0.5cc 12000cc Шестеренчатый насос гранулятор экструдер пластиковые гранулы

- Категория: >>>

- Поставщик: Zhengzhou Bate Melt Pumps Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 1601114614097:

Описание и отзывы

Характеристики

Products Description

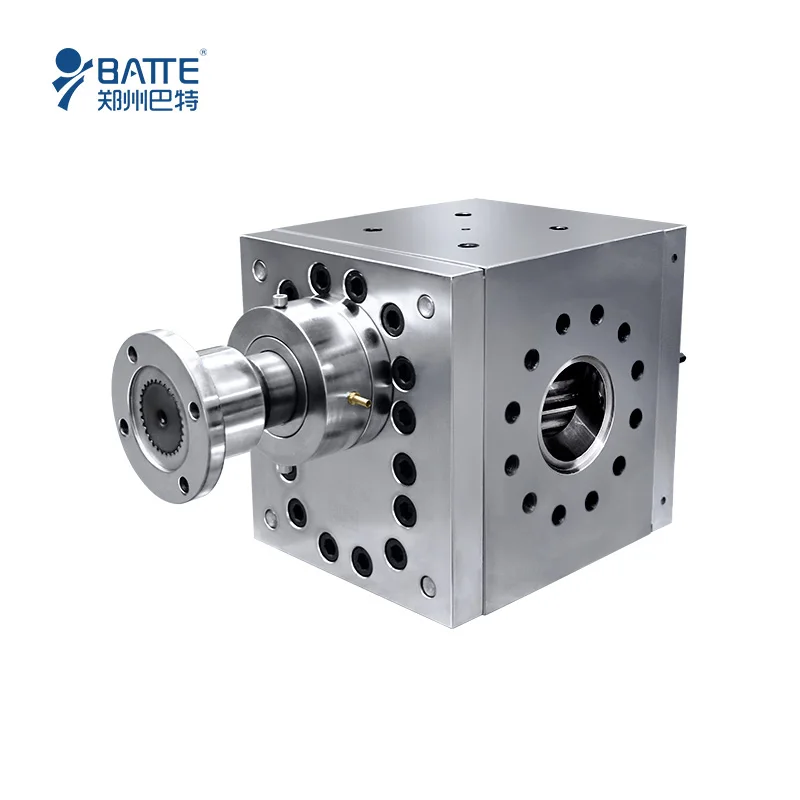

Batte zb-c melt pump is mainly used for metering, transfer and pressure boosting of low or high viscosity polymer melt. The pump parts can be selected to counteract abrasion and conform to various materials characteristics of the pumped media.

Batte hot melt glue pump can be applied in the Scope of Field as follows:

Technical polymers, e. g. PET, PBT, PA, PC, PB

Styrene polymers, e. g. GP-PS HI-PS, ABS, SAN, SB

Acrylic polymers, e. g. PMMA

Polyolefins , e. g. PP, PE

Bio polymers, e. g. PLA

Elastomers, e. g. PUR, TPE, TPU

High temperature thermoplastics, e. g. PEEK, PAI, PAEK, PSU, PI, LCP

Expandable polymers e. g. EPS, EPP

Special polymers, e. g. EVA, EVOH

Polymers with fillers and recycling materials

Styrene polymers, e. g. GP-PS HI-PS, ABS, SAN, SB

Acrylic polymers, e. g. PMMA

Polyolefins , e. g. PP, PE

Bio polymers, e. g. PLA

Elastomers, e. g. PUR, TPE, TPU

High temperature thermoplastics, e. g. PEEK, PAI, PAEK, PSU, PI, LCP

Expandable polymers e. g. EPS, EPP

Special polymers, e. g. EVA, EVOH

Polymers with fillers and recycling materials

Working Principles of BATTE hot melt glue pump (ZB-C Series):

This type of extrusion melt pump is mainly used in conjunction with extruders or kneaders. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. This type of extrusion melt pump is indispensable for the manufacture of precision films or micro granulate.

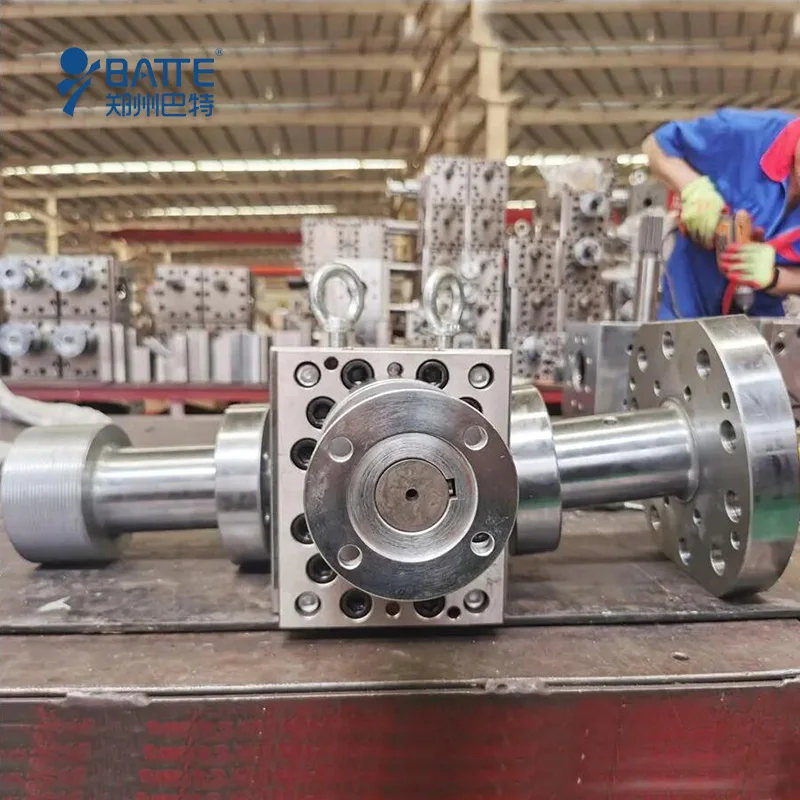

One Whole Set of BATTE hot melt glue pump (ZB-C Series) Comprise :

1. Melt Pump

2. Driven System: Motor + Reducer

3. Control System: PLC Touchscreen System

2. Driven System: Motor + Reducer

3. Control System: PLC Touchscreen System

The Performance Advantage of BATTE hot melt glue pump (ZB-CSeries):

1. Reducing stress on the extruder by means of shifting the job of building pressure to the melt pump;

2. Increasing the hourly output;

3. Removing the output variations and pressure pulsations, thus greatly improving the product quality;

4. Saving raw material by means of tighter manufacturing tolerances;

5. Improving the the dimensional accuracy during the production of sheets and profiles;

6. Optimizing the surface and optical quality during the production of films, sheets and profiles;

7. Improving the product quality with regard to homogeneity and pellet size in compounding;

8. Extending the lifetime of the upstream machinery;

2. Increasing the hourly output;

3. Removing the output variations and pressure pulsations, thus greatly improving the product quality;

4. Saving raw material by means of tighter manufacturing tolerances;

5. Improving the the dimensional accuracy during the production of sheets and profiles;

6. Optimizing the surface and optical quality during the production of films, sheets and profiles;

7. Improving the product quality with regard to homogeneity and pellet size in compounding;

8. Extending the lifetime of the upstream machinery;

Type | CC/Rev | Capacity (L/H) | Heating power (kw) | Dirven system (kw) | Pressure | Temperature |

ZB-0.2 | 0.2 | 0.2-0.6 | 0.5 | 0.37 | Inlet pressure:≥0Mpa Exit pressure: ≤35Mpa | Operating temperature:≤350℃ Clearing temperature:≤450℃ |

ZB-1 | 1 | 1-3 | 1 | 0.5 | ||

ZB-2 | 2 | 2-6 | 1 | 0.75 | ||

ZB-5 | 5 | 5-15 | 1 | 1.1 | ||

ZB-10 | 10 | 10-30 | 1 | 1.5 | ||

ZB-20 | 20 | 20-60 | 2 | 2.2 | ||

ZB-31.5 | 31.5 | 30-90 | 2 | 3 | ||

ZB-50 | 50 | 50-150 | 2 | 4 | ||

ZB-100 | 100 | 100-300 | 3 | 5.5 | ||

ZB-150 | 150 | 150-450 | 4 | 7.5 | ||

ZB-200 | 200 | 200-600 | 4 | 11 | ||

ZB-250 | 250 | 250-750 | 5 | 15 | ||

ZB-315 | 315 | 300-900 | 6 | 18.5 | ||

ZB-400 | 400 | 400-1200 | 8 | 22 | ||

ZB-500 | 500 | 500-1500 | 10 | 30 | ||

ZB-630 | 630 | 600-1800 | 12 | 37 | ||

ZB-800 | 800 | 800-2400 | 15 | 45 | ||

ZB-1000 | 1000 | 1000-3000 | 18 | 55 | ||

ZB-1500 | 1500 | 1200-4500 | 20 | 75 |

Certifications

What are the benifits of melt pump on extruder?

What are the benifits of screen changer on extruder?

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Gmach melt pumps and the extrusion dies

What are the benifits of melt pump on extruder?

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

What are the benifits of installation the screen changer and melt gear pump together?

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

What do we need to pay attention when using the screen changer nad melt pump?

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Gmach melt pumps and the extrusion dies

What are the benifits of melt pump on extruder?

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

What are the benifits of installation the screen changer and melt gear pump together?

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

What do we need to pay attention when using the screen changer nad melt pump?

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

Exhibition

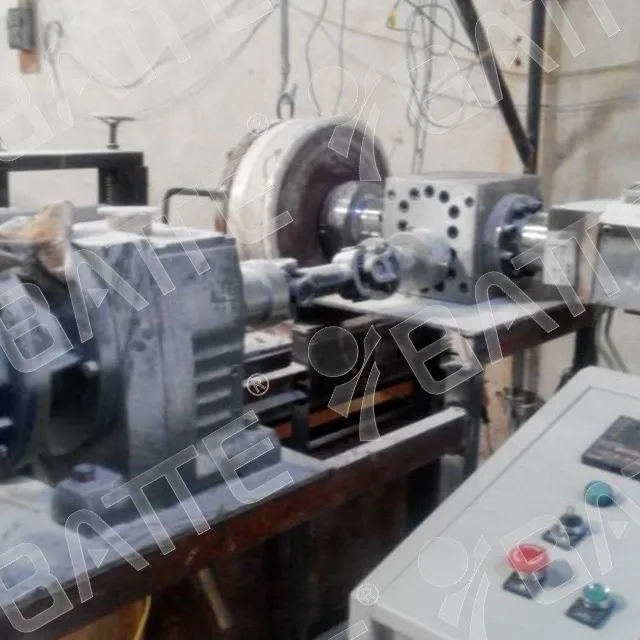

Installation of Our Melt Pump

The Installation of Our Melt Pump

Installation Method: Motor+Reducer+Universal Coupling+Melt Pump You can use control or direct current governor for the motor, and can adjust the flow to your demands optionally. Please well check our installation method below:

Company Profile

1). OEM services provided;

2). Excellent quality assurance;

3). Fast delivery;

4). Worldwide dealer or agent wanted.

Batte Melt Pump Zhengzhou Co., Ltd is one of the biggest manufacturer for melt pump, gear pump or metering pump products in China.

Being a professional supplier for melt pump products, we have been accumulating adequate experience on the application-specific

technique. In addition to providing services and spare parts for our own pumps, we also provide comprehensive service packages for

melt pump produced by other manufacturers.

Batte melt pump is mainly used for metering, transfer and pressure boosting of low or high viscosity polymer melt. The pump parts

can be selected to counteract abrasion and conform to various materials characteristics of the pumped media.

2). Excellent quality assurance;

3). Fast delivery;

4). Worldwide dealer or agent wanted.

Batte Melt Pump Zhengzhou Co., Ltd is one of the biggest manufacturer for melt pump, gear pump or metering pump products in China.

Being a professional supplier for melt pump products, we have been accumulating adequate experience on the application-specific

technique. In addition to providing services and spare parts for our own pumps, we also provide comprehensive service packages for

melt pump produced by other manufacturers.

Batte melt pump is mainly used for metering, transfer and pressure boosting of low or high viscosity polymer melt. The pump parts

can be selected to counteract abrasion and conform to various materials characteristics of the pumped media.

shipping

Batte will choose the most reasonable packing material and packing dimensions for our product, all wooden case package is fumigated, and dimensions are designed to be economical to container shipment. For shipping, we usually work on FOB/CFR/CIF.

We will supply related report and packing pictures of products before shipment to customers.

We will supply related report and packing pictures of products before shipment to customers.

FAQ

1. Which melt pump size we can use?

Before recommending our proper melt pump model for you, we need to confirm with you the following points:

1.1. The production line and the final product;

1.2. The material you deal with;

1.3. The viscosity of your material;

1.4. The hourly output;

1.5. The working temperature;

1.6. The working pressure;

2. What is your MOQ;

At present, our MOQ is 1 set;

3. How long is the delivery time?

In general, the delivery time is 4-5 weeks.

4. What is your guarantee term?

The warranty period for our products is one year.During the warranty period, the seller is responsible for replacing free

damageable parts , while the buyer pays for freight.

5. How about the oversea installation and debugging?

Our engineer can be assigned for installation and debugging. Or we can use long-distance technical assistance based on Industry

4.0.

Before recommending our proper melt pump model for you, we need to confirm with you the following points:

1.1. The production line and the final product;

1.2. The material you deal with;

1.3. The viscosity of your material;

1.4. The hourly output;

1.5. The working temperature;

1.6. The working pressure;

2. What is your MOQ;

At present, our MOQ is 1 set;

3. How long is the delivery time?

In general, the delivery time is 4-5 weeks.

4. What is your guarantee term?

The warranty period for our products is one year.During the warranty period, the seller is responsible for replacing free

damageable parts , while the buyer pays for freight.

5. How about the oversea installation and debugging?

Our engineer can be assigned for installation and debugging. Or we can use long-distance technical assistance based on Industry

4.0.

Quality Control System

• Fixed Q/C Equipments;

• Materials Qualified before Reaching Warehouse;

• Randomly Checking before Shipment.

• Materials Qualified before Reaching Warehouse;

• Randomly Checking before Shipment.

Our Value-added Service Package

1. Installation Services: During the period of installation and debugging, we shall offer training about effective operation and maintenance.

2. Technical Services: We can assist our clients to solve all kind of technical problems with our capable technical team, and we own adequate experience for production line transformation project.

3. Warranty Services: We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

2. Technical Services: We can assist our clients to solve all kind of technical problems with our capable technical team, and we own adequate experience for production line transformation project.

3. Warranty Services: We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

Похожие товары

HYDR-STAR фабричная поставка haskel-как HSF-151 портативный пневматический насос для хранения жидкого азота сниженного углеродного газа (СУГ)

139 051,47-154 595,35 ₽

Minya поршневой насос Дайвинг надувная бутылка Роторный Ручной Насос

6200904289 6200903762 HE00705080 HE00707161 5051014 9303043 9302201 5052012 0580095099 02149958 1000289934 A4VG насос

301 238,00 ₽

Двухступенчатый роторный вакуумный насос для вакуумной машины нанесения покрытия

2 626 795,36 ₽

Небольшой портативный высокого давления Поток диафрагмы водяной насос

2 891,89-3 373,87 ₽

Заводская поставка недорогой вертикальный глубоководный насос с двигателем погружной центробежный для бурения и воды

60 247,60 ₽

Высококачественный специальный энергоэффективный шестеренный насос Самовсасывающий Шестеренчатый для передачи смазочного масла

15 061,90-16 266,86 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $