2024 превосходная доска гипса делая машинный завод

- Категория: >>>

- Поставщик: Henan Dafu Mechanical Import And Export Co. Ltd.

Сохранить в закладки 1601154928430:

Описание и отзывы

Характеристики

202 Excellent gypsum board making machine plant

We are professional manufacturer in Henan Zhengzhou. Our engineers have about 20 years experience in this dustry . We give professional technical advice to every client . we will give our best service to meet your requirements .

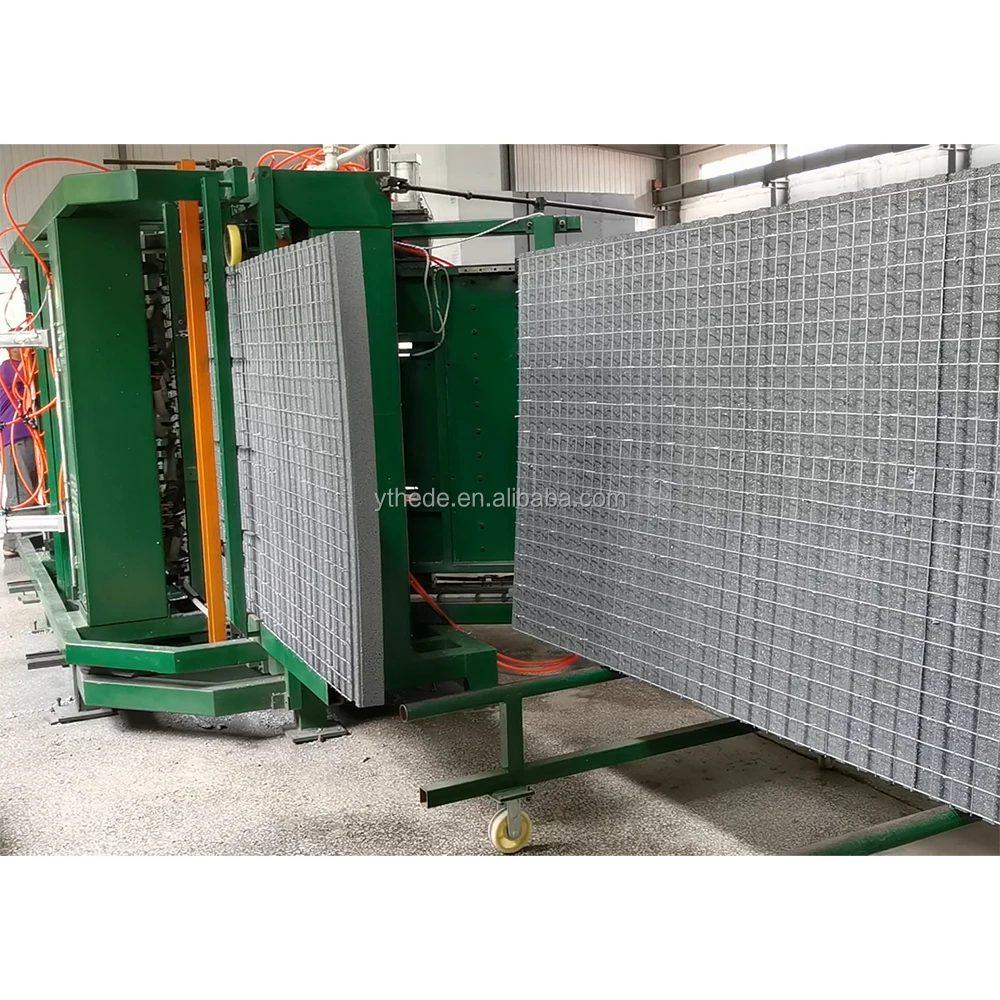

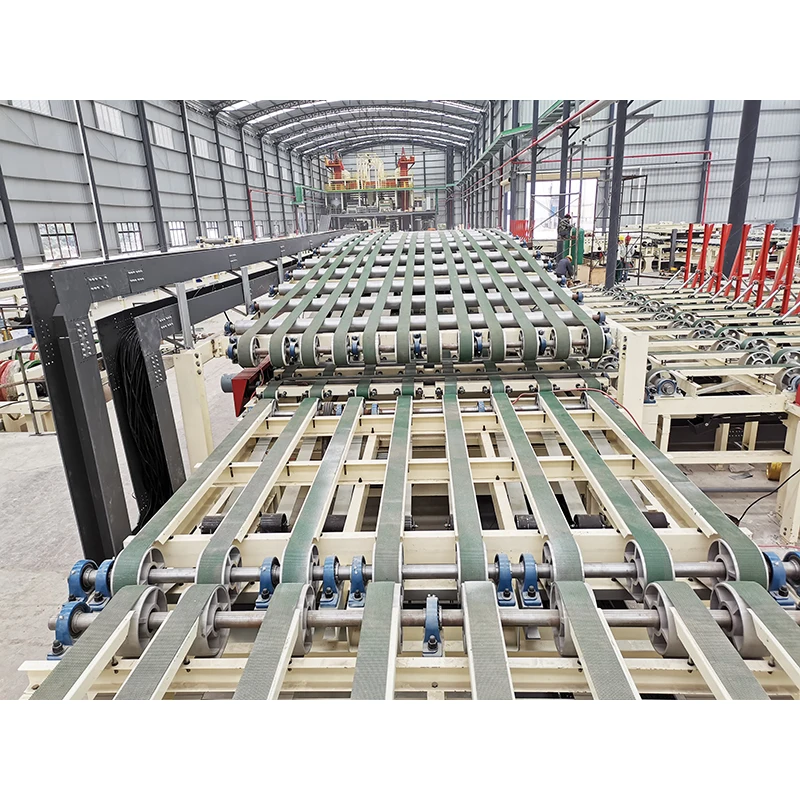

Gypsum board production line

Gypsum board,with two sides of paper, is mixed with appropriate Additive and Enhanced Fiber. The gypsum board is first invented in 1890 in America, then came into Europe in 1917. The gypsum board spread quickly, since it is light, warm, insulated, fire-resistant, green and easy to operate. It is estimated that the gypsum board annual output reached 1,9billion square meter in 1997. 80% of walling materials uses gypsum board.

Almost all the residential construction in America uses the gypsum board as the Internal Wall Material. As for the per capital consumption, it is 13.2 square meter per year in Canada, 8.1 square meters in America, 4.4 square meters in Japan and French, 2.6 square meters in United Kingdom. But in China, the per capita consumption is no more than 0.3 square meters per year; it is far lower than the consumption level in other countries. The gypsum board is popular in the past 100 years because of its high performance.

2.Advantages

1. Light weight, low consumption of cement and steel, the construction speed is quick, the labor expenditure is little and the increasing of the construction and usable area.

2. Farmland saving; Reduces the material consumption in the process of the production; May reduce the cartage expense.

3. Simple construction, dry work and low labor intensity

4. It can satisfy different buildings requirements in the aspect of heat preservation, heat insulation, sound proof, fire prevention, moisture proof and so on.

5. Easy to be maintained, good performance in dismounting. It can change the room area according to the requirement.

6. Gypsum block is an environment protection and energy-saving green product generalized by our country,because of its advantages of light weight,exact dimension,fire-proof function,shock-proof function,heat preservation and heat insulation,adjusting indoors dryness and humidity, good capability of manufacture and convenient construction,etc.

This project delivered goods at latter half year of 2007 and started to be installed in the first half year of 2008.We have 45 persons to install the line and this line has been planned to complete in August, 2008. This gypsum board equipment production line had been successfully inspected and accepted by the owner in Aug 10, 2008 and this gypsum board equipment plant has put into production.

Now, gypsum board equipment runs fine and its forming speed is 25/mm.

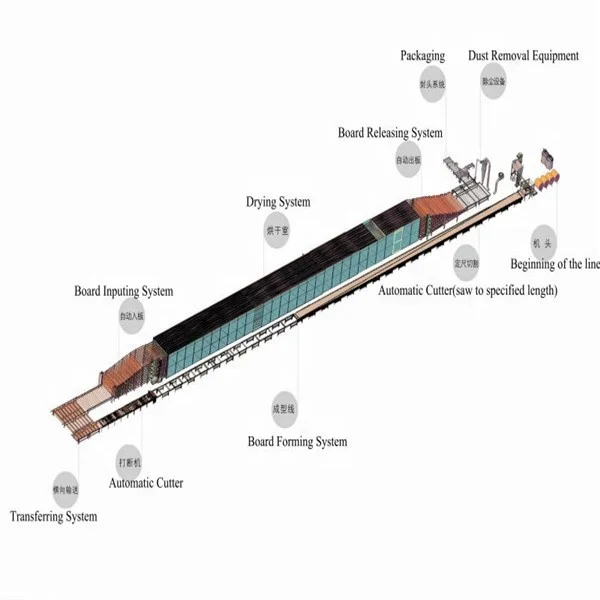

Production process mainly includes the following several aspects

paper supply system,water supply system,starch supply system,vesical supply system,forming section,transpotation system,transferring system,heat supply system,drying system board releasing system,dust collecting system,electricity -control system.

The gypsum board process is as following:

Plaster hopper---mixing---shaping---freezing---first cutting---drying---detailed cutting---packing ---finished products

Factroy overall picture:

Packaging Details: |

standard export packing, 20ft, 40ft container. equipment fittings,electric motor and power cabinet willbe packed in wooden case. bulk

|

Delivery Detail: |

30 working days after receiving the payment

|

Our machines and equipments are packed in standard package that fit for long distance road transportation and shipping. We ensure our customers can receive the undamaged machine in good condition.

If you are interested in themachineryby us, please Contact us or visit the website of the company for relevant prices and detailed technical parameters and specifications etc. Henan Dafu Mechanical Import and Export Co., Ltd. will assure you of our best service at all time!

//dafumachinery.en.alibaba.com/

Похожие товары

Сборная машина для производства стеновых панелей из бетона eps цемент

Машина для производства стеновых панелей

Машина для изготовления бумажной облицовочной декоративной линии производства гипсокартона

Машина для производства сэндвич-панелей

Hpl ламинированные огнестойкие доски Mgo с деревянным узором для внутренних общественных декоративных стен

Оборудование для производства гипсовых потолочных плит из ПВХ шпона линия по производству потолков высокопрочная потолочная плитка 595*595 мм продажи

2024 более дешевое и высокоэффективное оборудование производственной линии гипсокартона с Заводской ценой

Новые поступления

Новинки товаров от производителей по оптовым ценам