 | 12 | 8 | 155 | 9 | 133 | 7 | |||||

100×75×22 | 300 | 150 | 18 | 12 | 232 | 13 | 199 | 11 | |||||

100×100×22 | 400 | 200 | 24 | 16 | 310 | 18 | 265 | 15 | |||||

150×150×22 | 900 | 450 | 54 | 36 | 698 | 40 | 596 | 33 | |||||

200×200×40 | 1600 | 800 | 95 | 64 | 1240 | 58 | 1060 | 48 | |||||

Dia 40×22 | 40 | 20 | 3 | 2 | 39 | 2 | 33 | 2 | |||||

Dia 50×22 | 70 | 35 | 4.5 | 3 | 61 | 4 | 52 | 3 | |||||

Dia 60×22 | 100 | 50 | 6.5 | 4.2 | 88 | 5 | 75 | 4 | |||||

Dia 70×22 | 150 | 75 | 8.8 | 5.5 | 119 | 7 | 102 | 6 | |||||

Dia 75×22 | 170 | 88 | 10 | 6 | 137 | 8 | 117 | 6.5 | |||||

Dia 80×22 | 200 | 100 | 11 | 7.2 | 156 | 9 | 133 | 7 | |||||

Dia 90×22 | 240 | 120 | 14 | 9 | 197 | 11 | 169 | 9 | |||||

Dia 100×22 | 280 | 140 | 17 | 11 | 243 | 14 | 208 | 12 | |||||

Dia 125×22 | 400 | 220 | 24 | 16 | 380 | 22 | 325 | 18 | |||||

Dia 150×22 | 700 | 350 | 38 | 25 | 548 | 32 | 468 | 26 | |||||

Dia 200×40 | 1240 | 620 | 67 | 44 | 973 | 56 | 832 | 46 | |||||

Note:

Maximum size 300 MM ; Standard Thickness: 22 mm

Size and porosities:

* Different size can be made upon customer request.

* Length*width*height=(40-300)*(40-300)*(10-30)mm

* With round,square and rectangle shape.

* Tolerance:-1~0 mm

* Pore size: 10 PPI / 20 PPI / 30PPI

* Tolerance: ± 1-2PPI

Size and porosities:

* Different size can be made upon customer request.

* Length*width*height=(40-300)*(40-300)*(10-30)mm

* With round,square and rectangle shape.

* Tolerance:-1~0 mm

* Pore size: 10 PPI / 20 PPI / 30PPI

* Tolerance: ± 1-2PPI

Application

Installed in pouring cup

Commonly used in cast steel models to cover granular matter

Installed horizontally in

vertical runners

vertical runners

It is suitable for small molten steel parts , especially for casting systems where the vertical runner is located in the center of the mold and the horizontal runner is multi-branched

Installed vertically in horizontal runner

Improve the flow rate of molten metal and enhance the filling capacity. Since the molten metal directly impacts the filter, the impact resistance of the filter should be considered.

Installed horizontally in horizontal runner

Improve the flow rate of molten metal and enhance the filling capacity. Since the molten metal directly impacts the filter, the impact resistance of the filter should be considered.

Company Profile

Taiyuan Simis Investment Casting Co., Ltd

TaiyuanSIMIS Company was established in 2004 and has since expanded its business scope from Investment Casting to encompass the entire casting industry, including Sand Casting, Die Casting, and Forging Products.

In 2023, the company ventured into Refractories and Ceramic Foam Filters products closely associated with the casting industry.

In 2023, the company ventured into Refractories and Ceramic Foam Filters products closely associated with the casting industry.

Certifications

FAQ

1.Are you a factory? What is the monthly production volume?

We are a factory, specializing in the production of ceramic filters. The monthly output of filters is 3 million pieces.

2.How can I get quotation?

Please kindly send us the sizes and quantity requied, we will quote our best price in 24 hours. For special specifications, pl send the drawing. If you don't have the drawing, please kindly courier samples to us.

3. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce in stock, we can produce it according to customer's requirement. Please take note that the courier fee should be payed at destination.

4..What's the lead-time for samples and batch orders?

It is 7 working days for supplying samples. It is 10-15 working days for batch orders.

It is 7 working days for supplying samples. It is 10-15 working days for batch orders.

5.Can I visit you?

Sure. If you're sincere buyer and would like to visit our factory, please contact us to make an appointment.

Sure. If you're sincere buyer and would like to visit our factory, please contact us to make an appointment.

6.How long is your production cycle?

The production cycle will be determined according to the quantity of the order and the current production situation, usually the order production cycle is 15 days.

The production cycle will be determined according to the quantity of the order and the current production situation, usually the order production cycle is 15 days.

Похожие товары

4-полосная 90 градусов пластиковый коленчатый соединенитель по индивидуальному заказу высокое качество пластиковых продуктов трубки Разъемы

0,80-0,90 $

Запчасти для портативных машин капсулы кофе

Боулинг трофей на заказ награды Кубок приз Скульптура Подарки

Пользовательские пластиковые части ATM машина 3D печать считыватель карт для продажи

6,00-8,00 $

Прямая поставка с фабрики пластиковый полиэтиленовый гибкий гофрированный шланг выдувная формовочная трубка

0,20 $

Заводские пластиковые производители индивидуальные формы для продуктов гибкий шланг выхлопной трубы

0,20 $

Полипропиленовые волокна для изготовления услуг эффективно повышая трещину

1 494,90-1 494,92 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $