Vertical Automatic Hydraulic Forming Machine and Muti function Tilting Table for Precast Concrete House

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.Guangxi Ltd.

Сохранить в закладки 1601118206701:

Описание и отзывы

Характеристики

Product Description

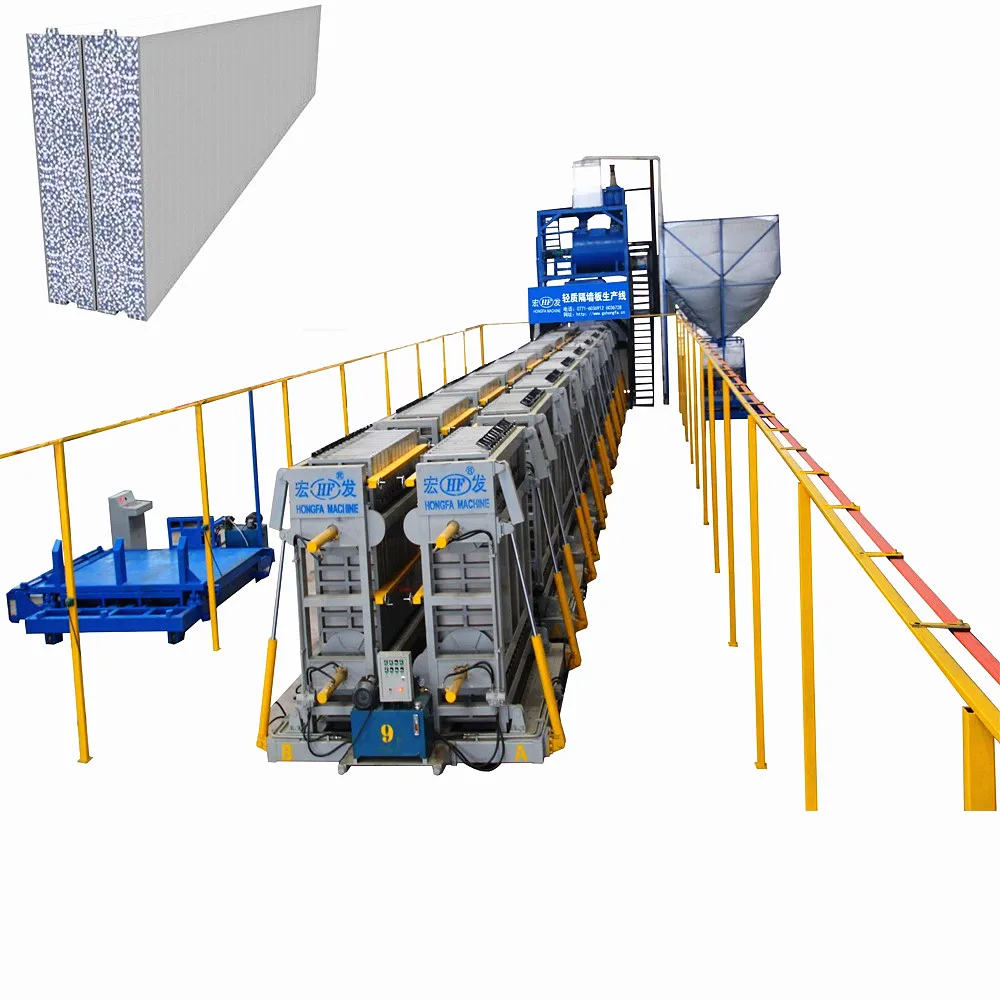

Vertical automatic hydraulic forming machine and muti-function hydraulic tilting table for precast concrete house

For EPS cement panel

Raw materials to produce the wall panel: Cement/sand/fly ash/EPS beads/HPMC and other chemical addtitives/water

Side/surface cover of the wall panel: Calcium silicate board/Cement fiber board, also can be without side cover

Usage of the wall panel: Partition wall construction of school,hospital,commercial building,office and residential house

For Precast concrete panel

Raw materials: sand, stone, cement

Usage of the panel: wall, floor and fence.

HFP530A Vertical Automatic Wall Panel Making Machine | ||||||||||||||

Overall Dimension mm | Power kw | Capacity of Each Mold with Different Wall Panel Thickness/Shift | ||||||||||||

60mm | 75mm | 90mm | 100mm | 120mm | 150mm | |||||||||

3340x3035x2894 | 4 | 40 pcs | 36 pcs | 32 pcs | 30 pcs | 26 pcs | 22 pcs | |||||||

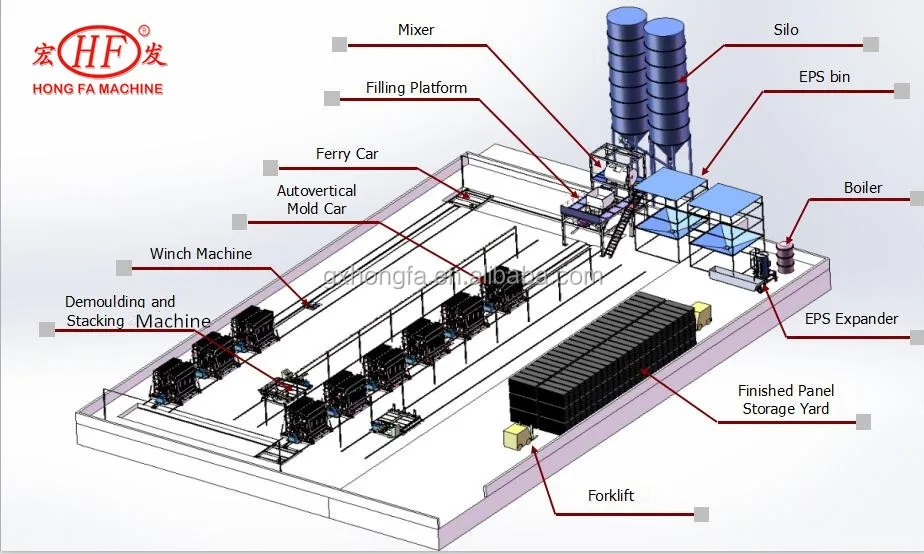

Typical Layout of the EPS Wall Panel Production Line

Main configuration machines and equipmemt:

1,Silo:storage cement/fly ash

2,Boiler: generates steam for the EPS expander

3,EPS Expander:Produce the foam EPS beads

4,Mixer:mix the raw materials into fine slurry

5,Filling Platform:fill the slurry into the mold car

6,Ferry Car: transport the mold car to the curing rails

7,Mold Car: form the EPS wall panel and curing

8,Winch Machine: move the mold car on the rails

9,Demolding and Stacking Machine: pull out the finished wall panel from the mold car and stack the panels for the forklift to transport to storage area.

1,Silo:storage cement/fly ash

2,Boiler: generates steam for the EPS expander

3,EPS Expander:Produce the foam EPS beads

4,Mixer:mix the raw materials into fine slurry

5,Filling Platform:fill the slurry into the mold car

6,Ferry Car: transport the mold car to the curing rails

7,Mold Car: form the EPS wall panel and curing

8,Winch Machine: move the mold car on the rails

9,Demolding and Stacking Machine: pull out the finished wall panel from the mold car and stack the panels for the forklift to transport to storage area.

