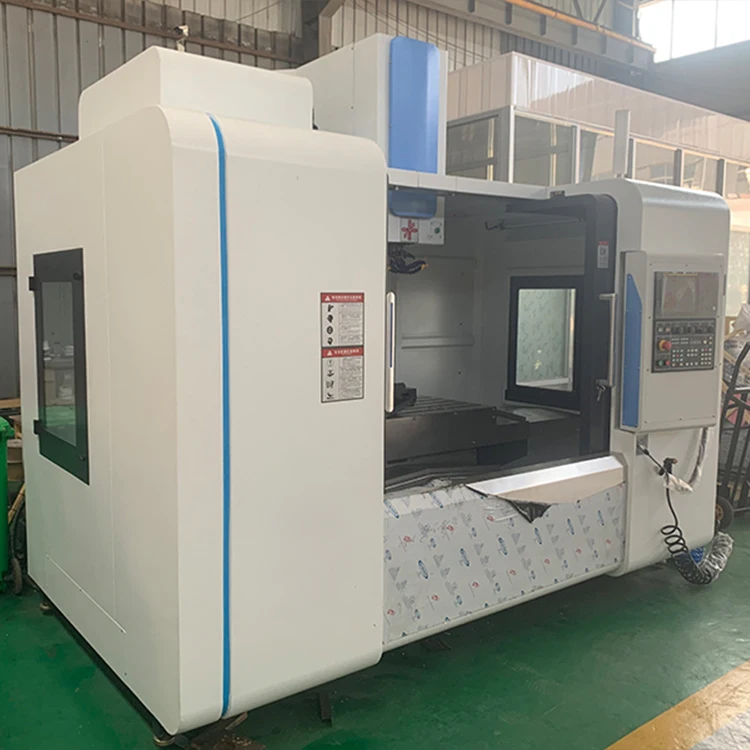

ЧПУ фрезерный станок VMC1580 4 осевой обрабатывающий центр

- Категория: >>>

- Поставщик: Henan rowdai Machinery Equipment Co. LTD

Сохранить в закладки 1601110806662:

Описание и отзывы

Характеристики

Product Description

CNC Vertical Machining Center

This product X, Y, Z three-axis servo direct control semi-closed vertical machining center, three-axis linear ball guide, guide rail load, span wide, high precision, suitable for heavy load,compact structure and size reasonable, the spindle is servo motor driven by the timing belt. It can realize the clamping of various parts such as discs, boards, housings, cams, and molds at one time. It can be used for drilling, milling, boring, expanding, reaming, rigid tapping, etc. The production of medium and small batch products can satisfy the processing of complex and high-precision parts.

Product Advantages

Product advantages

* CNC milling machine have stronger bearing capacity, three direction guide for quenching hardened rail, guide rail, wide span is big, reasonable, compact structure and dimension spindle for servo motor through the synchronous belt drive.Can be milling and drilling, reaming and reaming and other functions, can be achieved to the plate class, plate class, shells, mold and other complex, high precision parts processing, applicable to many varieties, in a variety of small parts of the plane, inclined plane,groove slots and other process, is the mechanical processing and mould manufacturing ideal processing equipment, canadapt from roughing to finishing processing requirements, has the characteristics of high precision, high efficiency, is widely used in aerospace, military industry, mould, automobile, internal combustion engines, textile machinery, chemical machinery processing, oil, electronics and other industries.

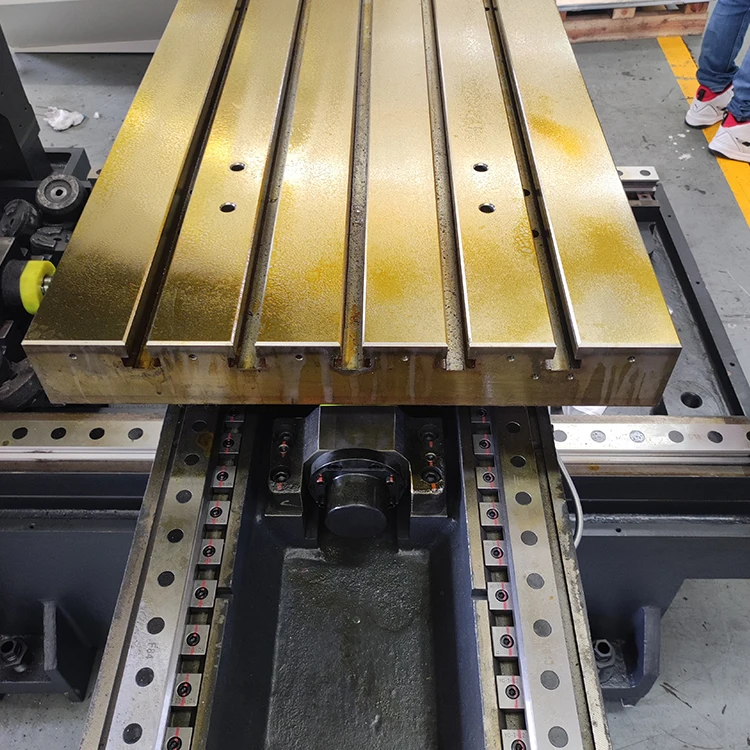

* The three-axis adopts rectangular guide rails with strong rigidity, which can withstand heavy cutting, the worktable is

precisely ground, and all non-slidable surfaces of the guide rails are subjected to ultra-high frequency quenching treatment, which greatly enhances the surface hardness; the sliding surfaces of the guide rails are inlaid with imported guide rails. Increase the wear resistance of the guide rail and improve the service life of the machine tool.

* The three-axis transmission adopts high-precision, high-rigidity ball screw pair, and is installed with Japanese NSK

high-precision ball screw special bearings to ensure positioning accuracy and repeat positioning accuracy.

* The three axes all use domestic absolute value servo motors and spindle motors, which provide strong power and ensure the feeding accuracy under the strong bearing capacity.

* All three shafts are directly connected, and high-precision couplings are used to ensure the transmission bearing capacity of each shaft.

* Adopting the P3 grade high rigidity and high precision spindle of the internationally renowned Taiwan brand ensures the

advantages of high reliability, long service life, low noise, low vibration and high precision of the spindle.

* Each axis adopts a sealed machine tool guide rail protection cover, which effectively protects the guide rail and the lead

screw and prolongs its service life.

* High-efficiency dual automatic lubrication system: The guide rail is lubricated by a volume distributor with oil injection, and the oil required for the guide rail is quantitatively supplied to reduce the waste of lubricating oil and avoid environmental pollution.

* The wiring in the electrical cabinet conforms to the national electrical safety regulations to ensure that the control system is free from external interference during operation. The heat exchanger is used to quickly discharge the hot air in the electrical box and maintain the constant temperature in the box, so that the control system can run stably for a long time.

* High-precision pitch compensation, each drive shaft is compensated by a high-precision laser measuring instrument, which makes the positioning accuracy of each axis more accurate, and is more suitable for machining high-precision parts and mold manufacturing.

* The external protection adopts three-dimensional semi-protection, and all materials are standard steel plates of 2mm, which ensures the safety of the machine tool.

* The three-axis adopts rectangular guide rails with strong rigidity, which can withstand heavy cutting, the worktable is

precisely ground, and all non-slidable surfaces of the guide rails are subjected to ultra-high frequency quenching treatment, which greatly enhances the surface hardness; the sliding surfaces of the guide rails are inlaid with imported guide rails. Increase the wear resistance of the guide rail and improve the service life of the machine tool.

* The three-axis transmission adopts high-precision, high-rigidity ball screw pair, and is installed with Japanese NSK

high-precision ball screw special bearings to ensure positioning accuracy and repeat positioning accuracy.

* The three axes all use domestic absolute value servo motors and spindle motors, which provide strong power and ensure the feeding accuracy under the strong bearing capacity.

* All three shafts are directly connected, and high-precision couplings are used to ensure the transmission bearing capacity of each shaft.

* Adopting the P3 grade high rigidity and high precision spindle of the internationally renowned Taiwan brand ensures the

advantages of high reliability, long service life, low noise, low vibration and high precision of the spindle.

* Each axis adopts a sealed machine tool guide rail protection cover, which effectively protects the guide rail and the lead

screw and prolongs its service life.

* High-efficiency dual automatic lubrication system: The guide rail is lubricated by a volume distributor with oil injection, and the oil required for the guide rail is quantitatively supplied to reduce the waste of lubricating oil and avoid environmental pollution.

* The wiring in the electrical cabinet conforms to the national electrical safety regulations to ensure that the control system is free from external interference during operation. The heat exchanger is used to quickly discharge the hot air in the electrical box and maintain the constant temperature in the box, so that the control system can run stably for a long time.

* High-precision pitch compensation, each drive shaft is compensated by a high-precision laser measuring instrument, which makes the positioning accuracy of each axis more accurate, and is more suitable for machining high-precision parts and mold manufacturing.

* The external protection adopts three-dimensional semi-protection, and all materials are standard steel plates of 2mm, which ensures the safety of the machine tool.

Product Paramenters

Specifications | Units | VMC650 | VMC850 |

Table size | mm | 800x400 | 1000x500 |

X axis travel | mm | 650 | 800 |

Y axis travel | mm | 400 | 500 |

Z axis travel | mm | 500 | 500 |

Max. worktable load | kg | 400 | 500 |

T slot(number-width-pitch) | 3-18x125 | 5-18x125 | |

Max. spindle speed | rpm | 8000(Optional:10000 ) | 8000(Optional:10000 ) |

Spindle taper | mm | BT40 | BT40 |

Main motor power | kw | 5.5 | 7.5 |

X/Y/Z rapid traverse speed | m/min | 24/24/20 (Optional:48/48/36 ) | 24/24/20(Optional:48/48/36 ) |

Cutting feed speed | mm/min | 1-10000 | 1-8000 |

Guide rail type | Linear rail | Linear rail | |

Distance from spindle axis to column surface | mm | 469 | 526 |

Distance between spindle nose and worktable surface | mm | 100-600 | 90-640 |

Positioning accuracy | mm | ±0.0075 | ±0.0075 |

Repeat positioning accuracy | mm | ±0.005 | ±0.005 |

Tool magazine | 16 Armless(Optional: Arm 24 ) | Arm 24 | |

Max. tool diameter | mm | φ90 | φ78 (Adjacent)/ φ120(Apart) |

Max.tool weight | kg | 8 | 8 |

Machine weight | kg | 4000 | 4000 |

Overall dimension | mm | 2400x2000x2550 | 2600×2000×2200 |

Different Models

Product Details

The high-precision grinding and processing

master machine ensures the flatness of the worktable, and the processing technology of tempering and high-frequency quenching

ensures the rigidity of the worktable.

master machine ensures the flatness of the worktable, and the processing technology of tempering and high-frequency quenching

ensures the rigidity of the worktable.

Standard configuration GSK

Optional:KND/Siemens/Fanuc

Optional:KND/Siemens/Fanuc

maximum speed is 8000-10000rpm.(12000rpm optional)

24T disc Magazine Tool,Taiwan OKADA

Taiwan HIWIN high-rigidity roller linear rolling guide, which has good bearing performance.

The X, Y and Z coordinate axes of the machine

tool adopt Taiwan HIWIN precision ball screws, and all three axes adopt the motor direct-connected structure, reaching 24m/min,

which shortens the processing time and improves the processing efficiency.

tool adopt Taiwan HIWIN precision ball screws, and all three axes adopt the motor direct-connected structure, reaching 24m/min,

which shortens the processing time and improves the processing efficiency.

The 4th Axis

Optional

Optional

Automatic Chip Removal System

Optional

Vertical Machining Center Features:

1 | CNC System: GSK/Syntec/Siemens/Fanuc/Mitsubishi |

2 | 24 Arm Tool Magazine |

3 | Taiwan Spindle |

4 | Japan NSK bearing |

5 | Taiwan HIWIN Line rail |

6 | Taiwan ball screw and locking nut |

7 | Germany R+W coupling |

8 | Taiwan Pressure Cylinder |

9 | Automatic lubrication system |

Workshop

Packing & Delivery

FAQ

1. What is your advance?

(1)We have ourselves factory. We accept the order if you want to customize products or design the product.

(2)Professional website platform and one-to-one online service.

(3)Various products in low MOQ and competitive prices.

(4)We have a strong R&D team and now we have more than 50 patents products.

(5)80% exporting products have been sold to Europe, America and Japan, high quality.

2. What's the minimum order quantity?

One set is acceptable.

3. How about the payment Term?

We accept T/T,Western Union,LC.

4. What's your port?

Shanghai, Ningbo, Qingdao, Shenzhen.

5. Can we use our own shipping agent?

Yes, you can. We had cooperated with many forwarders.If you need,we can recommend some forwarders to you and you can compare the price and the service.

6. Can we use our own LOGO or design for sticker?

(1)We have ourselves factory. We accept the order if you want to customize products or design the product.

(2)Professional website platform and one-to-one online service.

(3)Various products in low MOQ and competitive prices.

(4)We have a strong R&D team and now we have more than 50 patents products.

(5)80% exporting products have been sold to Europe, America and Japan, high quality.

2. What's the minimum order quantity?

One set is acceptable.

3. How about the payment Term?

We accept T/T,Western Union,LC.

4. What's your port?

Shanghai, Ningbo, Qingdao, Shenzhen.

5. Can we use our own shipping agent?

Yes, you can. We had cooperated with many forwarders.If you need,we can recommend some forwarders to you and you can compare the price and the service.

6. Can we use our own LOGO or design for sticker?

Yes, you just need to sent us more details about the LOGO or sticker.

7. How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock,it is according to quantity.

7. How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock,it is according to quantity.

8. Do you provide samples? Is it free or extra ?

A: Yes, we could offer the sample for cheaper price!

A: Yes, we could offer the sample for cheaper price!

If interested,pls contact me directly!

Ella

ella@rowdai.com

+86 166 03834131

Ella

ella@rowdai.com

+86 166 03834131

Похожие товары

Мягкая Обложка с принтом на заказ, художественная отделка поверхности, рабочая бумага, рекламная брошюра, флаер, печать листовок, печать и буклет

0,50 $ - 1,80 $

Верхняя ручка для камеры, ручка, установочный винт, монитор, микрофон, установка, Холодный башмак для Nikon Canon Sony DSLR камера, ручка-клетка

28 мм модельное блестящее конвеерная машина для розлива газированных безалкогольных напитков пластиковые бутылки с водой стеклянная бутылка нить крышками/28 мм шеи непрерывной резьбой шапки

0,01 $ - 0,02 $

Четырехконтактный двухступенчатый переключатель судового типа Прямая поставка от

0,13 $ - 0,15 $

Индуктор SMD с проволочной намоткой 4018 10uH 20% SWPA4018S100MT

0,33 $ - 0,50 $

Высококачественный новый вилочный погрузчик 1,5 тонны дуплексный дизельный вилочный погрузчик

2 580,00 $ - 4 940,00 $

Оптический Кливер Sumitomo 2 pin способ Мужской Женский Разъем Авто противотуманных фар лампа Разъем радара заднего хода разъем для Baojun Toyota RAV4 6189-0031

0,20 $ - 0,30 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $