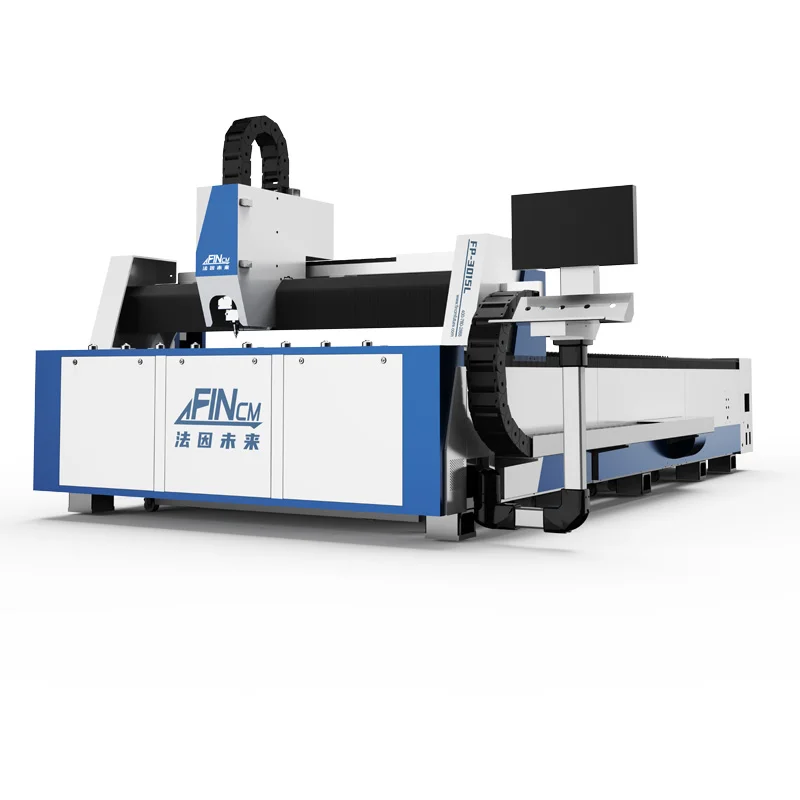

Высокоточные недорогие железные алюминиевые медные латунные из нержавеющей стали металлические 3015 Lleser резак Волоконно Лазерные режущие машины цена

- Категория: >>>

- Поставщик: Shandong Fincm Future Intelligent Manufacture Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601125062095:

Описание и отзывы

Характеристики

Specification

Model | FP-3015L | FP-4015L | FP-4020L | FP-6025L | |||

Working Area | 3050*1550 | 4050*1550 | 4050*2050 | 6050*2550 | |||

Laser Power | 1500W/2000W/3000W/4000W/6000W | ||||||

Laser Source Brand | MAX/RAYCUS/Customized | ||||||

Laser Cutting Head | Raytools/WSX/BOCI/OSPRI/PRECITEC/CUSTOMIZED | ||||||

Control System | HYPCUT | ||||||

Water Chiller | HANLI/S&A | ||||||

Product Description

Heavy-duty Welded Hollow Bed Design

1.The hollow structure helps to evenly dissipate heat, reducing thermal deformation caused by temperature changes, ensuring accuracy and stability during long-term operation.

2. The hollow bed design typically uses thick steel plate welding, providing extremely high rigidity and stability, effectively preventing precision loss due to vibration or deformation during cutting.

3. The hollow structure is typically designed with good internal channels, making it easy to clean smoke and debris produced during cutting, reducing wear on the equipment.

2. The hollow bed design typically uses thick steel plate welding, providing extremely high rigidity and stability, effectively preventing precision loss due to vibration or deformation during cutting.

3. The hollow structure is typically designed with good internal channels, making it easy to clean smoke and debris produced during cutting, reducing wear on the equipment.

Open Structure Design and Three Directions for Loading and Unloading

The single platform adopts gantry structure and open design, loading and unloading in three directions, which is more time-saving and eficient.

FP-6025L

FP-3015L

Details Images

Laser Cutting Head

Water Chiller

Laser Source

Control Panel

Reducer

Advantages:

1. High Energy Efficiency:Fiber laser cutting machines are known for their high energy efficiency. The fiber laser technology used in these machines

requires less power consumption compared to other laser types, contributing to cost savings over time.

2. High Speed and Productivity:

Fiber lasers can produce extremely high beam quality, allowing for faster cutting speeds. This results in increased productivity,

making fiber laser cutting machines suitable for high-volume production environments.

3. Low Maintenance Requirements:

Fiber laser cutting machines generally have lower maintenance requirements compared to other laser types. The solid-state nature of fiber lasers eliminates the need for gas replacement and maintenance associated with traditional CO2 lasers.

4 .Longer Lifespan of Laser Source:

The fiber laser source typically has a longer lifespan compared to other laser sources, contributing to lower operational costs over the machine's lifetime.

5. Excellent Beam Quality:

Fiber lasers produce a high-quality beam with a small focus diameter, enabling precise and detailed cuts. This is particularly advantageous for applications requiring fine features or intricate designs.

6. Versatility in Material Compatibility:

Fiber lasers are capable of cutting a wide range of materials, including metals like steel, aluminum, copper, and brass. This

versatility makes them suitable for various industries, from automotive to aerospace.

Save Freight charge

40 HQ container can ship 6 units 3015L machine, which save a lot of freight charge and suitable for the customers who prefer the bulk orders.

Samples

It is suitable for carbon steel,stainless steel,aluminum alloy, brass,cooper etc.

Company Profile

Shandong FINCM FUTURE Intelligent Manufacturing Co., Ltd. located in Jinan is the core subsidiary of Shanghai Huaming Power Equipment Co., LTD. (stock code 002270)]. We are committed to provide the ultra-high quality laser cutting machine, laser welding machine, laser profile cutting machine and other intelligent machine solutions for domestic and foreign manufacturing customers. With the professional R & D team, production team, quality inspection team, sales team, after-sales team, management team, all departments always adhere to the customer-centric business philosophy, work together to create unlimited value for users.

Packing & Delivery

Exhibition

Our Service

Pre-Sales Service

1. 24-hours online Inquiry and consulting support.

2.Support sample testing .

3.We welcome you to visit our factory.

After-Sales Service

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for two years

4.24-hour technical support by email or calling

5.Free technician training for customers.

1. 24-hours online Inquiry and consulting support.

2.Support sample testing .

3.We welcome you to visit our factory.

After-Sales Service

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for two years

4.24-hour technical support by email or calling

5.Free technician training for customers.

FAQ

1.Q: What thickness of material can a fiber laser cutting machine cut?

A: Fiber laser cutting machines are capable of cutting a wide range of material thicknesses, depending on the laser power and the type of material. They can typically cut thin sheets up to several centimeters thick with high precision.

2. Q:Is fiber laser cutting suitable for industrial applications?

A:Yes, fiber laser cutting machines are widely used in industrial manufacturing due to their high cutting speed, precision, and versatility. They are commonly used in industries such as automotive, aerospace, electronics, and metal fabrication.

3. Q:Does a fiber laser cutting machine require special training to operate?

A:While fiber laser cutting machines are generally user-friendly, operators should undergo training to learn how to operate the machine safely, program cutting parameters, perform maintenance tasks, and troubleshoot common issues.

4. Q:What maintenance is required for a fiber laser cutting machine?

A:Regular maintenance tasks for fiber laser cutting machines may include cleaning the optics, checking and adjusting the beam alignment, inspecting and replacing consumable parts (such as nozzles and lenses), and ensuring proper ventilation and cooling.

A: Fiber laser cutting machines are capable of cutting a wide range of material thicknesses, depending on the laser power and the type of material. They can typically cut thin sheets up to several centimeters thick with high precision.

2. Q:Is fiber laser cutting suitable for industrial applications?

A:Yes, fiber laser cutting machines are widely used in industrial manufacturing due to their high cutting speed, precision, and versatility. They are commonly used in industries such as automotive, aerospace, electronics, and metal fabrication.

3. Q:Does a fiber laser cutting machine require special training to operate?

A:While fiber laser cutting machines are generally user-friendly, operators should undergo training to learn how to operate the machine safely, program cutting parameters, perform maintenance tasks, and troubleshoot common issues.

4. Q:What maintenance is required for a fiber laser cutting machine?

A:Regular maintenance tasks for fiber laser cutting machines may include cleaning the optics, checking and adjusting the beam alignment, inspecting and replacing consumable parts (such as nozzles and lenses), and ensuring proper ventilation and cooling.

Похожие товары

130w 150w 180w Fabric Laser Cutter Sublimation Cutting Machines

6 890,00-6 980,00 $

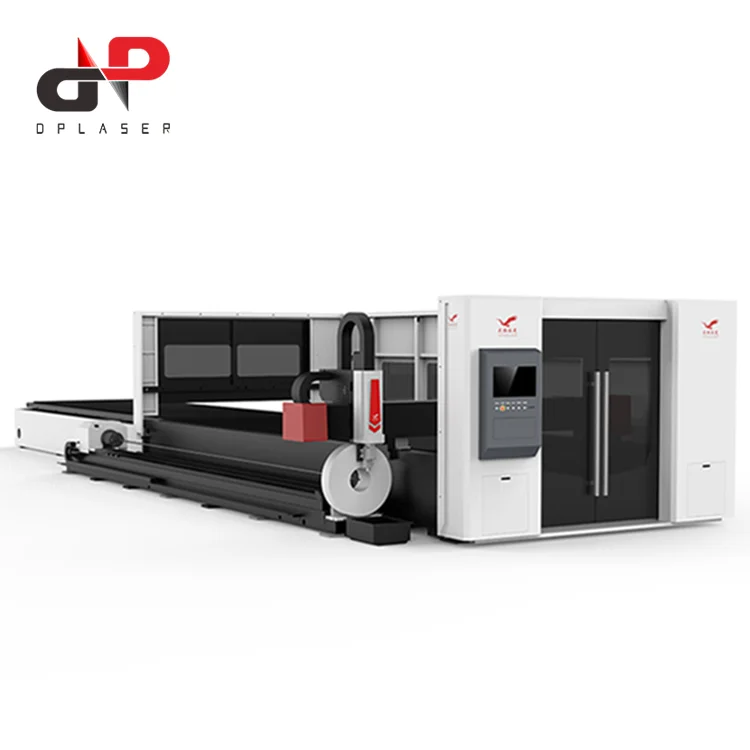

12025 6000W-20000W Metal Sheet and Tube Integration Laser Fiber Cutting Machine for Metals

12 100,00 $

Полное покрытие металлическая пластина из нержавеющей стали железная алюминиевая волоконная лазерная машина для резки высокой мощности 6000 Вт-30000 Вт

Скидка 10%! Небольшие машины для закупки дерева/кожи/ткани/акрила лазерная гравировальная машина 1390

800,00 $

Factory Price Fiber Laser Cutting Machine for Metal Sheet and Tube

32 140,00-45 100,00 $

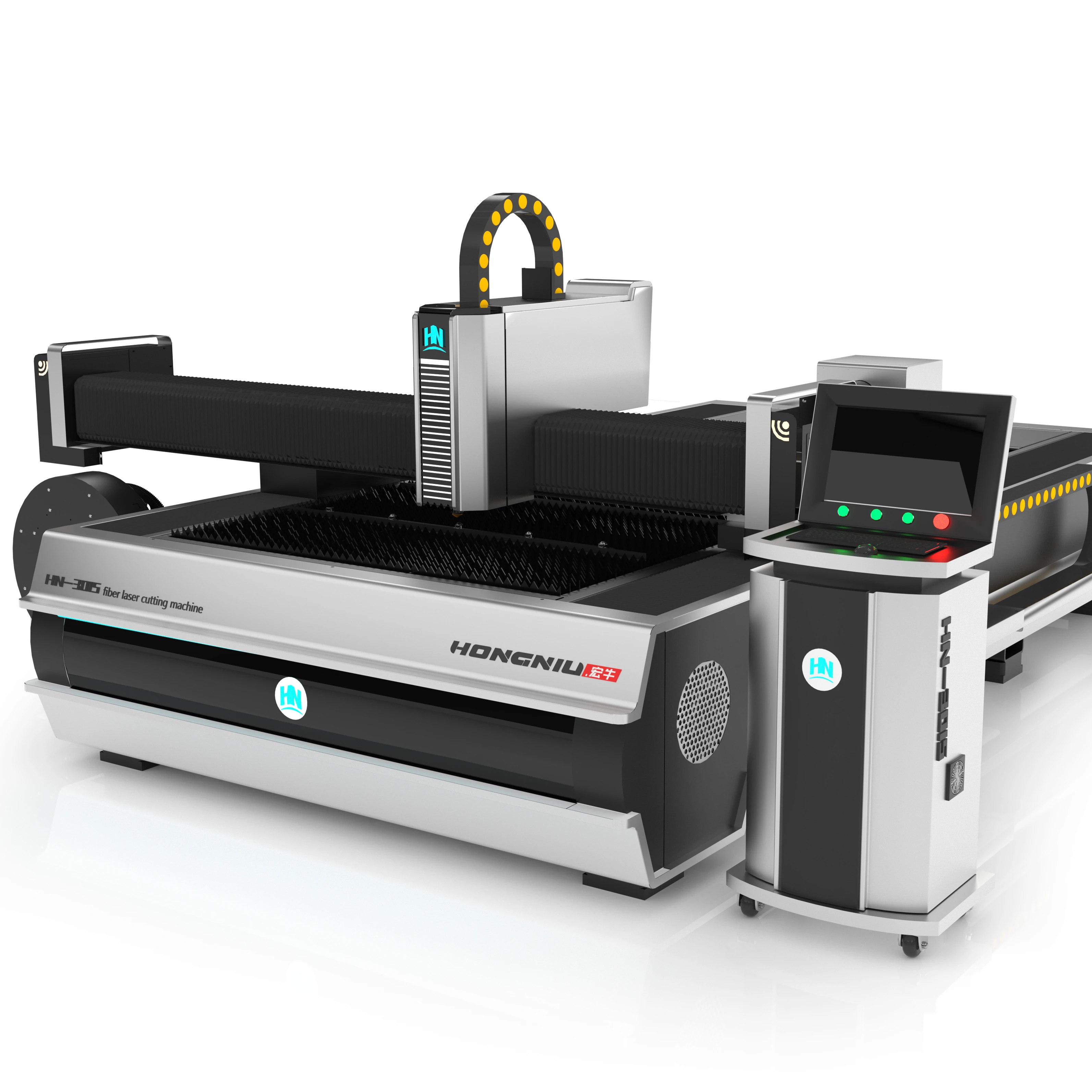

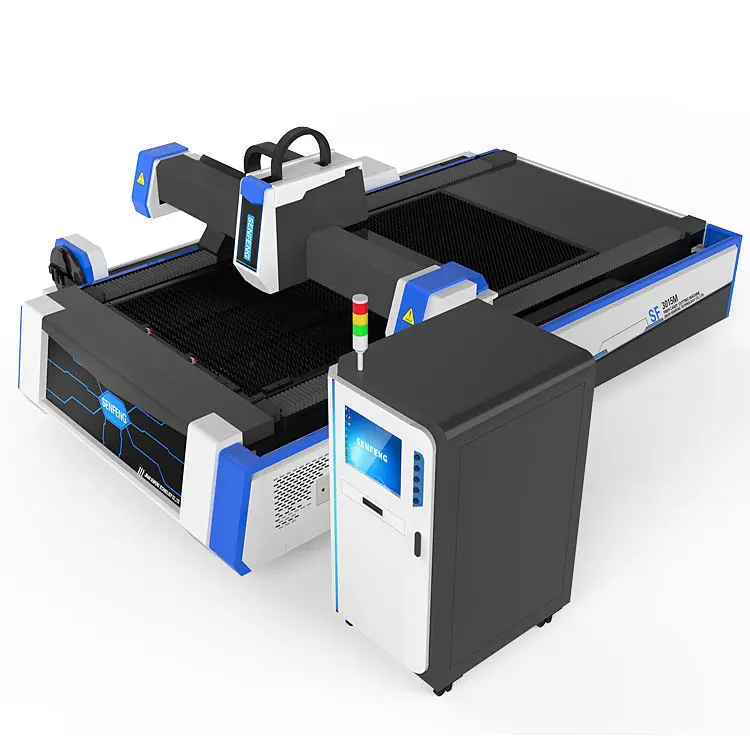

Highly Sold Fiber Laser Cutting Sheet and Pipe Machine SF3015

Good Optic Flat Metal 1kw 1.5kw 3kw Fiber Laser Sheet and Plate Cutter for Iron Aluminum Brass Cutting Machines Price

11 800,00-18 542,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $