SSIC силиконовый карбид механическое уплотнительное кольцо

- Категория: >>>

- Поставщик: Henan Aryan New Materials Co. Ltd.

Сохранить в закладки 1601125367402:

Описание и отзывы

Характеристики

SSIC silicone carbide sealing ring

Excellent corrosion resistance, high coefficient of heat conductivity, self-lubricity, low density high hardness and also provide customized production.

| Parameter | SSiC | RBSiC |

| Purity( % ) | >98 | >90 |

| Hardness( HRA ) | ≥92 | ≥90 |

| Grain Size( um ) | 0.5~0.7 | 8~20 |

| Density( g/cm3 ) | 3.10~3.15 | 3.03~3.08 |

| Bend Strength( MPa ) | 400-580 | 350-450 |

| Compressive Strength(MPa) | >2200 | >2000 |

| Fracture Toughness( MPA ) | 3.05-4.6 | 4.3 |

| Elastic Modulus( GPa ) | >400 | >360 |

| Thermal Conductivity(W/M.K) | 100~120 | 50~100 |

| Coefficient of heat Expansion( L/°C ) | 4.02x10-6 | 4.3x10-6 |

| Poisson Ratio | 0.14 |

0.15

|

1.Introduction of silicon carbide :

Silicon carbide is an inorganic non-metallic materials with high hardness, high wear resistance, low coefficient of friction, oxidation resistance, good thermal stability, low thermal expansion coefficient, thermal conductivity and thermal shock and great resistance to chemical corrosion, etc. excellent characteristics, can be used for a variety of requirements for abrasion, corrosion and high temperature mechanical equipment. Engineering and technical staff after years of unremitting efforts, has greatly improved the performance of silicon carbide. Now, silicon carbide has become an important engineering materials. Widely used in the field of machinery, metallurgy, petrochemical, shipbuilding, military equipment, etc., such as mechanical seal friction, plain bearings, nozzles, cutting tools, etc.

2.Features of sintered silicone carbide BGM120 :

1) Heat shock stablity

2) chemical corrosion-resistant( resistant to strong acid/strong alkali /salt / gas / deleterious )

3) High temper-endure(up to 1650°)

4) Wearing/corrosion/oxidation resistant

5) Highly performance of mechanical strength

6) Cleaning or etching the hardest sub-surfaces

7) long life high hardness resistant to wear; especially resistant to hydrofluoric acid

8) Used for grinding, lapping, and wire saw cutting as well as abrasive blasting

3.why chose us?

Our advantages

| High quality |

Competitive price | |

| Strict delivery time | |

| Good after-sales service | |

Professional producer for 10 years | |

Gold supplier 3th year | |

Strict quality control |

4.Applications of sintered silicone carbide BGM120 :

widely used in mechanical seal, grinding tools,boll grinding machine, canned pump, magnetic drive pump, vacuum pump, body armor,chemicals, petroleum, metallurgy, mineral processing, and mixing machine.

5.production lines:

Granulation-compression moulding-sintering-grinding -finishing and fining

the inspection for each step of the production is conducted strictly.

6 Factory real landscape

7.contact us:

If you are interested in any producta, please send your detail request by email , by skype or QQ or Mobile. We will quote you the competitive price with the superior standard professional technology .

We specialize in sintered silicone carbide BGM120 .

If you are interested in our cooperation, please send us samples or drawing for further check.including Dimension, Tolerance, Surface Roughness, Concentricity, Perpendicularity and other specification are upon your requirements.

And we warmly welcome friends from all over the world to visit our factories for business.

Send your Inquiry Details in the Below, Click "Send" Now!

Похожие товары

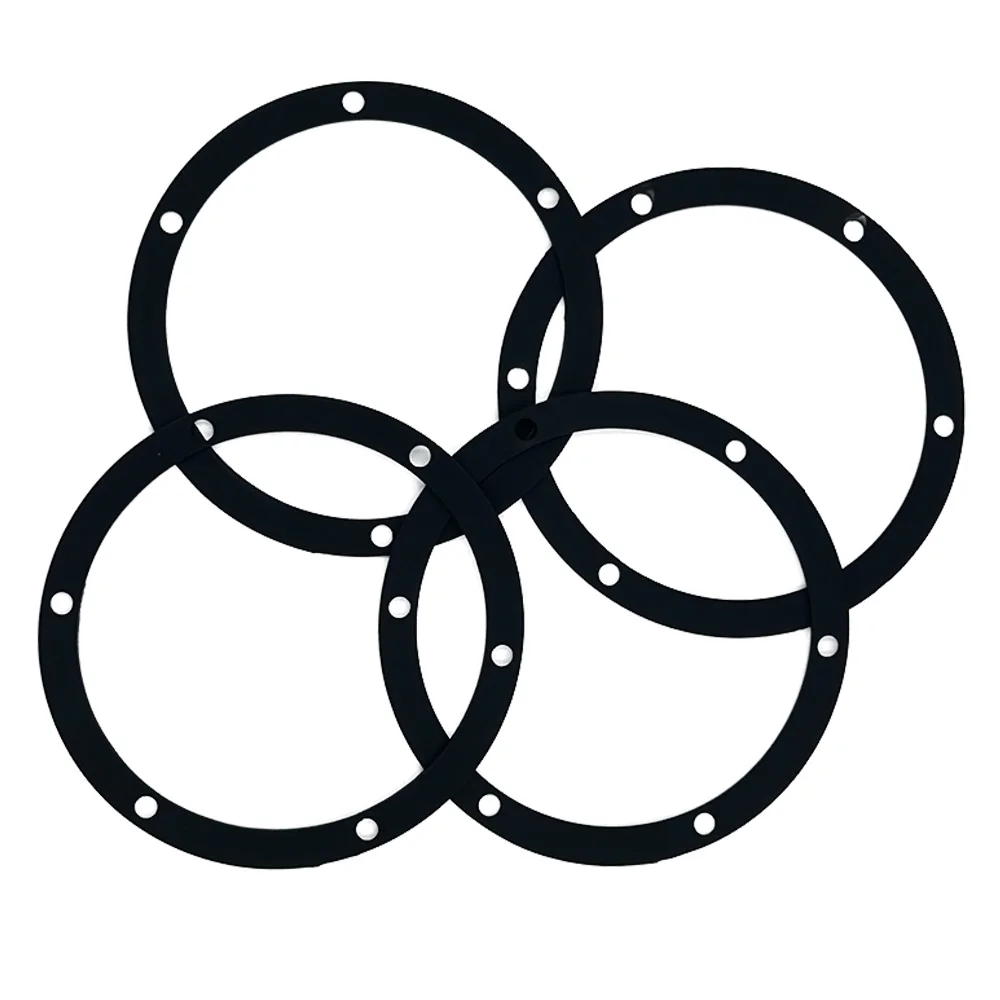

Хит продаж, бесплатный образец, резиновое уплотнительное кольцо для пищевых продуктов, Нитриловое Буна, FKM, NBR EPDM, силиконовые уплотнительные кольца

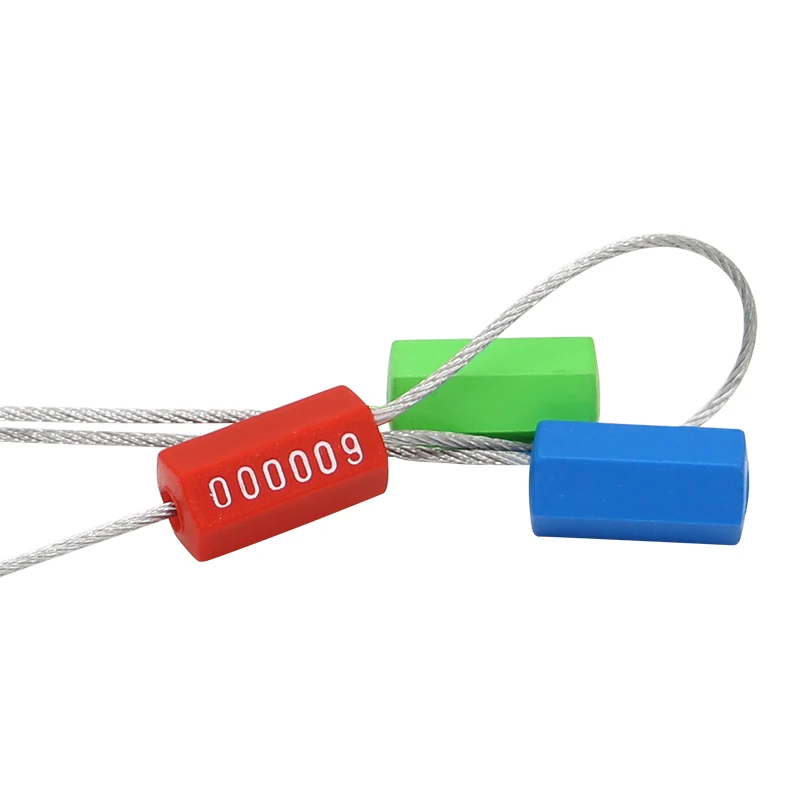

MA-CS3001 вандалоустойчивые шестиугольная регулируемая стальная проволока, охранные пломбы для кабелей

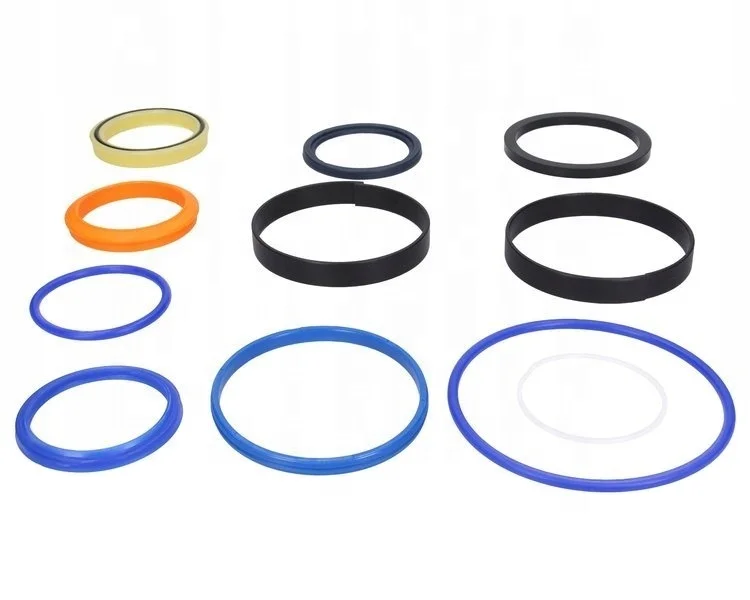

Комплект Уплотнений гидравлического цилиндра DLSEALS 991/20039 для экскаватора-погрузчика, комплект уплотнений interpump

Надувное уплотнение любого размера из силиконовой резины, уплотнительное кольцо, прокладка, дверь для холодного хранения

HED-PS104 бесплатный образец пластиковые защитные печатные метки для обуви пластиковые бирки на заказ пластиковые уплотнения

Высококачественная крышка клапана головки блока цилиндров, комплект резиновых прокладок для Volkswagen Metway T5 2,0 T Audi силиконовые прокладки

Бесплатные образцы Заводская поставка настраиваемые резиновые уплотнительные изделия

Новые поступления

Новинки товаров от производителей по оптовым ценам