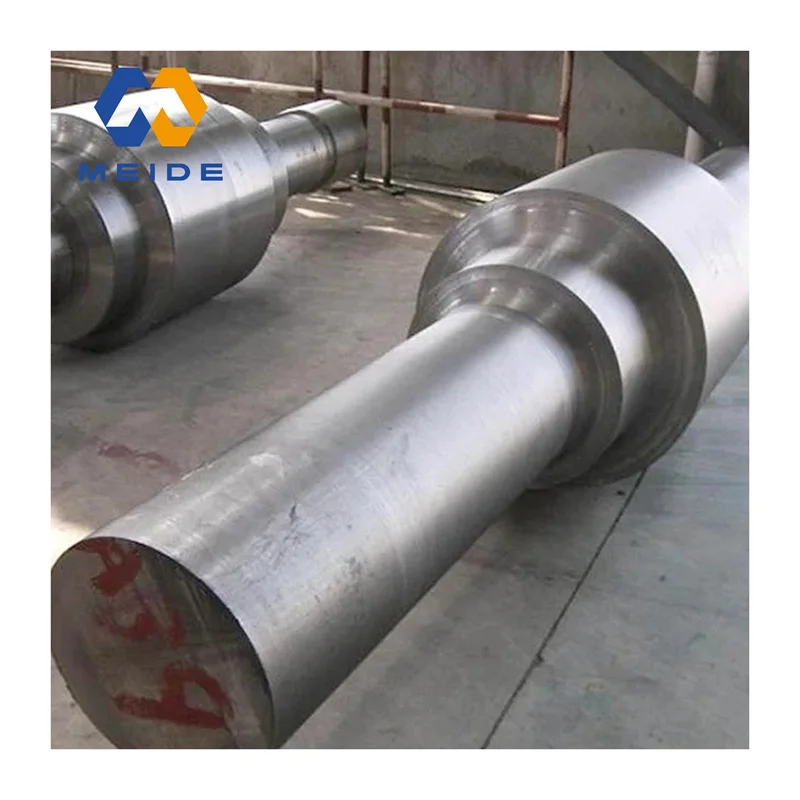

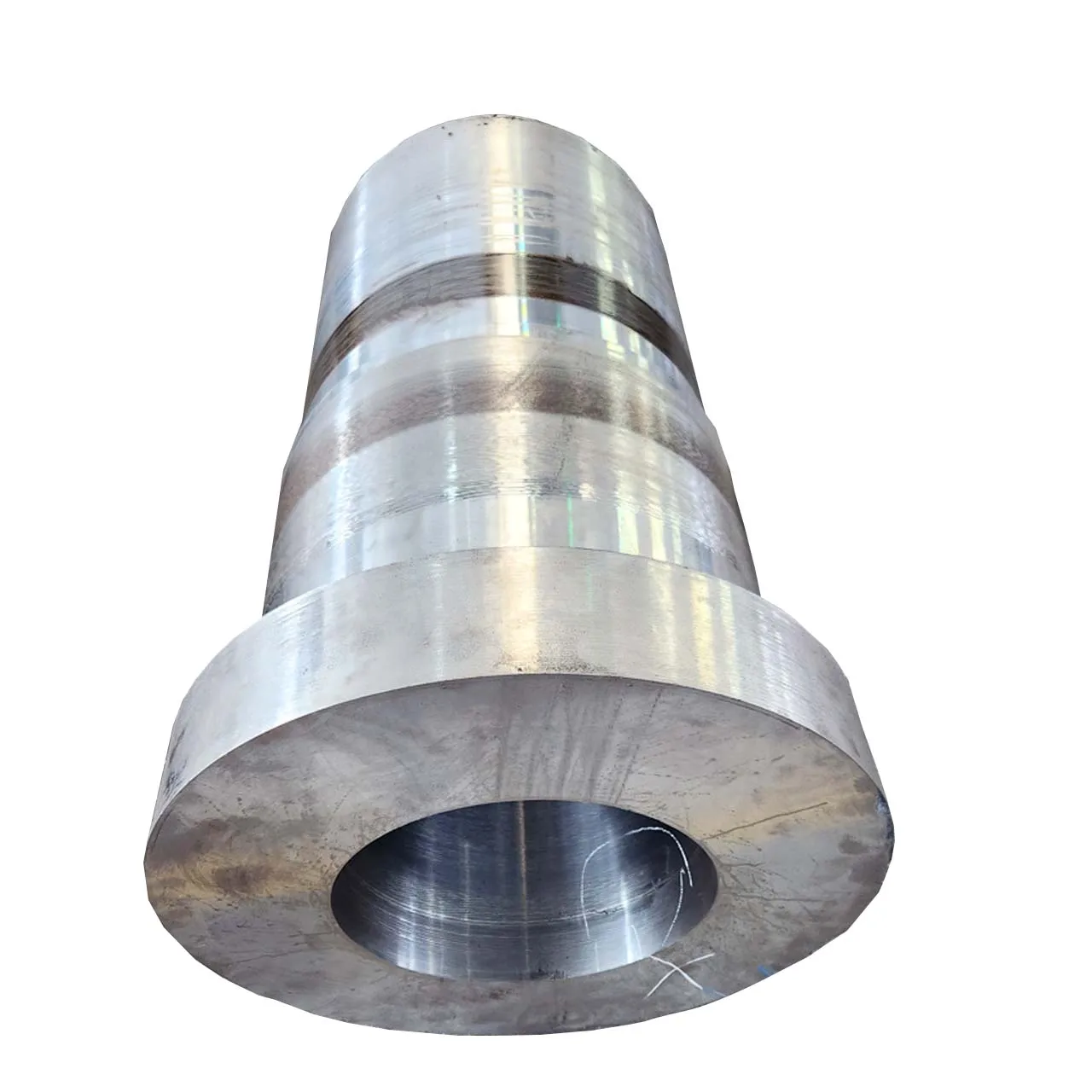

Вал ротора ветровой турбины большого размера кованая направляющая сталь легированная длинная трансмиссия кованый вал

- Категория: >>>

- Поставщик: Shandong Meide Import And Export Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601155331858:

Описание и отзывы

Характеристики

Technical Support

Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Our Advantage

1)We have our own factory, so we can guarantee the best quality mechanical products with the most competitive prices.

2).We not only produce high-quality products that meet customer needs, but also provide complete after-sales service, technical support, full production supervision and quality tracking services. Meet various special customization requirements of customers.

2).We not only produce high-quality products that meet customer needs, but also provide complete after-sales service, technical support, full production supervision and quality tracking services. Meet various special customization requirements of customers.

3)All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI,WPS&PQR, etc. as per request

Product Paramenters

Available Material: | 42CrMo, C45, alloy steel stainless steel customized, etc |

sort: | flange shaft, Wind Power Main shaft ,Gear, shaft, gear shaft, Long shaft |

Heat Treatment: | Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc. |

Length: | according to customer's request |

Diameter: | 100-6000mm,according to customer's request |

Technical: | hot treatment;cold forging;machining;customized |

Tolerance: | As per drawing.(+/-0.05mm,+/-0.01mm) |

Surface Treatment: | quenching and tempering+quenching;customized |

Lead Time: | 20-45Days Depends On Quantities and complexity |

Application: | Heavy Machinery;Mining Equipment;Wind Turbines;Heavy Vehicles;Oil and Gas Industry;Paper and Pulp Industry;Agricultural Machinery etc. |

Payment Term: | L/C at sightT/T 30% deposit and balanced 70% to pay before shipment. |

Port Of Loading: | Shanghai or Ningbo,etc. |

Production Equipment: | CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling and Tapping Machine,Gear Shaping Machine,etc. |

Inspection Equipment: | Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

QC: | 1.Incoming material will be checked before production. 2.Strict processing quality control. 3.100% inspection before shipment. 4.We are responsible for product quality to the end user. |

Package: | 1. Filling with anti-rust oil 2. Corved with Plastic paper 3. Corved with kraft paper 4. Corved with Blue tie 5. Put in wooden box |

After-sales Service: | We will follow up goods for customers and help to solve problems after sales. |

Product Description

DIMENSION

Dimensional accuracy are high, ISO ASTM, AISI, ASME, DIN, EN, AS, GB Grade.Carbon steel,alloy steel, stainless steel, according to drawing.The length not more than 10000mm and the diameter less than or equal to 1500mm

APPEARANCE

Polishing/Grinding/ Painting/Anti Rust Oil,No porosity, shrinkage cavity, burr and etc.Surface roughness: Ra1.6-3.2

Grey iron,Ductileiron,carbon steel,alloy steel,stainlesssteel,Aluminumalloy,Carbonsteel,Titanium alloy and etc.according to drawing

SHORT LEAD TIME

From design, mold, casting, processing, surface treatment, packaging delivery one-stop

Product material

Workmanship Process

Manufacturing capacity covers the entire production process of forging parts, from mold design and manufacturing, forging, secondary processing, heat treatment, surface treatment to finishing, to provide customers with ready-to-use products and services.

About us

Shandong Meide Import And Export Co., Ltd. focuses on the production and sales of forging, Shaped tubing, seamless tube, alloy steel, steel processing general machinery and equipment. The company has passed IS09001:2000 quality system certification, SGS, ROSH, TUV, REACH and other certifications. We can customize and develop new products according to customers' actual application, and provide products with different cost performance and performance requirements.

Factory Equipment

Packaging and Transportation

1) 0-150kg: express & air freight priority | |

2) >150kg: sea freight priority | |

3) As per customized specifications | |

All parts are custom made according to customer's drawings or samples, no stock. |

Certifications

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are an industrial and trading company with our own iron foundry and many outsourcing partners.

Q2: What is your lead time?

A: Approximately 15-35 days from the date of order.

Q3: Do you provide samples? Is it free or extra?

A: We can provide samples. If it's not too much, it's free. However, if we need to make the mold first, we need to charge 50% of the mold cost.

Q4: What are your payment terms?

1) Mold fee: 50% in advance, 50% after sample approval

2) Goods: 30% down payment, 70% should be received before delivery.

A: We are an industrial and trading company with our own iron foundry and many outsourcing partners.

Q2: What is your lead time?

A: Approximately 15-35 days from the date of order.

Q3: Do you provide samples? Is it free or extra?

A: We can provide samples. If it's not too much, it's free. However, if we need to make the mold first, we need to charge 50% of the mold cost.

Q4: What are your payment terms?

1) Mold fee: 50% in advance, 50% after sample approval

2) Goods: 30% down payment, 70% should be received before delivery.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Ковочный ролик и ковочный вал со стальным 4320 /20CrNi2Mo

4 735,17 ₽ - 10 668,95 ₽

Точная промышленная ковка индивидуальные механические шестерни компоненты цепного привода детали

213,62 ₽ - 272,96 ₽

Кованые кольца из нержавеющей стали 304/316 Пластины фланец ASME B16.5 ANSI DN100 Cl150lb 316L A403 кованые фланцы

29 668,93 ₽ - 41 536,50 ₽

ASME B16.5 ASTM A182 F53 GR.2507 Соединительный фланец CL600 4 дюйма

118 675,70 ₽

4140 42CrMo SUS304 стальная 6061 Алюминиевая медь бронзовая горячая ковка

118,68 ₽ - 237,36 ₽

16Crmo4 кованый сплав бар 133 поршень ковка моносталь моно 135 мм высококачественная сталь

3 429,73 ₽ - 6 028,73 ₽

Gr1 Gr2 Gr5 титановый плоский ковочный фланец для промышленности изготовленные по индивидуальному заказу титановые детали изделия

830,73 ₽ - 1 068,09 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $