Гибочный станок для гибочного станка

- Категория: >>>

- Поставщик: Maanshan Wila CNC Machine Tools Co. Ltd.Maanshan Ltd.

Сохранить в закладки 1601113829080:

Описание и отзывы

Характеристики

Product Overview

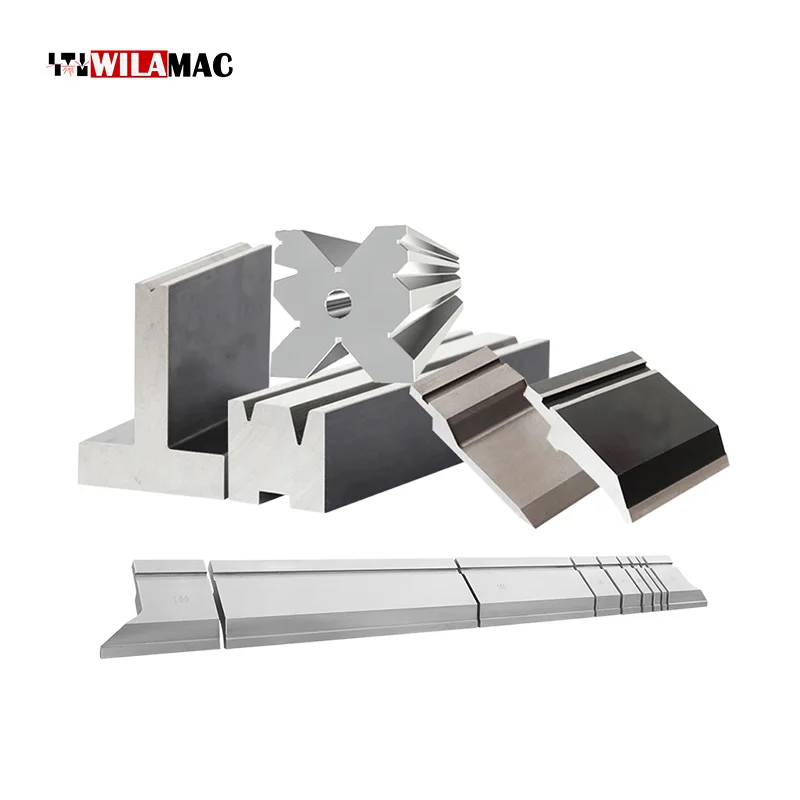

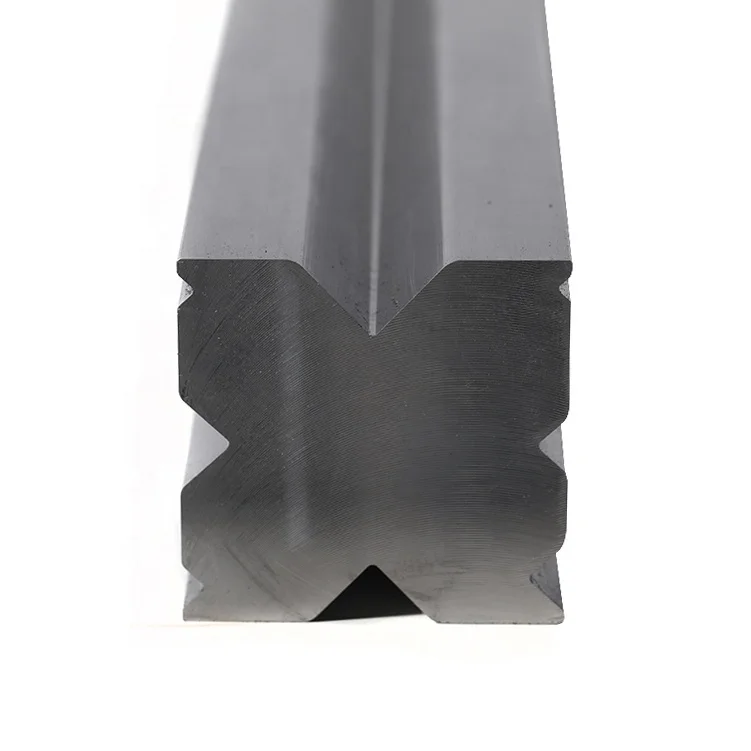

high quality hydraulic press brake punch and die

The press brake tools of CNC bending machine has a wide application with different requirement. It is widely used in sheet metalbendings, such as construction, Kitchenware, automobile, aircraft manufacturing, light industry, shipbuilding, container,elevator, railway vehicles, and other industries.

Mains Features of the Product

* We are one of Chinese earliest professional manufacturers in this line

* Manufacturing acording to your special drawings

* Mold material is 42CrMo, quench hardened HRC 47.Extremely high precision and bending performance.Super bearing capacity and the best durability.

* Fifteen years experience and We have our own mold-making workshops.We make steel by ourselves, so the materials are various

* Specializes in manufacturing all kinds of industrial cutting tools, including press brake tooling, metal shearing blade, progress stamping dies, hydraulic deep drawings, slitting knives, shearing blades, paper cutting, rubber cutting knife, ink knife, wear-resistant furnace sliders, tungsten inlaid blades, rollers, etc

* Each technical index reaches the international standard.

We have an experienced team of engineers in India who can provide after-sales service.

Good reputation and responsible after - sales are our company's philosophy.

FEATURES AT A GLANCE

Alloy tempered steel with high strength

Strong toughness good

Small orders accepted

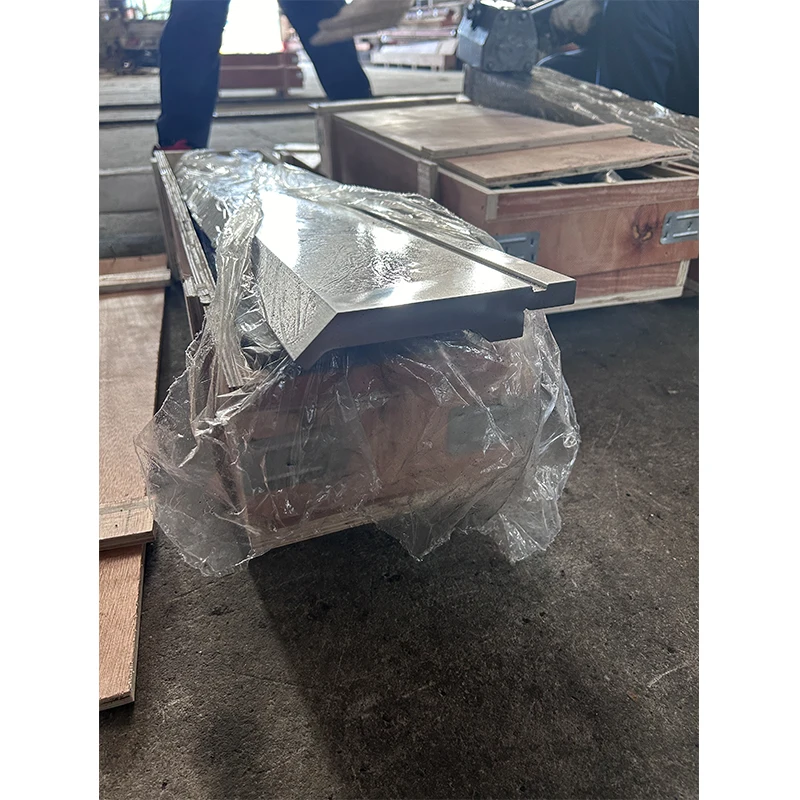

Fast delivery and safety package

OEM and ODM service accepted

Variety is complete, can be customized

Competitive price

Passed the ISO9001 quality certification in 2001

PRODUCT SPECIFICATIONS

Material | 42CrMo=SCM440=42CrMo4=4140 |

General Hardness | 47+/-2HRC |

Surface Tolerance | 0.02mm |

Supplying Brands. | amada, tokyo, trumpf, LVD, YSD, beyeler, etc |

OEM & ODM Service | Tavailable |

Operatinal Progress:

Steel-making— Blanking— Forging Steel— Rough Progressing— Heat Treatment— Finishing— Testing

We manufacture industrial knives up to 6500mm(255.905 inches) in length for cutting sheet steel etc.

Steel-making by medium frequency furnaces

Steel-making by medium frequency furnacesSteel-making begins from the start of this century in WILACNC Company. So the company can meet special requirements for materials. In order to guarantee the quality, WILACNC company imported spectrometer from Germany and is equipped with various tester, such as tensile tester, impact testing machine, metallography analyzer and so on.

Electro slag remelting

The largest ingot can reach 3 tons in WILACNC company. The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects. The segregation of the ingot(called macro-segregations) are substantially eliminated and the segregations of crystals(called micro-segregations)are significantly reduced. The ESR remelted material improve following mechanical characteristics:

. Improved toughness due to increased homogeneity and isotropy

. Improved creep resistance properties

. Best fatigue strength and tenacity properties as well as outstanding tensile strength

. Improved purity

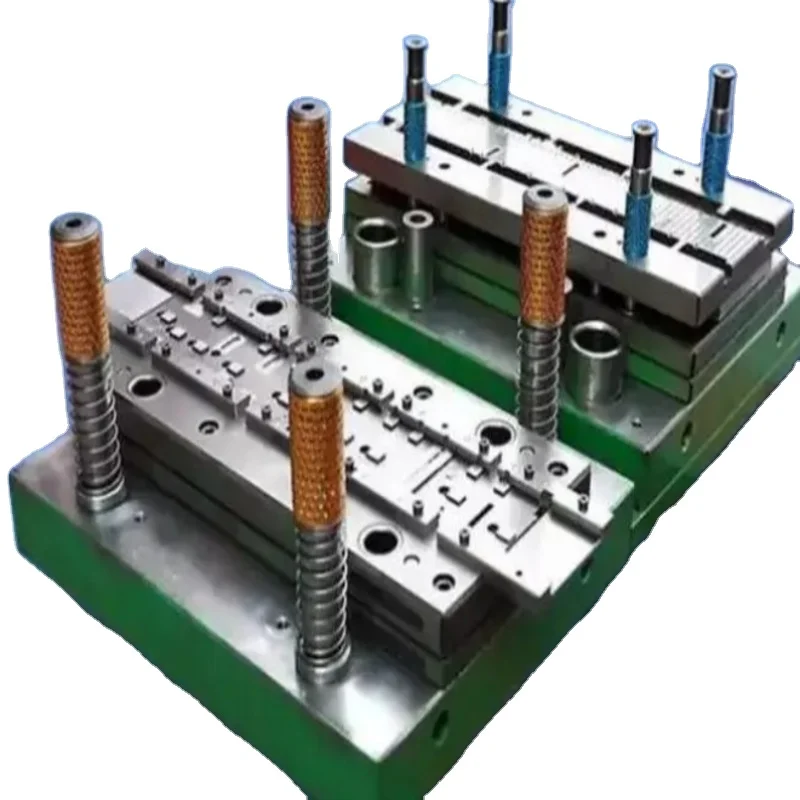

Forging steel

Forging process can trance to 1990s in WILACNC company. The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work here. After forging the inside microstructure becomes much closer and the metal grain size becomes much smaller. It can elevate the characteristics and quality of the knife ensuring a longer life of the knife.

Rough processing

No less than 40 sets of processing equipment in the rough processing workshop of WILACNC company, including lathe, milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Heat treatment

WILACNC company has independent workshop for heat treatment. Couples of skilled technicians work here. Actually, all blades(thickness less than100MM)can be fully hardened. Thus, the blades can be used after repairing until the size reached the minimum design dimension.

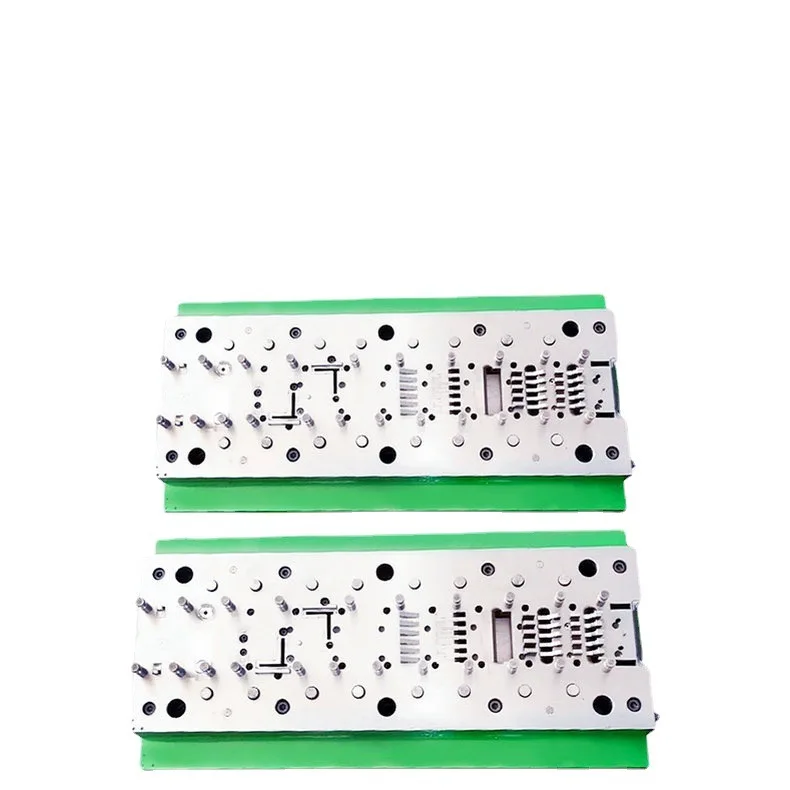

Finishing processing

WILACNC company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5800mm in length and slitting knives with 1400mm in outside diameter.

Testing

Various testers are put to use for testing its products in our laboratory. They are including tensile tester impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, hardness tester, caliper rule, microcalliper, etc. Testing is carried out after each step. And every products has a unique tracking number. Thus it is easy to trace back anytime.

. Improved creep resistance properties

. Best fatigue strength and tenacity properties as well as outstanding tensile strength

. Improved purity

Forging steel

Forging process can trance to 1990s in WILACNC company. The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work here. After forging the inside microstructure becomes much closer and the metal grain size becomes much smaller. It can elevate the characteristics and quality of the knife ensuring a longer life of the knife.

Rough processing

No less than 40 sets of processing equipment in the rough processing workshop of WILACNC company, including lathe, milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Heat treatment

WILACNC company has independent workshop for heat treatment. Couples of skilled technicians work here. Actually, all blades(thickness less than100MM)can be fully hardened. Thus, the blades can be used after repairing until the size reached the minimum design dimension.

Finishing processing

WILACNC company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5800mm in length and slitting knives with 1400mm in outside diameter.

Testing

Various testers are put to use for testing its products in our laboratory. They are including tensile tester impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, hardness tester, caliper rule, microcalliper, etc. Testing is carried out after each step. And every products has a unique tracking number. Thus it is easy to trace back anytime.

Company Profile

Похожие товары

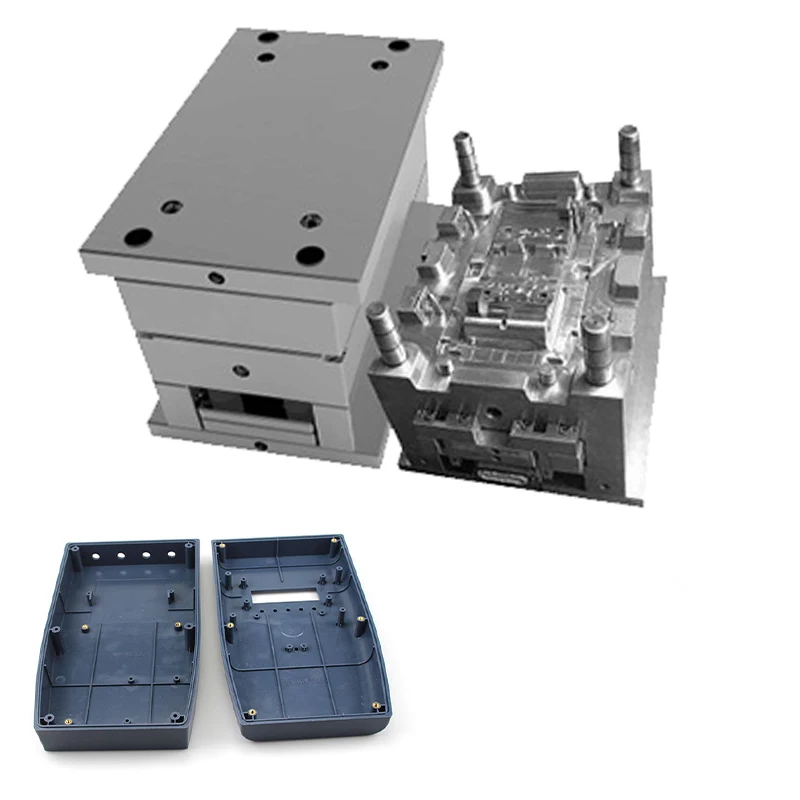

Индивидуальная услуга обработки с ЧПУ для точной штамповки пресс-формы компонент штамповочный продукт модель номер формы

500,00-600,00 $

Металлический штамп-пресс для штампа

0,10-1,00 $

Штамповочные формы для листового металла инструмент глубокого вытягивания штамповочная штамповка штамповочный штамп изготовления ключей

2 000,00-5 000,00 $

Гидравлический листогибочный станок с ЧПУ V-образный металлический гибочный нож лезвие для гибочного станка инструменты

Пластиковые формы небольшой автозажим изделия изготовленные штампы

Изготовленный на заказ пластиковый изготовитель прессформы литья под давлением

Дешевое производство 2020 Пластиковая форма для ведра под заказ

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $