Выставочный зал искусственная кварцевая плита каменная мраморная мозаика искусственный камень производственная линия бетонная делая машину

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.Guangxi Ltd.

Сохранить в закладки 1601124636696:

Описание и отзывы

Характеристики

| Showroom Artificial Quartz Slab Rock Marble Mosaic Artificial Stone Production Line Concrete Slab Making Machine |

What is the artificial quartz plate /Engineered quartz plate /quartz slab stone ?

The quartz stone slab production line is consist of following key machine:

1.continuous automatic grinding machine.

2.continuous automatic thickness calibrating machine.

3.Vacuum vibration pressing machine

4.Cutting machine

5.Quartz stone slab stacker

6.Plate turnover machine

1. LM series continuous automatic grinding machine.

LM series continous automatic grinding machine is used in process of artificial quartz stone slab. There is 4 / 12 / 16 / 20 heads difference size machine, and there is 1m / 1.7m/ 1.9m most width grinding difference desinged. The max lift range of the machine head is 100mm, which allows 50mm thickness of plate at most. The machine have been optimized and upgraded on based on combining domestic and foreign advanced technology, which enhances its lading position in the field. The machine are characterized by its unique structure of its bearing and guide bearing, automatic lubrication, being controlled and displayed by computer, automated detection and alarms reporting system about the situation of plate and abrasive, excellent performance of water and fog resistance, adjustable speed of oscillation and dransmission and being more convenient and safer to replace grinding head.

| Model | Grinding head No. | Plate max width of plate(mm) | Plate max thickness(mm) | Total Kw | Dimension (mm) | Weight(T) |

| 8LM100 | 8 | 1000 | 50 | 100 | 7600x2700x2460 | 9 |

| 8LM170 | 8 | 1700 | 50 | 100 | 7600x3400x2460 | 11 |

| 8LM1190 | 8 | 1900 | 50 | 100 | 7600x3600x2460 | 12 |

| 12LM170 | 12 | 1700 | 50 | 150 | 9800x3400x2460 | 15 |

| 12LM190 | 12 | 1900 | 50 | 150 | 7600x3600x2460 | 17 |

| 16LM170 | 16 | 1700 | 50 | 200 | 12200x3730x2460 | 19 |

| 16LM190 | 16 | 1900 | 50 | 200 | 12200x3930x2460 | 23.5 |

| 20LM190 | 20 | 1900 | 50 | 250 | 16300x3930x2460 | 32 |

2. LX series continuous automatic thickness calibrating machine

LX thickiness calibrating machine is designed for the process fo calibrate thickness before polishing artificial quartz stone. There are three size- 4 ends, 6 ends, 8 ends. It can process three width type quartz stone: 1m, 1.7m, 1.9m. Range of vertical stroke of the cutter is 60mm, the max thickness of precessable artificial quartz stone is 50mm. LX thickness calibrating machine serves an unique structure- main shaft and guide rail. All part self- lubrication, controlled and displayed by computer. Splash, water and fog proof state is well. Osciallation and transmission speed is adjustable.

| Model | Grinding head No. | Plate max width of plate(mm) | Plate max thickness(mm) | Total Kw | Dimension (mm) | Weight(T) |

| 4LX100 | 4 | 1000 | 50 | 70 | 5000x2800x2240 | 6 |

| 4LX170 | 4 | 1700 | 50 | 70 | 5000x3500x2240 | 7 |

| 4LX190 | 4 | 1900 | 50 | 70 | 5000x3700x2240 | 8 |

| 6LX100 | 6 | 1000 | 50 | 100 | 6200x2800x2240 | 8 |

| 6LX170 | 6 | 1700 | 50 | 100 | 6200x3500x2240 | 10 |

| 6LX190 | 6 | 1900 | 50 | 100 | 6200x3700x2240 | 11 |

| 8LX190 | 8 | 1900 | 50 | 130 | 7400x3700x2240 | 14 |

3. LY Vacuum vibration pressing machine

LY series vacuum vibration pressing machine is used to press bulk material into blank plate, which contains machine frame, vacuum box, vibration motor, lifting oil cylinder, pressurized cylinder, transmission parts, vacuum parts, hydraulic electric control etc. Compare with external type compressor, it has advantages such as low power consumption, light weight, low cost etc.. The machine can make max of 60mm plate thickness, three max width spec. 1000mm, 1700mm, 1900mm.

