Высокоточный 3 осевой процесс с ЧПУ заводская цена нержавеющая сталь алюминиевый 7075 6061 T6 5083 2017 мкм.

- Категория: >>>

- Поставщик: Dongguan Zhuotai Technology Co. Ltd.

Сохранить в закладки 1601110460097:

Описание и отзывы

Характеристики

Materials and processing | ||

Materials | aluminum、Copper, brass, bronze, red copper, special copper、Stainless steel (303, 304, 316)、Carbon Steel、Steel、Martensitic stainless steel (with chromium corrosion resistance) 414, 416, 420, 431, 440C、alloy、zinc alloy、Plastic PEEK、Engineering plastics | |

Processing method | CNC Machining、turning、milling、drilling、tapping、forging、milling-turning combined processing、die casting、sheet metal、powder metallurgy、Grinding | |

Post-Processing Techniques | Anodizing、electroplating、painting、sandblasting、baking paint、conductive electroplating、burnish、polishing、polishing、passivation、 electropolishing、heat treatment、powder spraying、 | |

Processing industry | Automation equipment parts, mechanical equipment parts, drone parts, automobile parts, watch strap parts, electrical equipment parts, 3C electronic products parts,Aerospace parts | |

Drawing Format | IGS, STP, X_T, DXF, DWG, Pro/E, PDF, PNG, JPG | |

Logistics mode | DHL, FedEx, EMS, UPS, or customer request | |

packaging | Household paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements | |

Specification

item | value |

CNC Machining or Not | Cnc Machining |

Type | DRILLING, Milling, Turning, Wire EDM, Rapid Prototyping |

Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, plastic |

Micro Machining or Not | Micro Machining |

Place of Origin | China |

province | Guangdong |

Brand Name | ZT |

Keyword | CNC Macining Parts |

Product name | Custom Precision Cnc Machining Parts |

Process | CNC Turning Milling |

OEM/ODM | OEM ODM Non-standard Processing |

Our Service | OEM ODM Customers' Drawing |

Packing | Plastic Bag+carton+pallet |

Logo | Accept Custom Logo |

Machines | CNC Turning Machining CNC Milling Machining |

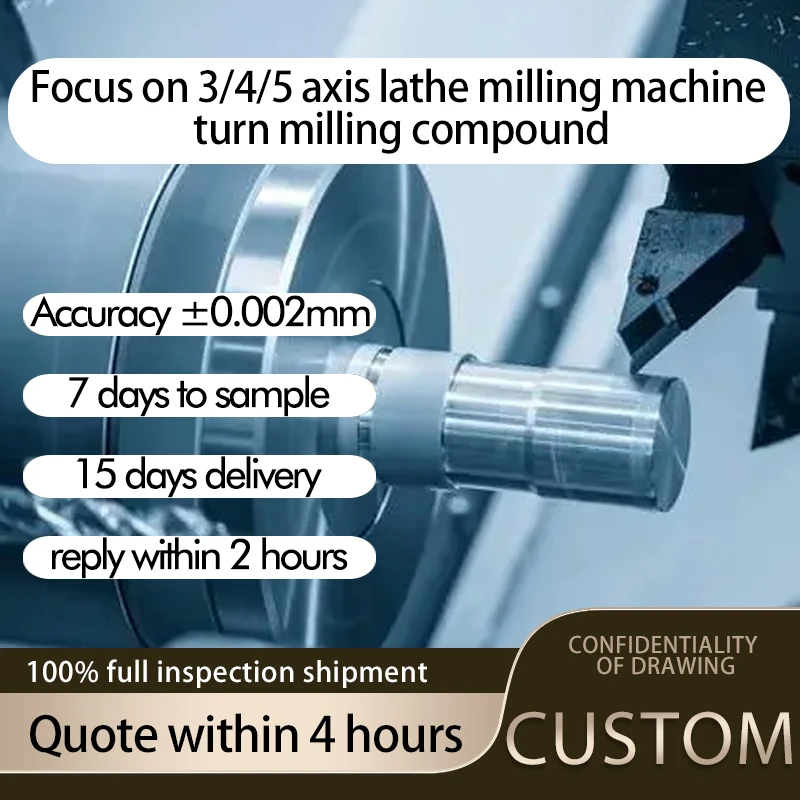

Processing Type | 3/4/5 Axis CNC Machining |

Sample | Within 7 Days |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Zhuotai Technology is based in Dongguan Changan, the capital of the world's factories and hardware molds, and is committed to serving the majority of factories and solutions in need of hardware parts; Benefit from favorable geographical location, complete supporting system and customer-oriented, quality-winning management and production philosophy, by the majority of customers support and trust.

Zhuotai Technology has always been committed to better product quality, faster reaction speed, and closer cooperation; Help customers from project development, to prototyping, to mass production, and finally iterative production. Achieve win-win situation with quality and service.

Our comprehensive plant area of 1500 square meters, with CNC lathes, automatic lathes, CNC machining centers and other mechanical equipment more than 50 sets, the downstream process with more than 30 factories, can meet the vast majority of customer product requirements and production capacity.

Zhuotai Technology has always been committed to better product quality, faster reaction speed, and closer cooperation; Help customers from project development, to prototyping, to mass production, and finally iterative production. Achieve win-win situation with quality and service.

Our comprehensive plant area of 1500 square meters, with CNC lathes, automatic lathes, CNC machining centers and other mechanical equipment more than 50 sets, the downstream process with more than 30 factories, can meet the vast majority of customer product requirements and production capacity.

FAQ

Q1: Can you customize products based on our design drawings?

A1: Certainly, we are a professional metal manufacturing factory equipped with an experienced engineering team that specializes in producing customized products according to customer drawings.

Q2: Will my design drawings be kept confidential once you receive them?

A2: Absolutely, we prioritize the security of your design and will not disclose it to any third party without obtaining your

permission. We can even sign a Non-Disclosure Agreement (NDA) before you share the drawings with us.

Q3: Does your company have the capability for mass production?

A3: Our company possesses independent production facilities and is well-equipped for large-scale production. With our

comprehensive one-stop service, including 70 CNC machine tools, 40 injection molding machines, and our own mold workshop, we ensure efficient mass production.

Q4: How do you handle surface treatment issues?

A4: To guarantee batch color consistency, we conduct sample color identification and dispensing. Additionally, we emphasize manual inspection to avoid any defective products related to surface treatment problems.

Q5: What measures are taken to prevent quality issues during mass orders?

A5: We proactively strengthen prevention and inspection throughout the entire production process. By focusing on key quality control points during important processes and conducting continuous inspections at every stage of production and processing, we effectively minimize potential quality problems in mass orders.

Q6:what can you buy from us?

A6:cnc machining,cnc turning parts,Hardware parts processing,cnc milling parts,casting parts

A1: Certainly, we are a professional metal manufacturing factory equipped with an experienced engineering team that specializes in producing customized products according to customer drawings.

Q2: Will my design drawings be kept confidential once you receive them?

A2: Absolutely, we prioritize the security of your design and will not disclose it to any third party without obtaining your

permission. We can even sign a Non-Disclosure Agreement (NDA) before you share the drawings with us.

Q3: Does your company have the capability for mass production?

A3: Our company possesses independent production facilities and is well-equipped for large-scale production. With our

comprehensive one-stop service, including 70 CNC machine tools, 40 injection molding machines, and our own mold workshop, we ensure efficient mass production.

Q4: How do you handle surface treatment issues?

A4: To guarantee batch color consistency, we conduct sample color identification and dispensing. Additionally, we emphasize manual inspection to avoid any defective products related to surface treatment problems.

Q5: What measures are taken to prevent quality issues during mass orders?

A5: We proactively strengthen prevention and inspection throughout the entire production process. By focusing on key quality control points during important processes and conducting continuous inspections at every stage of production and processing, we effectively minimize potential quality problems in mass orders.

Q6:what can you buy from us?

A6:cnc machining,cnc turning parts,Hardware parts processing,cnc milling parts,casting parts

Похожие товары

Прецизионная 5-осевая металлическая 3D-печать латунь алюминий нержавеющая сталь фрезерная деталь обрабатывающий центр с ЧПУ

110,22 ₽ - 219,33 ₽

TC4 прецизионная обработка из титанового сплава алюминиевая токарная фрезерная токарный станок с ЧПУ деталей

109,11 ₽ - 1 101,02 ₽

Линейный графитовый медный подшипник промежуточного круга удлинитель фланца LMFC6 8 10 12 16 20 25L

22 042,26 ₽

CNC processing The UAV carbon fiber composite frame

Высокое качество CNC резки на заказ детали из углеродного волокна непосредственно завод в Китае

Шпиндель 55 кВт с водяным охлаждением 1320 4 новичка Annycubic Mono 2K 3D Запчасти для принтера Cnc механическая обработка титановый топливный фильтр

31,97 ₽ - 109,11 ₽

304 автозапчасти из нержавеющей стали с ЧПУ

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $