Машина для выдавливания миндального масла BTMA виноградных кокосовых масел растительного

- Категория: >>>

- Поставщик: Henan Benteng Machinery Co. Ltd.

Сохранить в закладки 1601151920178:

Описание и отзывы

Характеристики

Automatic oil press

Products Introduction

Automatic oil press with the help of mechanical external force, by raising the temperature, activate the oil molecules, the grease from the oil extrusion machine. It is suitable for all kinds of oil extraction, widely used in all kinds of oil extraction industry.A screw oil press plays an essential role in the oil-making process in the market. While our oil press is very high in quality and performs very well, many customers want to know more about the oil press.

1.Automatic Seed Oil Extraction Machine Oil Making Machine Price Olive Oil Press Machine can work with automatic control by heating, oil pressing and filtering simultaneously.

2.It can press the rapeseed press before the press bore heating and heating to improve the oil yield, while in the squeezing process of hair Oil when filtering.

3.The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame,sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

2.It can press the rapeseed press before the press bore heating and heating to improve the oil yield, while in the squeezing process of hair Oil when filtering.

3.The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame,sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Structure And Working Principle

222

When the oil press is running, the processed oil enters the press chamber from the hopper. The press shaft turns to push the embryo into the press.Because the diameter of the squeeze shaft is gradually thickened, the pitch is gradually reduced, so when the squeeze press shaft rotates, the thread is hard, and the material embryo is squeezed by the squeeze bar row parts and the round row. To squeeze the oil out of the oil and flow out of the gap in the round row.

Details Images

1. It can save labor and save cost : only 1 people can finish the production.

2. Widely used to press various kinds of oil materials, like soybean, sunflower seeds, sesame,rapeseed, flax seed, camellia, cotton seed, cashew, hemp seed, linseeds, coconut,and all the oil content crops.

3. Different oil materials have different oil yielding.

4. Small-land using: only 10-20 square maters can meet the need of production.

5. The oil left in cake is less than 6%. And cake thickness can be adjusted once the machine stop running.

6. It is easy to operate. When operating, you should do as the instruction.

2. Widely used to press various kinds of oil materials, like soybean, sunflower seeds, sesame,rapeseed, flax seed, camellia, cotton seed, cashew, hemp seed, linseeds, coconut,and all the oil content crops.

3. Different oil materials have different oil yielding.

4. Small-land using: only 10-20 square maters can meet the need of production.

5. The oil left in cake is less than 6%. And cake thickness can be adjusted once the machine stop running.

6. It is easy to operate. When operating, you should do as the instruction.

Application

Automatic oil press is suitable for a variety of oil extraction, such as peanut, cottonseed, rapeseed, avocado, coconut and so on. Our screw oil press has the characteristics of high oil yield and low loss.

Automatic spiral oil press machine is mainly composed of electric control, automatic heating, adjustment, transmission and vacuum oil filter components.

Features about our products

Vacuum oil filter

1.Connect the Vacuum: Attach the vacuum pump or vacuum source to the filter

2.Filtering Process: Slowly pour the cooled cooking oil into the filter. The vacuum will draw the oil through the filter, removing impurities and particles.

3.Monitor Progress: Keep an eye on the filtering process. Depending on the amount of oil and the filter's capacity, this may take some time.

4.Store Filtered Oil: Once filtered, store the oil in a clean, airtight container suitable for cooking.

5.Clean and Maintain: After use, clean the filter thoroughly according to the manufacturer's instructions to ensure it's ready for future use.

2.Filtering Process: Slowly pour the cooled cooking oil into the filter. The vacuum will draw the oil through the filter, removing impurities and particles.

3.Monitor Progress: Keep an eye on the filtering process. Depending on the amount of oil and the filter's capacity, this may take some time.

4.Store Filtered Oil: Once filtered, store the oil in a clean, airtight container suitable for cooking.

5.Clean and Maintain: After use, clean the filter thoroughly according to the manufacturer's instructions to ensure it's ready for future use.

gradual compression and high pressure. It's like a conveyor belt for seeds or nuts, ensuring a steady flow into the press for

efficient oil extraction.

heating elements (if applicable), a pressure mechanism, an oil outlet, and a residual cake discharge system. These components work

together to efficiently extract oil from raw materials while automating the process for ease of operation.

Electric control cabinet

1. **Motor Control:** It regulates the speed and direction of the motor responsible for driving the screw feed device and other moving parts of the press.And control vacuum oil filter system.

2. **Temperature Control (if applicable):** For presses equipped with heating elements, the control cabinet manages temperature settings to optimize oil extraction efficiency and prevent overheating.

3. **Safety Features:** The control cabinet may incorporate safety features such as emergency stop buttons, overload protection, and circuit breakers to ensure safe operation and prevent accidents.

2. **Temperature Control (if applicable):** For presses equipped with heating elements, the control cabinet manages temperature settings to optimize oil extraction efficiency and prevent overheating.

3. **Safety Features:** The control cabinet may incorporate safety features such as emergency stop buttons, overload protection, and circuit breakers to ensure safe operation and prevent accidents.

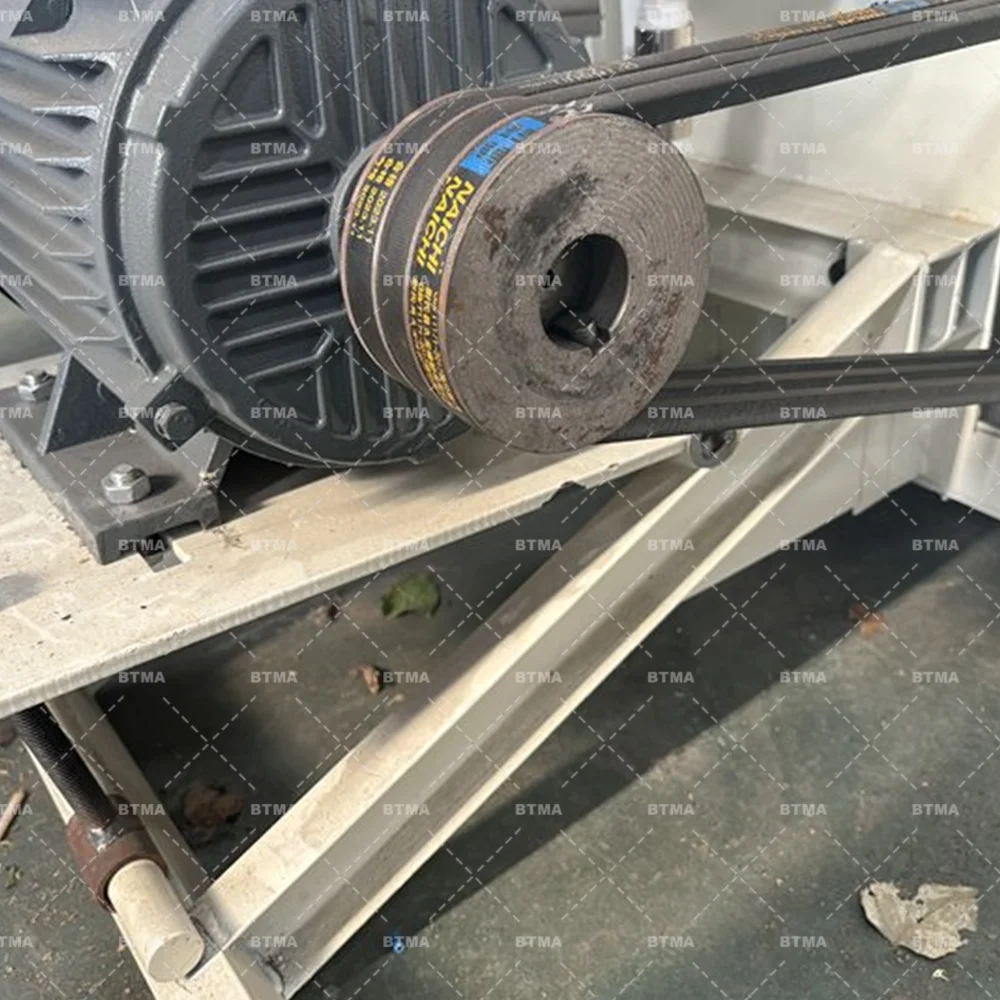

A pure motor is an electric device that converts electrical energy into mechanical motion. It consists of a rotor and a stator and

operates solely on electricity. Types include DC motors, AC motors, synchronous motors, and induction motors, with applications

ranging from electric vehicles to household appliances and industrial machinery.

operates solely on electricity. Types include DC motors, AC motors, synchronous motors, and induction motors, with applications

ranging from electric vehicles to household appliances and industrial machinery.

The oil press adjustment handle allows for manual control of pressure and feed rate during the oil pressing process, ensuring

optimal extraction efficiency and quality.

optimal extraction efficiency and quality.

Oil Press Workshop

Our oil press is packed in wooden cases, which fully guarantees the safety of product delivery.

In the packaging, the oil press is split, which is conducive to saving the packaging area.

We have the good quality shipping agent company at the main port of China, can get the best shipping price to save your money.

Company Profile

He Nan benteng Machinery Equipment Co., Ltd. is a professional manufacturer of agricultural machinery. Our company mainly engaged in oil press, oil filter, refining machine, small oil production line. The technical indicators of the products have reached the advanced level of similar products at home and abroad, with a wide range of performance parameters, easy to use, high efficiency, long service life and other advantages.

FAQ

Q: What are your terms of payment? When I decide to buy a machine, how do I pay for it?

A: Our payment methods include T/T, and Alibaba Platform Pay.

A: Our payment methods include T/T, and Alibaba Platform Pay.

T/T: The settlement shall be in the form of foreign exchange cash, and you shall remit the amount to the foreign exchange bank account designated by our company, the specific account number will be informed in the proforma invoice.

Q: How soon will you arrange shipment?

A: We will immediately inform the factory to produce the machine for you after receiving the deposit. Generally, the production can be completed within two weeks after receiving the deposit. After you pay the balance, the goods can be delivered.

Q: How soon will you arrange shipment?

A: We will immediately inform the factory to produce the machine for you after receiving the deposit. Generally, the production can be completed within two weeks after receiving the deposit. After you pay the balance, the goods can be delivered.

Q: How long does it take to arrive after delivery?

A: If you are in Southeast Asian countries, the goods usually arrive at the destination port within two weeks after shipment .

If you are in Central Asian countries, generally goods can arrive at the destination port within 20-30 days after shipment .

If you are in an African country, generally goods can arrive at the destination port within 30-40 days after shipment .

If you are in South American countries, generally goods can reach the destination port within 60-70 days after shipment .

A: If you are in Southeast Asian countries, the goods usually arrive at the destination port within two weeks after shipment .

If you are in Central Asian countries, generally goods can arrive at the destination port within 20-30 days after shipment .

If you are in an African country, generally goods can arrive at the destination port within 30-40 days after shipment .

If you are in South American countries, generally goods can reach the destination port within 60-70 days after shipment .

No matter where you are, we will arrange the fastest speed to safely deliver the goods for you.

Q: What kind of prices do you usually quote? Does that include freight?

A: We can quote EXW, FOB, CIF prices for our customers. If you have your own freight forwarder or shipping company, we can also deliver the goods to your freight forwarder.

A: We can quote EXW, FOB, CIF prices for our customers. If you have your own freight forwarder or shipping company, we can also deliver the goods to your freight forwarder.

Q: What countries does your factory export to each year?

A: Exports to a wide range of countries or regions, involving Africa, India, the Philippines, Indonesia, Australia and South America,Brazil, Peru and other countries.

A: Exports to a wide range of countries or regions, involving Africa, India, the Philippines, Indonesia, Australia and South America,Brazil, Peru and other countries.

Q: Do you have technicians and engineers in your factory?

A: Our factory has professional engineers all the year round to provide technical support, can meet all your design requirements.

A: Our factory has professional engineers all the year round to provide technical support, can meet all your design requirements.

Q: How can i become a distributor of Benteng?

A: Contact us immediately for further details by sending us an inquiry.

A: Contact us immediately for further details by sending us an inquiry.

Our service

* 1 year free warranty,whole lifetime maintenance.

* Supplying wearing parts all year around

* Supplying technical solutions at any time

* Helping design and plan the oil plant's construction

* Providing installation vedeo

* Tried orders are available

* Developing agents with good policies around world.

(Our oil press machine attracted large numbers of visitors with its wide application and refined crafts.)

* Supplying wearing parts all year around

* Supplying technical solutions at any time

* Helping design and plan the oil plant's construction

* Providing installation vedeo

* Tried orders are available

* Developing agents with good policies around world.

(Our oil press machine attracted large numbers of visitors with its wide application and refined crafts.)

Похожие товары

Оборудование для переработки кокосового винограда

7 048 333,50 ₽

Неожиданная цена, автоматическая машина для холодного отжима масла для приготовления подсолнечника

238 450,55 ₽ - 281 824,91 ₽

Машина Для Экстракции Масла СО2 грецкого ореха/облепихи/виноградных косточек/рисовых отрубей

3 253 077,00 ₽

Небольшой Автоматический Масляный Пресс для малого бизнеса, домашний Американский экстрактор масла из виноградных косточек

10 474,91 ₽ - 12 569,89 ₽

Небольшая ручная машина для холодного отжима

119 279,49 ₽

Масляный пресс для семян винограда

97 700,75 ₽ - 184 232,60 ₽

Кофе какао Виноградные семена полностью арахисовое масло пресс

1 084 359,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $