Раствор для травления из нержавеющей стали

- Категория: >>>

- Поставщик: Beijing Lingye Yidong Technology Co. Ltd.

Сохранить в закладки 1601149874920:

Описание и отзывы

Характеристики

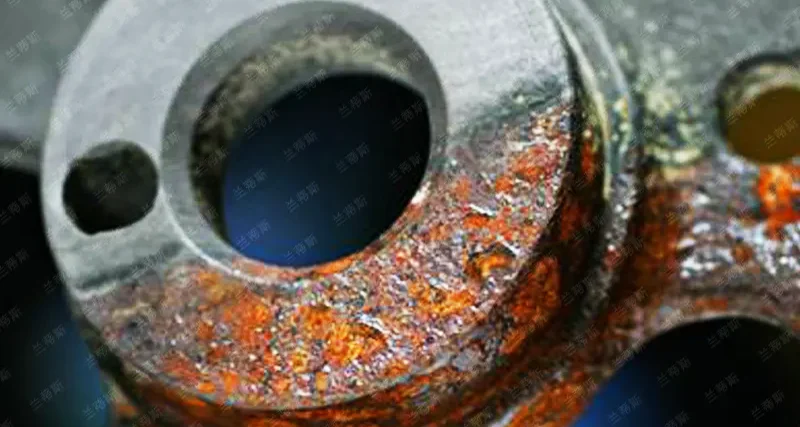

B5101 is a multi-purpose general-purpose antirust oil, known for its economy, high performance and multi-purpose, which can meet the needs of soft film anticorrosion in various fields such as aerospace, ships, conventional weapons, metallurgy and chemical industry, hardware and light industry, transportation, electronics and civil use. Since it has all-round excellent performance such as dehydration, surface rust removal, rust prevention with rust, open air/indoor sealing rust prevention, inter-process rust prevention, fast drying and ultra-thin layer rust prevention, it can replace most functional rust prevention oils that focus on a certain performance, so it can significantly reduce the difficulty of user selection.

This product has excellent acid resistance, alkali resistance, salt spray resistance, humidity and heat resistance and atmospheric corrosion resistance, and has excellent freshwater/sea water replacement ability, far exceeding the performance indexes required by China's military standard GJB-3459-98, national industry standard SH/T0354-92 and U.S. Army MIL-E-16173E standard, and is at the leading level at home and abroad. The product is applied to the pipeline head sealing of the pipeline troops under the General Logistics Department of the People's Liberation Army, and has withstood the severe test of various climatic environments in the outdoor exposure test for three years, further verifying the super anti-corrosion and anti-rust performance of the product.

Although the film thickness of the product is only about 10 microns, the strong anti-scratch ability and long-lasting efficacy also make the product dosage significantly reduced, and the painting area per kilogram is up to 30-40m². Coupled with the multi-purpose characteristics of the product (users no longer need to stock a variety of rust inhibitors), the production/maintenance costs of users are greatly reduced. As a typical representative of military high-tech products turned into dual-use products, B5101 solvent-based film rust preventive oil compound will definitely have a broad development prospect.

Suitable for long-term protection of non-ferrous and ferrous metals, alloy parts and cast iron products both indoors and outdoors. It is especially suitable for the protection of various parts during storage, such as engine parts, automobile parts and machining, and surface rust prevention between processes. After application, the oil film dries quickly and has a transparent and bright texture, and can be used directly without any surface treatment when opening and sealing, effectively isolating from acidic and other aggressive atmospheres. It is especially suitable for outdoor sealing in high humidity and coastal areas, with a sealing period of not less than 2 years and indoor sealing period of not less than 3-5 years.

Suitable for intermediate processing protection for machining, pickling, phosphating and electrochemical treatment. It can quickly replace water and leave an ultra-thin protective layer of oil, which is especially suitable for protecting high-precision machined parts that must not have a thick protective film, and effectively insulates parts from damage caused by acidic and other aggressive atmospheric conditions between processes.

It is suitable for rust protection of steel cables on ocean-going vessels, port container handling equipment and offshore vessels. The product has strong adhesion and penetration, excellent resistance to salt spray and humidity and heat, and can easily penetrate into the surface and core of the steel cable along the oil supply tank, and form a strong protective film quickly. The new extreme pressure anti-wear agent (without corrosive components) contained in the product formula can also greatly improve the anti-wear performance of steel cable. In terms of temperature adaptability, even in extreme high temperature (below 60℃) and low temperature (above -41℃) climate conditions can still maintain the oil film does not crack, drip.

The quality index of this product greatly exceeds the relevant requirements of the U.S. military standards. In the most critical performance of rust preventive oil, the salt spray test time of 45# steel sheet reaches 288h, which exceeds the industry standard (144h). The damp heat test 45# steel sheet reaches 2520h, which is 3.5 times of the industry standard (720h). The performance is not only much higher than similar products in China, but also better than the high-end antirust oil in the market. The product also has excellent freshwater/seawater replacement, fast dehydration/dehumidification, and strong adhesion ability after film formation. Dewatering, cleaning and anti-corrosion treatment can be completed simultaneously in one process, which can significantly improve production efficiency and effectively control production costs for parts processing enterprises.

Похожие товары

Оптовая продажа RELIFE RL-538 ОСА Эффективная жидкость для удаления клеевой полоской OCA ремонта мобильного телефона

Высокое качество 60 кг НАТУРАЛЬНЫЙ КОНЦЕНТРИРОВАННЫЙ КОВЕР ШАМПУНЬ

VEAS заводской поставщик уход за автомобилем 200 л антифриз/охлаждающая жидкость для радиатора двигателя

Заводская поставка уход за автомобилем быстрый спрей для очистки автомобильного стекла легкий очиститель Автомобильный Спрей чистки пены

Оптовая продажа средства по уходу за автомобилем удаление стеклянного клея для кузова автомобиля спрей снятия

F110 очиститель велосипедных цепей спрей средство для удаления пятен продукт смазка мотоциклетной цепи 450 мл анти-ингибитор ржавчины

Лидер продаж многофункциональная смазка для мотоцикла полностью синтетическое моторное масло и антикоррозийное смазочное автомобиля

Новые поступления

Новинки товаров от производителей по оптовым ценам