Профессиональная полностью автоматическая линия для консервирования консервов и фруктов

- Категория: >>>

- Поставщик: Shanghai Genyond Technology Co. Ltd.Shanghai Ltd.

Сохранить в закладки 1601102492229:

Описание и отзывы

Характеристики

Yellow Peach production line equipment is our leading product, over the years through dozens of customers to use, has accumulated rich experience, equipment performance and use effect are in the level, and the customer's affirmation and praise. The main equipment of a yellow peach can production line, the main special equipment are: Peach cutting machine, fruit lifting machine, tunnel waterfall type leaching machine, peeling machine, bubble neutralization elevator, pre-cooking machine, cooling trough, peach petal grading machine, slicing machine, slicing machine, chip removal machine, etc. The main general equipment are: empty tank washing machine, sugar pot, storage pot, milk pump, double filters, inkjet conveyor belt, soup conveyor, sealing machine (purchased) , pasteurization low temperature machine, can cleaning machine, labeling machine, conveyor belt for line. The line is made of high-quality stainless steel material. It is transported by flat belt, stainless steel mesh belt, roller, belt scraper mesh belt, chain bucket and flow channel, it not only has the advantages of good half-cutting effect, high automatic turn-over effect, even and moderate leaching alkali, clean peeling, neutralization, good pre-cooking and cooling effect, etc. , it also has the advantages of high output, less material loss, continuous automatic production, automatic temperature control, sanitation and low energy consumption. Three Yellow Peach can production line model, our company can provide 2-3 tons/hour, 3-4 tons/hour, 4-5 tons/hour, 5-6 tons/hour four kinds of production capacity of canned peach production line equipment for customers to choose.

Description

1. Processing raw material 0.5-20 tons per hour.

2 Canned fruit project, including research and design, manufacture, installation, commissioning, training etc.

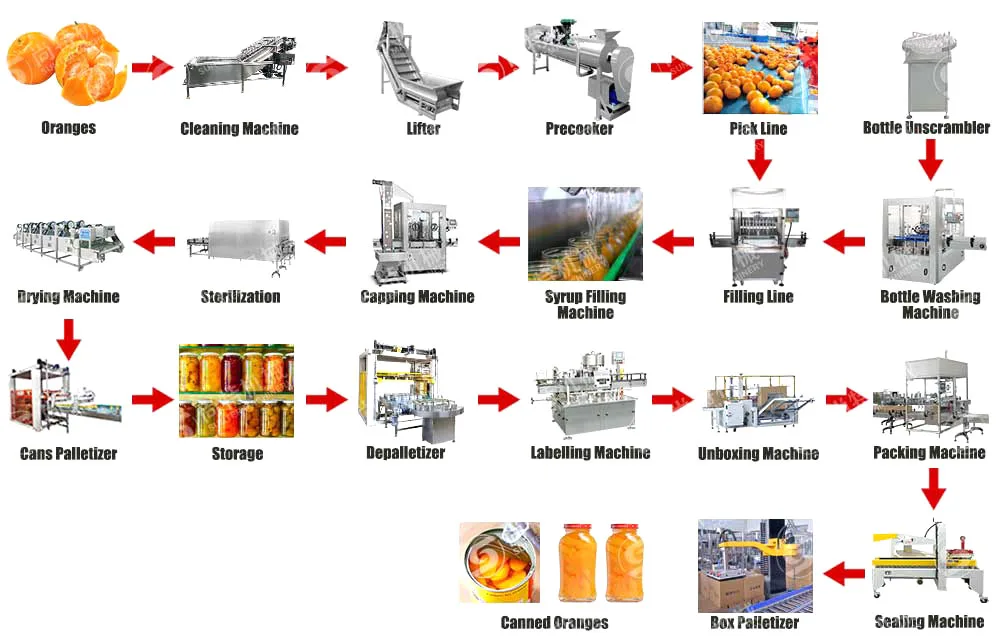

3. Supply whole set of machines, Including elevator, Cleaning machine, Sorting machine, Pitting machine, Cutting machine Conveyor, Filling, Sterilization, etc

4. High Automatic for all the line, PLC control.

5. We can design as the client workshop and technics demand.

6. High quality of equipment, ISO and CE certification etc .

capping→sterilization→drying→labeling and date printing→can carton packing In addition, if your capacity is bigger, you also need can washing machine,

you also can process it by manual. Because there maybe iron particle into the can.

| Capacity | 100-10000kg per hour customized. |

Похожие товары

Машина для производства льда и машина

Коммерческая машина для производства льда домашнего использования

Машина для упаковки овощей

Лидер продаж производитель Takoyaki для домашнего использования высокопроизводительная стальная кастрюля приготовления газа сертифицированные закуски на основе яиц мороженое в розницу

Вакуумная упаковочная машина из нержавеющей стали

Новый Дизайн Мыла Лапши производственной линии корейский рамен сухой лапши делая машину

Машина для сортировки чеснока

Новые поступления

Новинки товаров от производителей по оптовым ценам