| Model | Plate max width of plate(mm) | Plate max length (mm) | Plate max thickness (mm) | Total vibration No. | Dimension (mm) | Weight(T) |

| LY100X250 | 1000 | 2500 | 50 | 6 | 4760x1900x2400 | 8 |

| LY100X310 | 1000 | 3100 | 50 | 6 | 5360x1900x2400 | 9 |

| LY170X250 | 1700 | 2500 | 50 | 6 | 4760x2480x2400 | 14 |

| LY170X330 | 1700 | 3300 | 50 | 6 | 5560x2480x2400 | 17 |

| LY190X330 | 1900 | 3300 | 50 | 6 | 5560x2680x2400 | 19 |

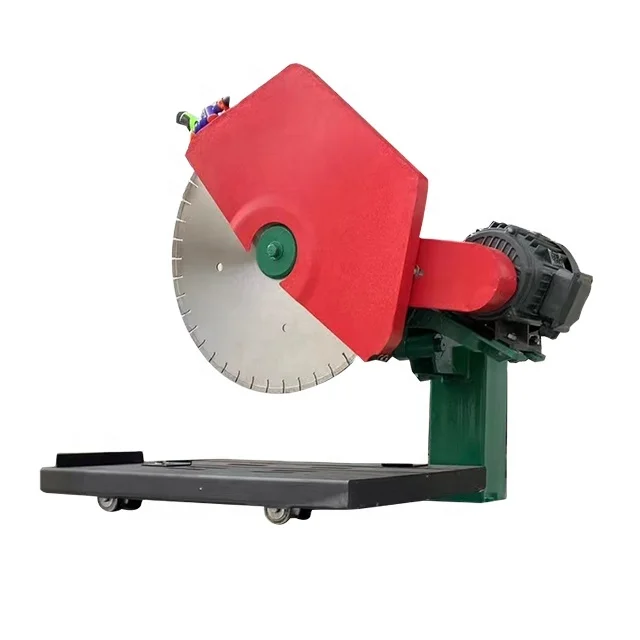

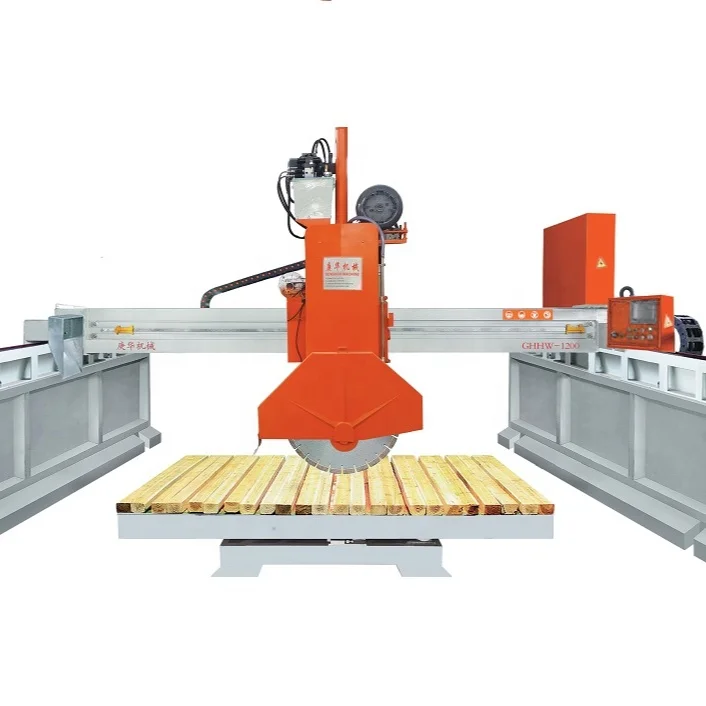

4. LQ Cutting machine

LQ series cuting machine is used in vertical and holizontal cutting for the plate of quartz stone. It can make the plate pass continuously on the production line and cut down turnover of the plate. There are 4 blade and 5 blade two types according to the different thickness of plate, the plate can be cut to two part. The biggest plate can be cut into 3 sizes, 2500mm, 3100mm, 3300mm and so on, reliable guide rail and spindle structure make sure the incision straigtness, automatic control operational process, computer show data, the length and width can be adjusted within certain limits.

| Model | Plate max thickness of plate(mm) | Plate max length (mm) | Conveyor motor power (Kw) | Dimension (mm) |

| LQ80X250 | 800 | 2500 | 7.5 | 4150x2020x2000 |

| LQ80X310 | 800 | 3100 | 7.5 | 4790x2020x2000 |

| LQ170X330 | 1700 | 3300 | 7.5 | 5000x2920x2000 |

| LQ190X330 | 1900 | 3300 | 7.5 | 5000x3120x2000 |

A full line of artificial quartz slab:

The raw materials for artificial quartz slab

The new style building materials could be used for kitchen tops, bathroom vanity top,worktops, laundry,table tops,bench top, bar tops, backsplashes, shower stalls, tub surrounds ,wall tile, wall cladding, floor tile, and airport, station, shopping mall, hotel, bank, hospital.and so on.

Get the best price. Contact us now! >>>>>>>>>

We provide brick sample testing service for free, contact us now!

We provide pallet sample for free, contact us now!

Pre-sales Service

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory, feasibility analysis for panel machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of panel).

(3) Welcome to visit our factory and production line anytime.

(4) Introduce the company file, product categories and production process.

After-sales Service

(1) Training how to install the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly, get feedback in time, keep well communication with each other.

From the day our products sold, we will promise to do as follows:

(1) Provide corresponding technical solutions and site layout;

(2) Provide guidance equipment installation and operation for users.

(3) For each equipment ,we will train mainly operating personnel 5-10.

(4) 12 months guarantee, and provide lifelong technical support.

(5) Feedback within 24 hours after consulting.

(6) Build customers using and maintaining files as soon as dispatch machines;

(7) After finish debugging of equipment, users inspect and sign the acceptance certificate according to the situation of site service.

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: 20~30 days after receipt of deposit and molds confirmation from Buyer.

Q: What is the product guarantee period ?

A: One year after installation finished at buyer's factory.

Q: What is your terms of payment ?

A: Payment:30% deposit, 70% payment before shipment TT or LC

factory direct sale agglomerated artificial quartz stone slab machinery artificial quartz slab making machine

Contact me to get more pictures,videos and free quote.

Foreign trade department:Poppy Jiang

Guangxi Hongfa Heavy Machinery Co., Ltd. (more than 30 years experience!)

Mob./WhatsApp: +86 18031925793

Website: www.gxhongfa.cn

Skype: poppyjiang1

Factory add.: Yilingyan Industrial Zone, Nanning city, Guangxi province, China

Похожие товары

Продажа с завода глубокая пила для резки 23 см мостик укладывания дизельный карьер миниатюрная машина алмазного камня

Машина для резки камня гранита

Марка HANBON машина для резки мрамора камня

Инфракрасная полностью автоматическая машина для резки кромок толстой плиты

Машина для резки плитки машина Высококачественная автоматическая керамической зданий

Точный лазерный цифровой шаблон для столешницы измерительный инструмент резки плитки Набор кухни лестницы ванной комнаты

Машина для резки мрамора 45 градусов

Новые поступления

Новинки товаров от производителей по оптовым ценам