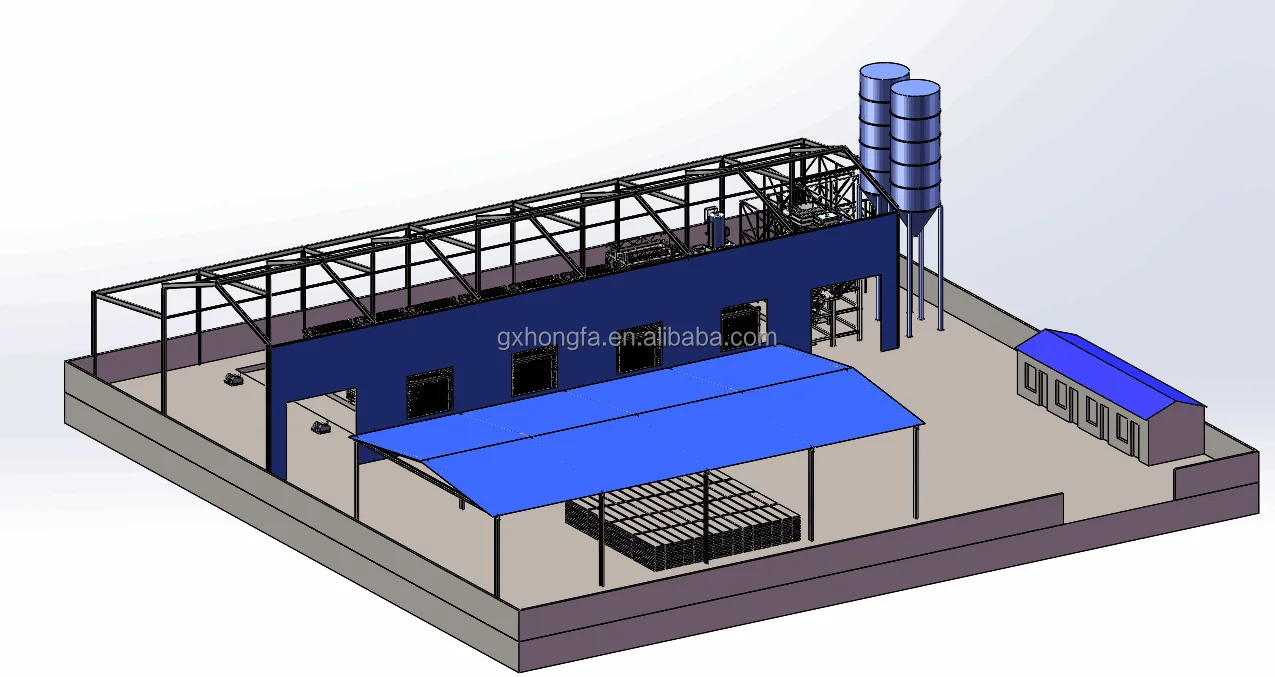

Factory of the Wall Panel Production Line

Land requirements: 2000 to 4000m2 workshop with 9 meters high roof is required for a reasonable size plant however this can change depending on the capacity of the plant. Lot of storage and open space will be needed to store the raw materials and finish products.

Water requirements: To produce 1000m2 panels per day we require 20 ton of water only. No special requirements of water quality, ordinary clean water can be used for production.

Electricity requirement: Installed power about 150 kw (depending on the capacity).

Requirements of Air and Steam: Air compressor 1 set, and 0.5t capacity boiler.

Workers requirement: A staff & workers’ strength of about 20 is enough to run a 20 mold car plant.

Water requirements: To produce 1000m2 panels per day we require 20 ton of water only. No special requirements of water quality, ordinary clean water can be used for production.

Electricity requirement: Installed power about 150 kw (depending on the capacity).

Requirements of Air and Steam: Air compressor 1 set, and 0.5t capacity boiler.

Workers requirement: A staff & workers’ strength of about 20 is enough to run a 20 mold car plant.

Detailed Images

Samples of Main Raw Materials of the EPS Wall Panel

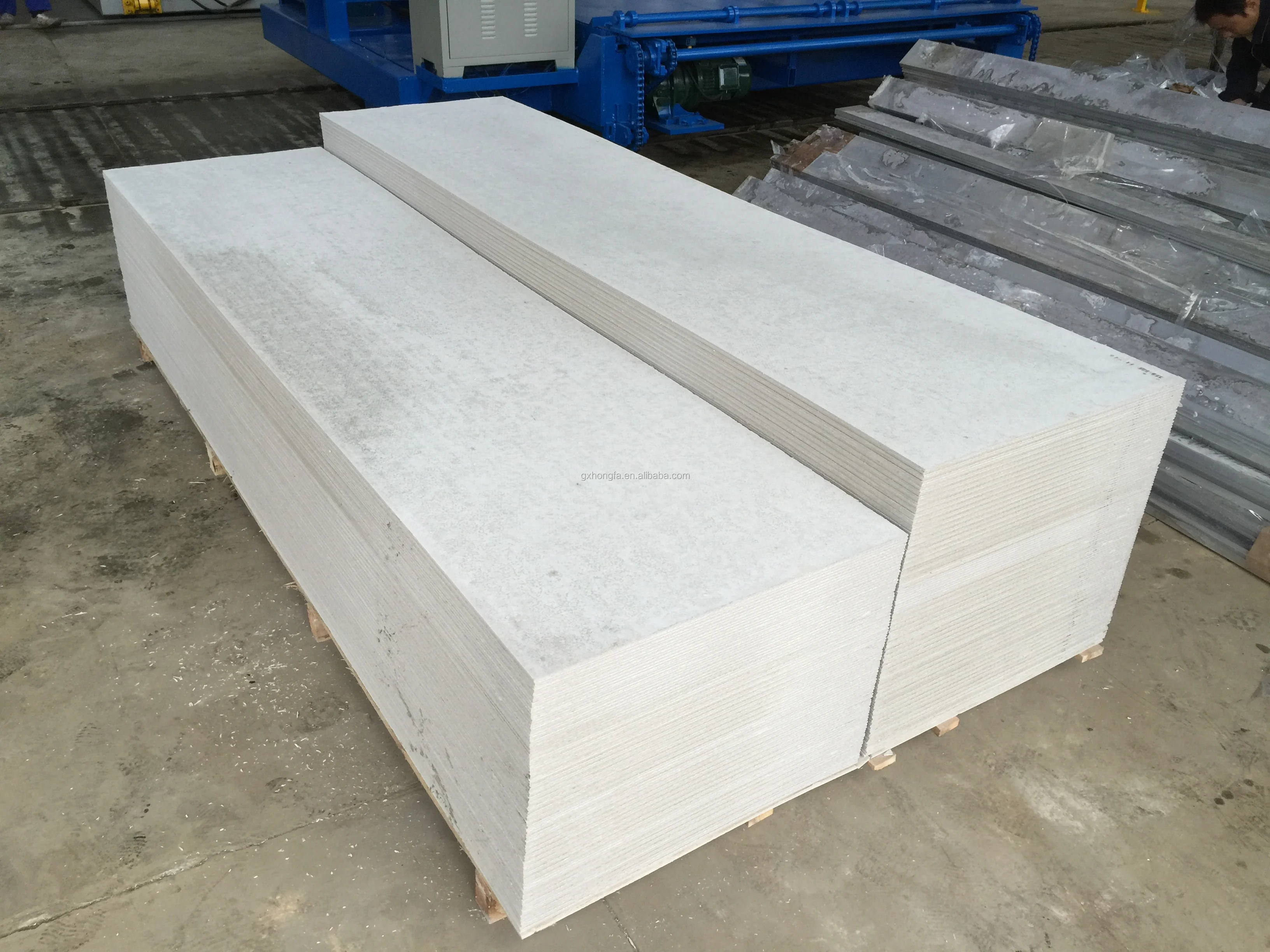

Small Wall Panel Samples

Finished Wall Panel Demolding

Finished Wall Panel in the Storage Yard

Nine advantages of interior walls

1. The most energy-efficient, environmentally friendly, and lightweight

Due to the extensive use of polystyrene particles in Wanke wall panels, which have good insulation performance, the heat dissipation rate is much lower than that of brick wall masonry, greatly improving the energy-saving efficiency of buildings. All raw materials do not contain harmful substances to human health and are environmentally friendly products recommended by the state. The capacity is only 650kg/m3, free of plastering, which is 1/6 of the weight of brick wall masonry.

2. Most economical area

Compared to the inner wall with a thickness of 120mm, the inner wall with a thickness of 75mm can increase the practical area by 1 square meter every 12 meters. A 100 square meter residential area can increase by 4.16 square meters.

3. The most waterproof and moisture-proof

Due to the special properties of sturdy mud panels, their moisture-proof and water-resistant functions are particularly prominent. Experimental results have shown that wall panels can be bonded with cement to form a pool filled with water without any waterproof finish. The back of the wall can remain dry without leaving any marks, and there will be no condensation water droplets on the wall even in humid weather.

4. Maximum fire protection level

The combustion test at a high temperature of 1000 ℃ for 240 minutes showed no damage. After inspection by the National Fire Protection Building Material Quality Supervision and Inspection Center, the fire resistance performance reached the national A-level standard, ensuring absolute fire resistance.

5. The most soundproof

42dB sound insulation effect, in accordance with the Chinese national sound insulation testing standard GBJ121-88; Due to its high density and easy reflection, the material has a strong sound insulation effect, which is superior to general masonry. The sound insulation effect of general masonry is 35dB.

6. Optimal hanging force

Wall panel panels can be bonded with building mortar, cement, slurry, etc., and wall decoration with tiles does not require special treatment; It can be nailed, drilled, and installed with expansion bolts at any position, with a single point hanging force of over 50 kilograms. Provided great convenience for the later decoration work.

7. Optimal seismic and impact resistance performance

Due to being a prefabricated wall, the board itself is a three in one structure, and the boards are connected by mortise and tenon as a whole. Its performance in impact resistance, bending resistance, and other aspects cannot be compared to masonry walls.

8. Thin web walls with maximum span and height

Due to its high strength and good overall performance, it can be used as a wall spacing for high floors and large spans. As long as steel structures are simply used for anchoring and steel sections are buried inside the wall, large-span and high floors of the wall do not require additional columns. Its impact resistance is 1.5 times that of general masonry, and the maximum single layer construction height is 16.8m.

9. The most civilized, hygienic, and efficient construction

The construction transportation is simple, the stacking is hygienic, the operation is dry, there is no excess mud, the loss is low, there is little waste, the construction is convenient, there is no need to lay bricks or plaster, the construction period is shortened, the installation is urgent, the slotting is fast, the installation of water and electricity pipelines is convenient, the construction efficiency is 8-10 times that of general masonry, and it is a high-quality wall that can be reused.

Eight unparalleled advantages of exterior walls:

1. Energy saving, insulation, and good insulation properties

Due to the fact that the outer wall panel core of Wanke is made of polystyrene particle concrete, its thermal insulation performance is good, and it has a significant efficiency in reducing energy consumption in buildings, which is difficult to solve for walls made of other materials.

2. Lightweight economy

Due to the lightweight of the exterior wall panels of Wanke, with a capacity of 800-900kg/m3, the transportation volume is reduced and the structural load is reduced.

3. Save practical space

1. The most energy-efficient, environmentally friendly, and lightweight

Due to the extensive use of polystyrene particles in Wanke wall panels, which have good insulation performance, the heat dissipation rate is much lower than that of brick wall masonry, greatly improving the energy-saving efficiency of buildings. All raw materials do not contain harmful substances to human health and are environmentally friendly products recommended by the state. The capacity is only 650kg/m3, free of plastering, which is 1/6 of the weight of brick wall masonry.

2. Most economical area

Compared to the inner wall with a thickness of 120mm, the inner wall with a thickness of 75mm can increase the practical area by 1 square meter every 12 meters. A 100 square meter residential area can increase by 4.16 square meters.

3. The most waterproof and moisture-proof

Due to the special properties of sturdy mud panels, their moisture-proof and water-resistant functions are particularly prominent. Experimental results have shown that wall panels can be bonded with cement to form a pool filled with water without any waterproof finish. The back of the wall can remain dry without leaving any marks, and there will be no condensation water droplets on the wall even in humid weather.

4. Maximum fire protection level

The combustion test at a high temperature of 1000 ℃ for 240 minutes showed no damage. After inspection by the National Fire Protection Building Material Quality Supervision and Inspection Center, the fire resistance performance reached the national A-level standard, ensuring absolute fire resistance.

5. The most soundproof

42dB sound insulation effect, in accordance with the Chinese national sound insulation testing standard GBJ121-88; Due to its high density and easy reflection, the material has a strong sound insulation effect, which is superior to general masonry. The sound insulation effect of general masonry is 35dB.

6. Optimal hanging force

Wall panel panels can be bonded with building mortar, cement, slurry, etc., and wall decoration with tiles does not require special treatment; It can be nailed, drilled, and installed with expansion bolts at any position, with a single point hanging force of over 50 kilograms. Provided great convenience for the later decoration work.

7. Optimal seismic and impact resistance performance

Due to being a prefabricated wall, the board itself is a three in one structure, and the boards are connected by mortise and tenon as a whole. Its performance in impact resistance, bending resistance, and other aspects cannot be compared to masonry walls.

8. Thin web walls with maximum span and height

Due to its high strength and good overall performance, it can be used as a wall spacing for high floors and large spans. As long as steel structures are simply used for anchoring and steel sections are buried inside the wall, large-span and high floors of the wall do not require additional columns. Its impact resistance is 1.5 times that of general masonry, and the maximum single layer construction height is 16.8m.

9. The most civilized, hygienic, and efficient construction

The construction transportation is simple, the stacking is hygienic, the operation is dry, there is no excess mud, the loss is low, there is little waste, the construction is convenient, there is no need to lay bricks or plaster, the construction period is shortened, the installation is urgent, the slotting is fast, the installation of water and electricity pipelines is convenient, the construction efficiency is 8-10 times that of general masonry, and it is a high-quality wall that can be reused.

Eight unparalleled advantages of exterior walls:

1. Energy saving, insulation, and good insulation properties

Due to the fact that the outer wall panel core of Wanke is made of polystyrene particle concrete, its thermal insulation performance is good, and it has a significant efficiency in reducing energy consumption in buildings, which is difficult to solve for walls made of other materials.

2. Lightweight economy

Due to the lightweight of the exterior wall panels of Wanke, with a capacity of 800-900kg/m3, the transportation volume is reduced and the structural load is reduced.

3. Save practical space

Application of the Wall Panel

Application of the Wall Panel: Wall construction of commercial building,,skyscraper,office,school,hospital,residential houses,etc.

Packing&Shipping

The Wall Panel Making Machine and Production Line Equipment will be well prepared and proper packaged with Plastic Film Wrapping.All process are accordance with international standard, which ensure the machines and equipment in the container are seaworthy.

After Sales Service

Company Introduction

Guangxi Hongfa Heavy Machinery Co.,Ltd is a diversified manufacturer of Construction Materials Machinery and Production Line.We provide complete chain of construction machinery in one-stop.

Our main products: Concrete block/brick/paving brick making machine and production line, EPS lightweight wall panel production line machine, AAC production line, Artificial quartz slab/stone machine, Terrazzo tile making machine, Concrete pipe making machine, Concrete batching plant, Block machines pallets, etc. We've provided services and machines, plants&solutions to clients from more than 120 Countries and regions. Such as the USA,Russia, Thailand, Myanmar, Laos, Cambodia, Philippines, Vietnam, India,Indonesia, Pakistan, Bangladesh, Iran, Iraq, Saudi Arabia, Lebanon, Bahrain, South Africa,Botswana, Namibia, Angola, Nigeria, Zambia, Uganda, Mozambique, etc.

Our main products: Concrete block/brick/paving brick making machine and production line, EPS lightweight wall panel production line machine, AAC production line, Artificial quartz slab/stone machine, Terrazzo tile making machine, Concrete pipe making machine, Concrete batching plant, Block machines pallets, etc. We've provided services and machines, plants&solutions to clients from more than 120 Countries and regions. Such as the USA,Russia, Thailand, Myanmar, Laos, Cambodia, Philippines, Vietnam, India,Indonesia, Pakistan, Bangladesh, Iran, Iraq, Saudi Arabia, Lebanon, Bahrain, South Africa,Botswana, Namibia, Angola, Nigeria, Zambia, Uganda, Mozambique, etc.

Похожие товары

Composite Panel Machine 3d Fence Concrete Wall Making Low Price

25 000,00 $

Precast Concrete Wall Panel Machine Sandwich Manufacturing for Sale

25 000,00 $

Китайское Оборудование для производства глотков

100 000,00 $

Китайская производственная линия гипсокартона с немецкой технологией/производитель немецкого Типа ISO

98 000,00 $

Предварительно напряженная машина для изготовления Т-образных балок/машина панелей с полым сердечником

4 800,00-5 000,00 $

2024 оборудование для производства гипсокартона из фарфоровой бумаги мощностью 2 миллиона квадратных метров в год

8 888 888,00 $

Made in China CNC Automatic 3D 2D 3 Axis Wire Rod Steel Bar Bending Spring Forming Machine for 2-6mm

8 000,00-8 500,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $