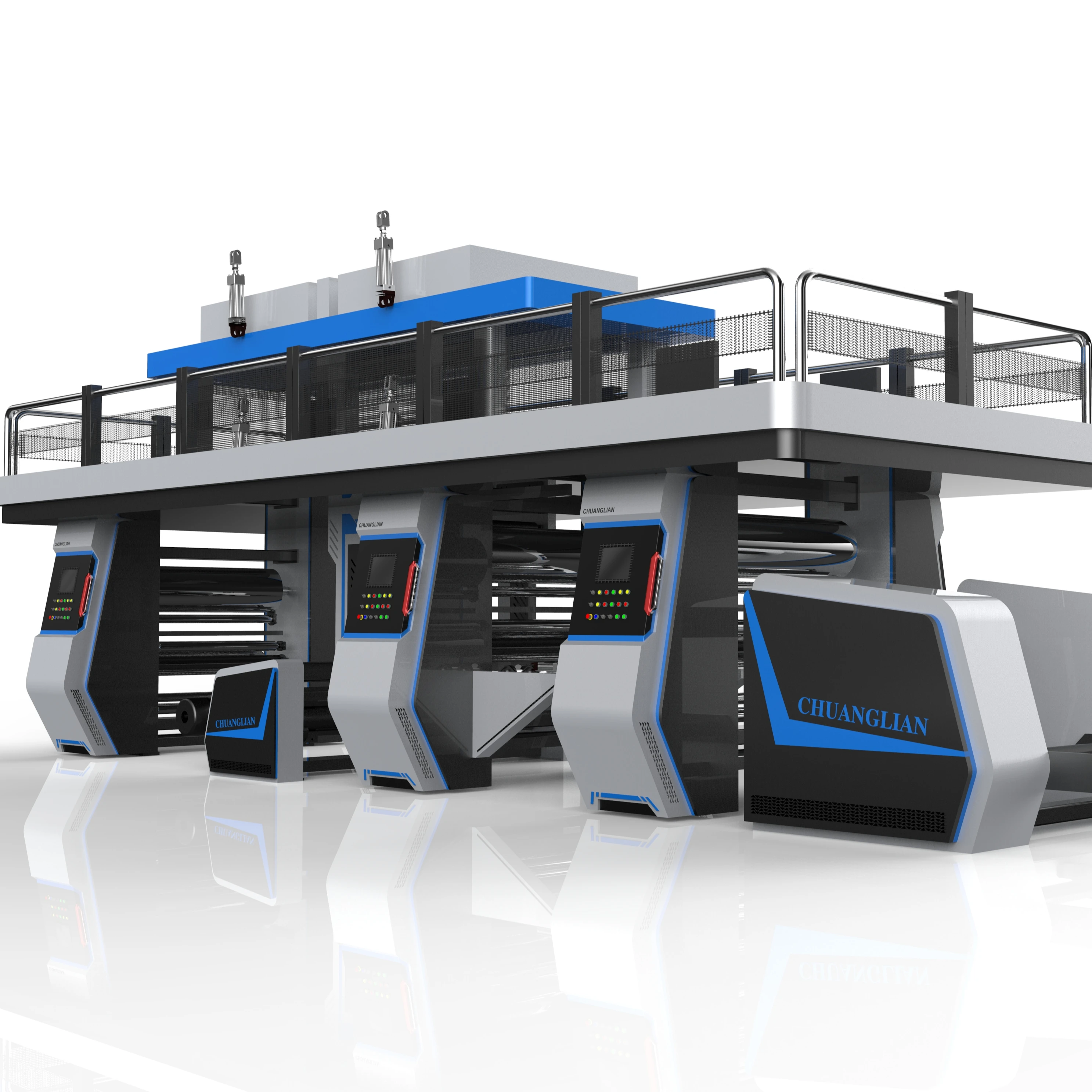

Высокоскоростная гофрированная картонная коробка многоцветная флексографская печатная машина

- Категория: >>>

- Поставщик: Hebei Shengli Paper Chest Equipment Manufacturing Co. Ltd.

Сохранить в закладки 1601124206229:

Описание и отзывы

Характеристики

Specification

Item | Unit | GYK-1270*2200 Specifications |

Machine inside width | mm | 2400 |

Design speed | Sheets/min | 200 |

Maximum feeding size | mm | 1200*2200 |

Minimum feeding size | mm | 380*700 |

Feeding by partition | mm | 1600*2200 |

Maximum printing size | mm | 1200*2040 |

Printing accuracy | mm | ±0.5 |

Thickness of standard printing plate | mm | 7.2 |

Thickness of printing paperboard | mm | 3-11 |

Minimum slotting space | mm | 290*60*290*60 |

Maximum slotting depth | mm | 300 |

Die cutting slotting thickness | mm | 3-8 |

Maximum die cutting size | mm | 1200*2150 |

Printing department

*The surface of the printing roll is plated with hard chrome and polished.The balance correction is made to make it run smoothly.Using ratchet fixed plate, and a full - format plate slot, can make the printing plate cling on the printing roller.Loading and unloading printing plate, foot switch can be used to electrically control the positive and negative rotation, easy to operate.The dimensions of printing roller axial manual adjustment are ±2.5mm in all5mm.

*The rubber rollers are coated with wear-resistant rubber. The rubber roller is parabolic.To compensate force deformation, improve the effect of ink transfer.The rubber is butadiene rubber with a hardness of 60° or above. After special polishing, the ink transfer effect is good.The rubber roller is driven by the deceleration motor when the host machine stops, and the ink is automatically evenly when the machine stops.*The large diameter design of the anilox roller makes the anilox roller under pressure not to deform, the surface is polished, and the hexagon hard chrome plating is refined to make the printing effect more precise. The unidirectional bearing is the same as the rubber roller. Rubber roller and anilicon roller, anilicon roller and plate clearance manually adjust the dial display. (Anilox roll mesh can be selected according to customer requirements).

*PLC touch screen and electric digital 360° adjustment (stop or work) are adopted for printing phase.

*Printing ink supply system adopts pneumatic diaphragm pump circulation supply, stable ink supply, simple operation and maintenance, pneumatic diaphragm pump is a domestic brand.

*The printed phase fixing device adopts pneumatic brake mechanism, which restricts the rotation of the machine and keeps the original gear position fixed when the machine is separated or adjusted.

*The printing plate rolls horizontally electronically.The material and heat treatment of the gear in the printing department is the same as that in the paper feeding department.Ink washing motor, can start the motor evenly ink after main motor stopping, prevent the ink dry, and easy to clean the ink roller.

Die cutting unit

* The roller is plated with hard chrome on the surface of high quality steel, and the dynamic balance correction is made to increase its operation stability and reliability.The gap between the die cutting roller and the rubber cushion roller is adjusted manually.The phase of the die-cutting roll adopts planetary structure, high precision, large bearing capacity, stop, operation can be electrically digital 360° adjustment.* When the paper feeding is stopped, the pneumatic clutch will separate the two rollers and reduce the wear of the soft rollers.The rubber pad is made of polyurethane felt sheath produced in Taiwan, which can achieve a 100% cutting rate and smooth incision.

* The replacement order of the rubber pad shall be subject to the loading and unloading operation manual of the rubber pad.

* The rubber cushion roller adopts the mechanical CAM type left and right moving device, each knife is in the different position,effectively prolongs the service life of the felt sheath.

* The cutting die roller can be adjusted by manual axial distance ±10mm.Die cutting upper and lower roller diameter is different, but the two roller linear speed is equal. Can control the die - cutting knife in the circular direction of infinite non - circular work, so that the wear of rubber sleeve more uniform.

* Linear speed compensation device, when the diameter of the soft roller changes, automatic linear speed compensation device automatically track compensation, no need to manually adjust the speed, to ensure that each batch of carton die-cutting size is exactly the same, and greatly extend the service life of felt sleeve and knife die.

* The soft roller automatic repair device can repair the worn felt sheath for many times. The repaired felt sheath is smooth and clean, maintaining the same performance as the new felt sheath. Greatly improves the reuse rate of felt mats.

* The diameter of the die cutting roller is 392mm, the transverse hole distance is 100mm, the circumferential direction is 18 equal,and the center has holes. It is equipped with a synchronous knife slotting device.

Stacking unit

* Paper receiving arm adopts pneumatic bidirectional control.* The paper receiving arm can be operated manually or automatically, and there is an insurance mechanism to prevent the paper receiving arm from falling suddenly, so as to ensure the safety of operators.

* Bed platform lifting strong chain drive.

* Pneumatic paper lifting mechanism, when the cardboard pile to the predetermined height, the paper lifting arm is opened, the table rises quickly so that the staff can remove the cardboard.

* The running speed can ensure synchronization with the host.

* The maximum height of the mass of paper is 1600mm.

* The tilt height of the bed is automatically adjusted with the height of the board, and the lifting motor is equipped with the brake function to keep the table in a fixed position without sliding down, which is safe and reliable.

* The conveying belt is a flat corrugated belt to prevent the cardboard from sliding down.

Q:1. who are we?

Q:5.what services can we provide?

A:We are based in Hebei, China, start from 2001, sell to Domestic Market(8.33%), South Asia(8.33%), Central

America(8.33%), Western Europe(8.33%), Eastern Asia(8.33%), Mid East(8.33%), Oceania(8.33%),Africa(8.33%),Southeast Asia(8.33%),

Eastern Europe(8.33%), South America(8.33%), North America(8.33%). There are total about 201-300 people in our office.

America(8.33%), Western Europe(8.33%), Eastern Asia(8.33%), Mid East(8.33%), Oceania(8.33%),Africa(8.33%),Southeast Asia(8.33%),

Eastern Europe(8.33%), South America(8.33%), North America(8.33%). There are total about 201-300 people in our office.

Q:2. how can we guarantee quality?

A:(1) Always a pre-production sample before mass production; (2) Always final Inspection

before shipment;

before shipment;

Q:3. what can you buy from us?

A:Paperboard Production Line,carton printing machine,corrugated cardboard printer, carton making

machine,carton box printer.

machine,carton box printer.

Q:4.why should you buy from us not from other suppliers?

A:Our company has been enaged in carton equipments manufacturing over 30years, we have the best team for saling, manufacturing, technical, service. We can support from

equipemtns, technical, service for our clients.

equipemtns, technical, service for our clients.

Q:5.what services can we provide?

A:(1) Accepted Delivery Terms: FOB,CIF,Express Delivery;

(2) Accepted Payment Currency:USD,EUR,CNY;

(3) Accepted Payment Type: T/T,L/C,Western Union;

(4) Language Spoken:English,Chinese;

Похожие товары

Красочная коробка гофрокартона бумажная коробка Флексографская печатная машина

6 289 282,20 ₽

Taobao Express коробка флексографская печать машины для гофрированных картонных коробок по цене

1 030 141,05 ₽

Автоматическая 3 вида цветов флексографическая печатная гофрированная картонная коробка делая машину

975 923,10 ₽

3 цвета, машина для печати гофрированных коробок для пиццы, машина для печати на гофрированном картоне, мини-пластиковых пакетах, машина для флексографской печати

433 743,60 ₽ - 520 492,32 ₽

Гофрированный картон, полностью автоматический высокоскоростной флексографский картон, автоматический печатный станок 20 кВт

1 084 359,00 ₽

HJRY-420 флексографский принтер для обработки коронавируса, пленка, фольга, гофрированная бумага, полипропиленовая печатная машина

867 487,20 ₽ - 1 442 197,47 ₽

Полностью автоматический вакуумный переводчик флексографских принтеров

4 033 815,48 ₽ - 4 066 346,25 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $